Patents

Literature

58 results about "Tunnellers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tail sealing grease for shield tunneller

The invention discloses a sealing grease for a shield tail of a shield tunneller, which comprises by weight the following components: basic oil 17.5-19 portions, thickener 8-15 portions, waterproof sealing material 58-65 portions, lubricant 1.5-3 portions, antioxidant 1-2 portions, anti-rust agent 0.5-1.5 portions, and tackifier 4-6 portions. The invention is of low cost, strong adhesion, good sealing performance, good pumping effect, environmental friendliness, good lubrication and steadiness, is resistant to aging and oxidation, free from separation and dry contracting during the quality warranty period of the product.

Owner:刘延鹏

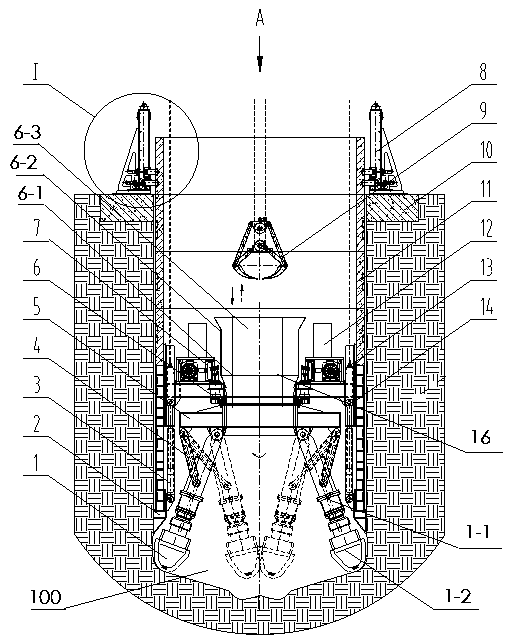

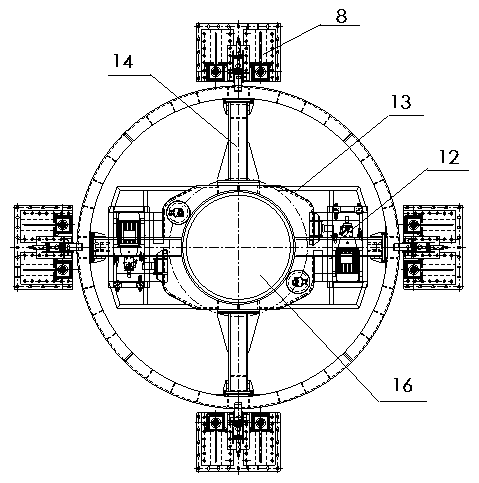

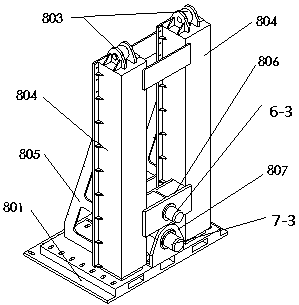

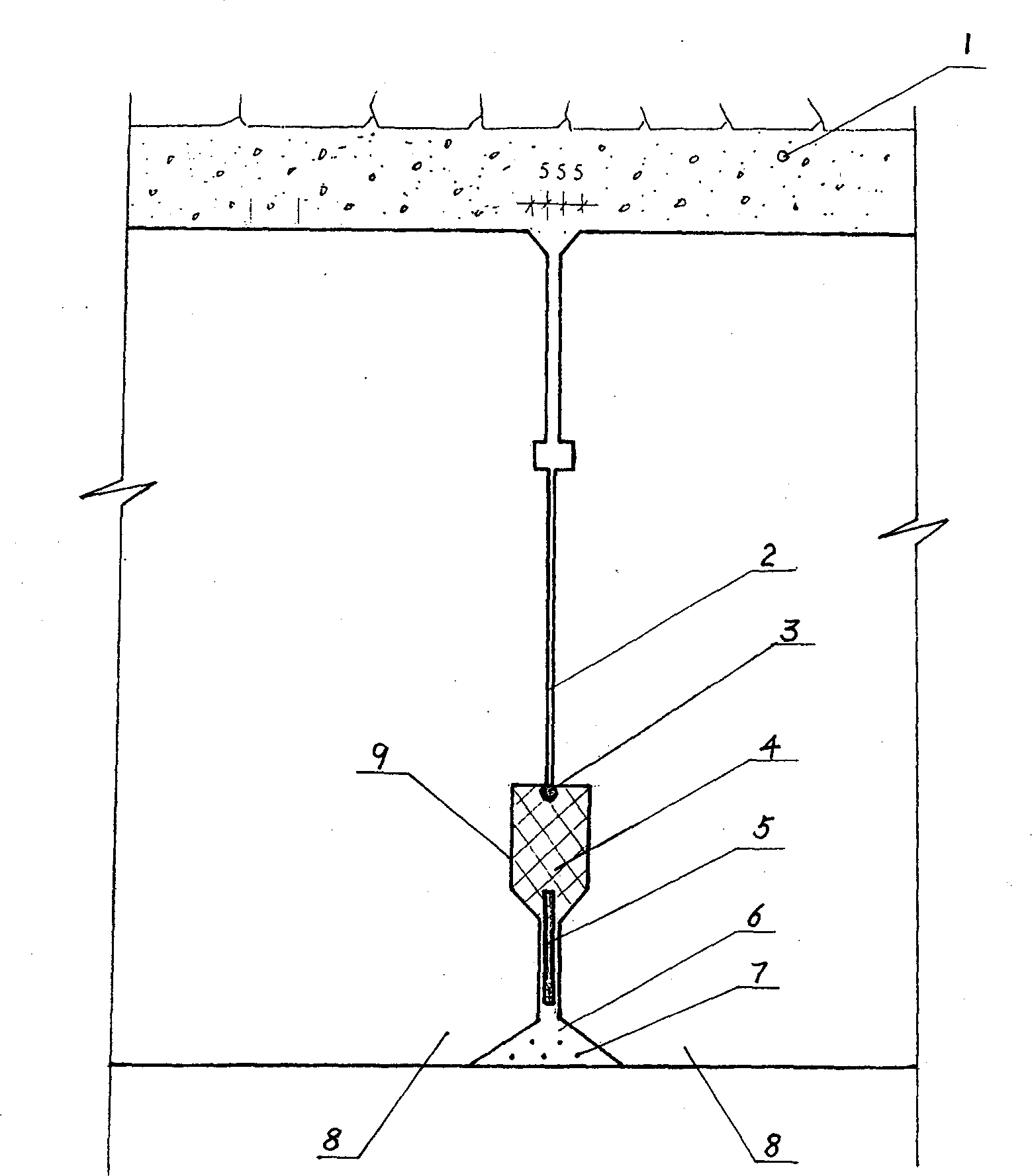

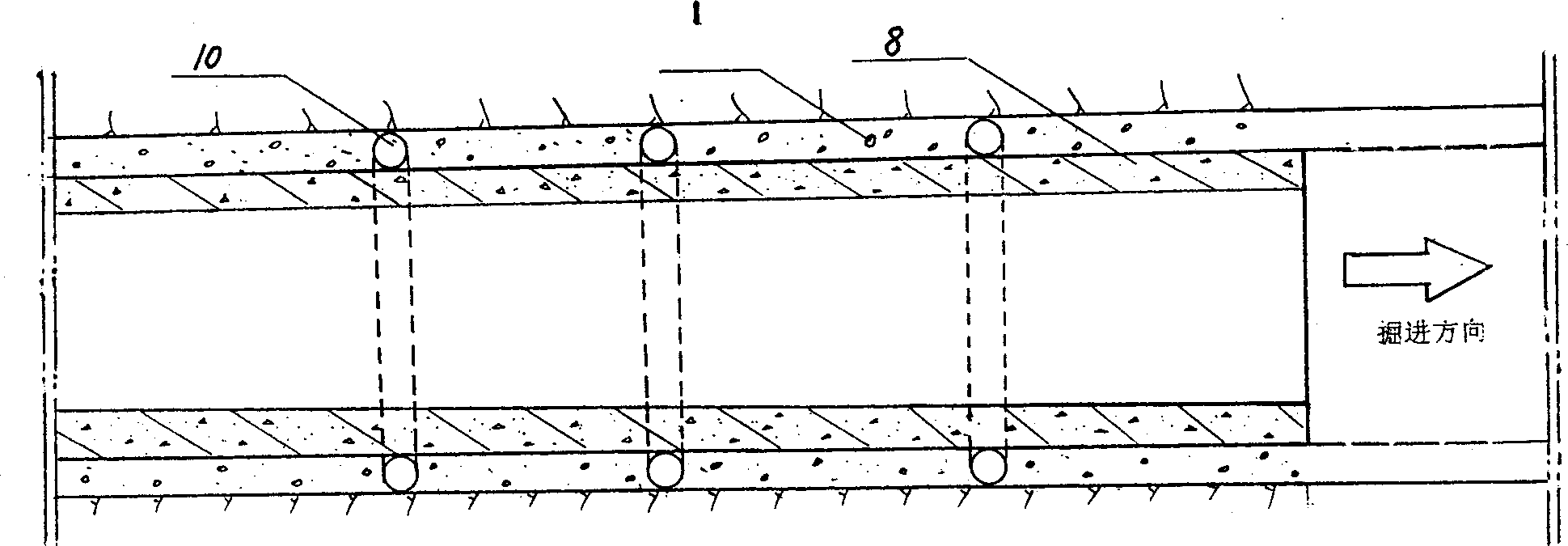

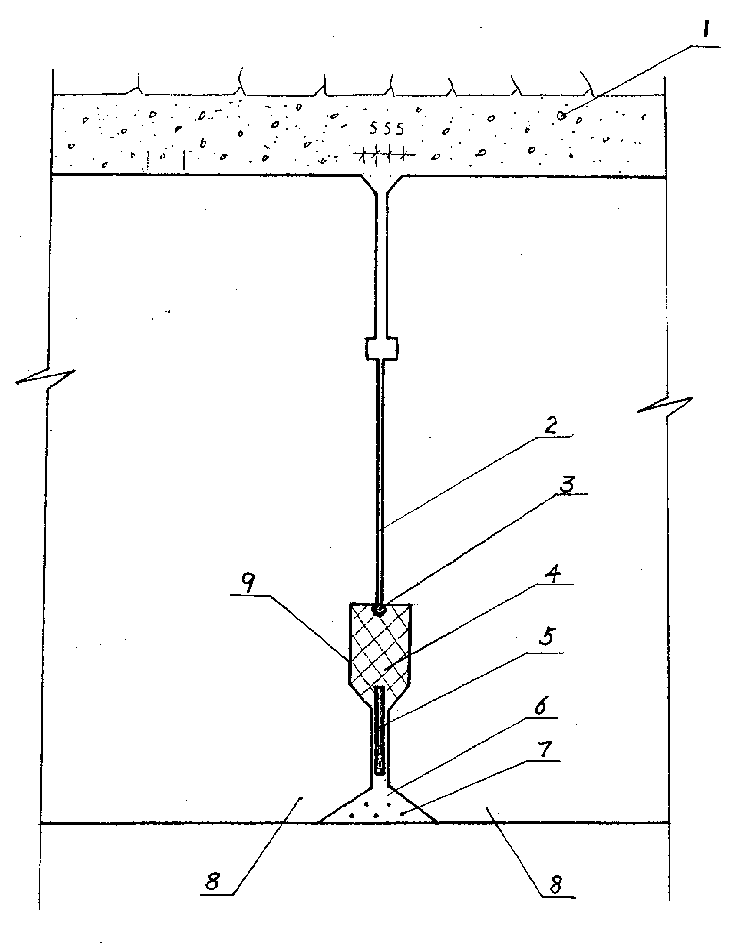

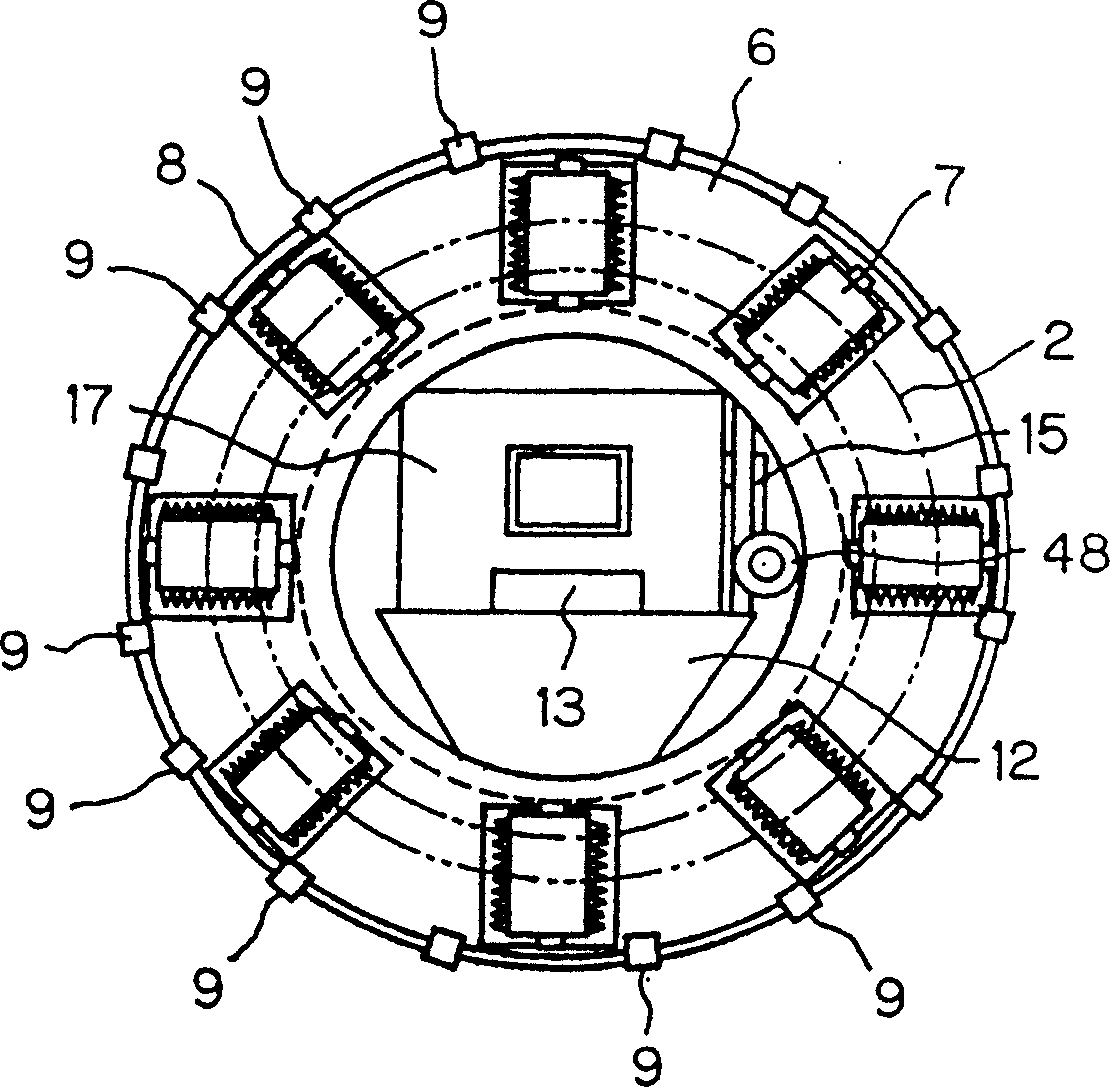

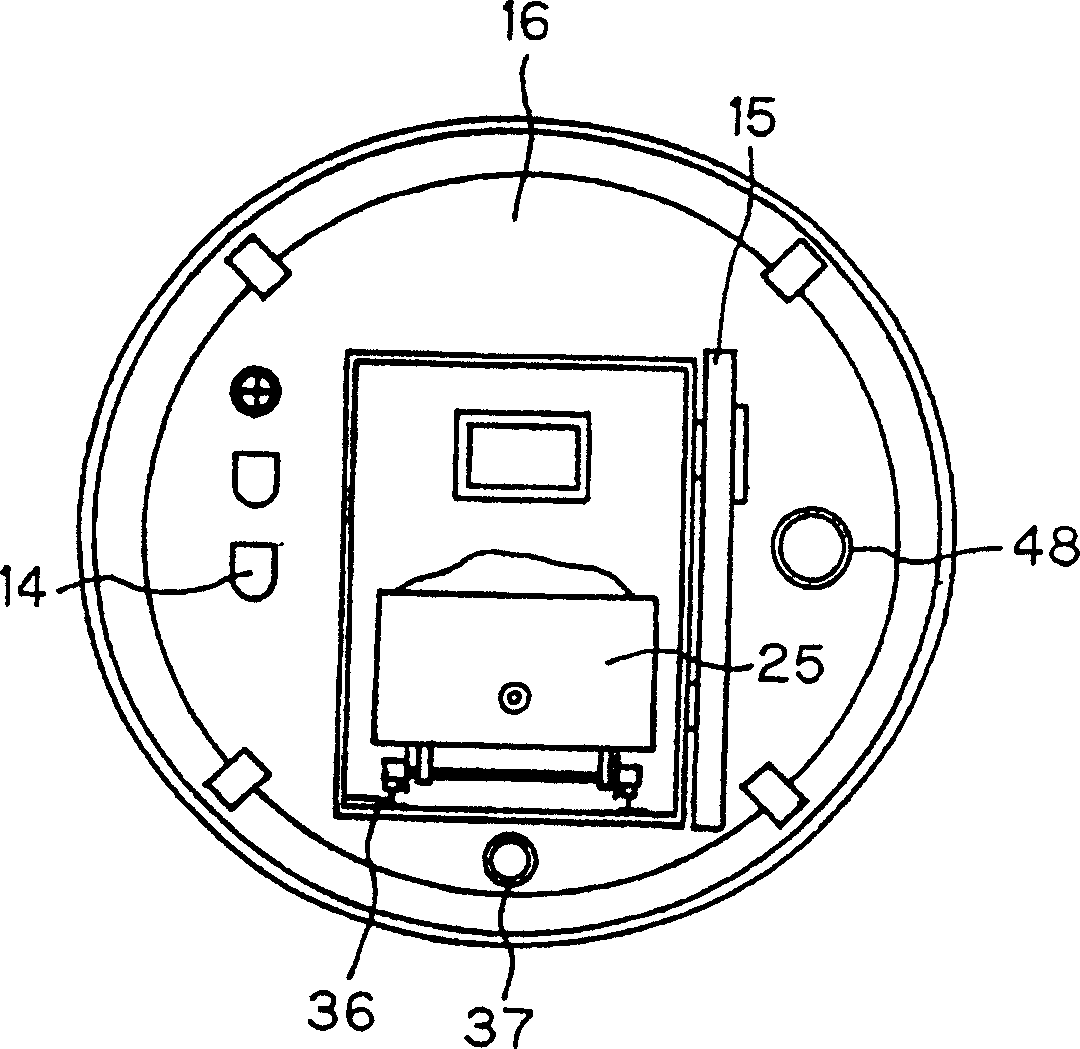

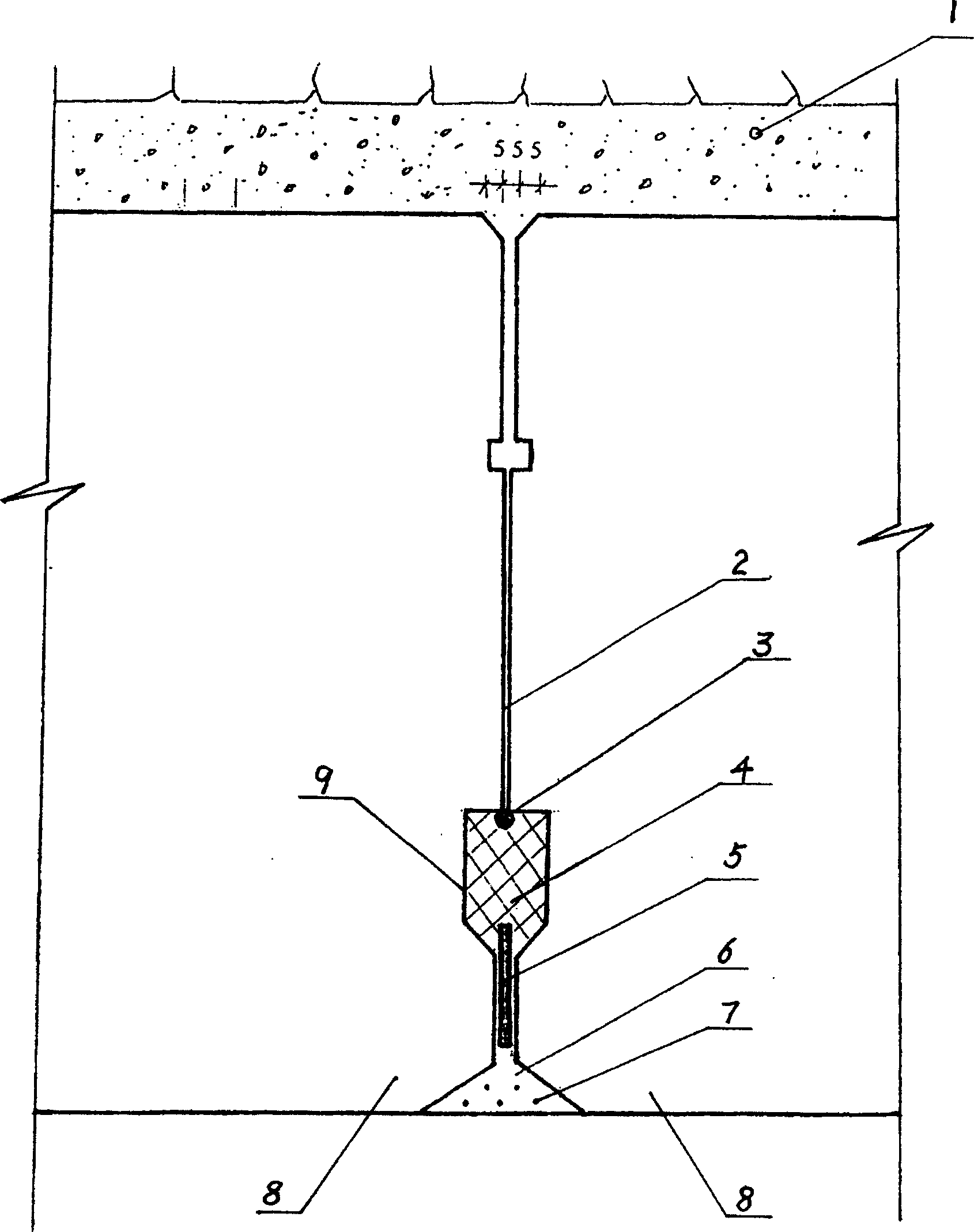

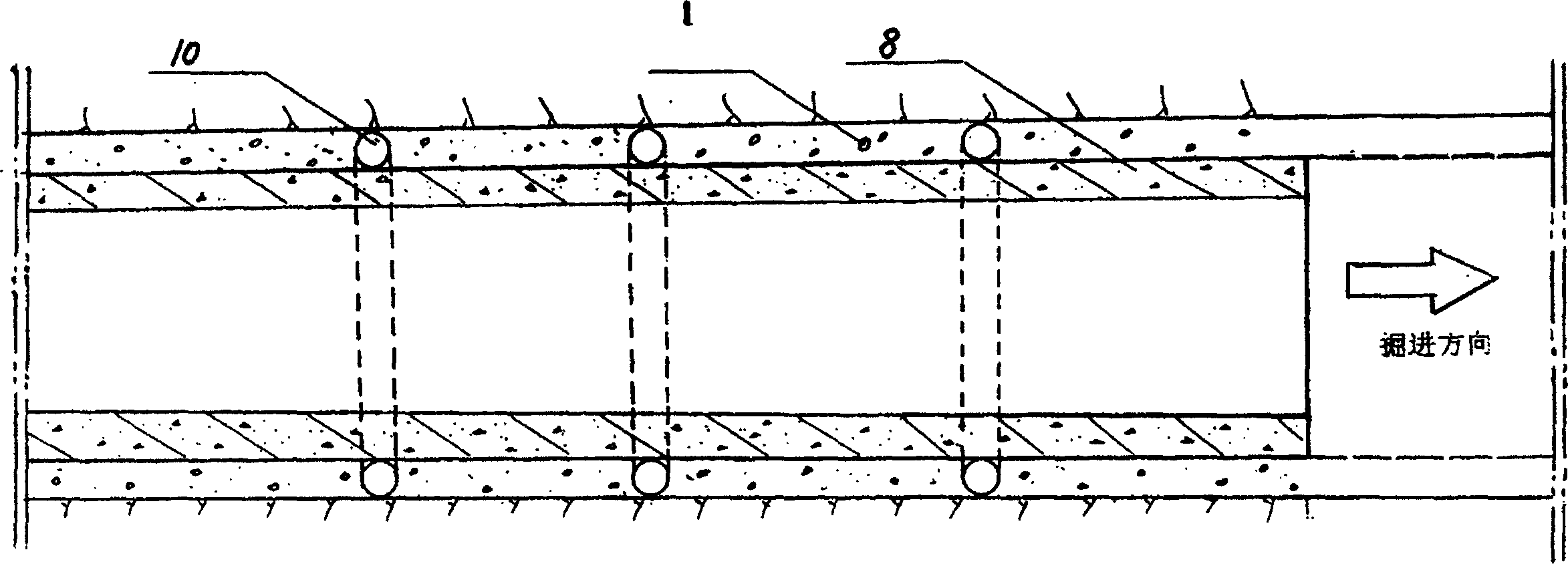

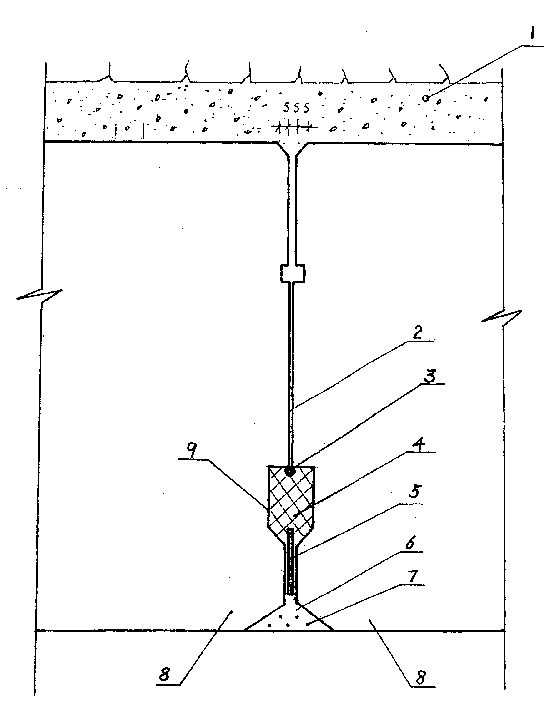

Drop-shaft-sinking-based shaft well tunneller and construction method thereof

PendingCN109139017AEasy maintenanceEasy to operateShaft sinkingHydro energy generationSlagControl system

The invention discloses a drop-shaft-sinking-based shaft well tunneller and a construction method thereof so that problems of shaft well excavation mechanization, low automation degree and high risk coefficient in the prior art can be solved. The drop-shaft-sinking-based shaft well tunneller comprises a tunneling system, a control system and a detection system. The tunneling system includes an excavation device and a well wall lifting and pressing device. A bottom pipe joint and a guiding base are arranged in a starting shaft well; the bottom pipe joint is arranged below the guiding base; anda driving fixation rack is arranged at the guiding base and the lower part of the driving fixation rack is connected with the bottom pipe joint by a propulsion cylinder. A rotating device is arrangedat the driving fixation rack; a rotation rack is arranged at the lower part of the rotating device; and an excavating device is connected with the rotation rack. A hydraulic pump station, a driving device and a slag discharging device are arranged at the rotating device; and the slag discharging device corresponds to a lifting grab bucket. The drop-shaft-sinking-based shaft well tunneller is a modular shaft well tunneling machine that is used for mechanical excavation and support of a shaft well; the excavation precision and excavation speed of the whole process are improved; the mechanical automatic construction is realized; and the work efficiency and construction safety factor are increased.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

