Pneumatic development machine for replacement of existing concrete conduit and replacing method therefor

A technology for roadheaders and concrete, which is applied in earth-moving drilling, tunneling, mining equipment and other directions, and can solve problems such as difficulty in operation, generation of soil, and shaking of foundation parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

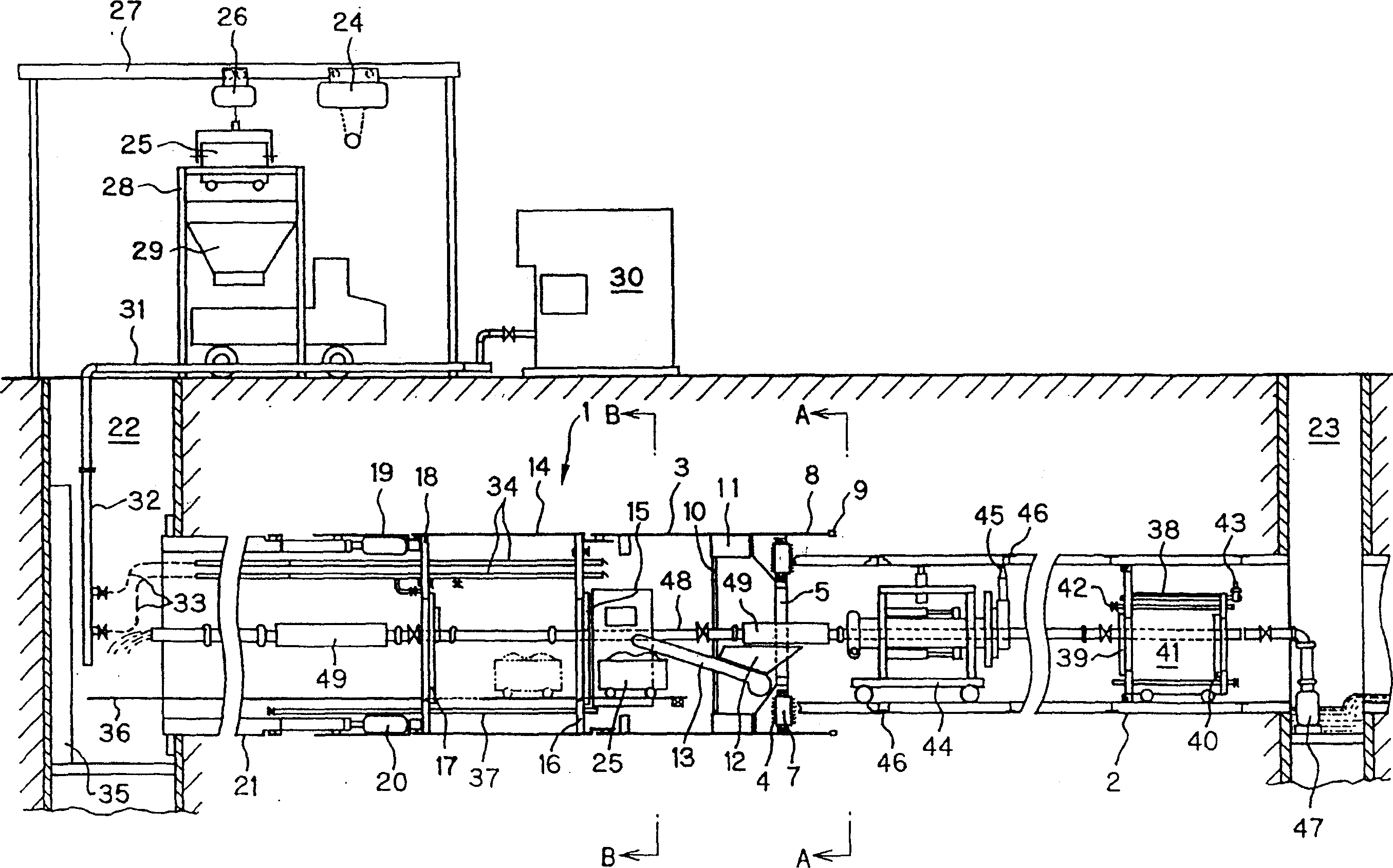

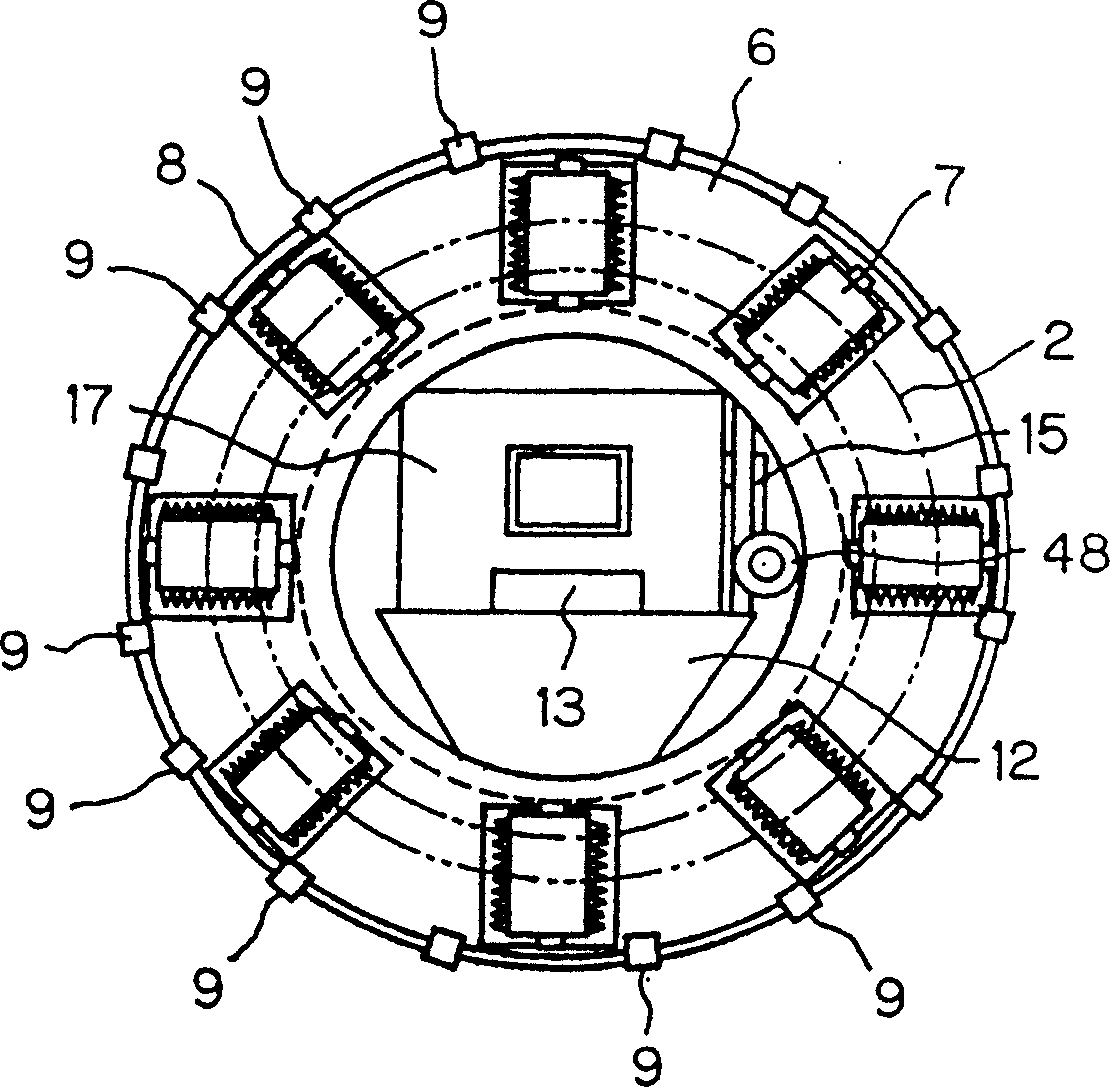

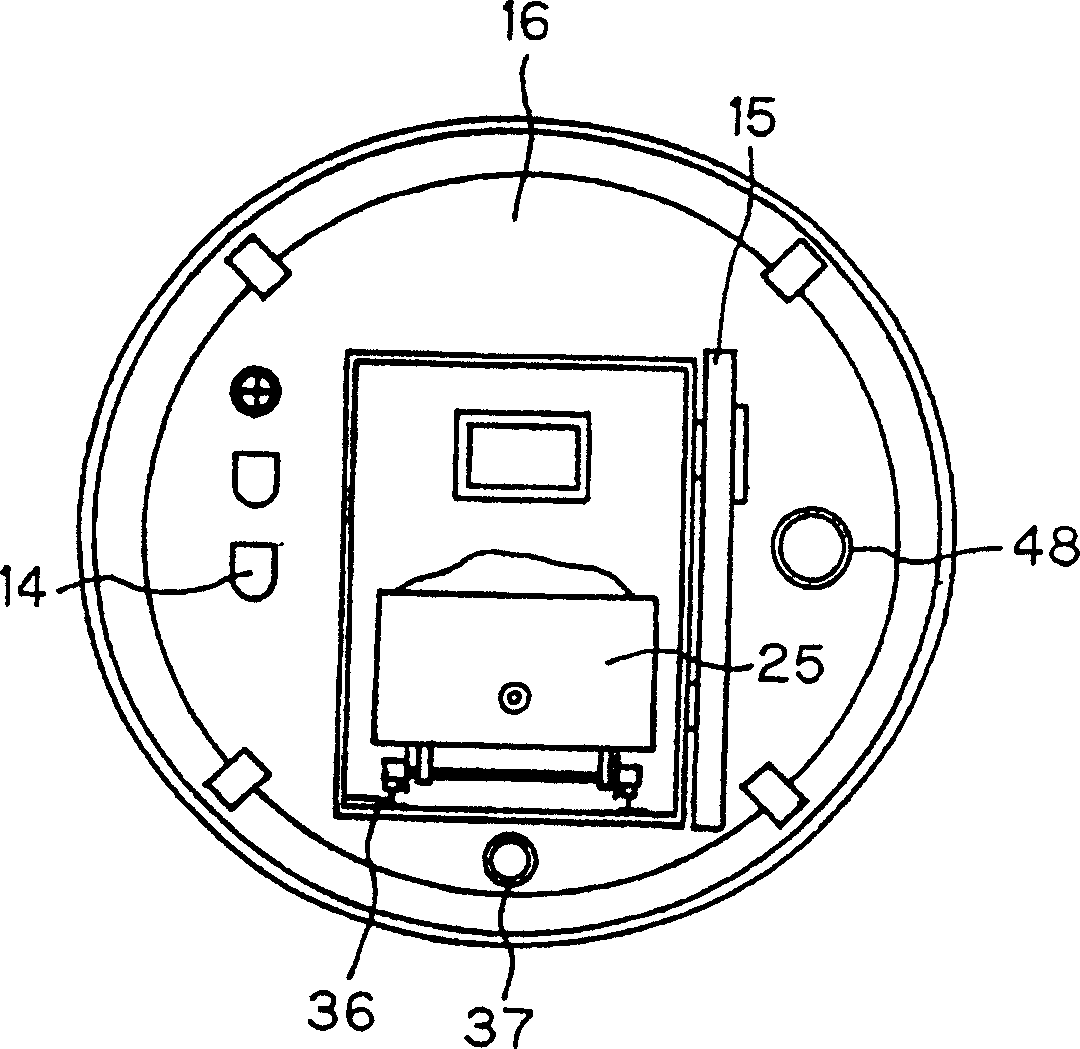

[0035] Example 1, see figure 1, the air pressure roadheader 1 used for updating the existing concrete pipeline has a roadheader main body 3, the inner diameter of the roadheader main body 3 is larger than the outer diameter of the existing concrete pipeline 2 buried in the ground, and the outer diameter of the roadheader main body 3 is roughly equal to The outside diameter of the new pipe. The inner diameter of the newly laid pipe should be able to cover the maximum center error of the existing concrete pipe 2 . The front of the roadheader main body 3 is a wheel-shaped head 4, which is rotated by a driving source. The wheel-shaped head 4 is only equipped with cutters in the necessary annular position when the existing concrete pipeline 2 is broken. The ring-shaped head 4 has a cutter head 6, the center of the cutter head 6 forms an opening 5 that can enter and exit operators, materials, operating machines and broken objects, and a free cutter head is installed at a certain d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com