Method of inhibiting smoke plug-holing to improve natural smoke extraction efficiency of vertical shaft

A shaft and flue gas technology, which is applied to shaft equipment, ventilation of mines/tunnels, and earth-moving drilling and mining, etc., can solve the problems such as the decline of the smoke exhaust effect of the shaft, and achieve the improvement of smoke exhaust effect, simple operation, high safety and reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

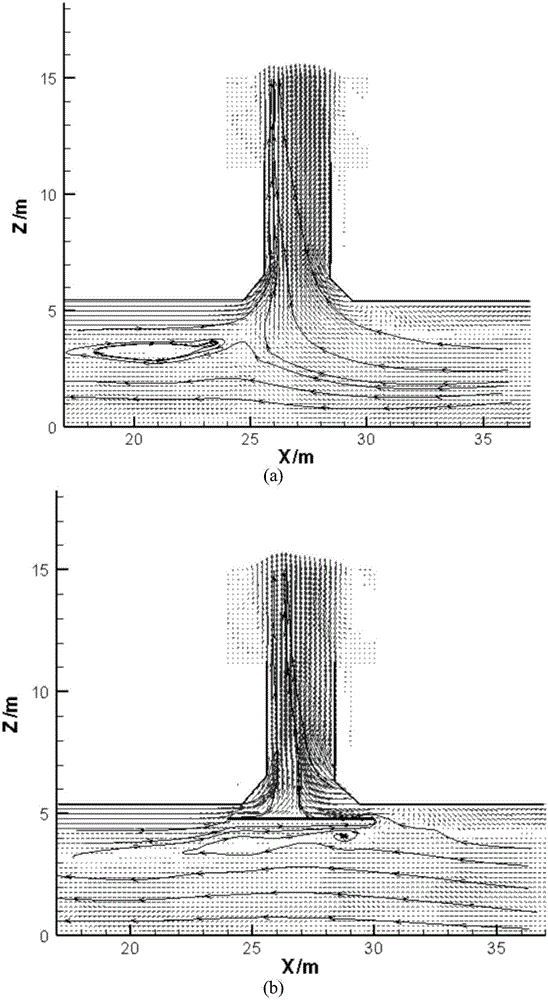

[0031] Below in conjunction with the accompanying drawings, the present invention will be further described by taking a certain longitudinal structure of a tunnel provided with an inclined shaft as an example.

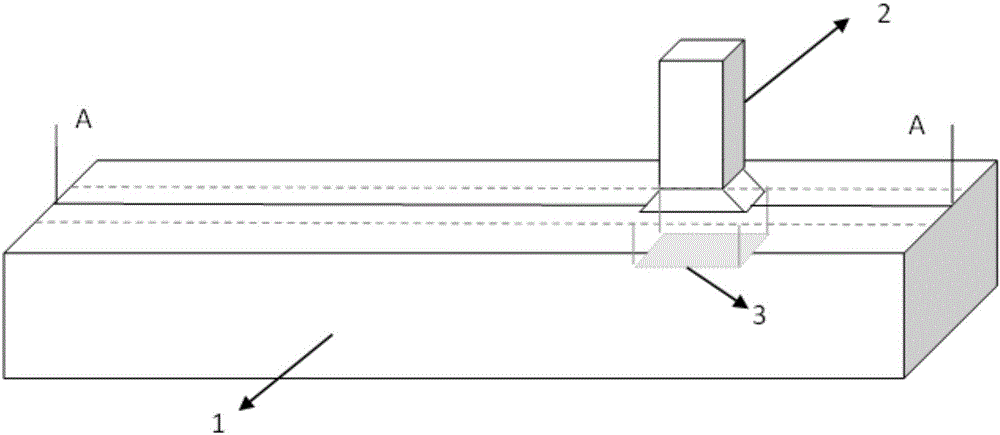

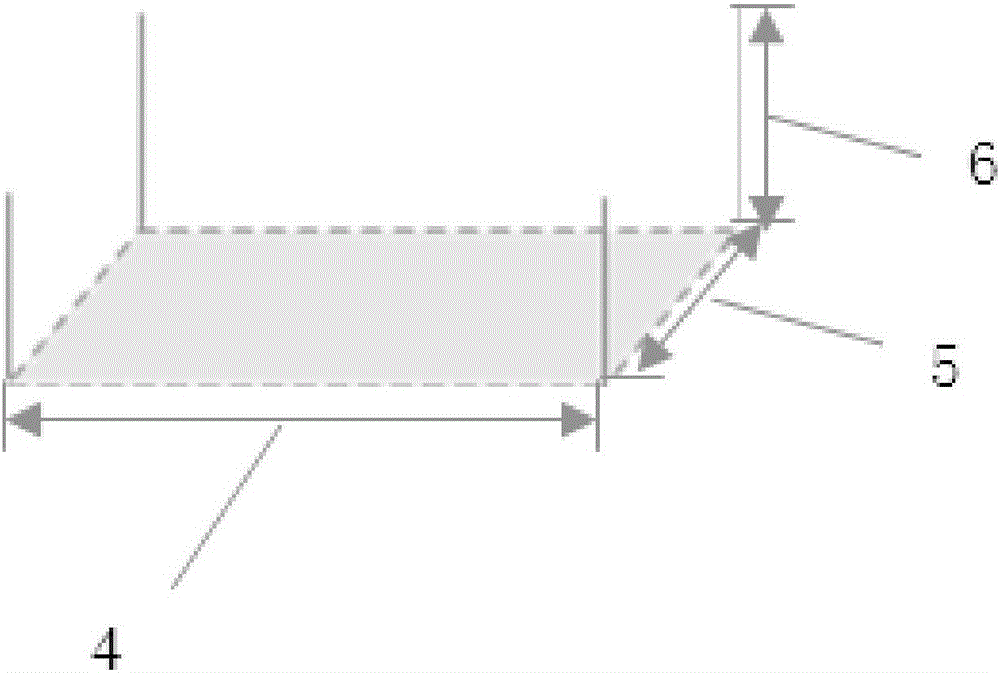

[0032] see figure 1 , The tunnel with an inclined shaft above the ceiling includes a tunnel main body 1, an inclined shaft 2 and a baffle 3 fixed on the ceiling. The length of the main body of the tunnel is 60 meters, the inner height of the tunnel is 5.4 meters, the width is 12 meters, the height of the inclined shaft is 6.0 meters (in actual engineering, the height of the shaft is related to the thickness of the soil layer above the tunnel), and the upper opening of the inclined shaft is horizontal. The section size is 3 meters (length) * 3 meters (width). There are two triangular prism spaces at the part where the lower part of the shaft is connected to the tunnel (including the upstream and downstream directions of the tunnel). ) is 1 meter, the connection angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com