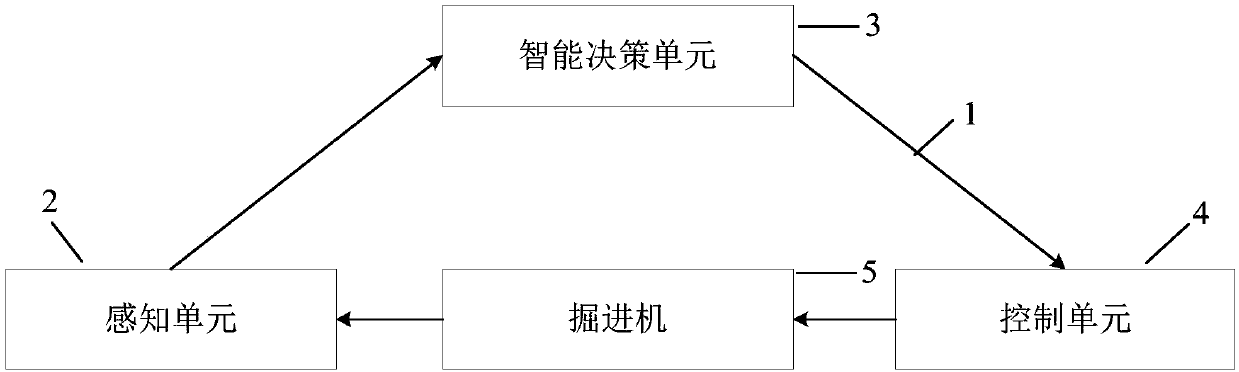

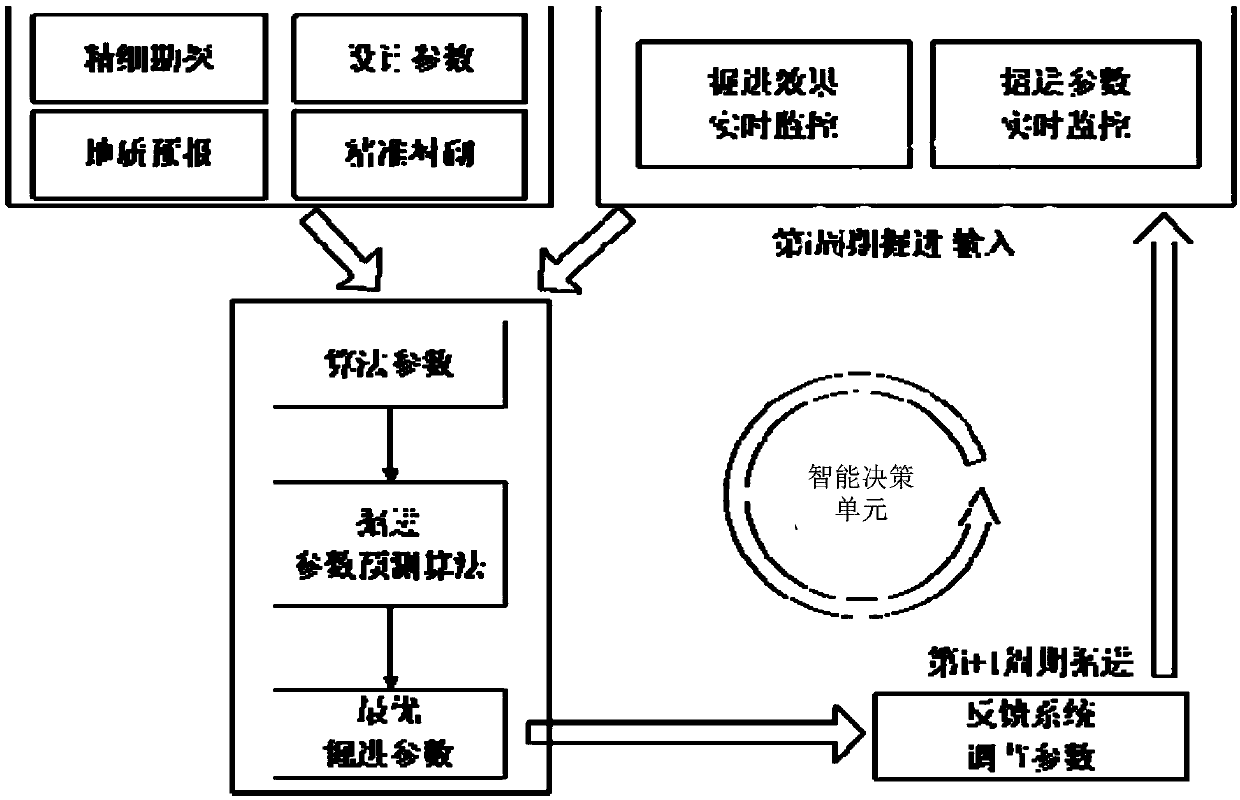

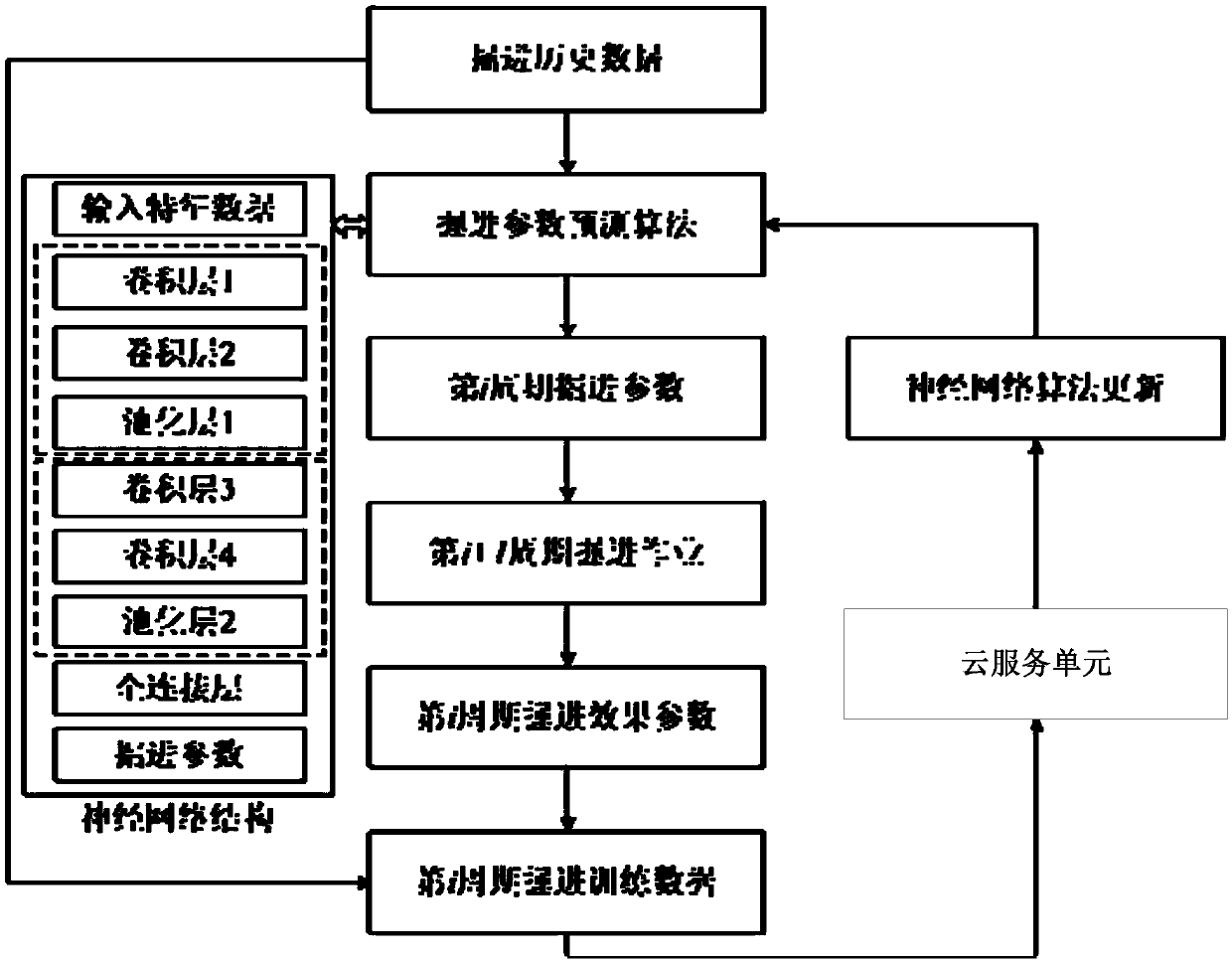

Tunneling robot for tunneling and remote mobile terminal command system

PendingCN109630154AEasy to operateRealize remote controlTunnelsTotal factory controlPrediction algorithmsRemote control

The invention discloses a tunneling robot for tunneling and a remote mobile terminal command system. The robot comprises a body tunneller of the tunneling robot, a sensing unit arranged on the tunneller, an intelligent decision-making unit and a control unit, wherein the sensing unit is communicatively connected with the intelligent decision-making unit, the intelligent decision-making unit is communicatively connected with the control unit, the sensing unit senses a current cycle in real time, the tunneller obtains tunneling operation data during the tunneling operation according to tunnelingparameter setting information, the intelligent decision-making unit receives the tunneling operation data sent by the sensing unit and generates tunneling parameter setting information of a next cycle according to a preset prediction algorithm, the tunneling operation data and desired tunneling effect prediction, and the control unit receives the information and controls the tunneller to executethe next cycle of the tunneling operation according to the tunneling parameter setting information. The robot can execute on-line monitoring, independent decision-making feedback control and unmannedtunneling operation in the tunneling process and achieves unmanned operation or remote control of the tunneller.

Owner:HUANENG YARLUNG TSANGPO RIVER HYDROPOWER DEV INVESTMENT CO LTD +2

Cutting head type shortwall coal-winning machine and comprehensive mechanized coal mining technology

ActiveCN101798925AReduce cutting powerReduce electricity costsUnderground miningSlitting machinesControl systemElectrical control

The invention discloses a cutting head type shortwall coal-winning machine and comprehensive mechanized coal mining technology. A tunneller type cutting device is used, and the coal-winning machine is a hydromechatronics coal-winning machine which is in electric traction, electrically drags a cutting head, carries out hydraulic drive to change a cutting arm pitch angle and swings inside and outside the working face. The coal-winning machine mainly comprises a machine body, a cutting device, a travelling mechanism, a coal shovelling device, an auxiliary device, an auxiliary hydraulic system and an electrical control system. The coal-winning technology uses technical equipment, such as a coal-winning machine, a hydraulic support, a scraper conveyor, an elevating conveyor, a breaker, a crossheading belt, an advance support hydraulic support and the like. The technical flow is as follows: the coal-winning machine retracts to the working surface tail, a scraper-trough conveyer is pushed tocoal wall, coal is cut to the machine head, the machine is retracted, coal is cleaned, and the support is pulled. The coal-winning machine has compact structure, small volume and weight, strong adaptability and convenient installation and transportation, can solve a series of problems of four low, three high, two long and one poor in small and medium coal mining technology and provides matching coal mining technology.

Owner:闫振东

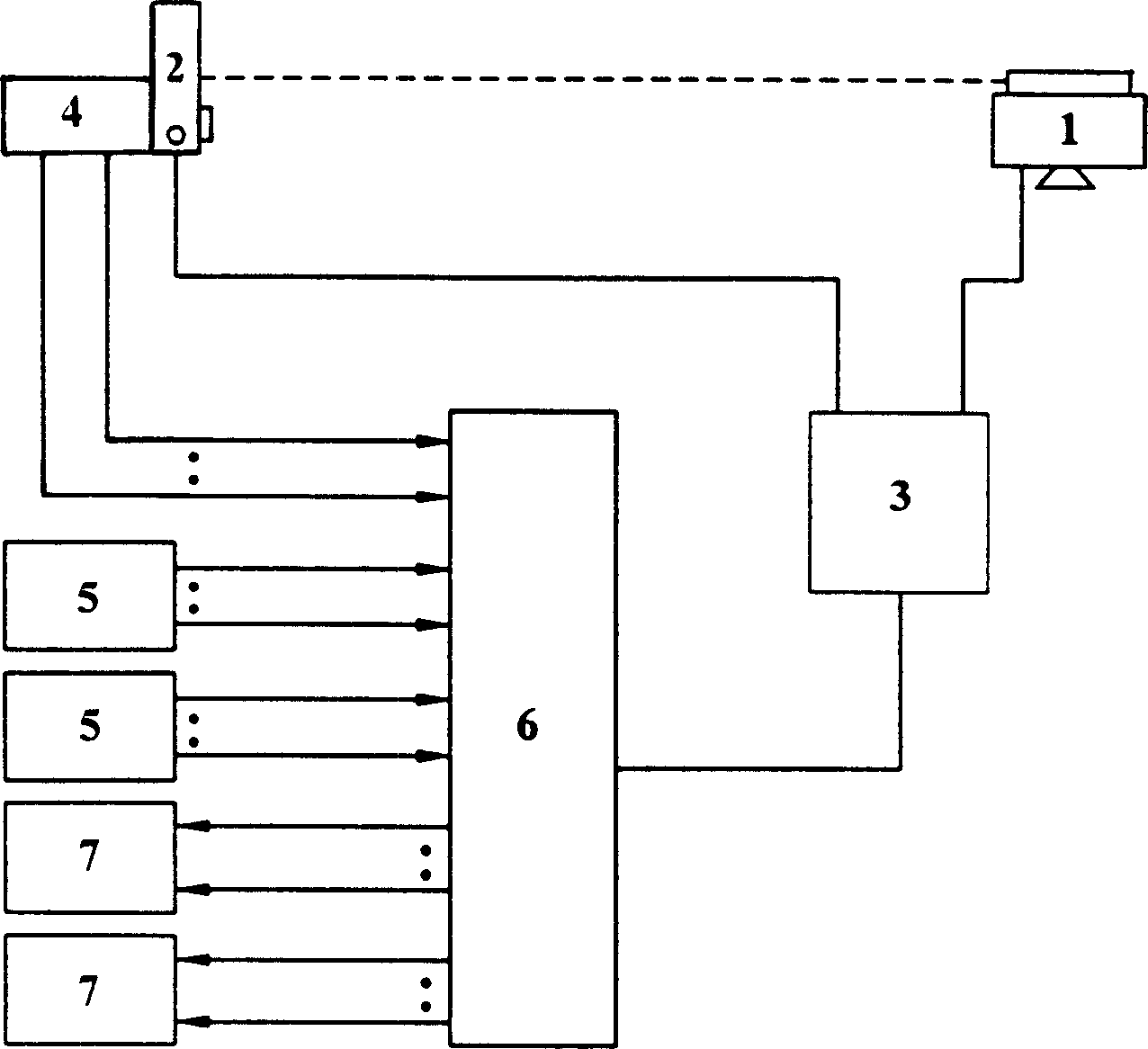

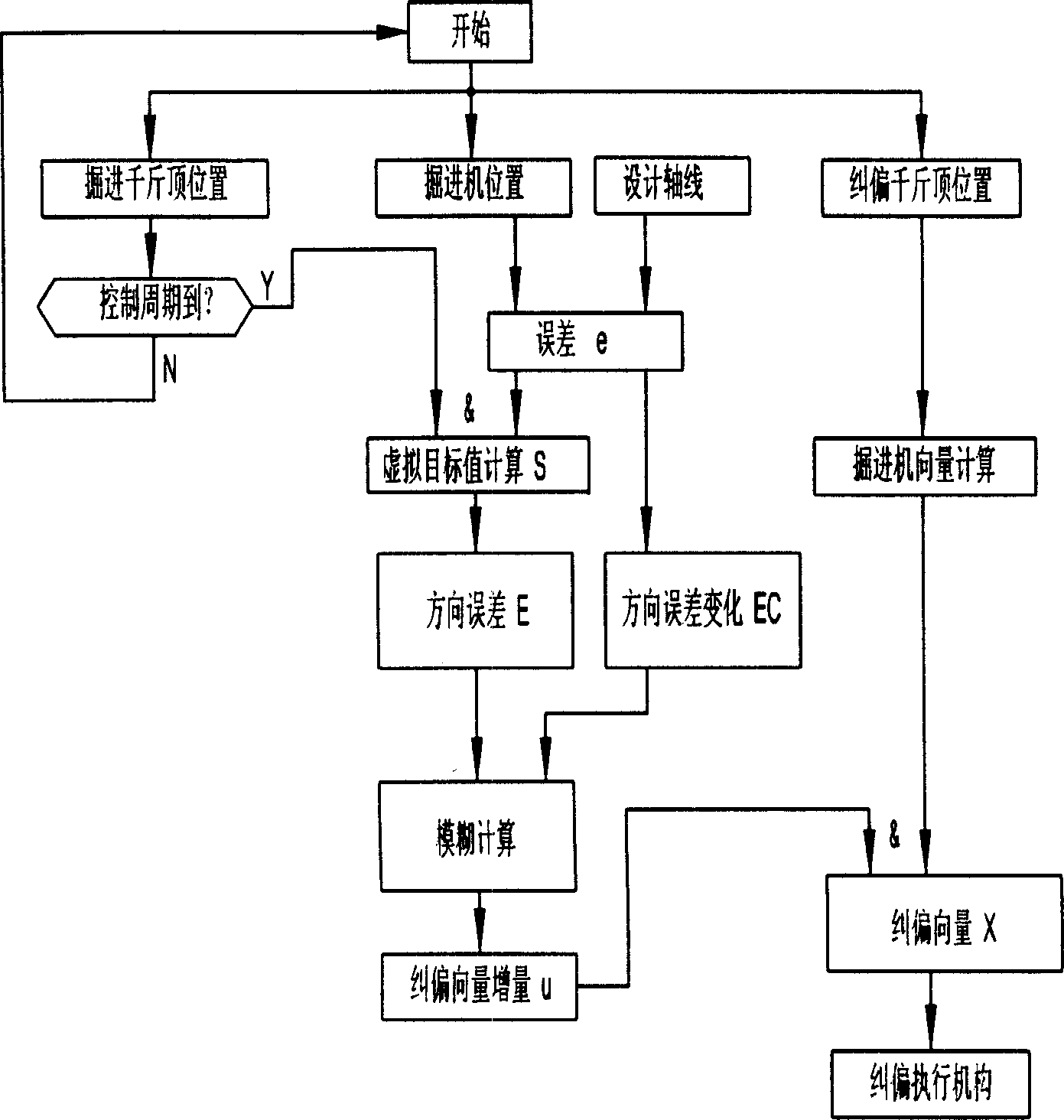

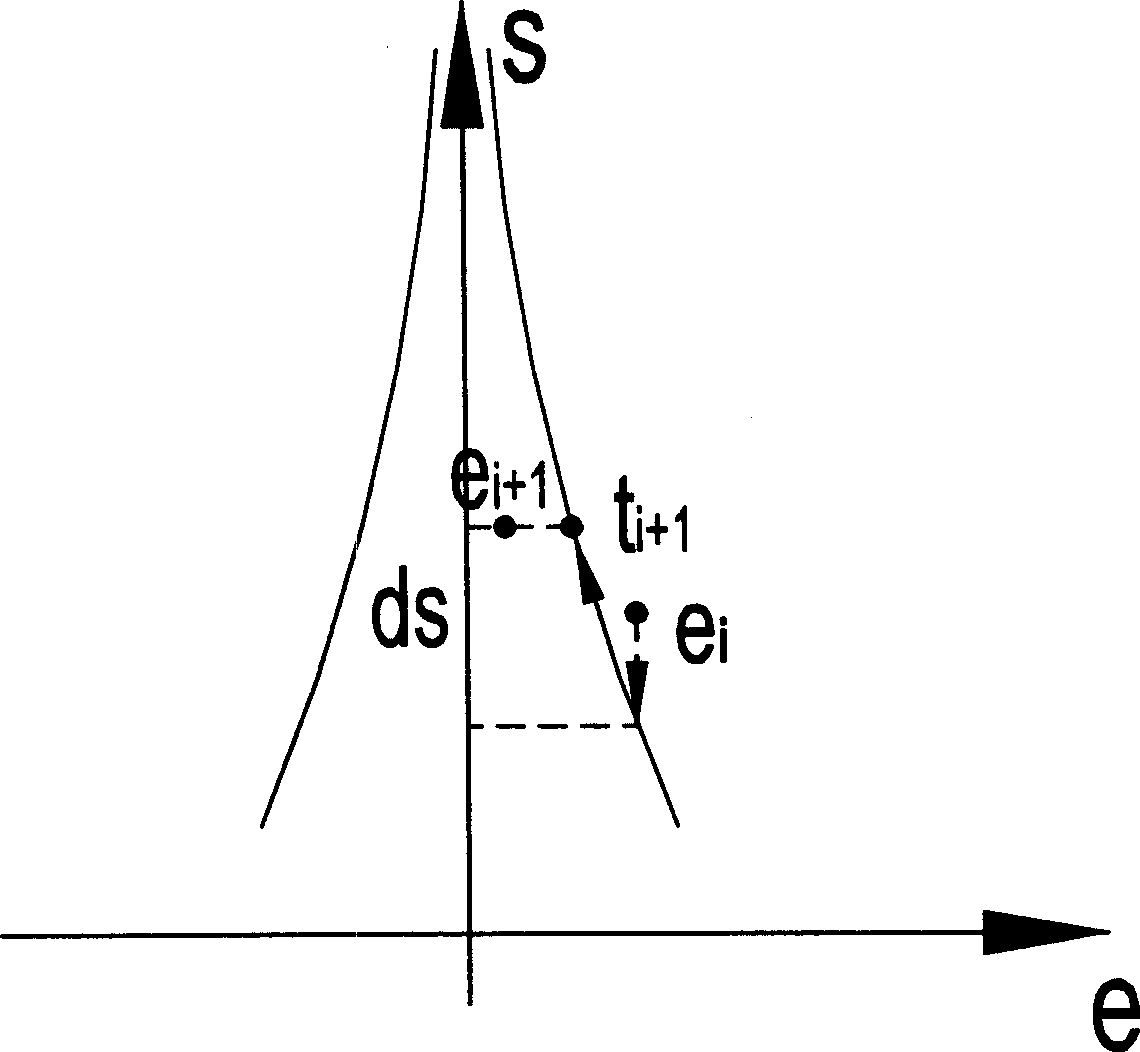

Method for autocontrolling excavation direction of underground excavator using virtual track

InactiveCN1877080ASolve the insurmountable problems of fuzzy controlAvoid Excessive CorrectionTunnelsAutomatic controlUnderground tunnel

The invention relates to a method for automatically controlling the moving direction of underground tunneller via virtual track. Wherein, the correct controller gives the virtual track, based on error between present position and state of tunneller, and the designed axis, and the working condition; said correct controller calculates out the direction error via the virtual track and the axis error, and the variable of direction error, as the input, to obtain the output correct signal via fuzzy control. The invention can gradually correct the underground tunnel, to confirm the construction quality and reduce the axis error. The invention can be used in the underground tunneller with cut pressure balance function.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

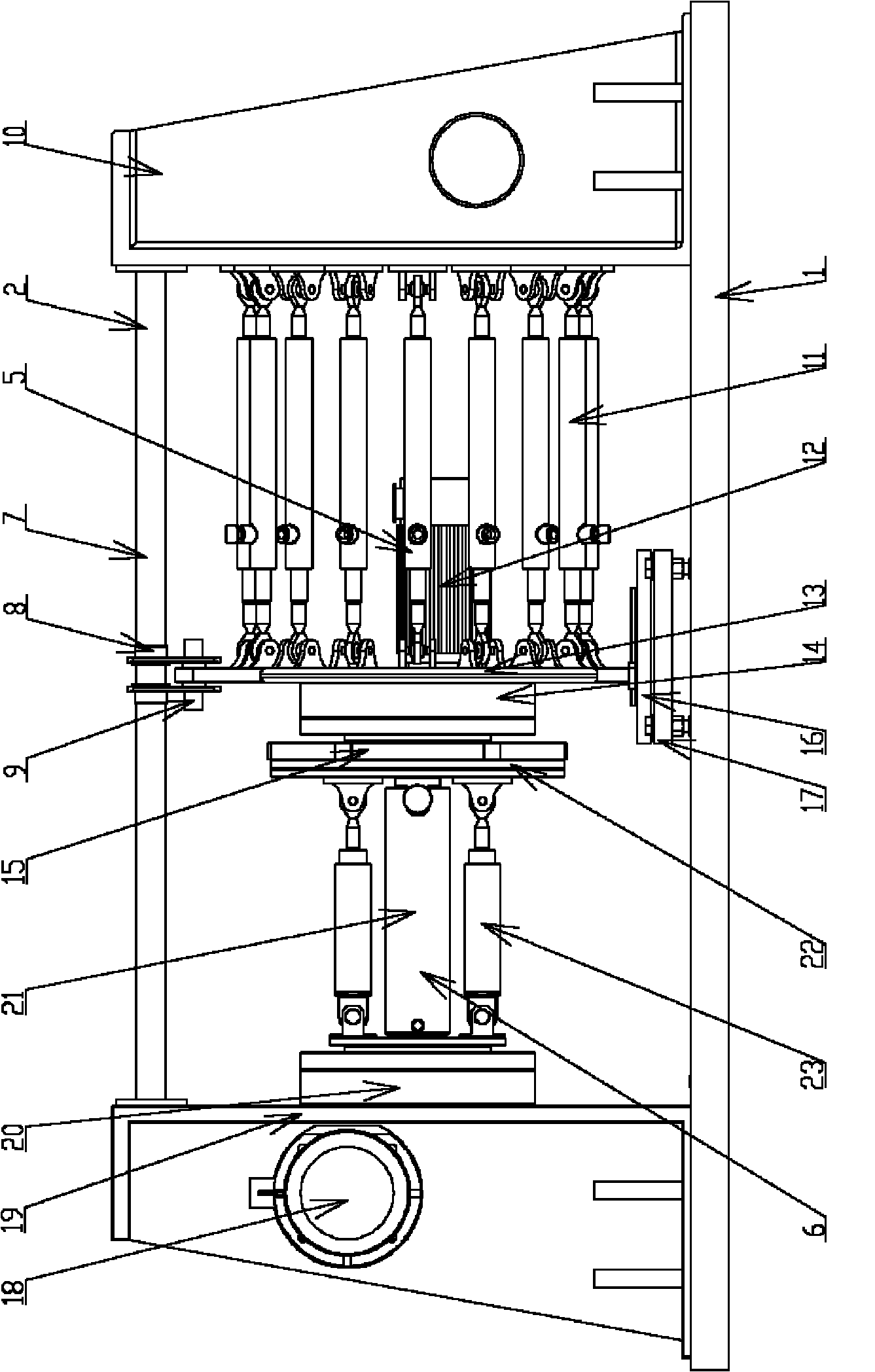

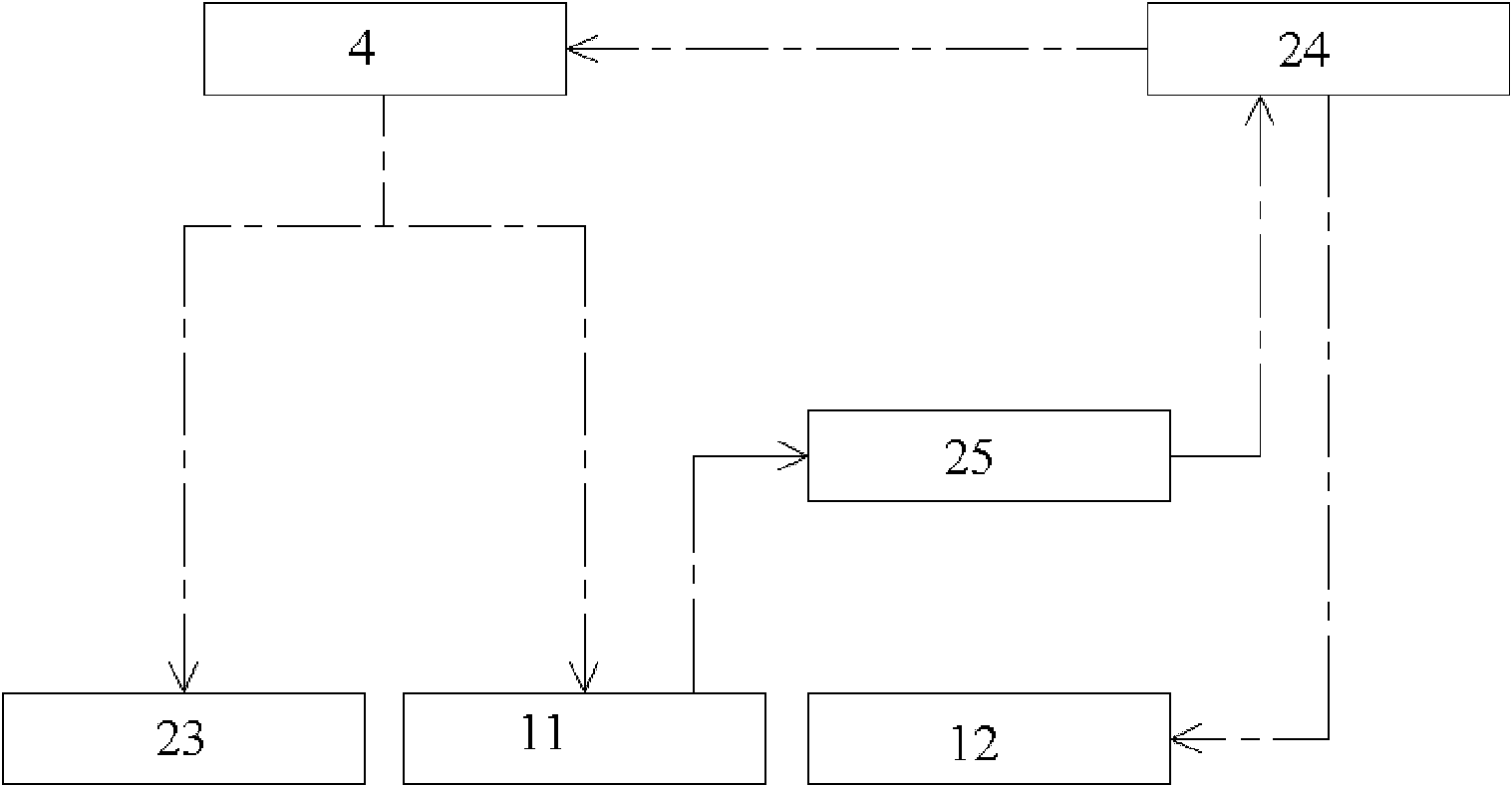

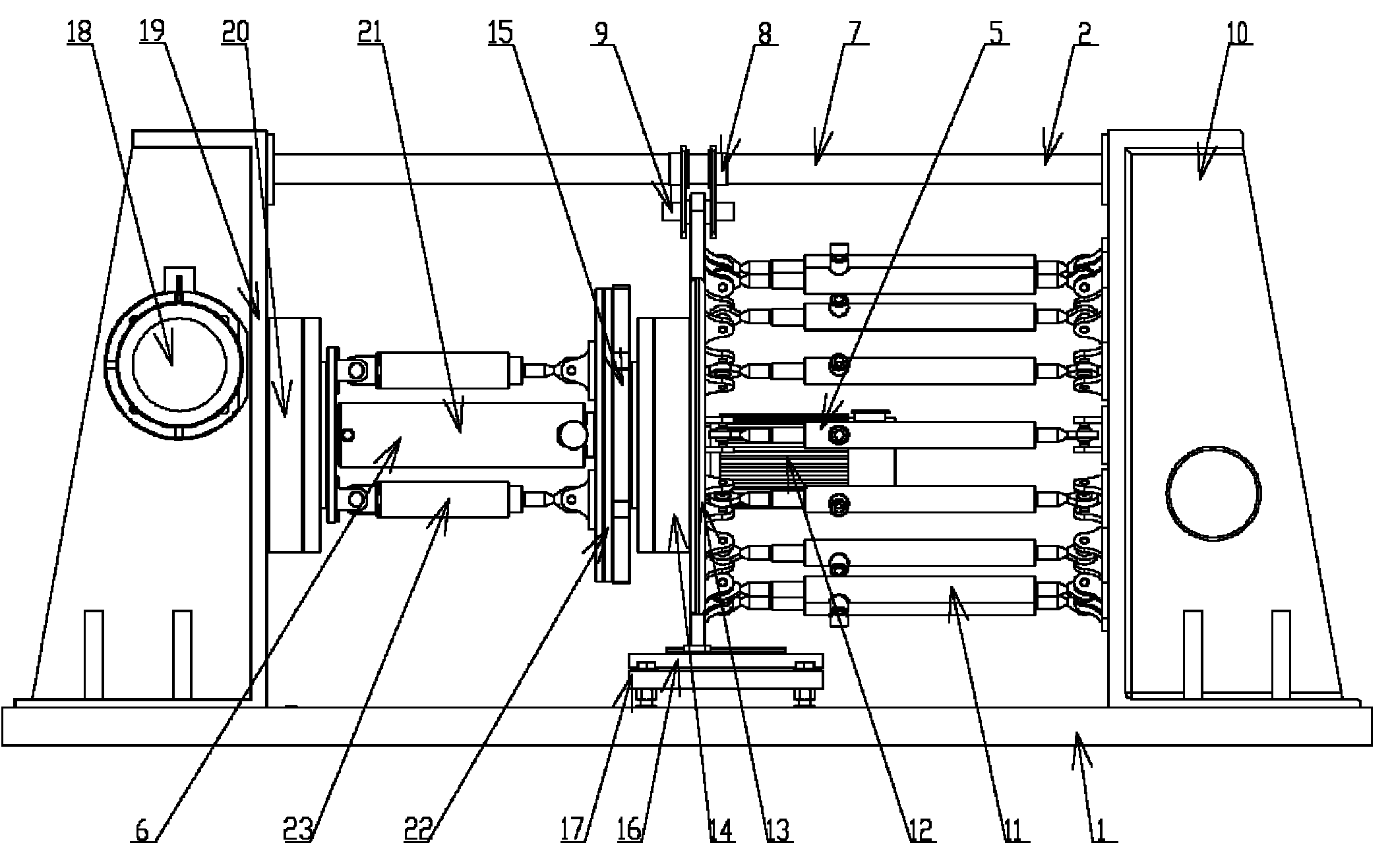

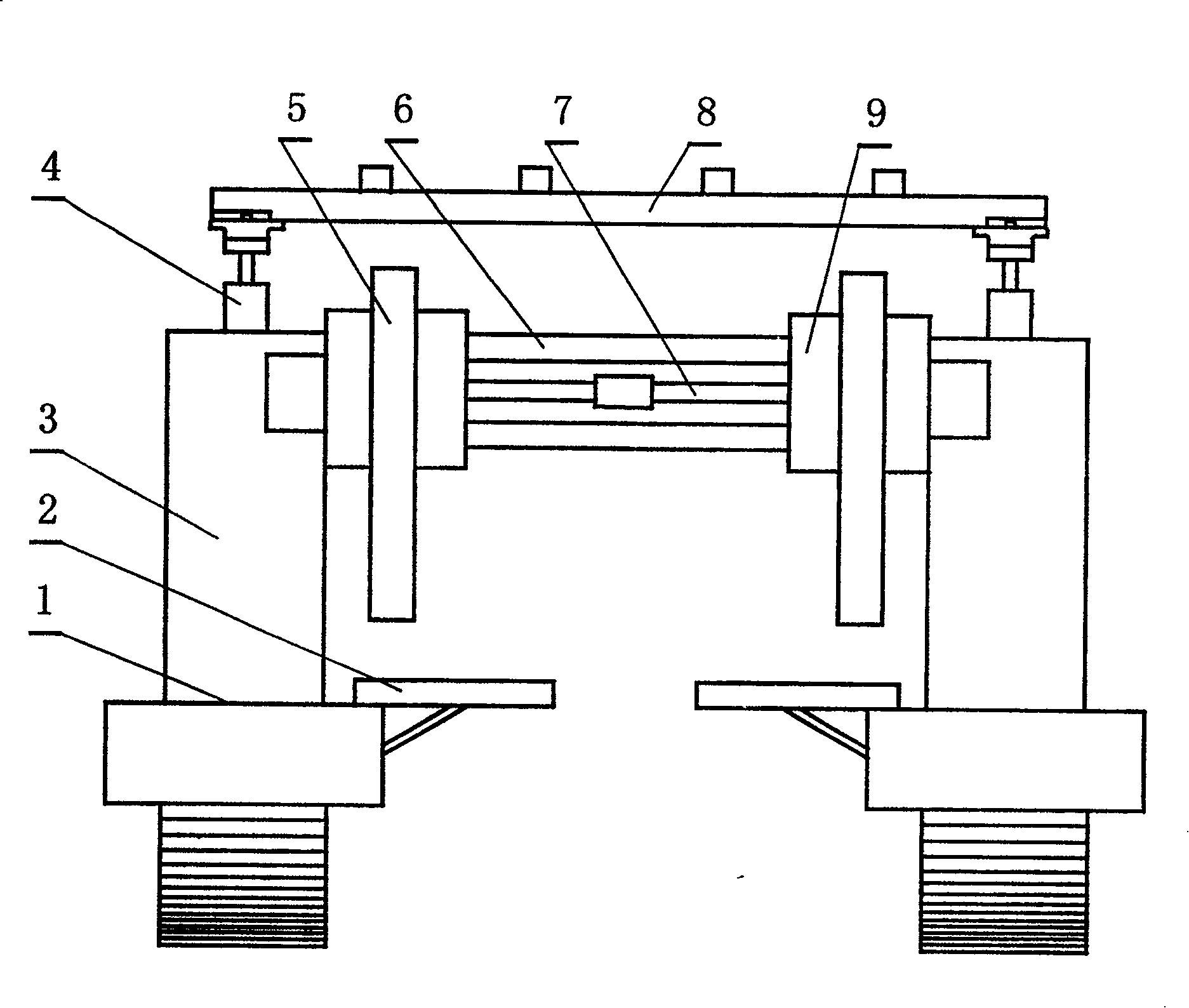

Device for testing force transmission characteristics of tunnellers

InactiveCN101788406AStructural/machines measurementHydraulic/pneumatic force measurementEngineeringTunnellers

The invention provides a device for testing force transmission characteristics of tunnellers in the technical field of tunnel engineering. The device comprises a base, a main top mechanism, a control mechanism, a hydraulic mechanism, a shield simulation mechanism and a load simulation mechanism, wherein the shield simulation mechanism and the load simulation mechanism are arranged on the base; the main top mechanism is connected with the shield simulation mechanism and the load simulation mechanism respectively; control mechanism is connected with the shield simulation mechanism and the hydraulic mechanism respectively; the hydraulic mechanism is connected with the load simulation mechanism and the shield simulation mechanism. The device can simulate various working conditions of shield machines in the tunneling process and qualitatively analyze the force transmission characteristics of shield-machine propulsion devices in the tunneling process so as to lay a foundation for compliance scheme design of the shield machines.

Owner:SHANGHAI JIAO TONG UNIV

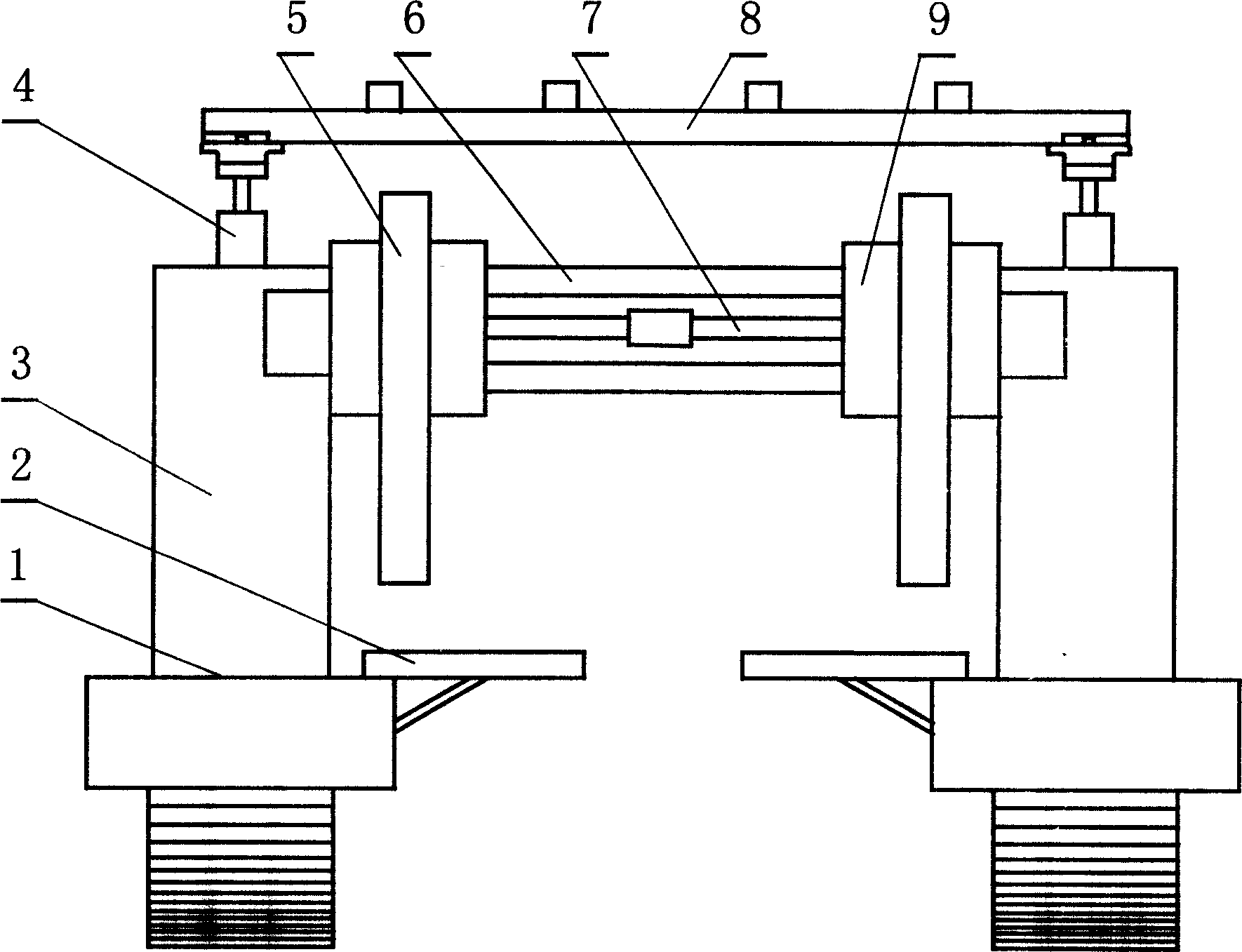

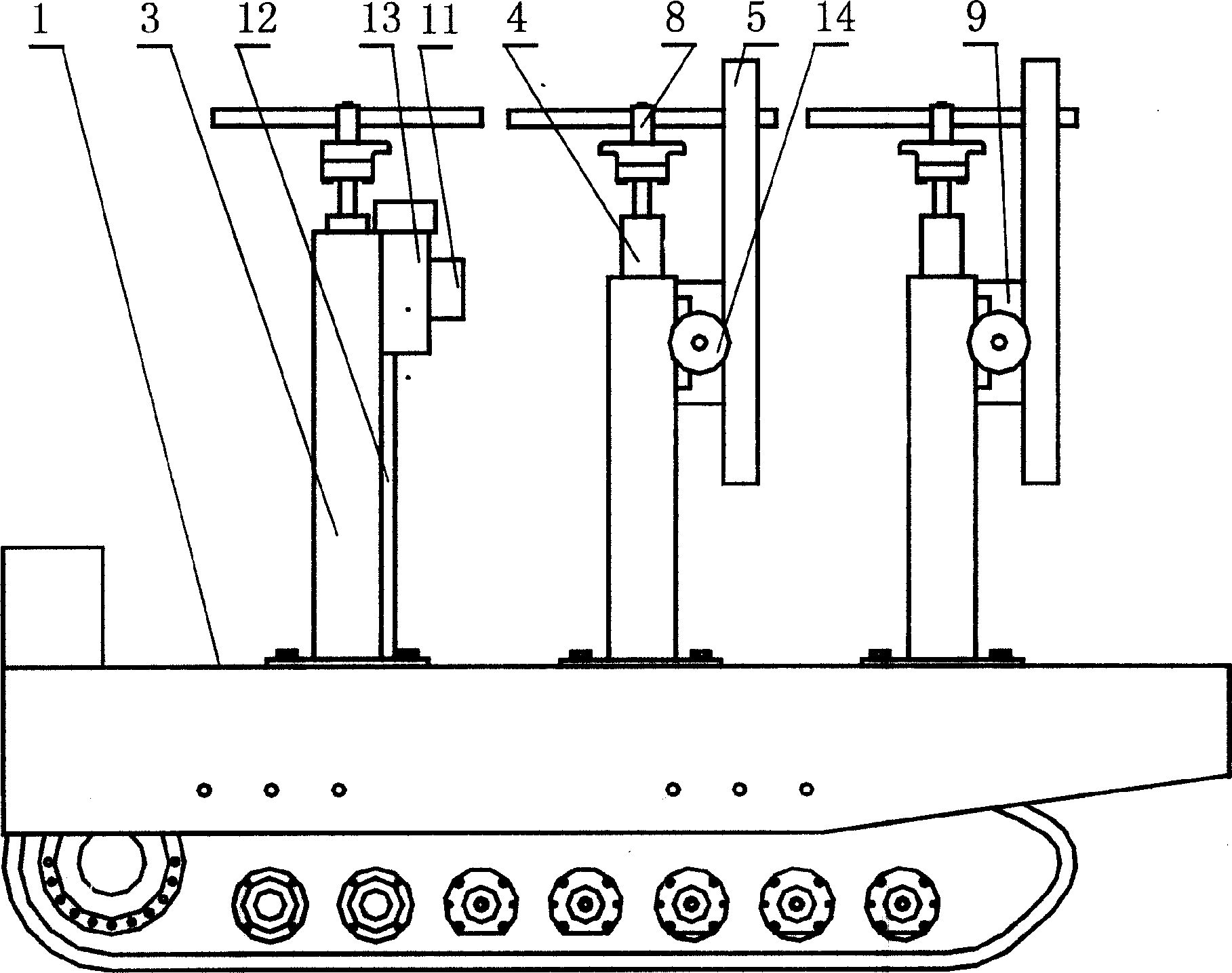

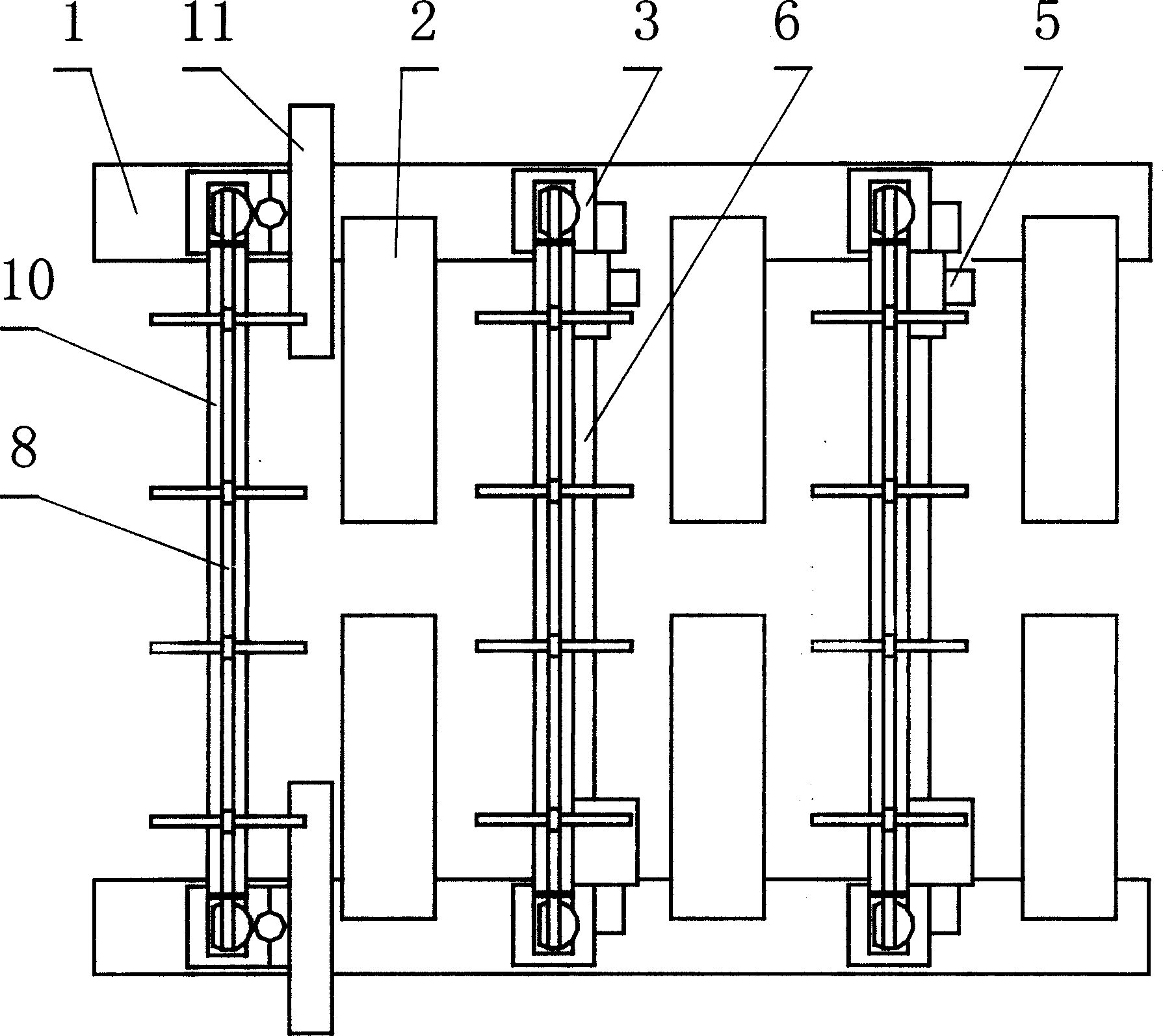

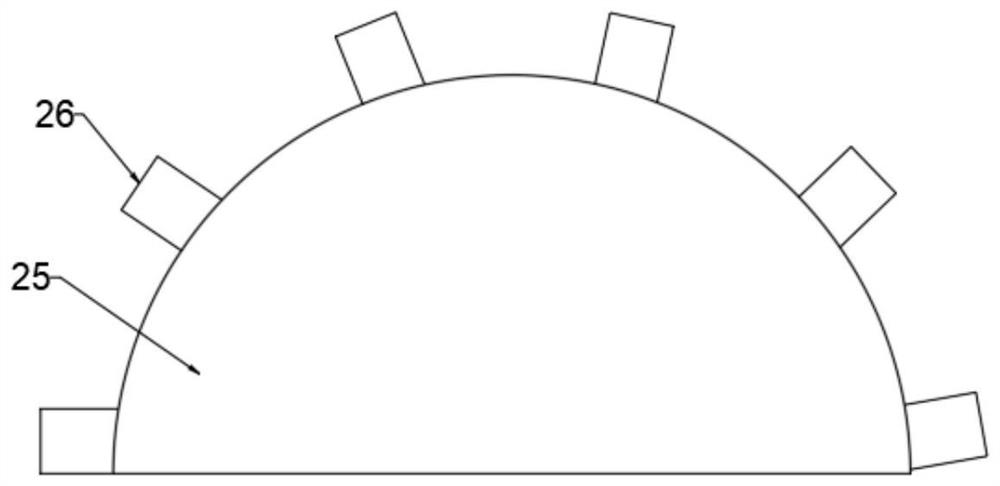

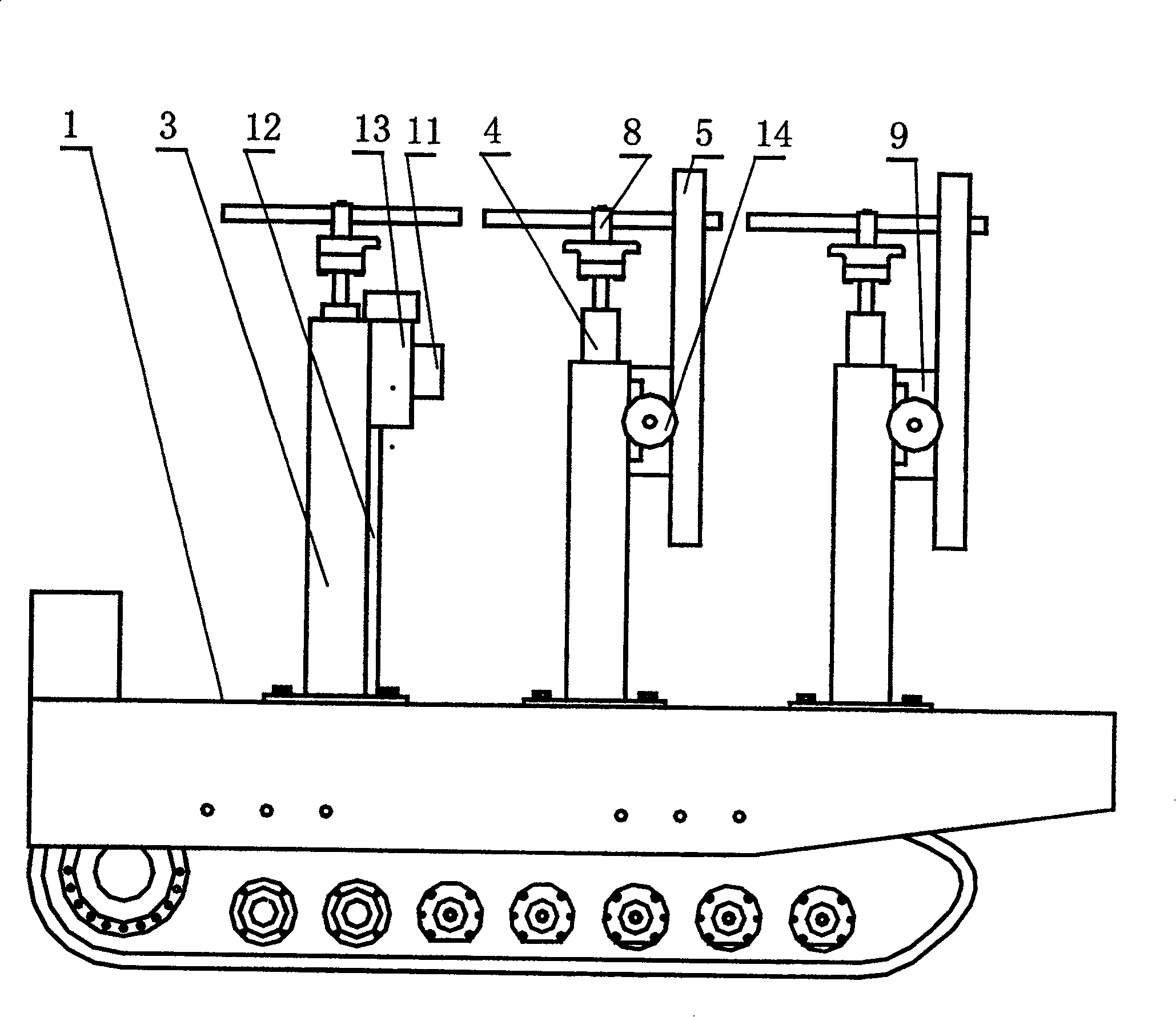

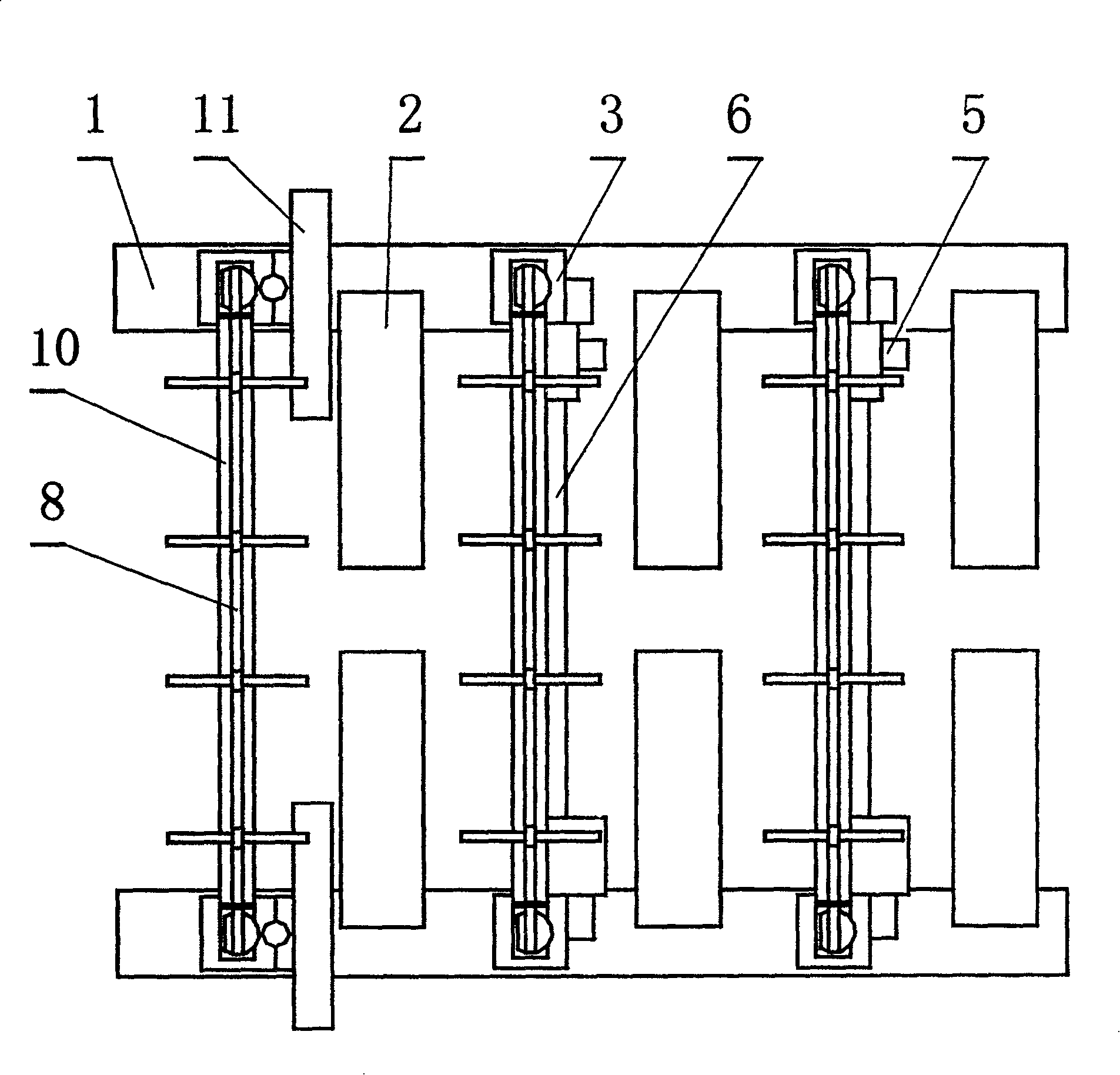

Gantry type self-walking roofbolter

InactiveCN1884785AGuaranteed non-interferenceImprove work efficiencyConstructionsRotary drillingEngineeringTunnellers

The invention relates to a tunnel constructing device, especially providing an automatic anchor rod driller for supporting the top plate and side wall, wherein said invention is formed by track walking device, frame and the drilling machine mounted on the frame; said invention can not work with tunneller, to cause low working efficiency. The invention is mainly formed by two separated portable frames mounted on the track walking device; the longitudinal and transverse drilling machines are independently mounted on the beam and upright post of portable frame; the tunneller can move at the middle of portable frame, to improve the working efficiency.

Owner:SHANXI DONGHUA MACHINERY

Wet type dust collector for crag lane or half coal crag lane

InactiveCN101892858AImprove visibilityAvoid pneumoconiosisDust removalFire preventionVisibilityMental health

The invention mainly relates to a dust reducing and removing device for a mine, in particular to a wet type dust collector for a crag lane or a half coal crag lane suitable for tunneling a working face of the crag lane or the half coal crag lane. The wet type dust collector is formed by combining an air intake pipe assembly, a frame, a wet filter type dust collector, an axial flow fan and a water quality filter component, wherein the wet filter type dust collector, the axial flow fan and the water quality filter are all arranged on the frame; the air intake pipe assembly consists of an air intake square pipe I, an air intake square pipe II, an air intake square pipe III and a negative pressure air duct; the air intake square pipe I, the air intake square pipe II, the air intake square pipe III and the negative pressure air duct are connected in turn; an air inlet at the front of the axial flow fan is connected with the negative pressure air duct; and an air outlet of the axial flow fan is connected with the wet filter type dust collector. The device has efficient dust removing effect, greatly improves the visibility of a tunneller operator, further improves the work efficiency, effectively prevents production workers from pneumoconiosis and plays an important role in ensuring physical and mental health of the workers for tunneling the working face and safe production of a coal mine.

Owner:CHANGZHI YINGSHENG TECH DEV

Dust removal device

The invention provides a dust removal device, which comprises a horizontally arranged dust removal box body, wherein an inner cavity of the dust removal box body is a gas flow channel; an air inlet is formed at one end of the dust removal box body, and the other end of the dust removal box body is connected with a fan; an air outlet is formed on the rear part of the fan; a plurality of water sprayers are arranged in the dust removal box body; a filter layer is arranged behind the sprayers; a vibration motor is arranged on the rear part of the filter layer; and a labyrinth-type dehydrator is arranged behind the filter layer. According to the dust removal device, dust in the air is stopped effectively, and an effect of purifying the air is achieved; water-containing dust is removed from the filter layer through the vibration of the vibration motor, so that further self-purification of the filter layer is realized, the probability that the filter layer is blocked is reduced greatly, and the maintenance frequency is reduced; and the dust removal device has a small volume, light weight, high dust removal efficiency, a simple structure, long service life and low energy consumption, is convenient to maintain, safe and reliable, and meets demands for ventilation, dust extraction and dust-containing air purification on working surfaces or other dust production working sites of coal mine underground tunnellers.

Owner:SANY HEAVY EQUIP

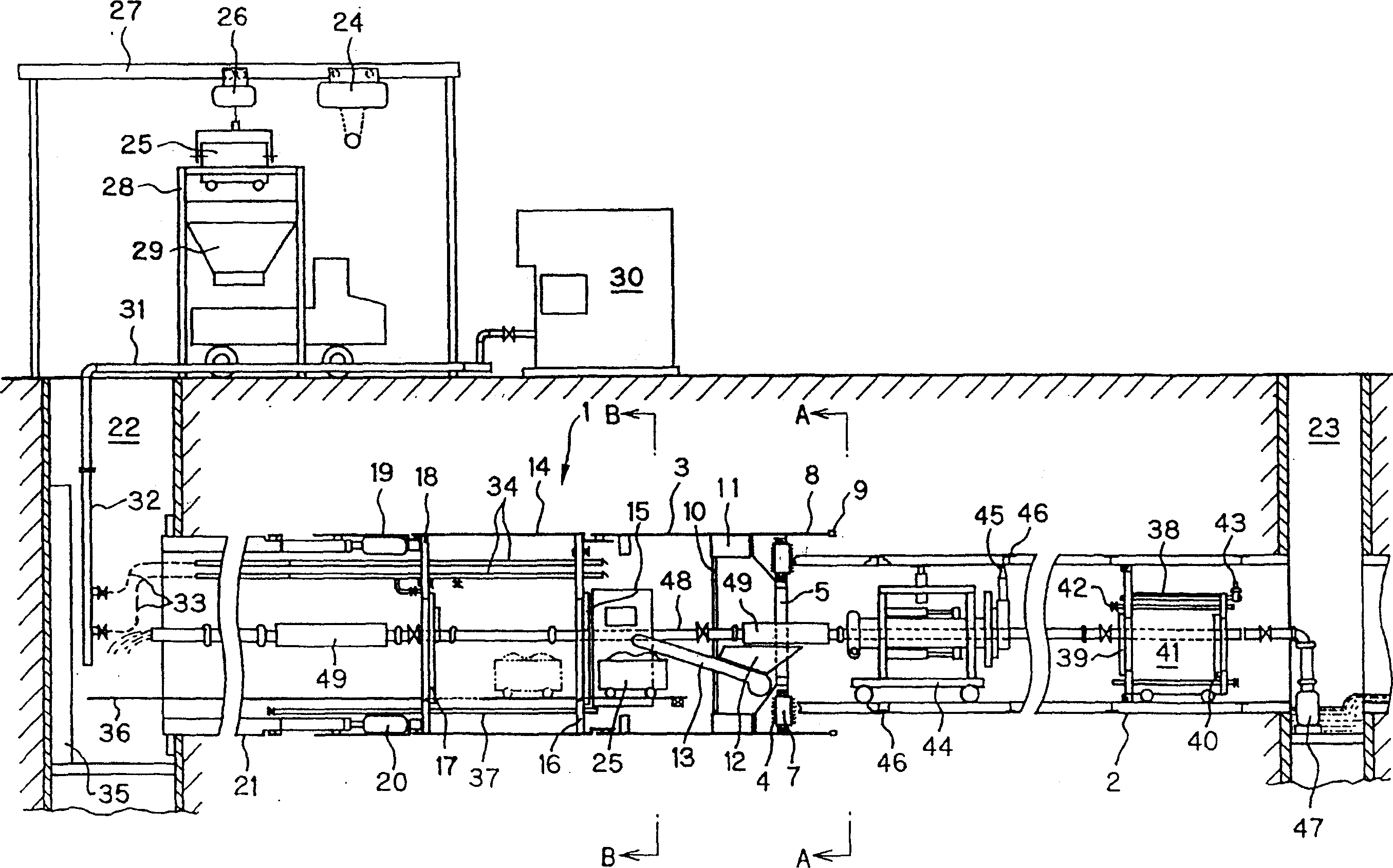

Construction mode with full cross-section tunneller

The full-section entry-driving machine construction method includes the following processes of cutting rock, lining pipe-sheet, pipe-sheet water-stopping, backfilling gravel and pouring cement slurry, in which the pipe-sheet water-stopping process includes the following steps: butt-jointing pipe-sheets, placing the filling strip on the butt joint of bottom of filling groove, inserting the plasticwater-stopping material into filling groove, wedging iron wedge from top of filling groove and backfilling high-strength cement slurry into butt-joint seam is pipe-sheet surface, and the process of backfilling gravel and pouring cement slurry includes the following steps: sectionalizing periphery of pipe-sheet, placing rubber hose along the periphery of pipe-sheet, air-inflating hose, backfillinggravel, pouring cement slurry, finally releasing air from hose and pouring cement slurry.

Owner:刘丽萍

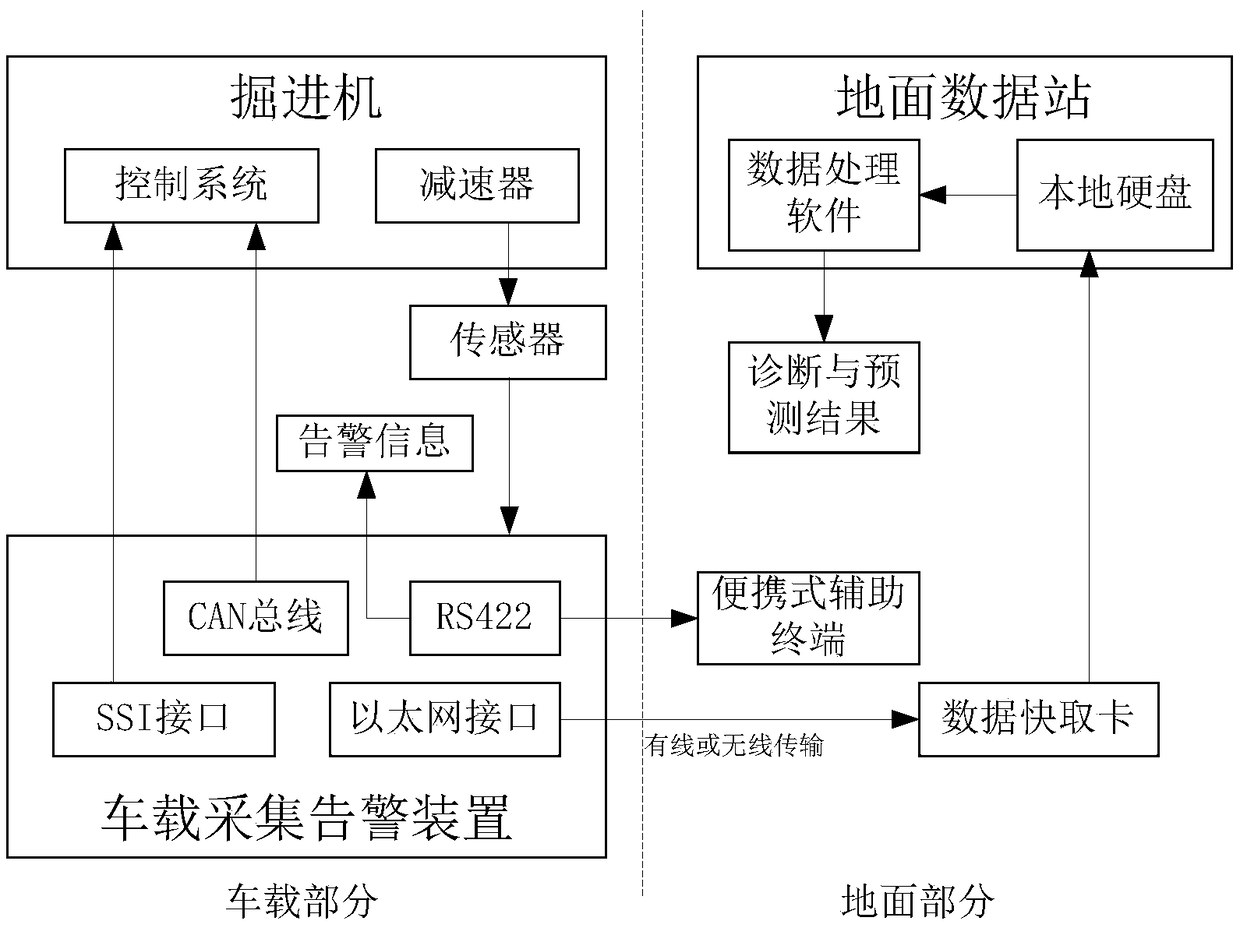

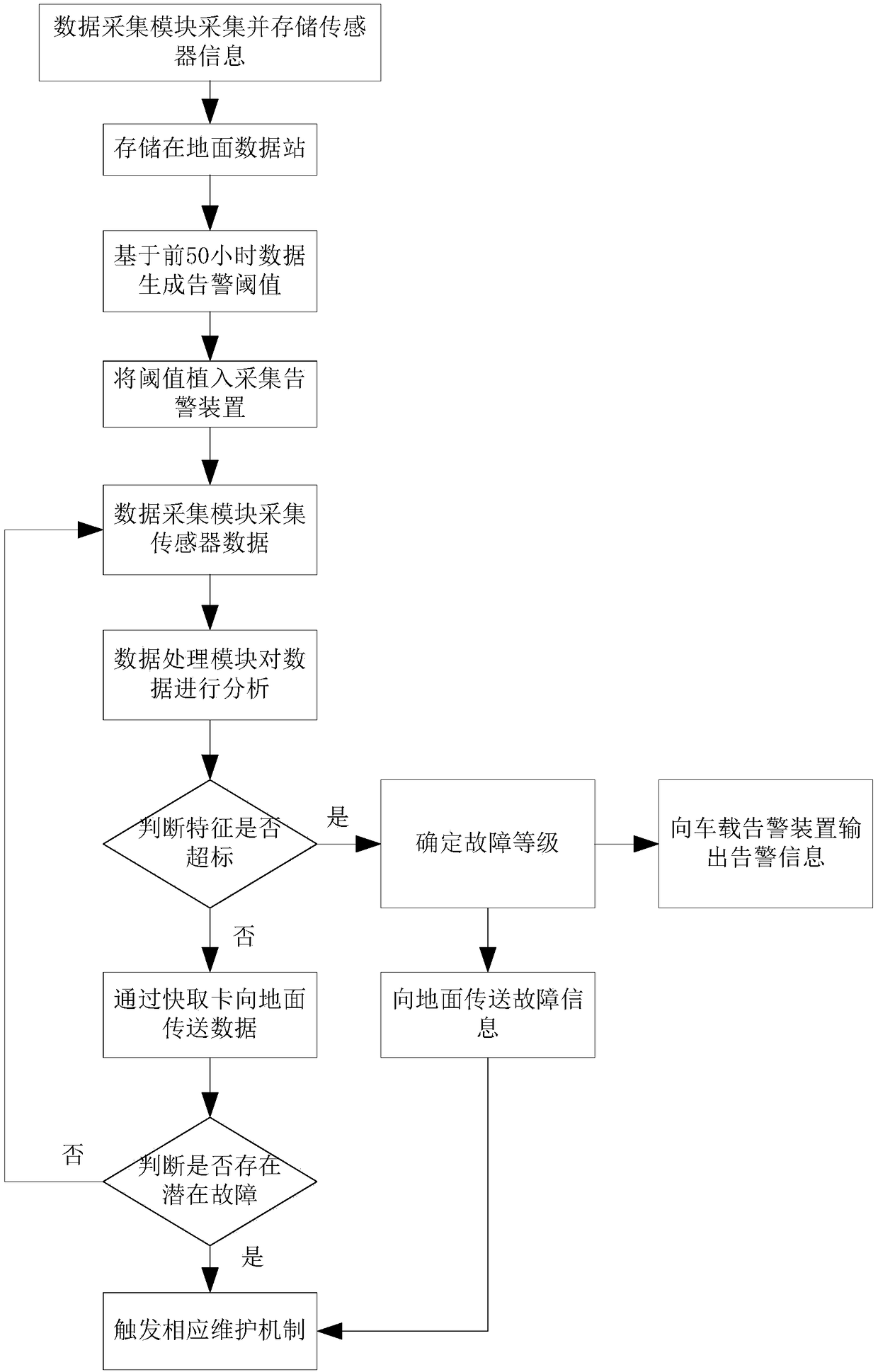

System and method for predicting fault of working arm reducer of tunneller.

ActiveCN109405889AReduce configuration requirementsLower requirementMeasurement devicesFeature extractionState parameter

The invention discloses a system and method for predicting the fault of a working arm reducer of a tunneller. The system comprises a vehicle-mounted part and a ground part. The system is capable of realizing state parameter monitoring and potential fault prediction of a gearbox of a working arm of a tunneller. The vehicle-mounted unit collects using state parameters of the gearbox of the working arm of the tunneller, carries out feature extraction and alarm judgment on the using state parameters, and determines an alarm part and generates a maintenance suggestion code. The ground system downloads data collected by the vehicle-mounted part and carries out data analysis to realize potential fault prediction and discovered fault location of a key part. With the system and method, the economyand safety of the running of the tunneller are improved.

Owner:AVIC SHANGHAI AERONAUTICAL MEASUREMENT CONTROLLING RES INST

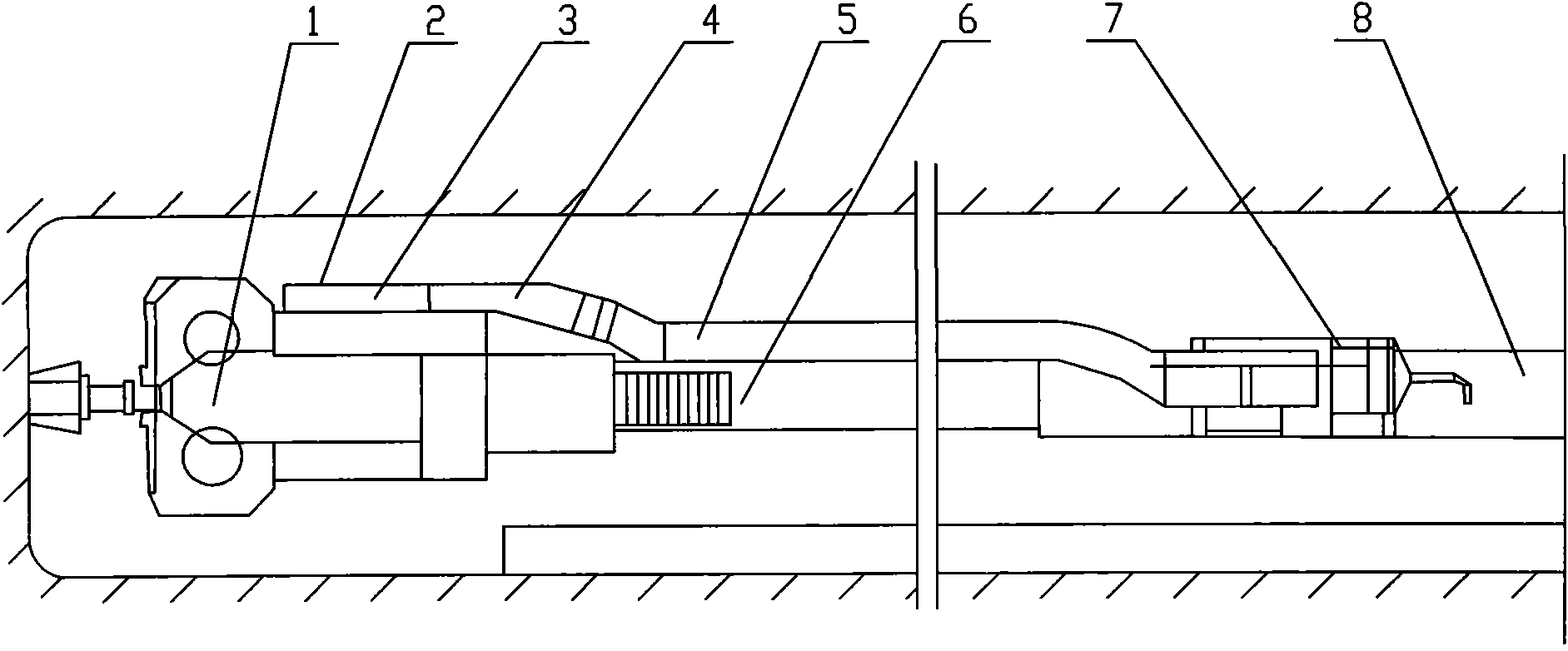

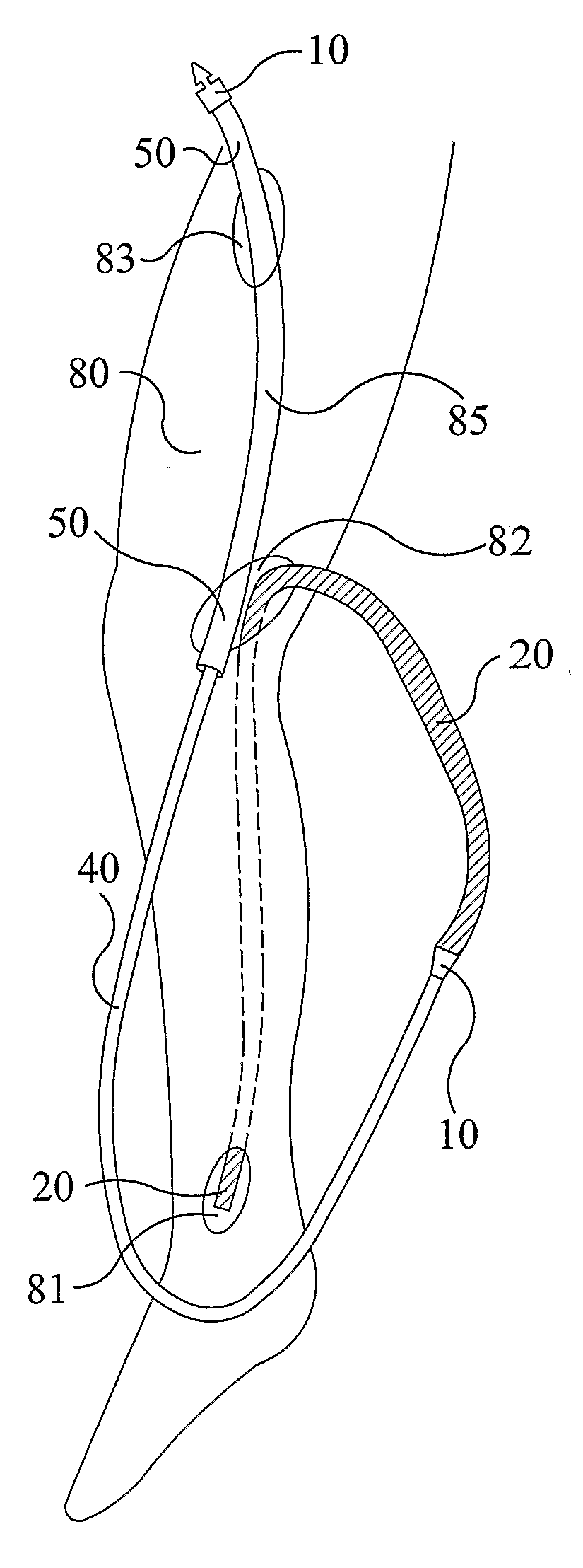

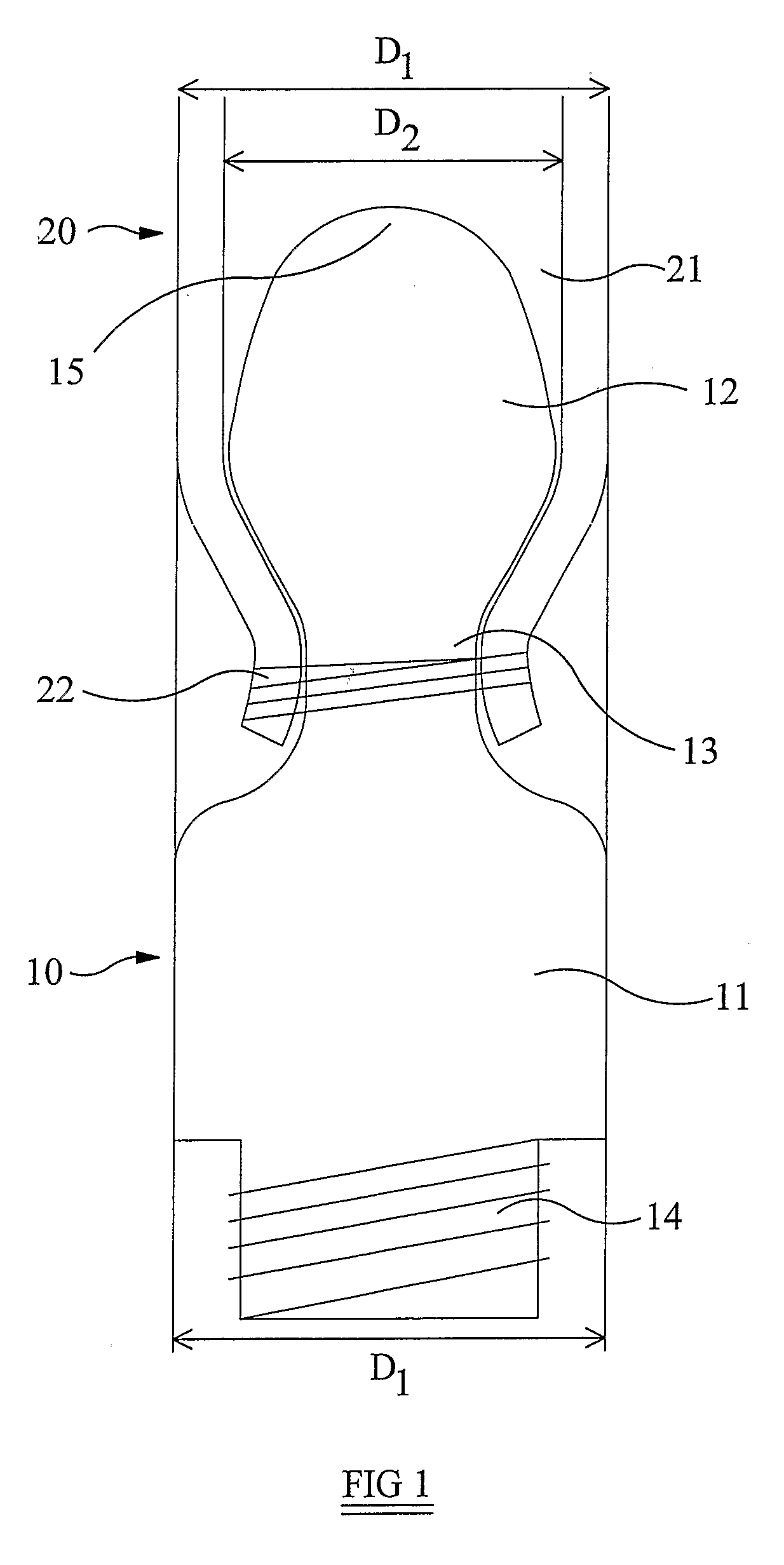

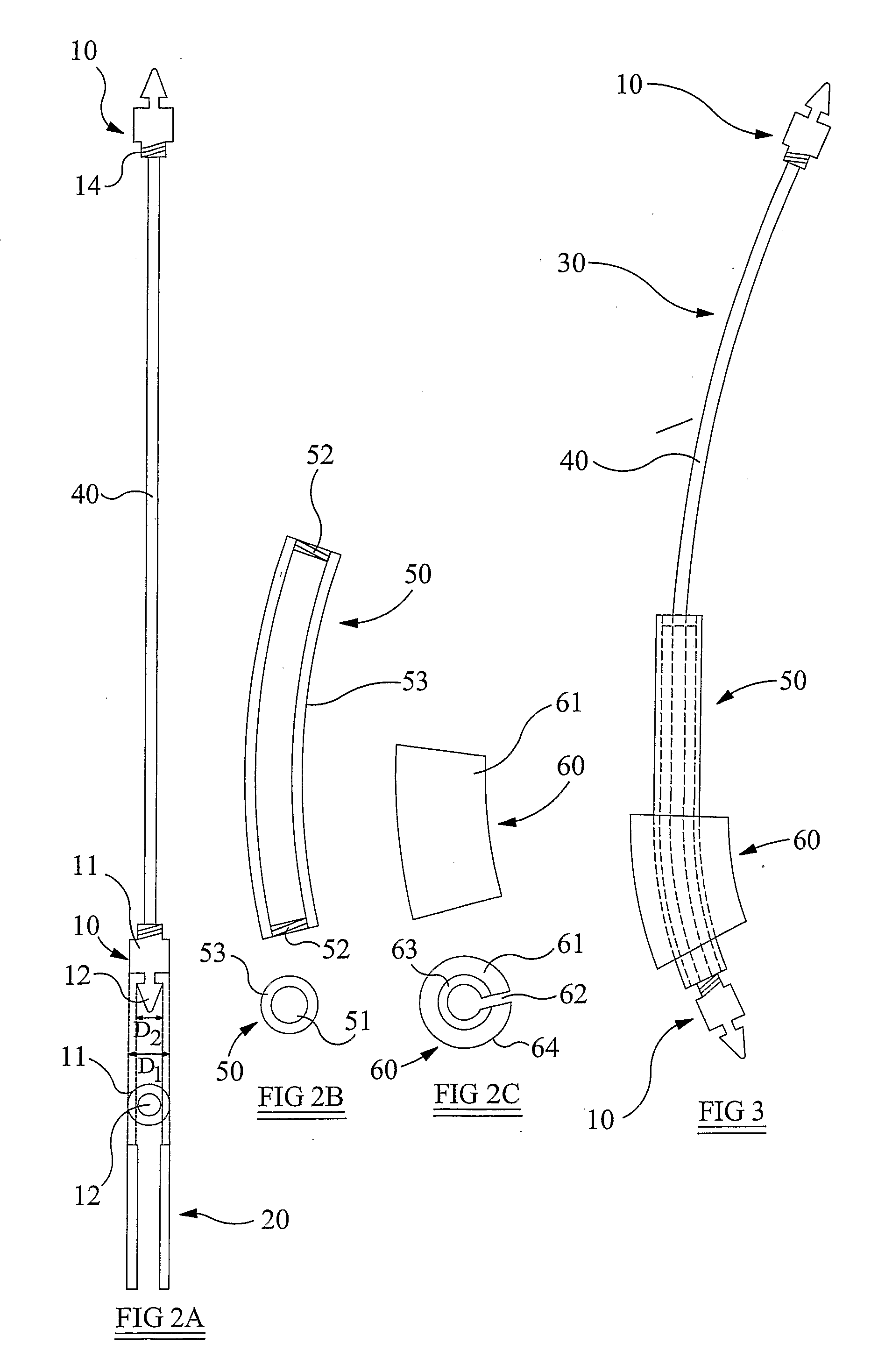

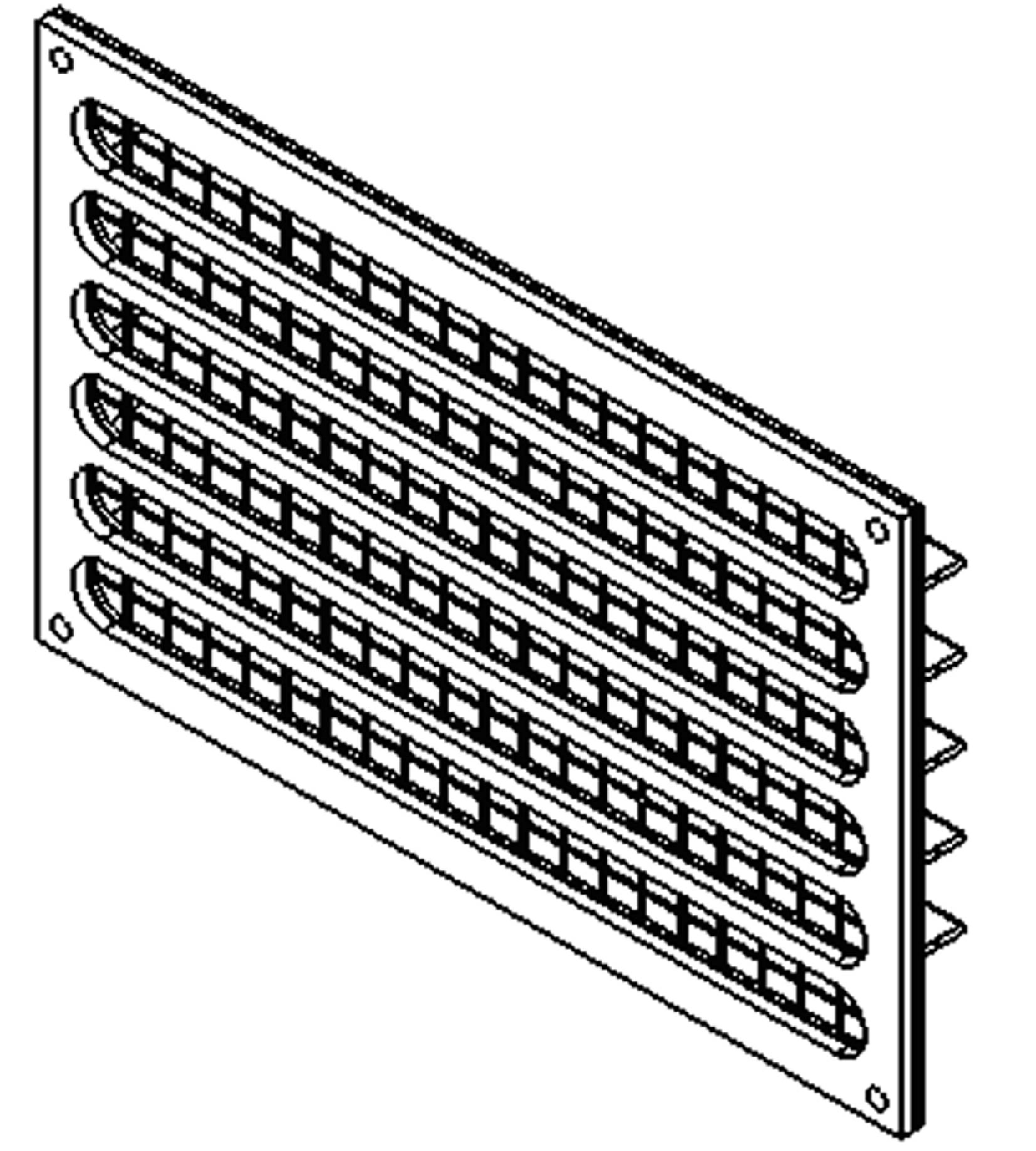

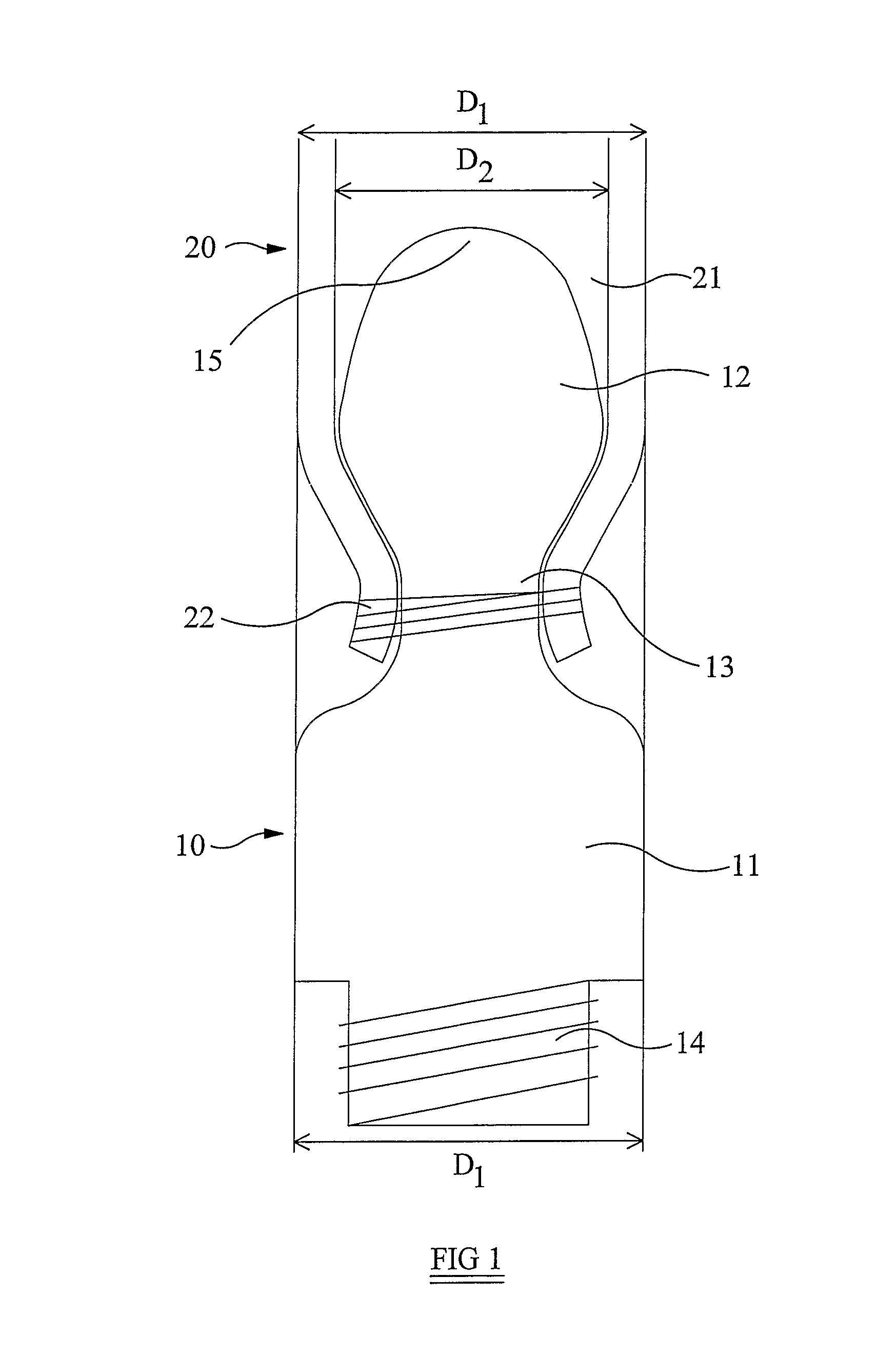

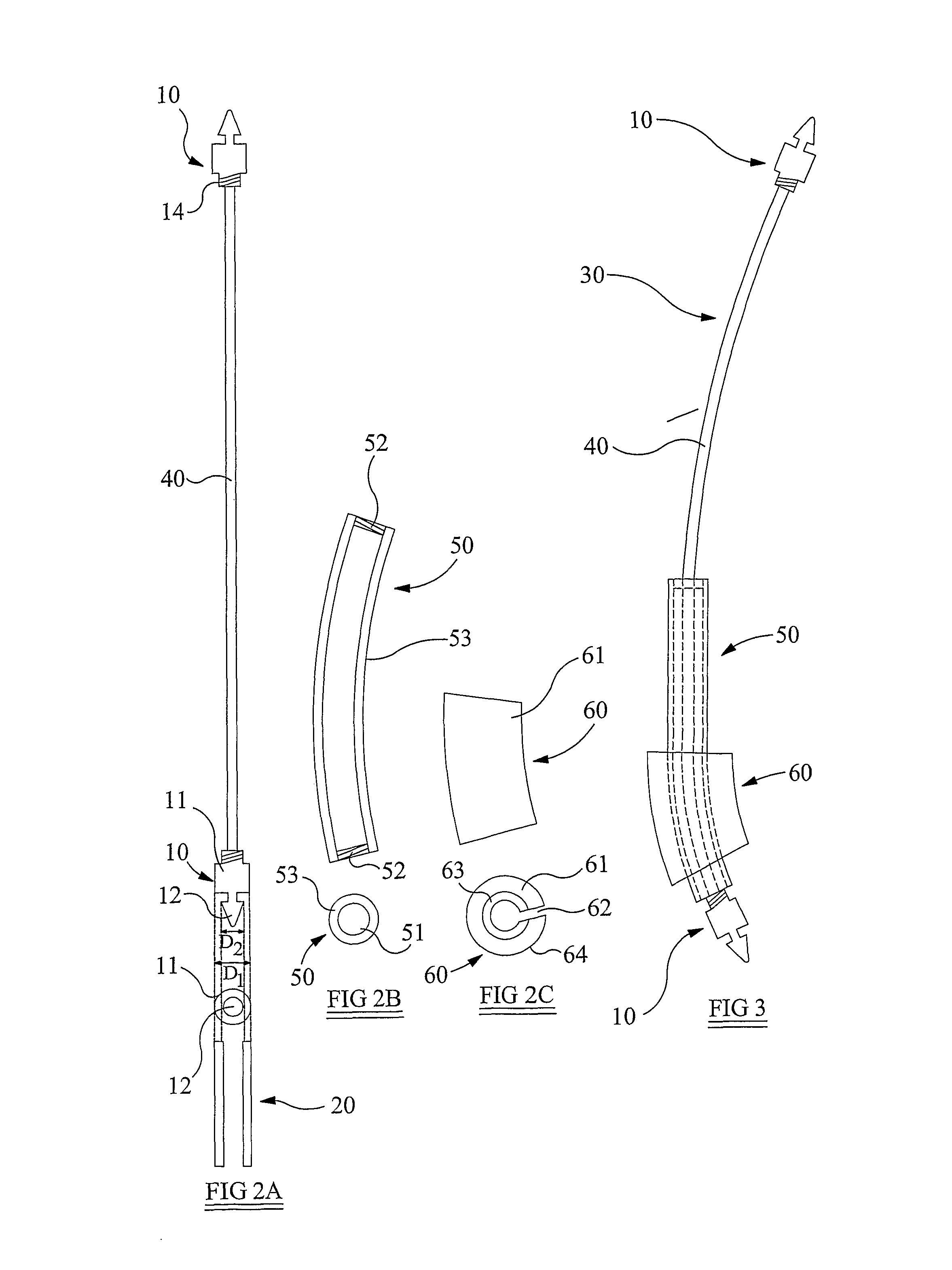

Tunnelling Instrument for Subcutaneously Placing an Article, and Method of Use of Said Instrument

ActiveUS20090299377A1Addressing Insufficient ControlSteering precisionEar treatmentSurgical needlesPortion sizeEngineering

An improved tip and handle for a tunnelling instrument are provided along with an improved tunnelling instrument. The tip is configured for attachment to a tunnelling instrument and includes a first portion configured to form a tunnel, a second portion sized to fit within a tubular component to be placed in the tunnel, and a third portion configured for attachment of the tubular component. The handle is configured to be attached to and detached from a tunneller shaft of a tunnelling instrument, at any point along the length of the tunneller shaft. The tunnelling instrument comprises a pair of tips, a connection means for forming a link between the tips, and a tunneller shaft slidably engagable with the connection means and attachable to either of the tips. Various forms of use of the tunnelling instrument are also disclosed.

Owner:PLASMED

Pneumatic development machine for replacement of existing concrete conduit and replacing method therefor

The invention relates to an air-pressure tunneller for breaking concrete tube, which has a head and a knife disk its front. It is characterized in that: said head is a wheel head with central cut and said knife disk is a wheel knife disk with a central cut and mounted with several rotational hob cutters, while their inner diameters are larger than the outer diameter of concrete tube; the invention has one air-pressure room connected to the air compressor while its front and back parts are both mounted with air locker. The inventive improvement comprises: the back of main body is fixed with the air-pressure room and the semi-shield machine via pins; the semi-shield jack is fixed with several back new tubes via pins; the invention also contains discharge tube that extending in the concrete tube and through the main body, air-pressure room and the semi-shield machine. The invention also provides a relative method to refresh the concrete tube. With said invention, workers can enter into the tube.

Owner:柏素秦

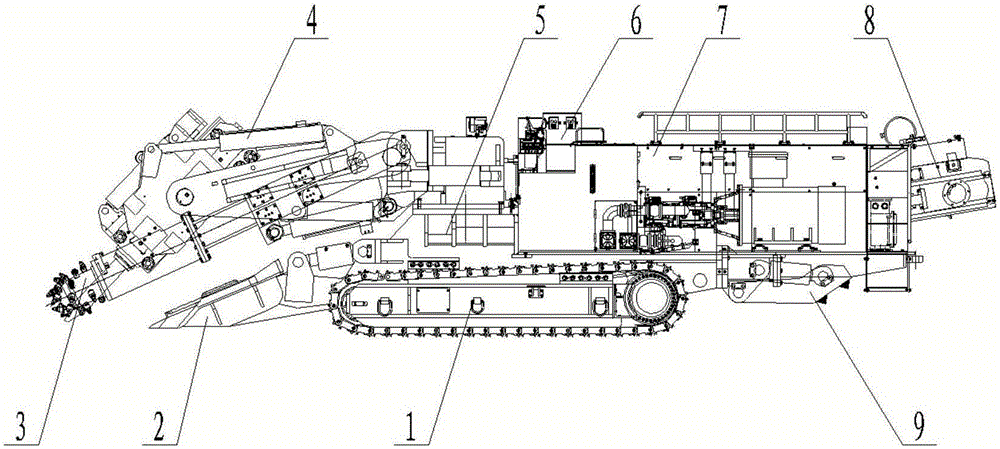

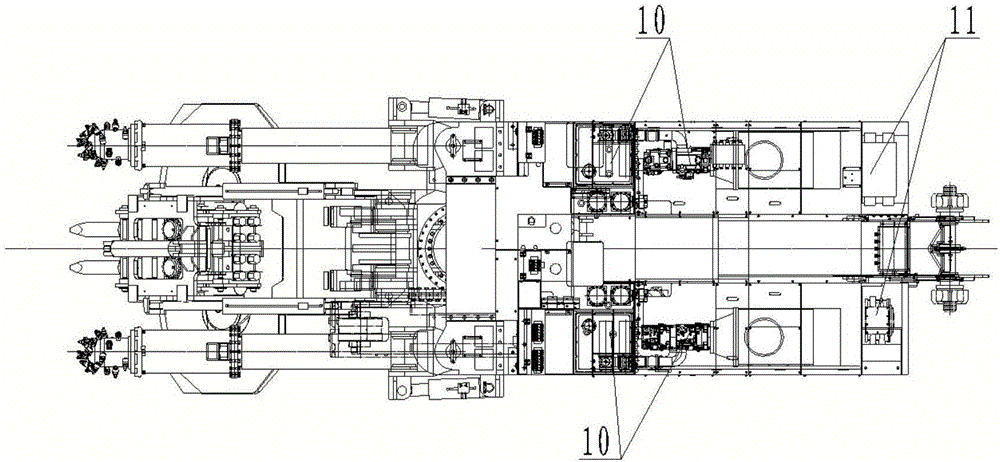

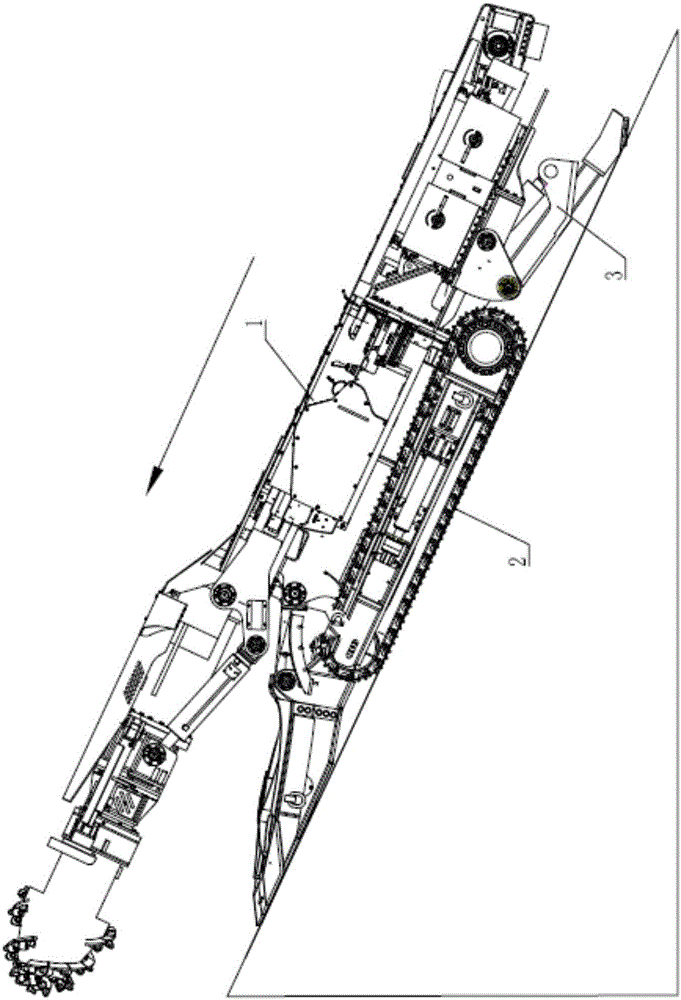

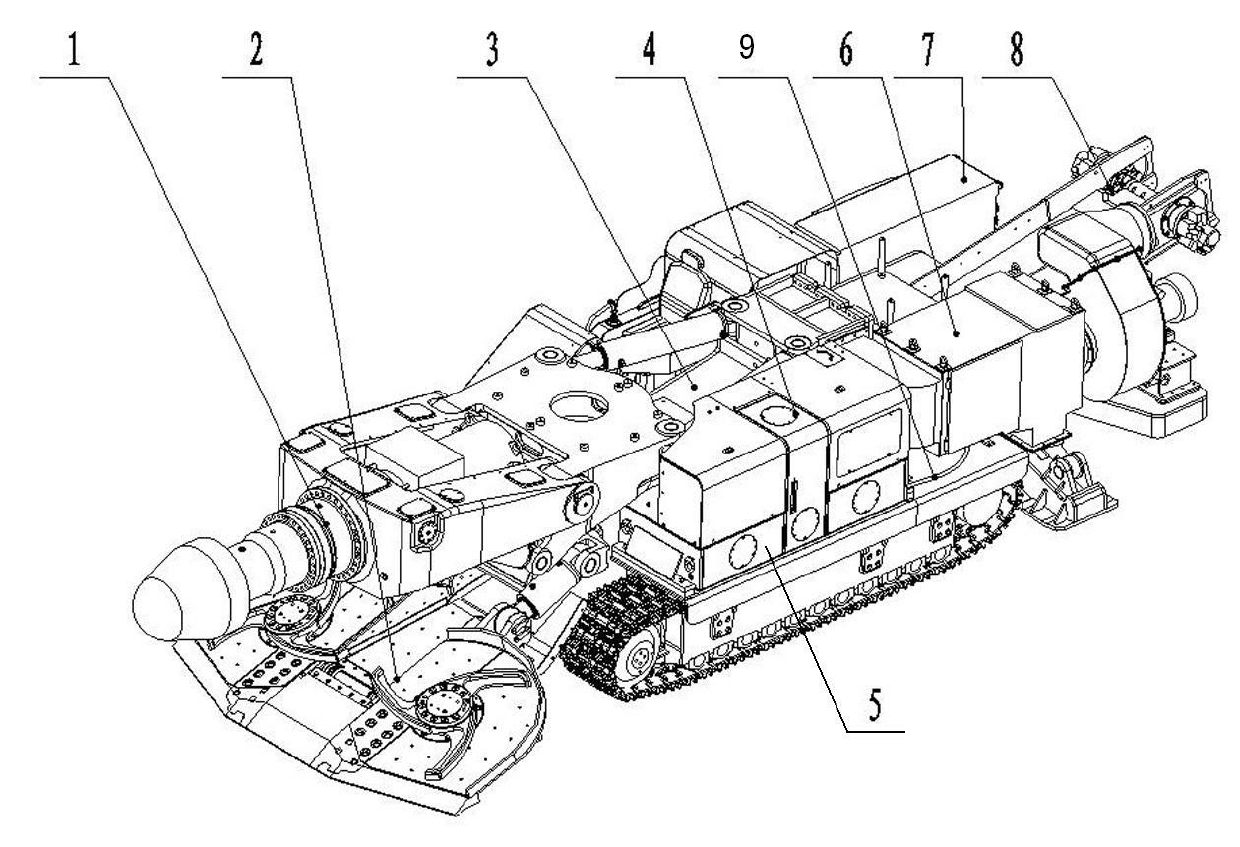

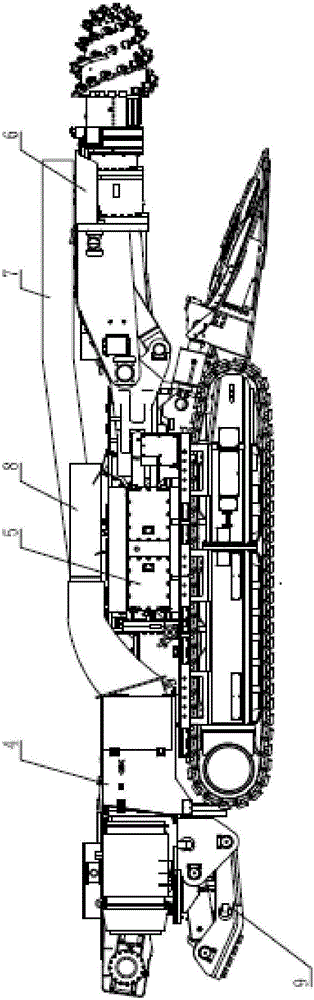

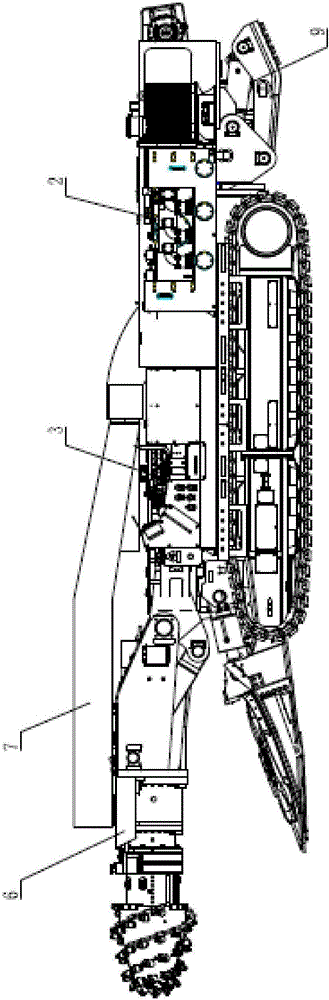

Efficient rapid rock drift tunneller

The invention belongs to the technical field of underground coal mine developing equipment, particular relates to an efficient rapid rock drift tunneller, and aims at solving the problems that rock drift tunnelling efficiency is low, rock drift forming is poor, the worker labor intensity is large, and many potential safety hazards exist. The efficient rapid rock drift tunneller comprises a walking part, an insertion board part, two cutting arms, a telescopic part, an engine body part, a control part, a guard board part, a conveying part, a rear support part, two hydraulic systems and electric systems; the walking part is arranged below the engine body part, the insertion board part is hinged to the front end of the engine body part, the telescopic part is arranged in the middle of the upper front portion of the engine body part, the cutting arms are symmetrically arranged on the left side and the right side of the upper front portion of the engine body, the conveying part is arranged in the middle of the engine body part, the rear support part is installed on the rear portion of the engine body, the hydraulic systems are symmetrically arranged on the left side and the right side of the middle of the engine body part, an operating part is installed above the engine body part, the guard board part is fixed on the two sides of the engine body part, and the electric systems are arranged on the two sides of the tail part of the engine body part.

Owner:SHANXI TIAN JU HEAVY IND

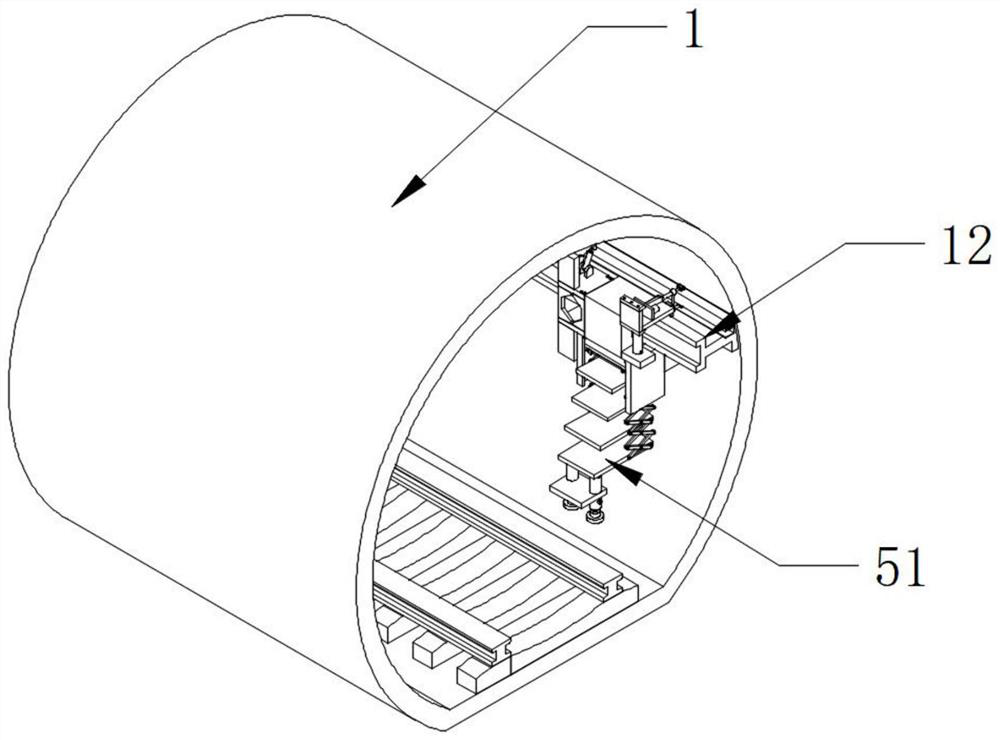

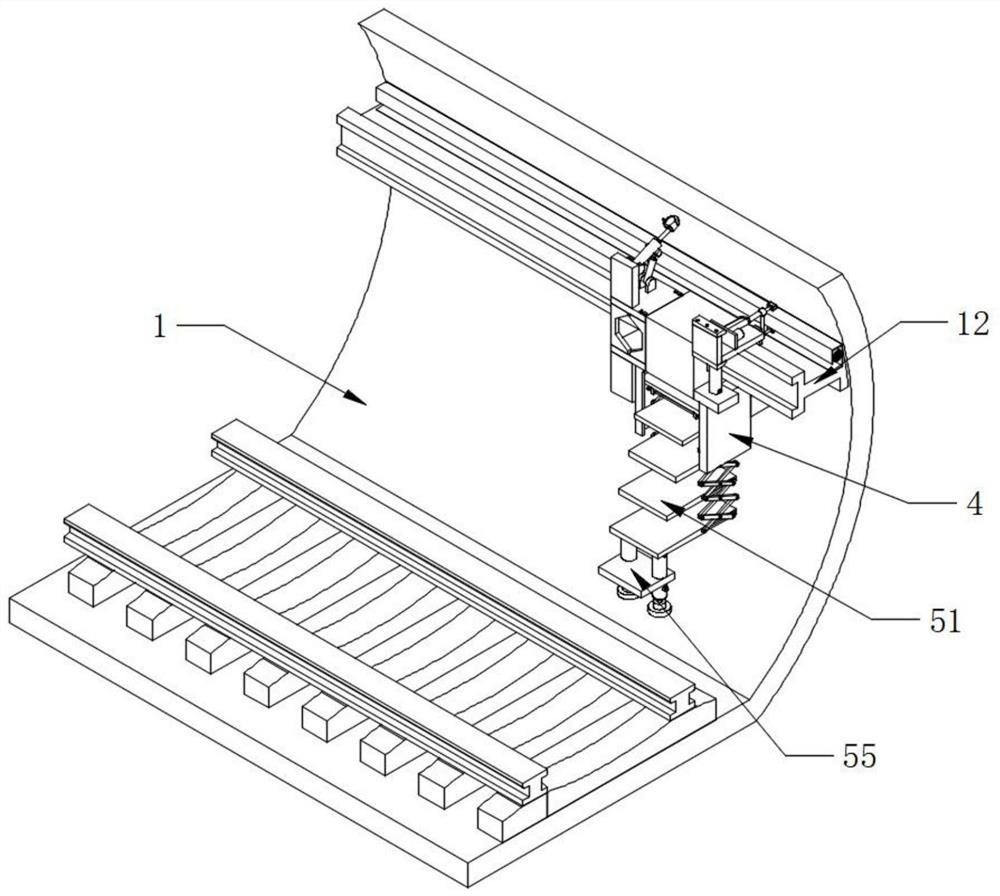

Rail transit tunnel manual maintenance robot

InactiveCN113997296AEasy to observeEasy to openManipulatorLaddersControl engineeringStructural engineering

The invention belongs to the technical field of rail transit, and particularly relates to a rail transit tunnel manual maintenance robot which comprises a tunnel and a cable and further comprises a guide rail, an insulation box, a moving device, an inspection device and a lifting device. The outer surface of the guide rail is fixedly arranged on the inner side wall of the tunnel; the outer surface of the insulation box and the outer side face of the guide rail are fixedly installed, and the outer surface of the cable and the inner side wall of the insulation box are fixedly installed. According to the rail transit tunnel manual maintenance robot, by arranging the lifting device, a maintainer can conveniently climb and maintain cables needing to be overhauled, through stretching and retracting of the shear shank, a plurality of satay parts can be lifted to form the shape of an extension ladder, the maintainer can conveniently climb, and when the robot does not need to be used, the robot can be folded and can be stored in the storage groove body, the occupied space is reduced, use of the rail is not affected, and therefore maintenance personnel can conduct maintenance conveniently, and operation is convenient.

Owner:NANJING NIEBO INTERNET OF THINGS TECH CO LTD

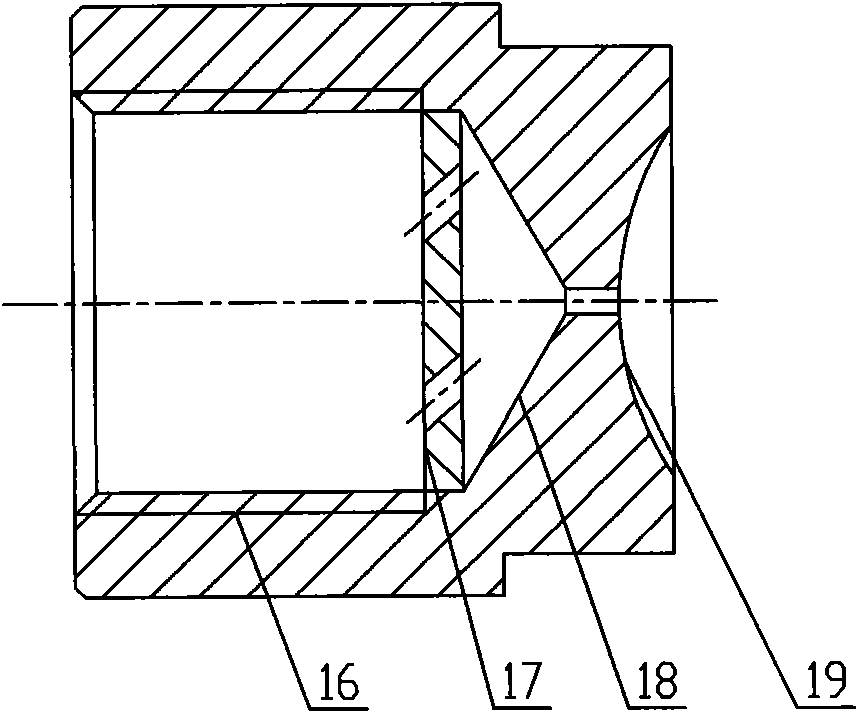

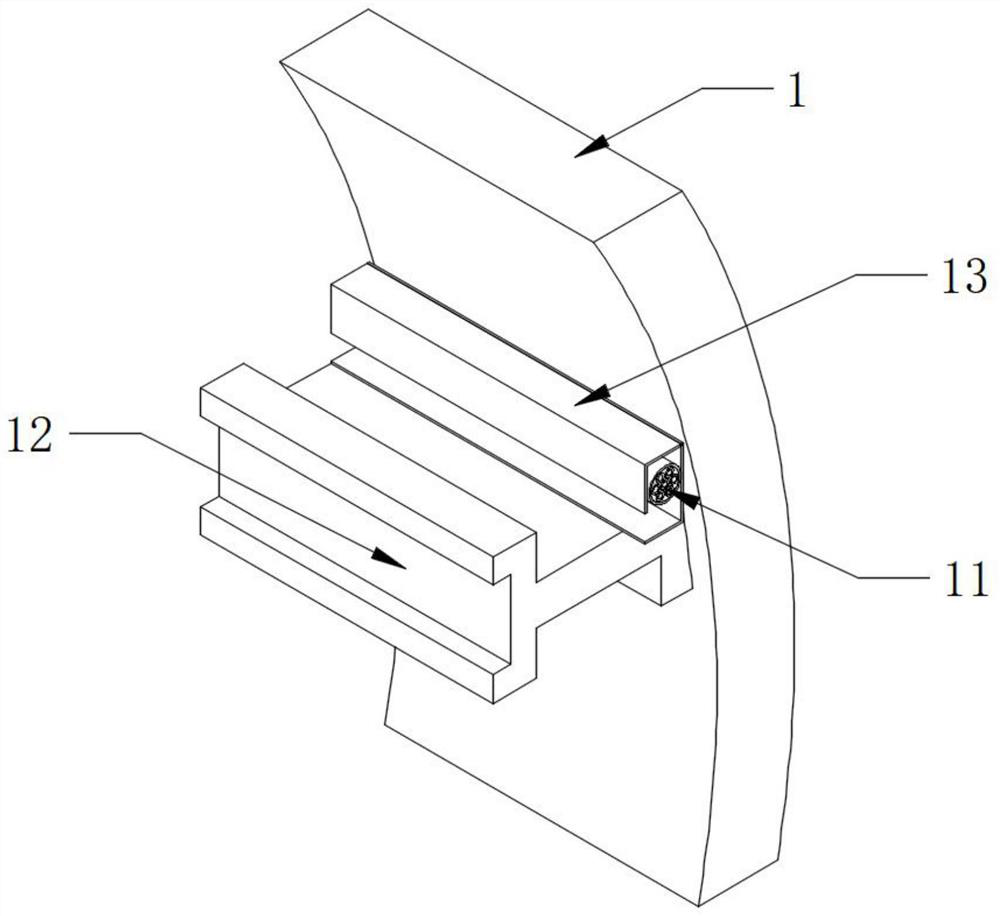

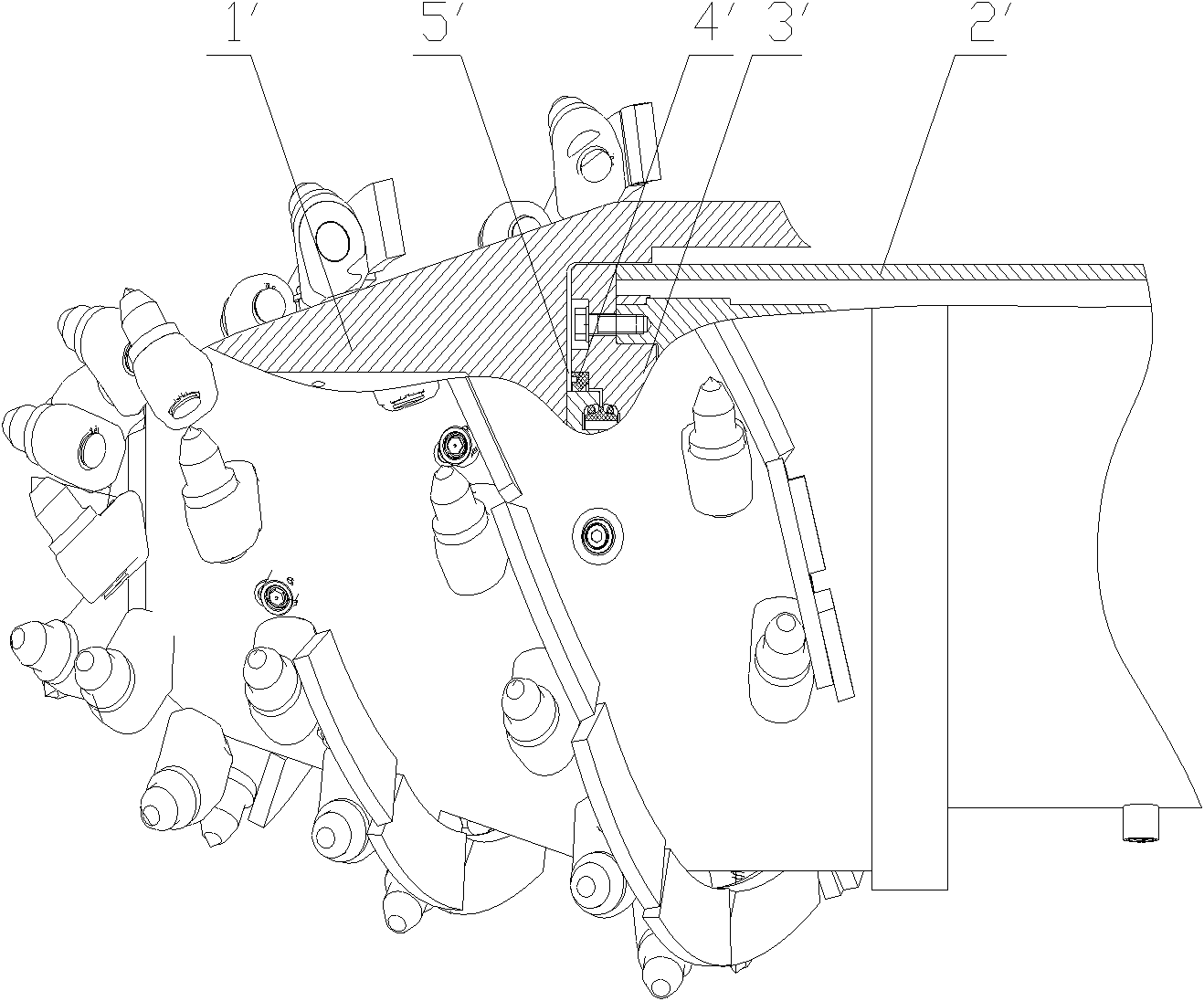

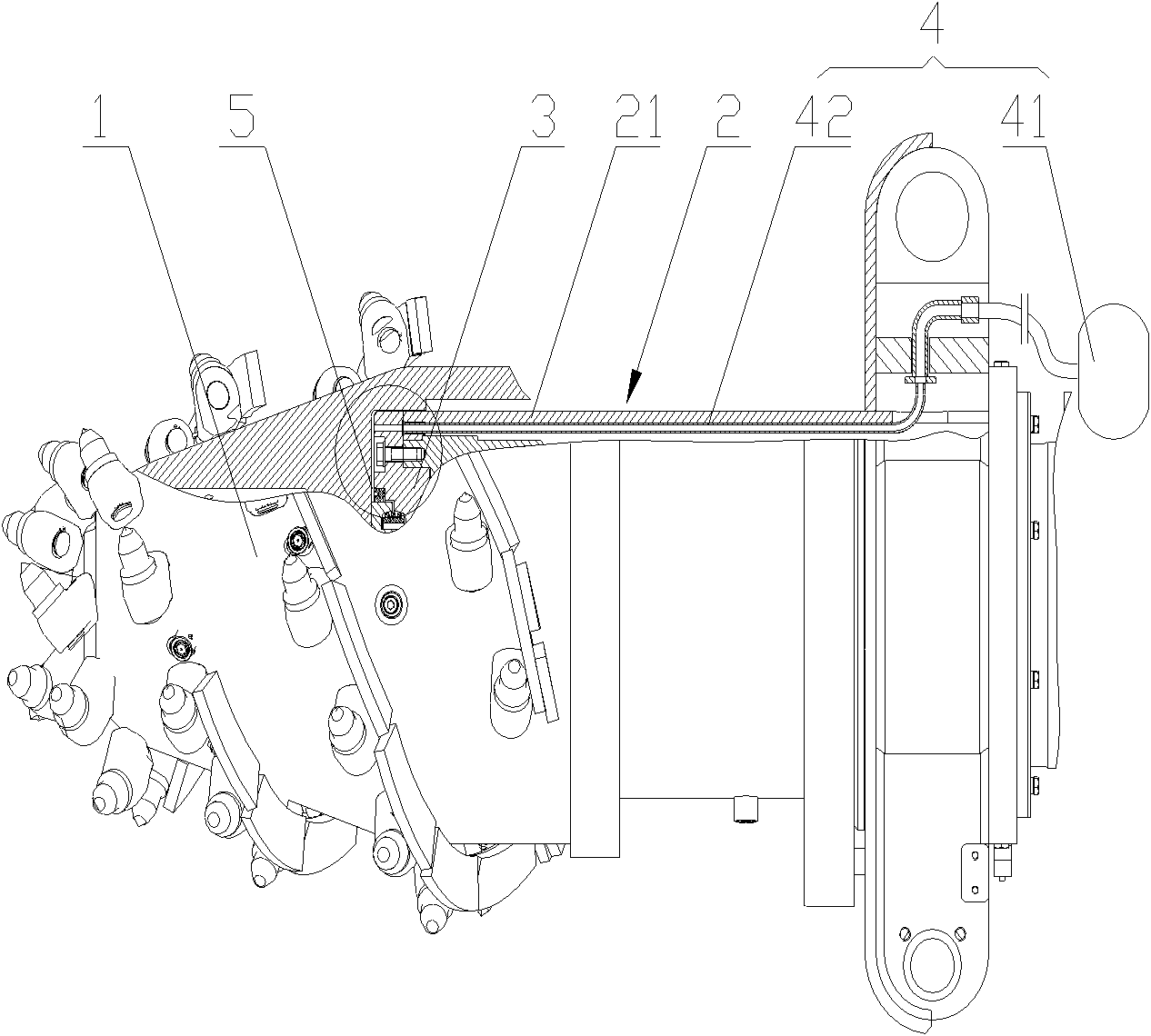

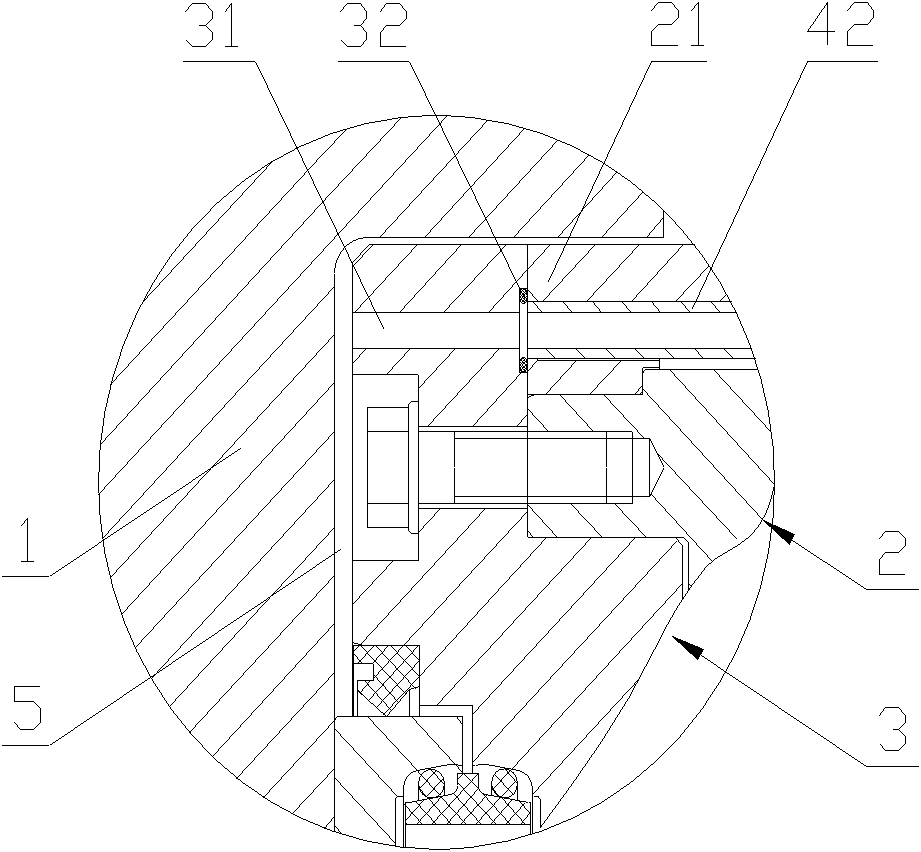

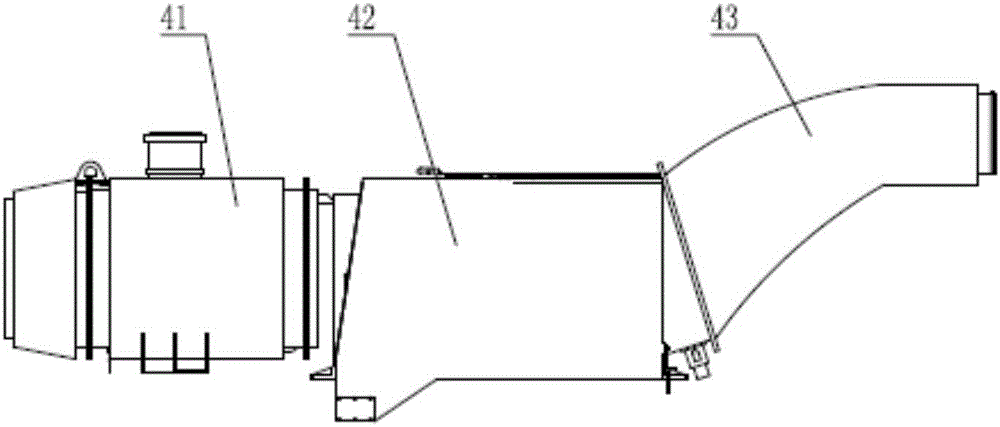

Tunneller and cutting mechanism thereof

The invention discloses a cutting mechanism of a tunneller, which comprises a cutting head (1), a telescopic part (2) and a floating seal frame (3), wherein the floating seal frame (3) is connected between the cutting head (1) and the telescopic part (2); a cavity (5) is arranged between the cutting head (1) and the floating seal frame (3), and the outer end part of the cavity (5) is communicated with the air; the cutting mechanism further comprises a dustproof mechanism (4); the dustproof mechanism (4) comprises an air compressor (41) and a ventilation pipe (42) which are connected with each other; the air inlet end of the ventilation pipe (42) is communicated with the air outlet end of the air compressor (41), and the air outlet end of the ventilation pipe (42) is communicated with the inside of the cavity (5). The cutting mechanism has the continuous tightness. The invention further discloses a tunneller which comprises a cantilever supporting mechanism and the cutting mechanism, wherein the cutting mechanism is supported on the cantilever supporting mechanism. The tunneller has the same technical effect.

Owner:SANY HEAVY EQUIP

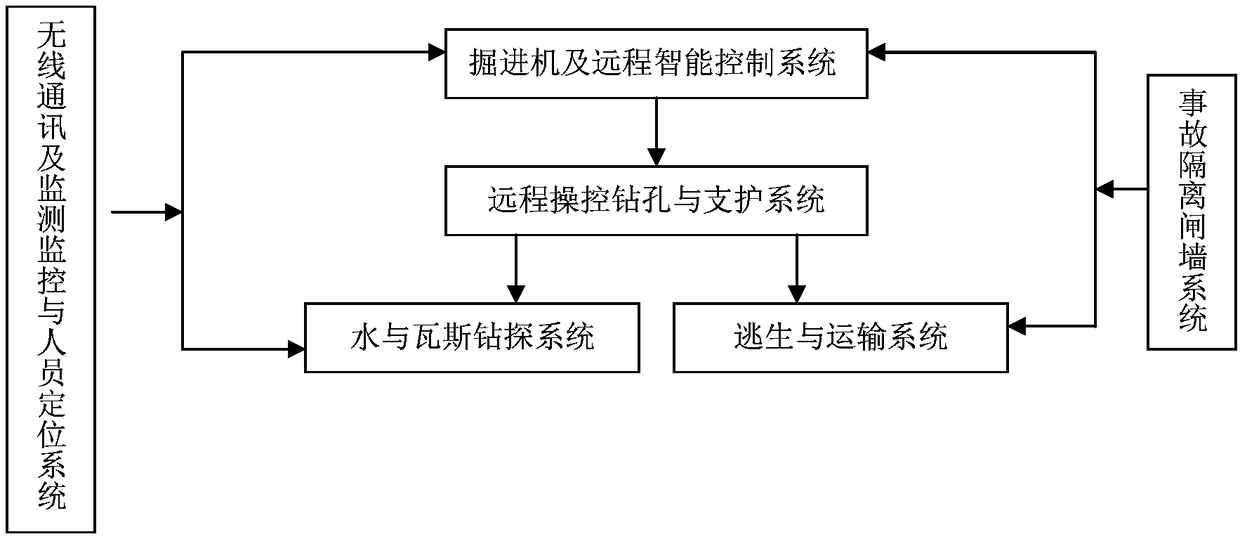

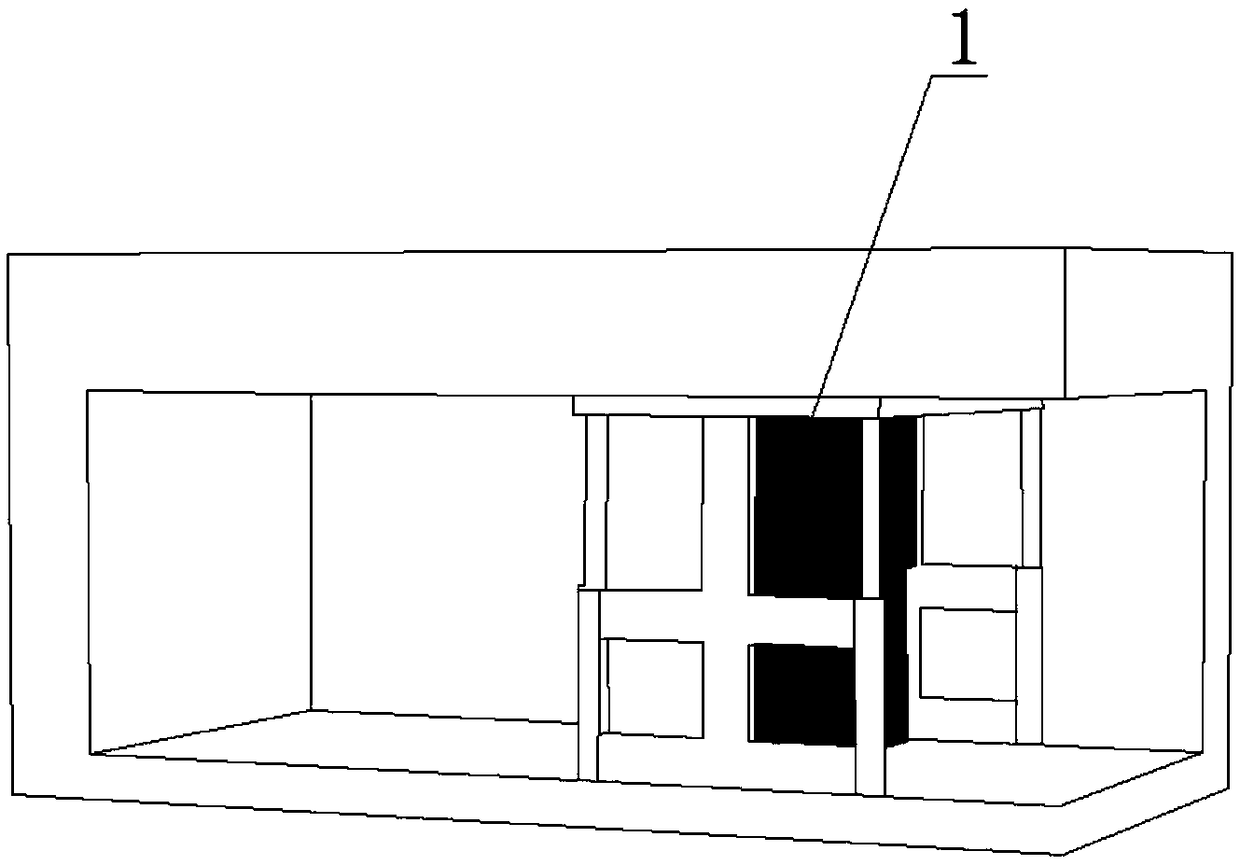

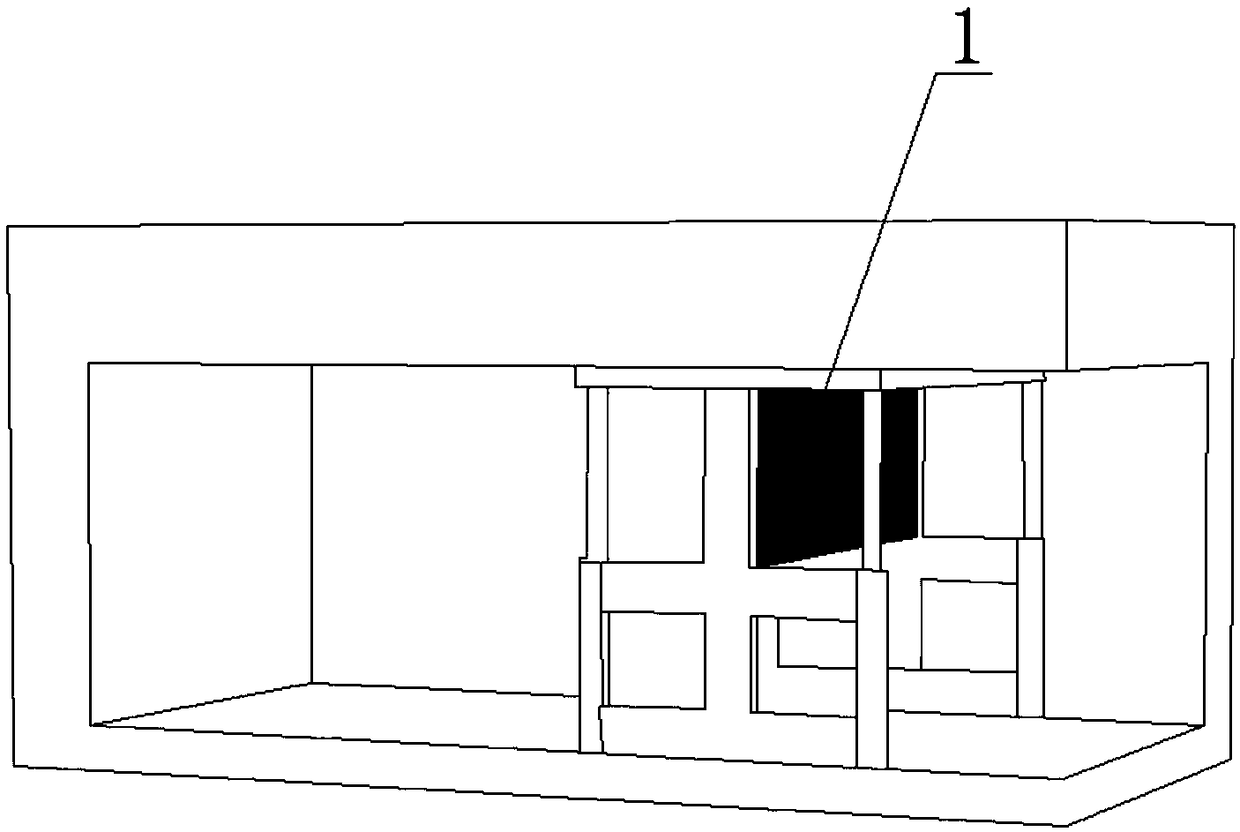

Unmanned tunneling system and method of coal mine roadway

ActiveCN109162721AAddress security needsMechanize the evacuationMining devicesTunnelsSupporting systemTransit system

The invention relates to the technical field of coal industry, in particular to an unmanned tunneling system and method of a coal mine roadway. The system comprises an accident isolation gate wall system, a remote intelligent tunneller control system, a remote control drilling and support system, an escape and transportation system, a water and gas drilling system and a wireless communications, monitoring and personnel positioning system. Therefore, urgent safety demand of the coal mine operation can be satisfied; effects of unmanned one-hundred-meter roadway danger elimination, catastrophic accident closure, and mechanical personnel evacuation are realized; and five kinds of disasters of water, fire, gas, coal dust and roof for tunneling of the roadway can be reduced or eliminated and thecoal mine casualties can be reduced by more than 50%. Moreover, the actual production demand can be satisfied; the tunneling speed is increased; the continuously tension situation of tunneling is changed; and the tunneling efficiency can be improved by 50% to 100%. The tunnel forming cost is lowered and the economic benefits are increased.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

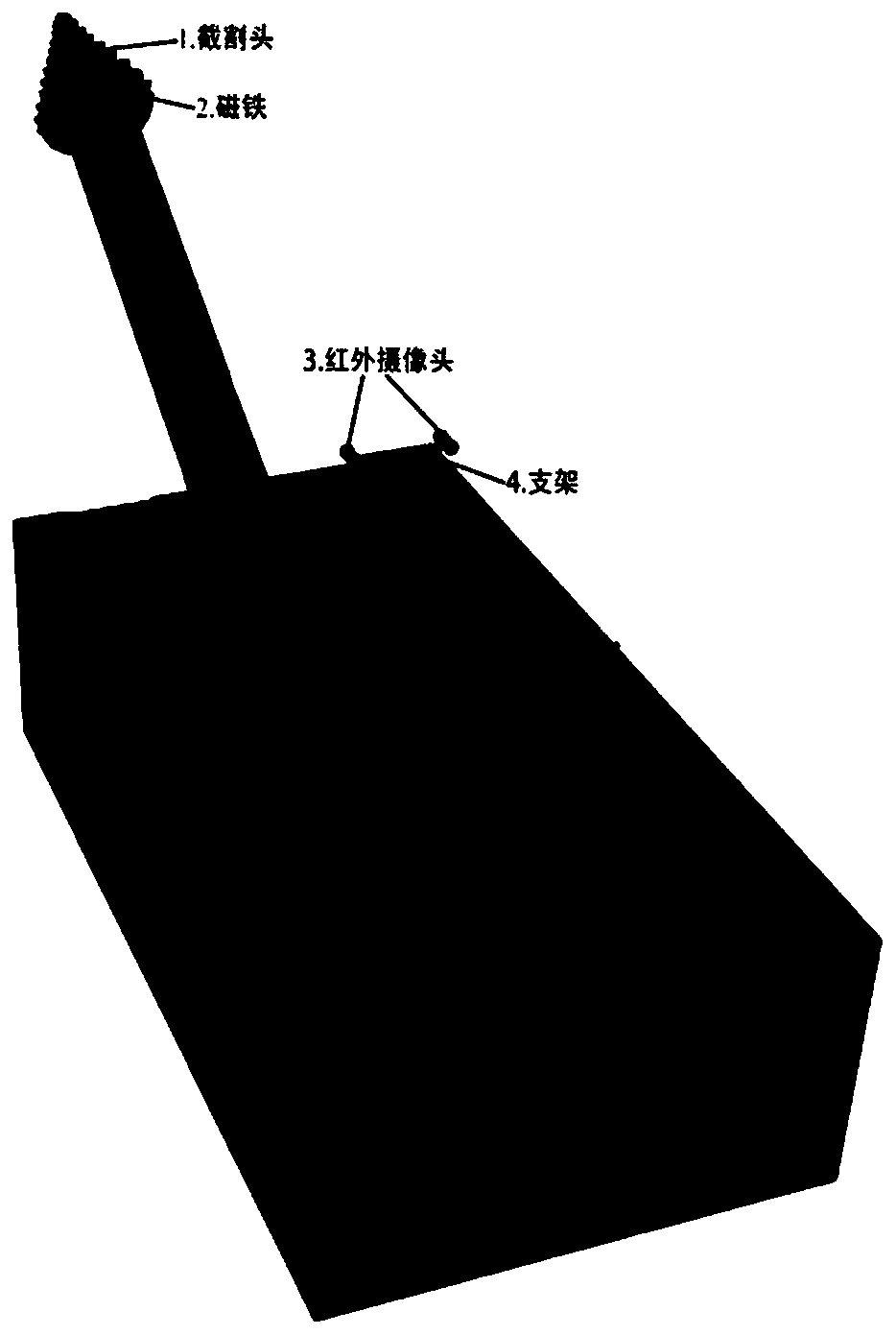

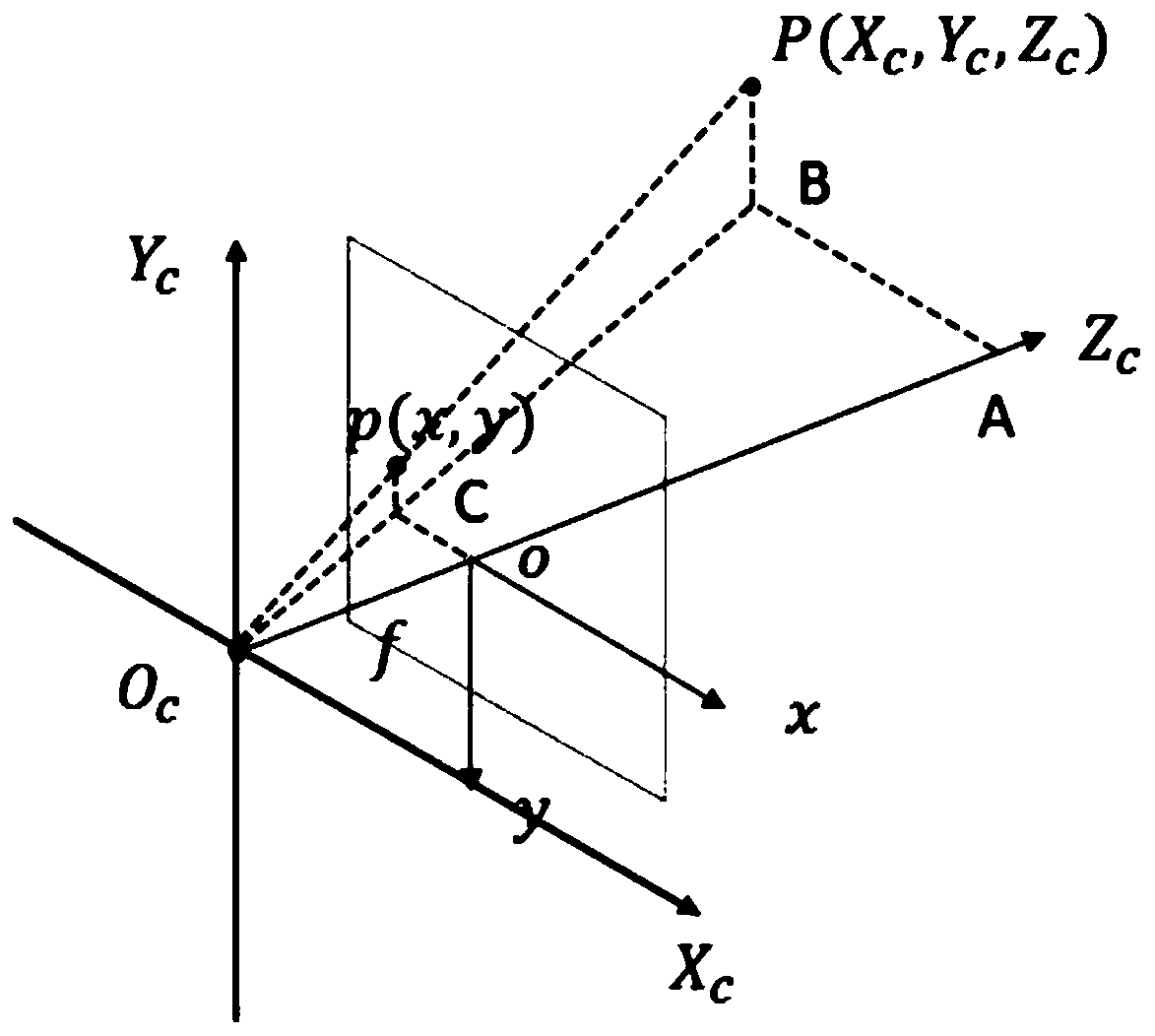

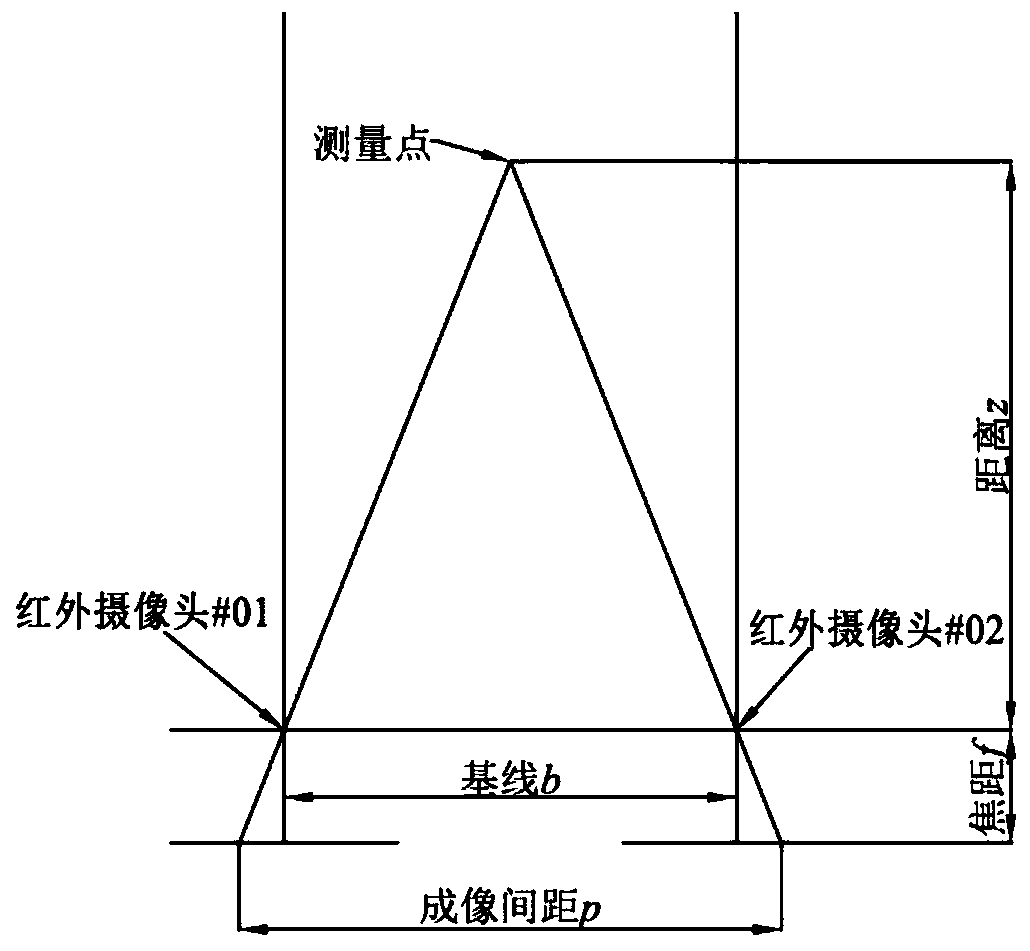

High-precision positioning system and method

PendingCN109709497ANo loss of trackingThe positioning result is accuratePhotogrammetry/videogrammetryMagnitude/direction of magnetic fieldsPattern recognitionComputer vision

The invention discloses a high-precision positioning system and method, thereby realizing positioning of the cutting head of a tunneller during ore mining. The method comprises a magnetic field positioning method. According to the magnetic field positioning method, positioning is carried out based on a machine learning method; the machine learning method is optimized and an optimal performance parameter is selected for machine learning method optimization; and an optimized magnetic field positioning model is obtained by using the optimized machine learning method. Therefore, the positioning accuracy is improved; and the real-time high-precision tracking and positioning of the cutting head in real time are realized.

Owner:JIZHONG ENERGY FENGFENG GRP +1

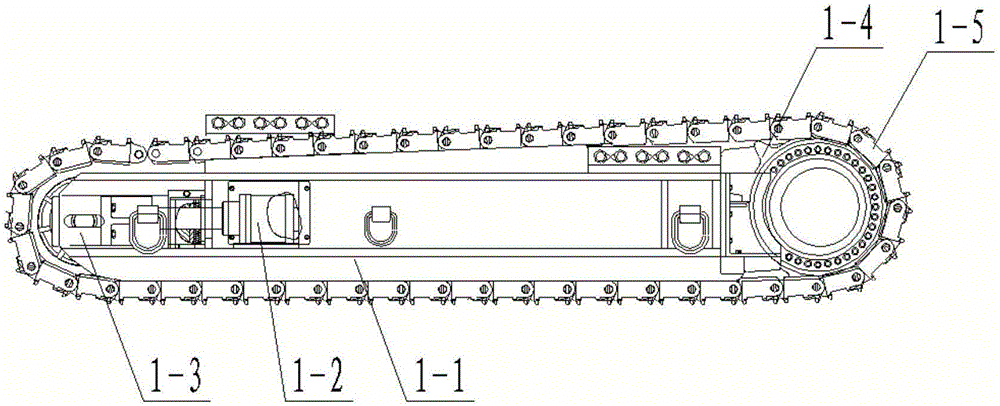

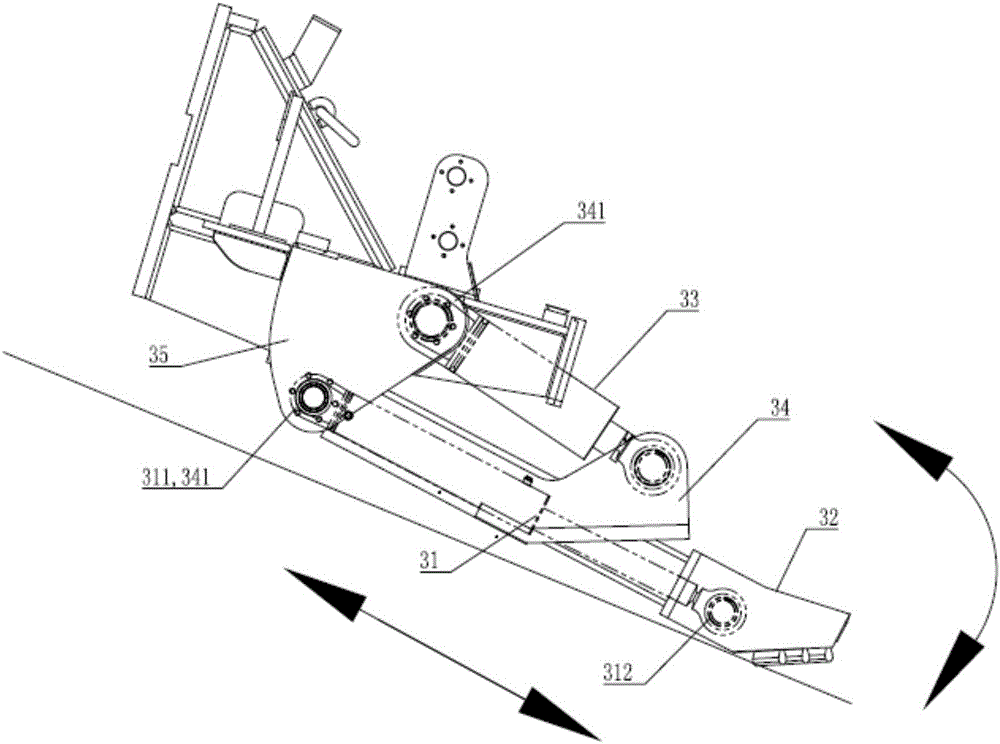

Auxiliary pushing mechanism for tunneller

The invention discloses an auxiliary pushing mechanism for a tunneller. The auxiliary pushing mechanism is installed at the tail of the tunneller and comprises a telescopic component and a pushing component. The pushing component is connected to the output end of the telescopic component. When the telescopic component stretches out, the pushing component applies thrust to the walking surface of the tunneller, so that the tunneller has a forward movement trend. In the uphill process of the tunneller, the telescopic component drives the pushing component to apply thrust to the walking slope surface of the tunneller, and the counter force of the thrust enables the tunneller to have a forward movement trend; and meanwhile, after the counter force of the thrust is overlaid with the advance force of the tunneller, the complete tunneller has enough uphill power, the phenomena of slipping and the like are not prone to happening, and the safety of working personnel on the site is ensured. The auxiliary pushing mechanism can be applied to auxiliary pushing of tunnellers.

Owner:SANY HEAVY EQUIP

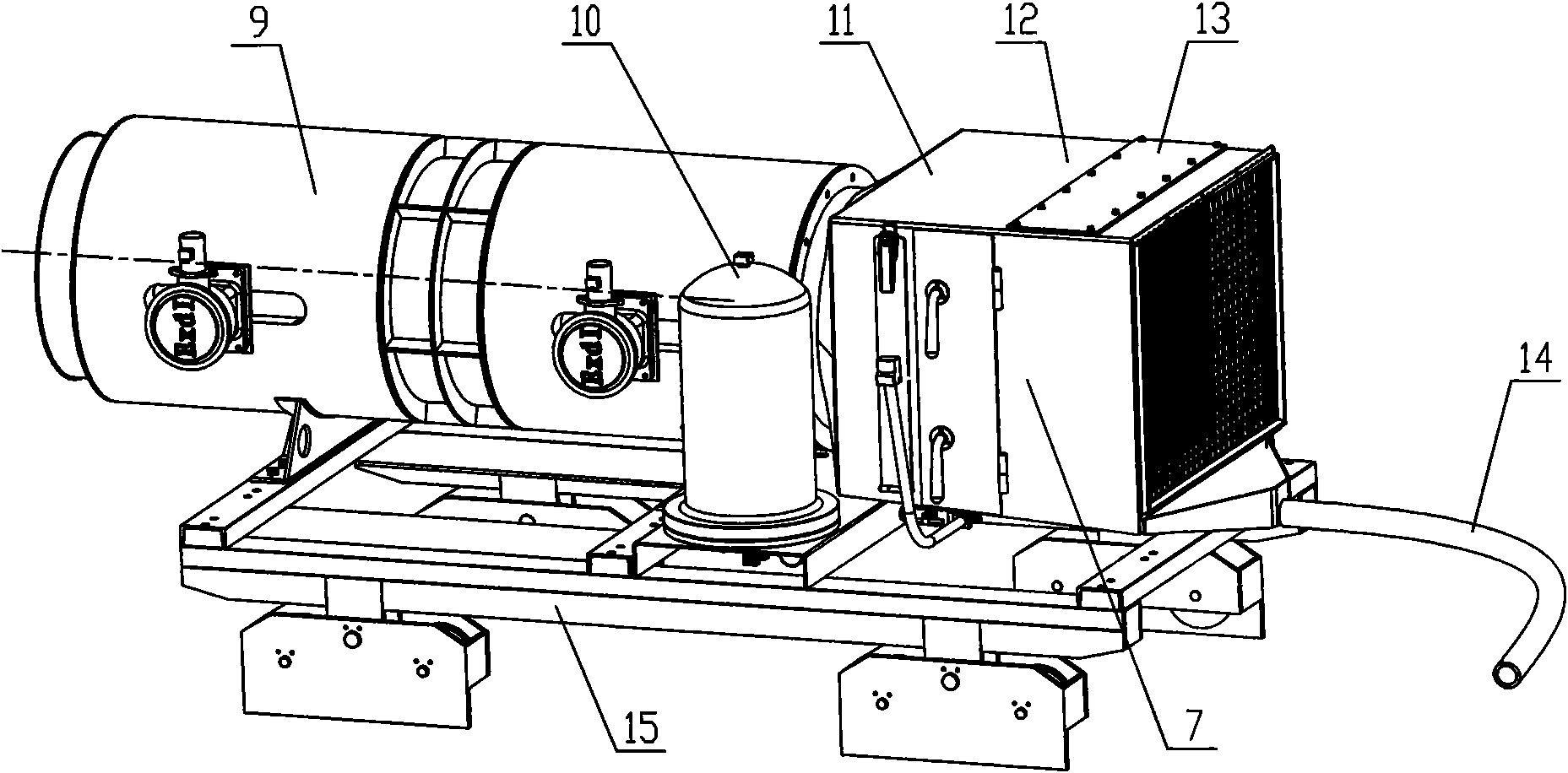

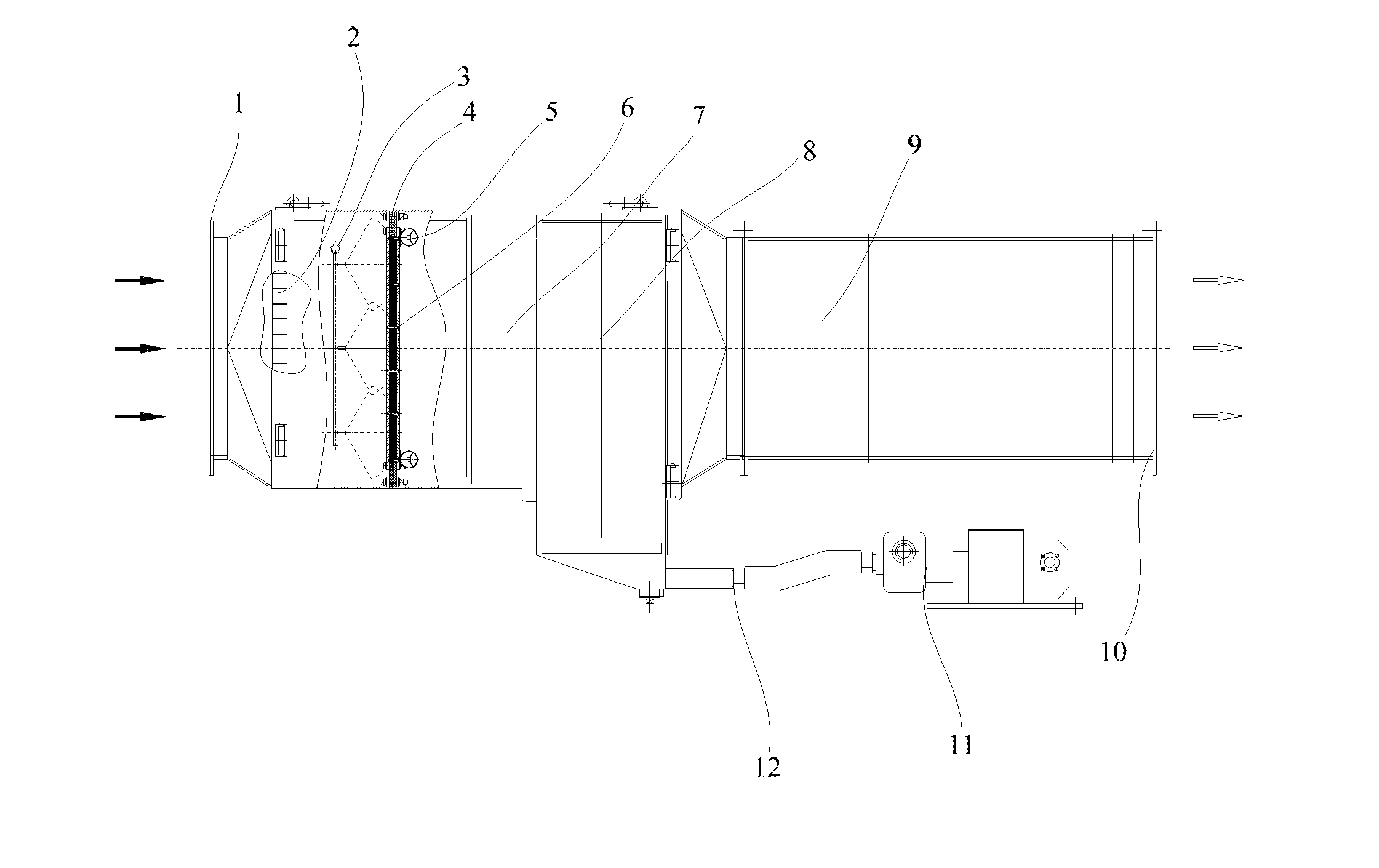

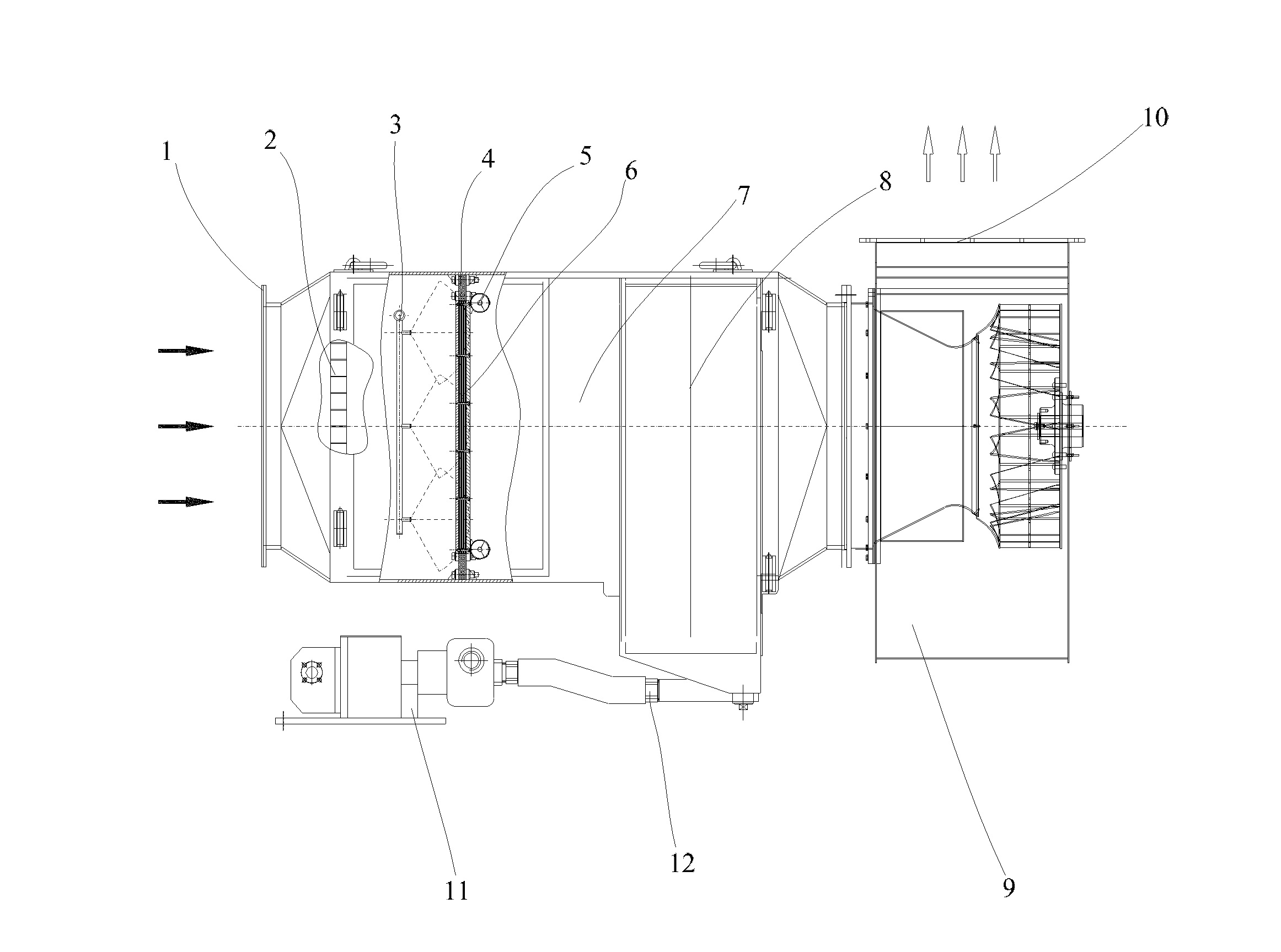

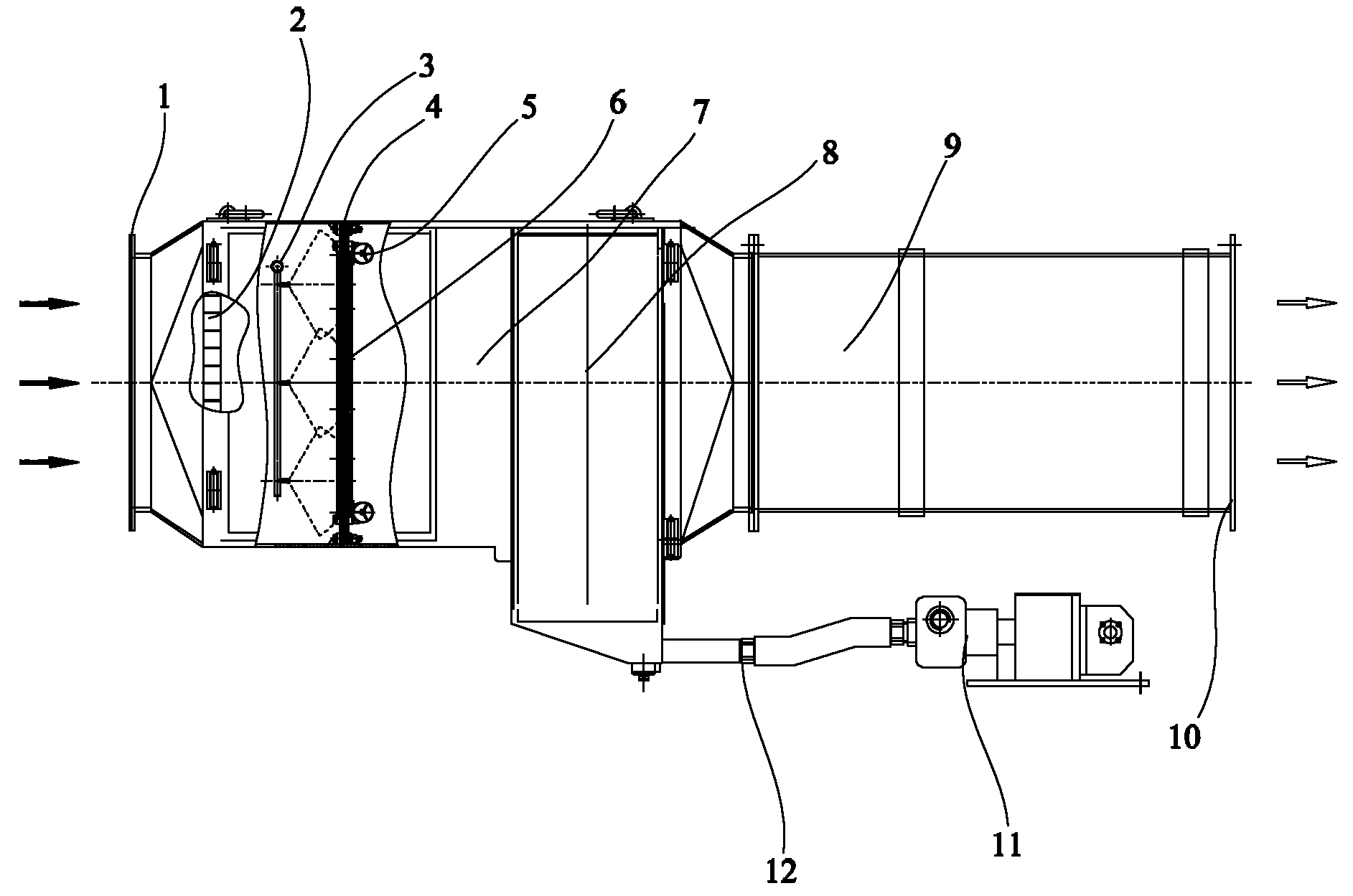

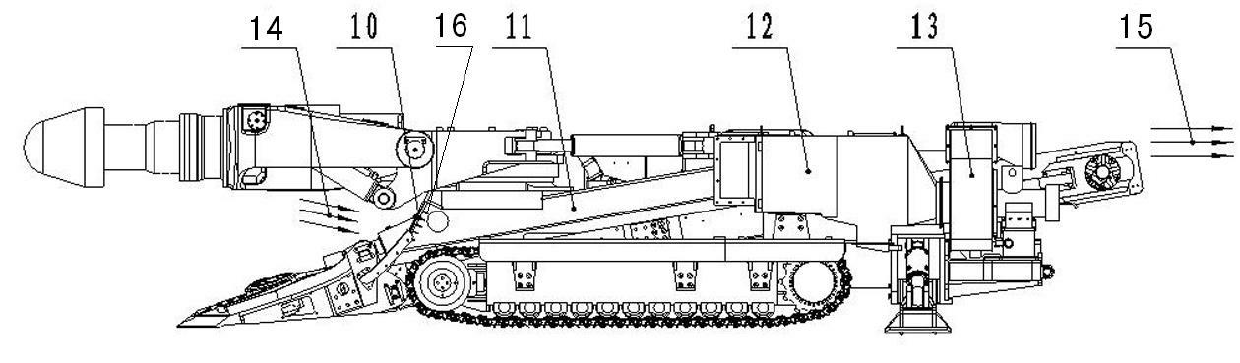

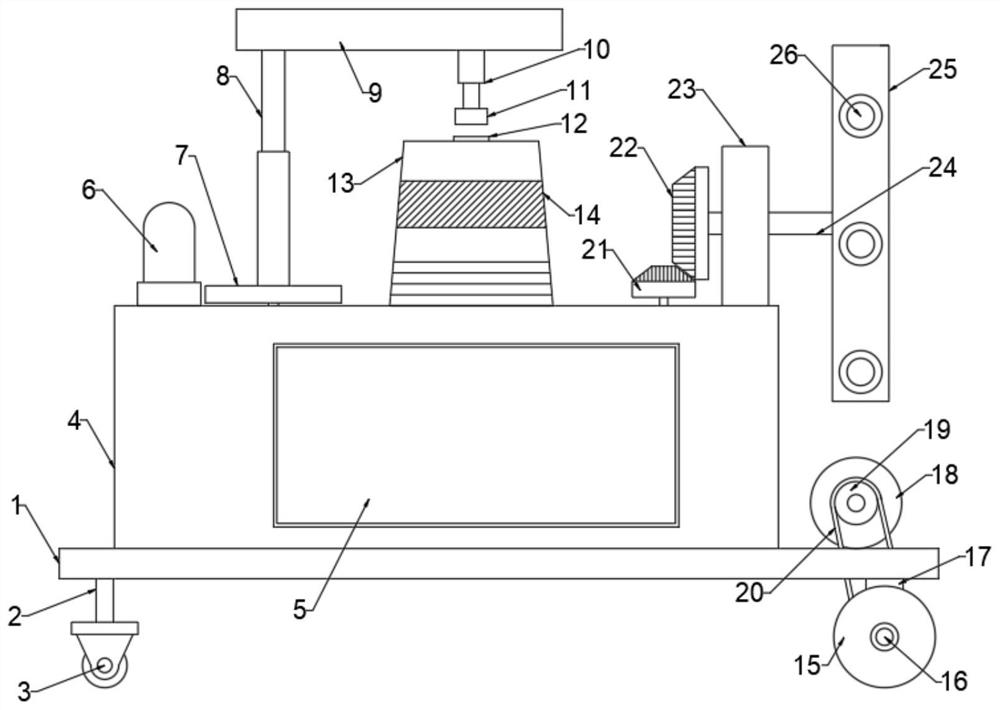

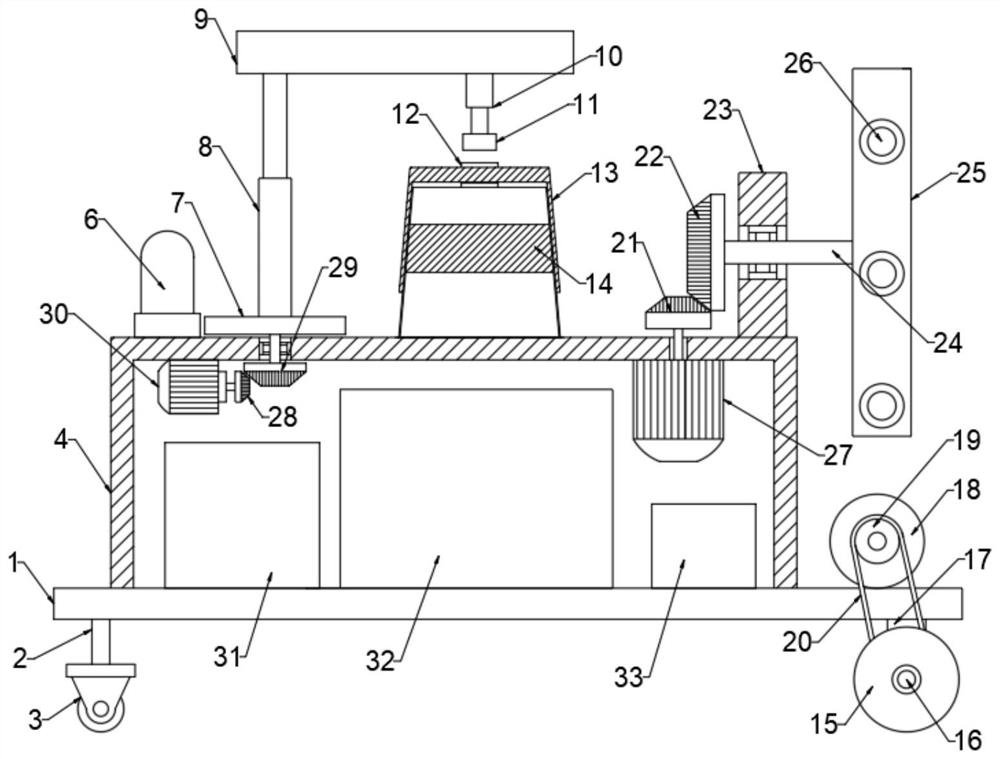

Tunneller for integrated wet type dust removal device

ActiveCN102383798AAchieve high integrationAchieve dust controlSlitting machinesCutting machinesUnderground tunnelWorking environment

The invention belongs to the technical field of coal mine underground tunneling surface tunneling equipment and in particular relates to a tunneller for an integrated wet type dust removal device. The invention solves the problems that a rear supporting dust removal device of the existing tunneller affects the operation and the use of the tunneller, and in addition, the dust removal effect is not ideal. The tunneller for the integrated wet type dust removal device comprises a vehicle-mounted dust removal system; the vehicle-mounted dust removal system comprises an air inlet and a flue, wherein the air inlet is arranged at the front end of a machine frame between a cutting part and a loading part of the tunneller; and the flue is arranged at the middle part of the machine frame and is of an integrated structure together with the machine frame. The invention has the beneficial effects that the wet type dust removal device is highly integrated on tunneller; while the quick tunneling of a big section and a total-rock and half-coal rock roadway is realized, the control and the removal of dust on the tunneling surface are successfully realized; and under the situation that the roadway adaptability of the tunneller, the cutting vision of a tunneller driver and the maintenance of the entire tunnneler are not affected, the working environment of operators is greatly improved.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

Tunnelling instrument for subcutaneously placing an article, and method of use of said instrument

InactiveUS9119603B2Addressing Insufficient ControlSteering precisionSurgical needlesBlunt dissectorsPortion sizeEngineering

Owner:PLASMED

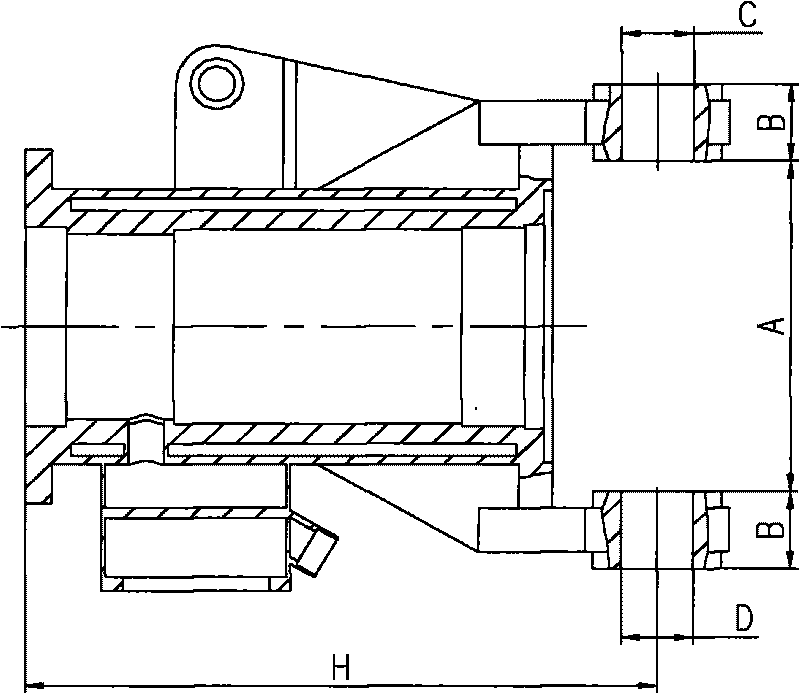

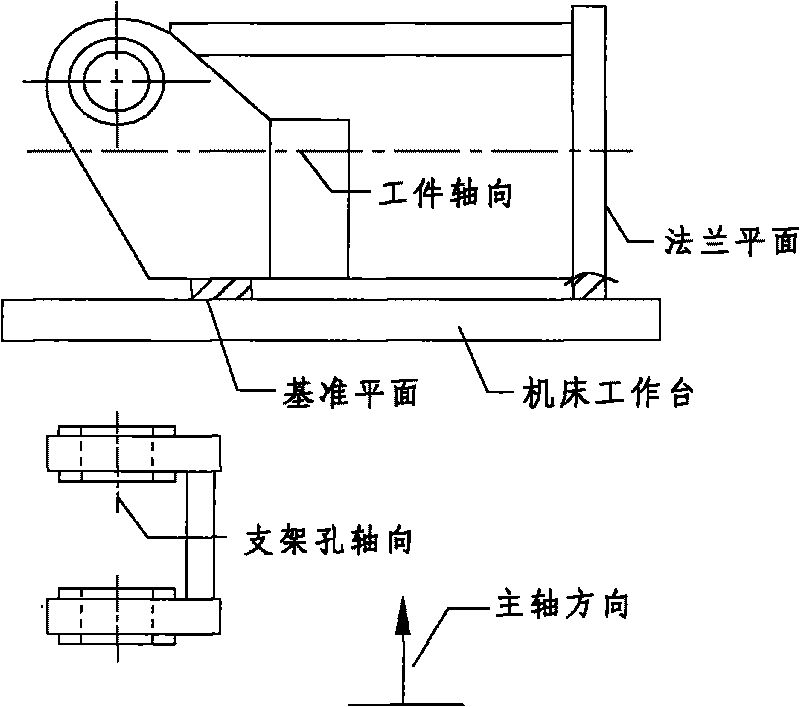

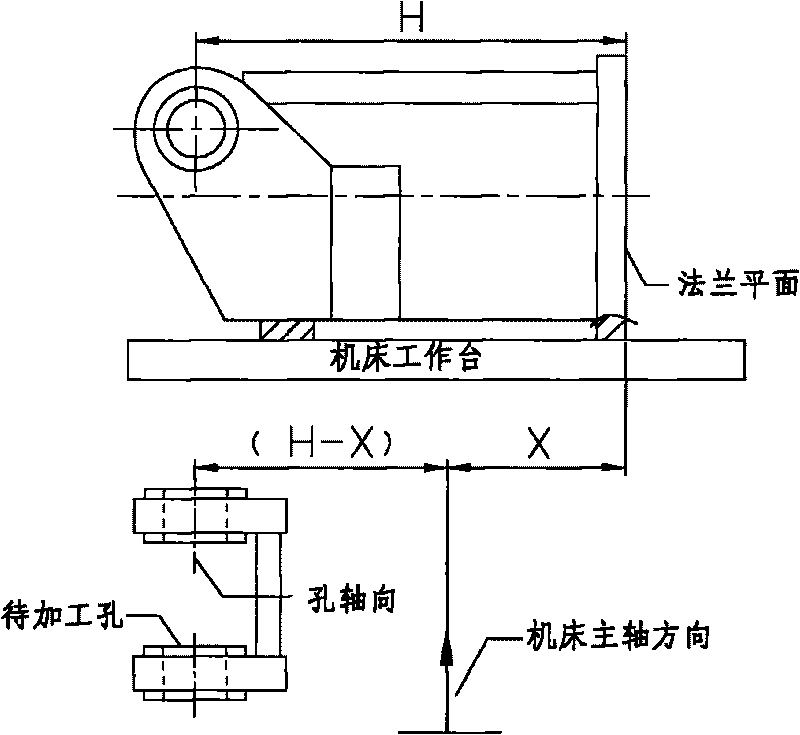

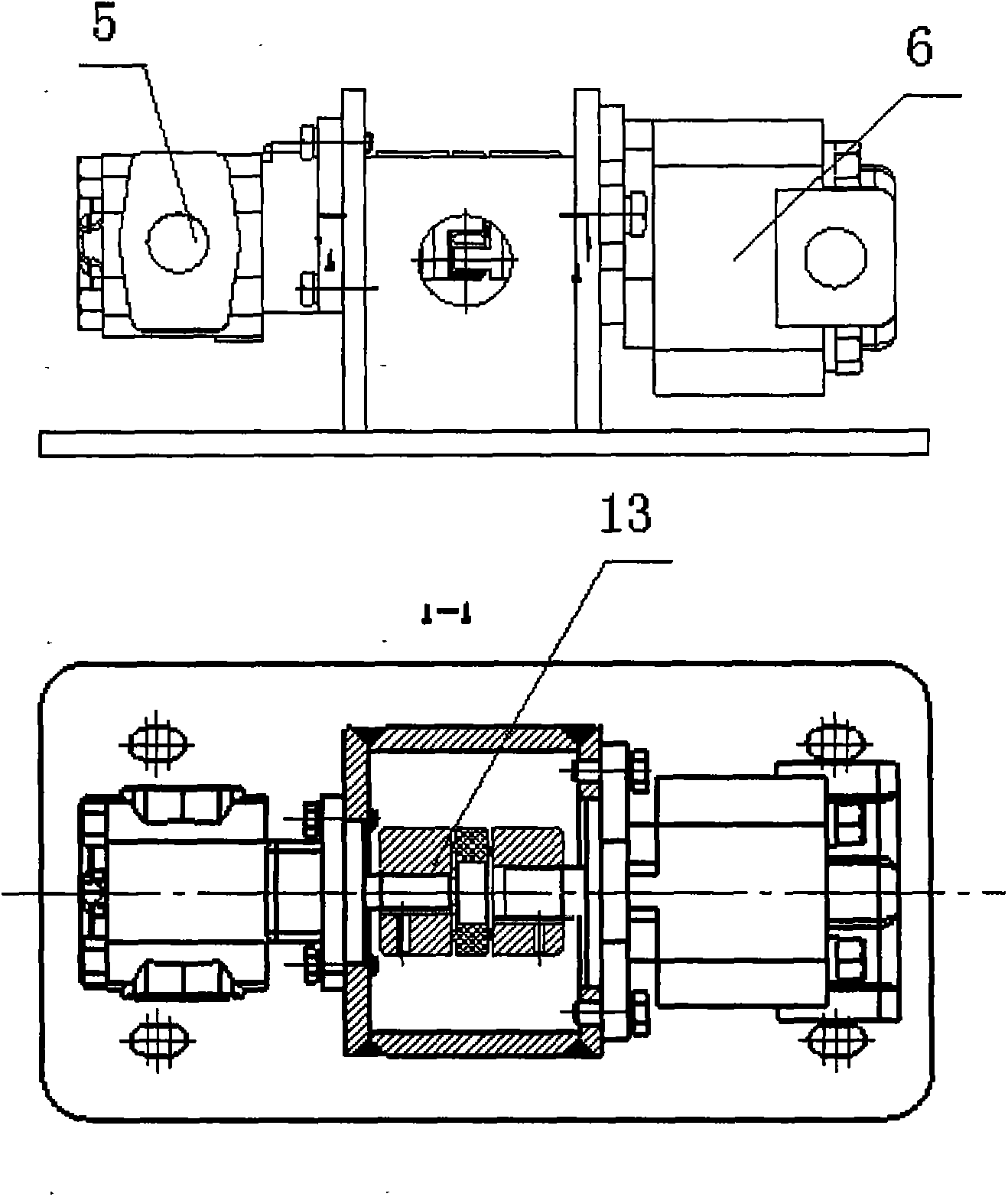

Processing method of bracket holes of tunneller type asynchronous motor

InactiveCN101764482AIncrease productivityReduce labor intensityManufacturing dynamo-electric machinesInduction motorEngineering

The invention discloses a processing method of bracket holes of a tunneller type asynchronous motor. The method comprises the following steps: a, finishing the processing of a left end surface and a right end surface of a work piece; b, processing a datum plane as a subsequent alignment datum; c, aligning the center of a machine working table; d, finding the distance (H-X) between the center line of the bracket holes C and D and an origin (the center of the machine working table) by taking the center of the machine working table as the origin; e, aligning the center of a bracket hole to be processed by utilizing coordinate translation and then processing; and f, revolving the machine working table 180 degrees by taking the origin as the center, aligning an unprocessed hole by utilizing coordinate translation, comparing with the distance when the first hole is aligned, the distances are equal and are both (H-X) but of opposite directions; after reverse alignment, ensuring a main shaft center of a boring machine to be coincident with the central axis of the hole to be processed, and then half-finish boring and finish boring another bracket hole. The method has the advantages: 1, increasing the production efficiency; 2, reducing the labor intensity of workers; and 3, saving the manufacturing cost.

Owner:FUSHUN COAL MINE MOTOR MFG

Onboard dust removing tunneller

InactiveCN105971601AIncrease inhalationImprove dust removal effectSlitting machinesCutting machinesEngineeringTunnellers

The invention discloses an onboard dust removing tunneller. The onboard dust removing tunneller comprises a machine body, a hydraulic system, an operating platform, an onboard dust removing device and an electric control box, wherein the hydraulic system and the operating platform are located on one side of the machine body, and the onboard dust removing device and the electric control box are located on the other side of the machine body. A cutting part is arranged at the front end of the machine body. An air inlet duct is connected to the onboard dust removing device. An inlet of the air inlet duct extends to the cutting part and is linked with the cutting part. According to the onboard dust removing tunneller, the inlet of the air inlet duct extends to the cutting part and is linked with the cutting part, hence, the inlet of the air inlet duct and the cutting part can synchronously and rotationally go up and down when the cutting part tunnels, and the inlet of the air inlet duct can be closer to the tunneling surface at any time during tunneling, so that flying dust near the tunneling surface is sucked advantageously, and the dust removing effect is improved. The onboard dust removing tunneller can be applied to dust removing during tunneller tunneling.

Owner:SANY HEAVY EQUIP

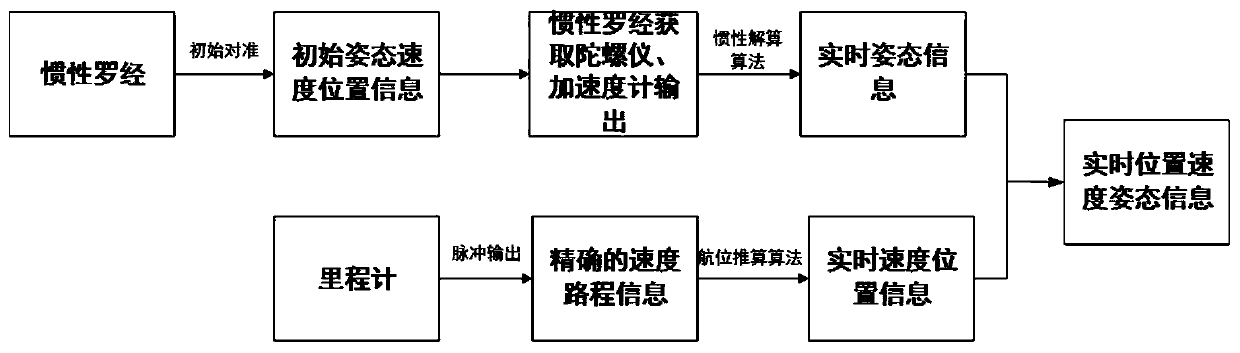

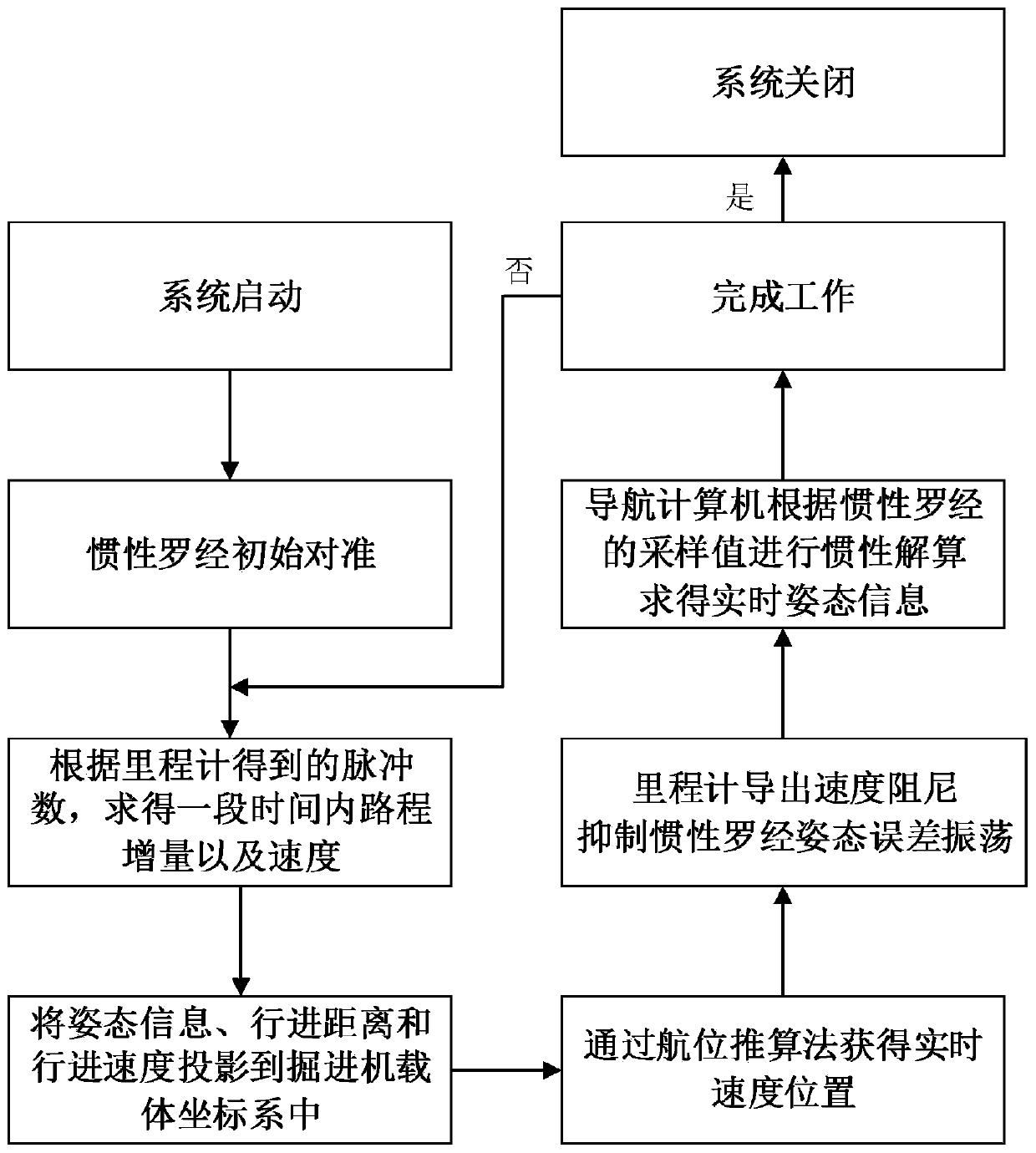

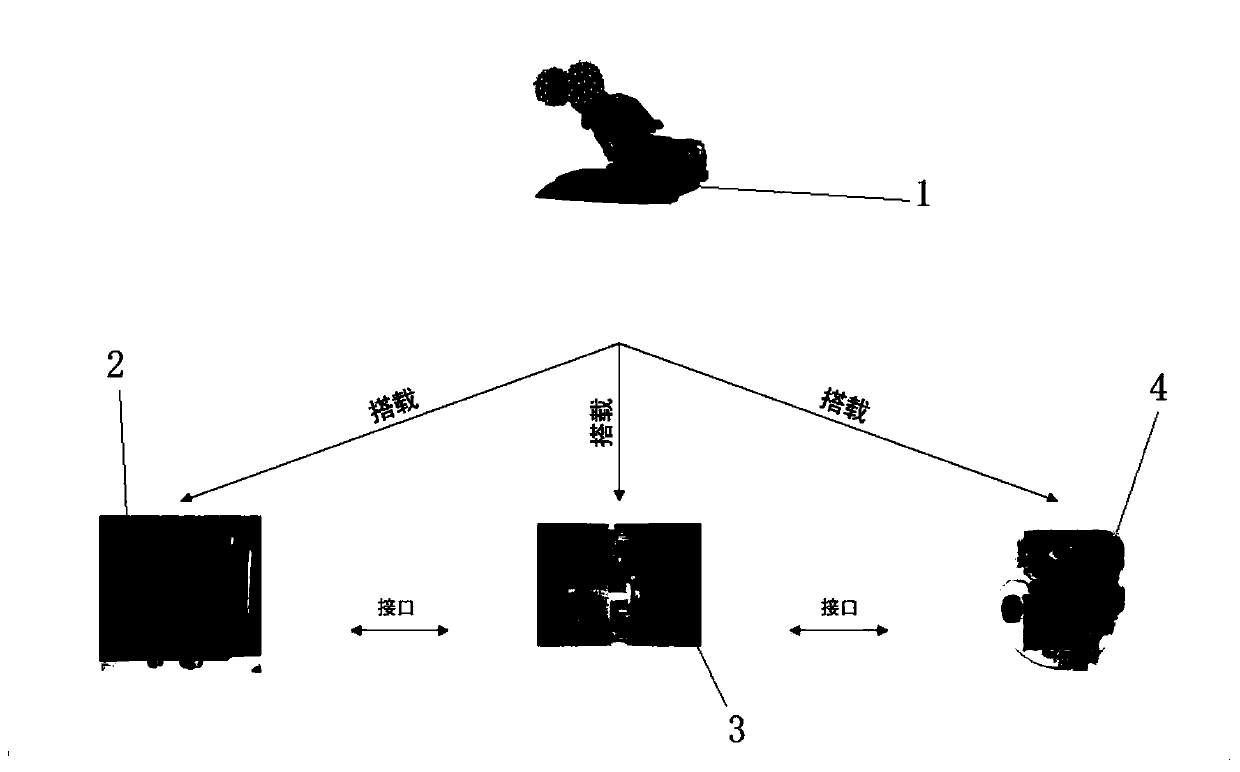

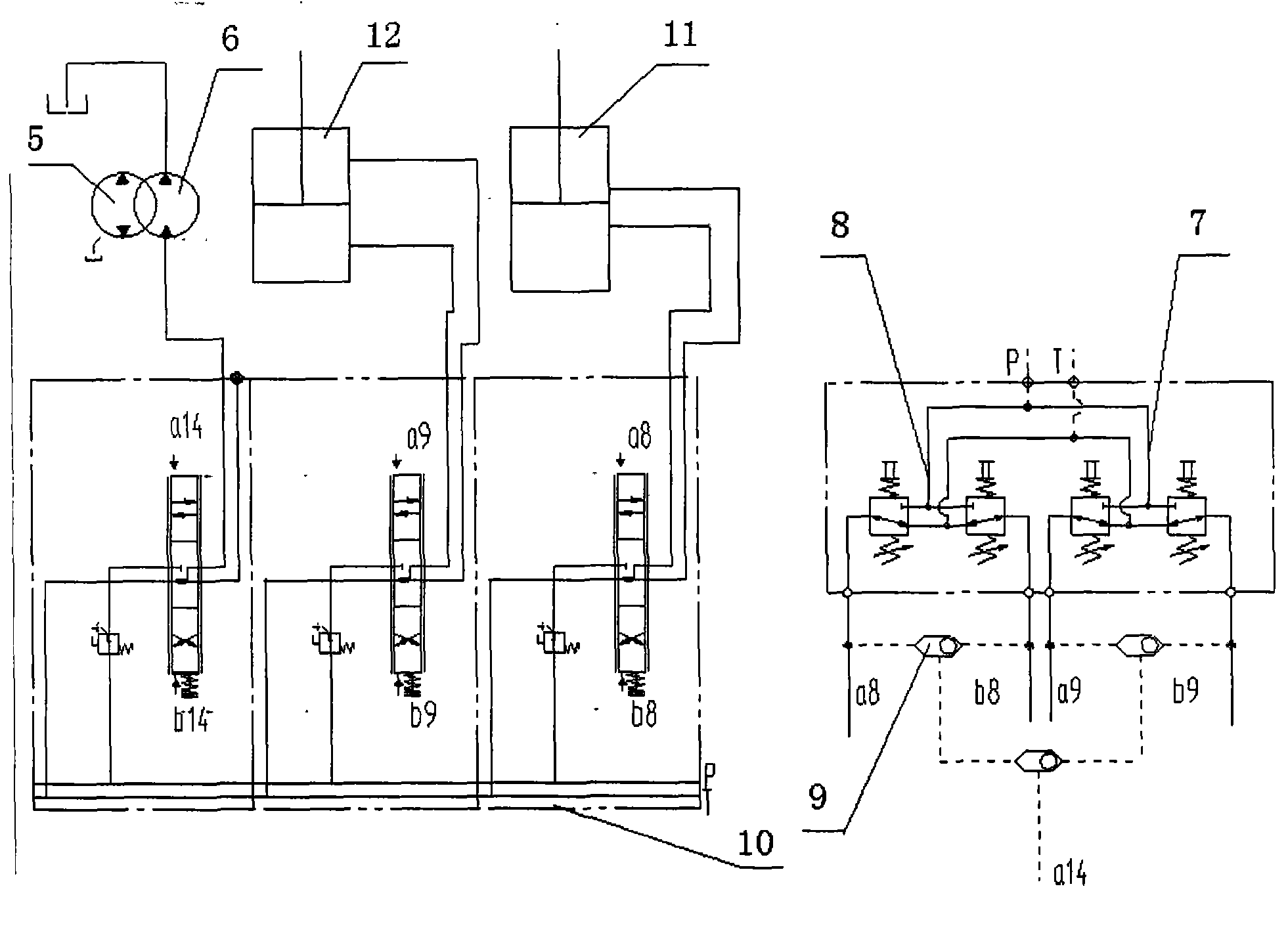

Method for positioning and orientation of tunneller and apparatus thereof

PendingCN110095135AAccurate attitude, velocity and position informationLabor savingNavigation by speed/acceleration measurementsHigh level techniquesQuaternionControl engineering

The invention provides a method for positioning and orientation of a tunneller. The method comprises a navigation position calculation process for acquiring real-time speed and position information ofa tunneller and an inertia calculation process for acquiring real-time attitude information of the tunneller. During the inertia calculation process, an attitude quaternion is introduced to calculatereal-time attitude information of the tunneller and is obtained by calculating corresponding speeds and intermediate speeds on all direction axes of a navigation coordinate system, wherein the navigation coordinate system includes an x axis, a y axis, and a z axis. With the provided method, the influence of the working environment on the positioning and orientation of a tunneller canb e eliminated; full autonomous navigation can be realized; the trouble of setting the rear tunnel reference manually can be saved; and the construction efficiency can be improved substantially. In addition, the invention also provides an apparatus for the method for positioning and orientation of a tunneller. The apparatus has a simple structure; and a problem of low positioning accuracy of the tunneller dueto the working environment in the prior art is solved.

Owner:CENT SOUTH UNIV

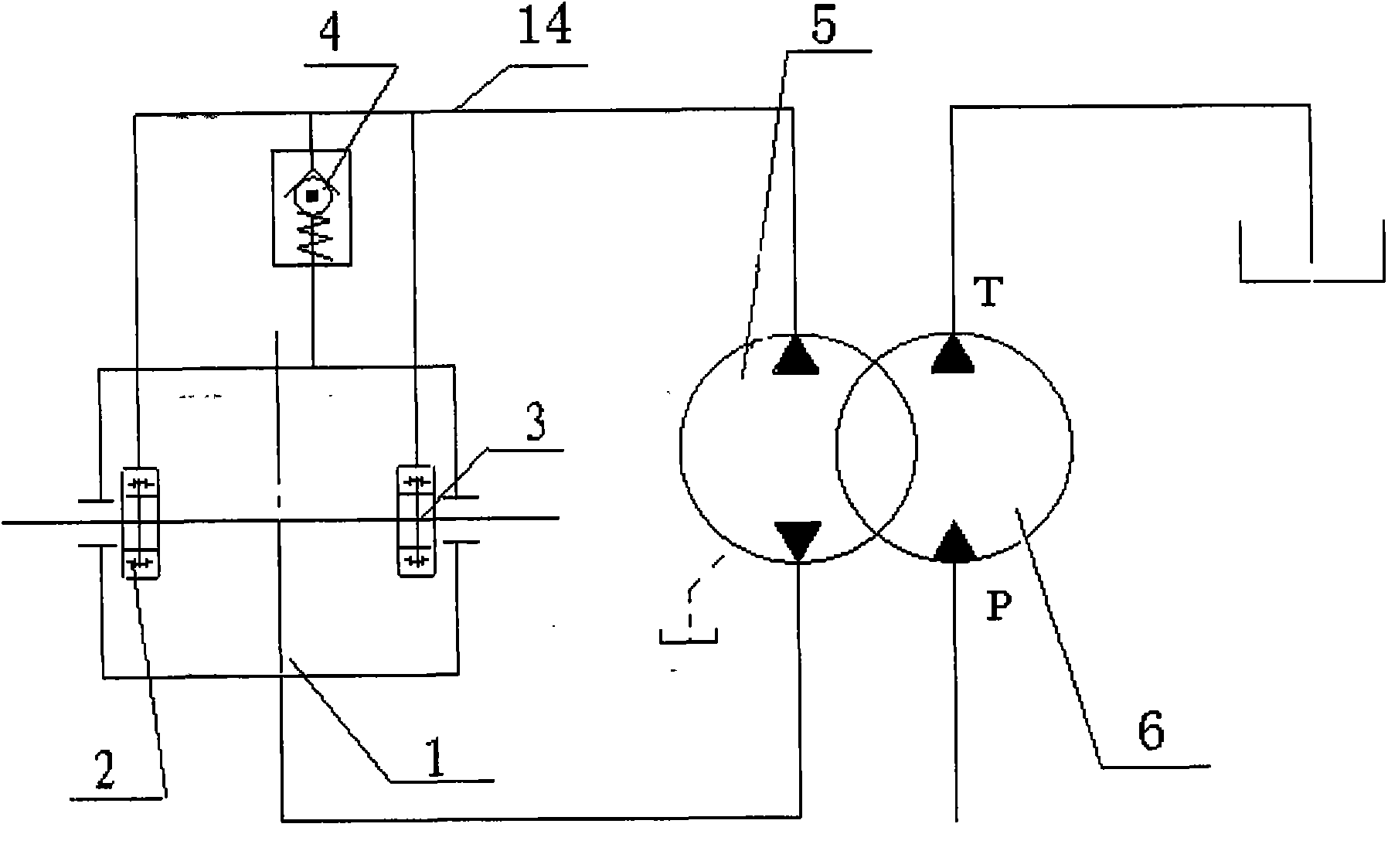

Forced lubrication system for cutting speed reducer of tunneller

InactiveCN103670403ALubrication mandatoryRealize forced lubricationGear lubrication/coolingDriving meansHydraulic motorLow speed

The invention relates to excavating and mining of large-slope coal mine tunnels, in particular to a forced lubrication system for the cutting speed reducer of a tunneller and solves the problem that when a traditional tunneller works at a slope of above 23 degrees, the bearing at the high-speed end or the low-speed end of the cutting speed reducer cannot be lubricated. Through the adoption of the forced lubrication system, the bearing at the high-speed end or the low-speed end of the cutting speed reducer can be lubricated above the level of lubricating oil. In a large-slope tunnel, when the tunneller goes up a slope to cut a roof, the bearing at the low-speed end of the cutting speed reducer is below the level of lubricating oil and thus cannot be lubricated; when the tunneller goes down the slope and the cutting head performs bottom sweeping, the bearing at the high-speed end of the cutting speed reducer is below the level of the lubricating oil and thus cannot be lubricated. A lubricating pump is driven by the hydraulic motor of a hydraulic system; when a cutting arm goes up and down, or rotates, lubricating oil at the bottom of the cutting speed reducer is pumped to the bearing cavities at the high-speed end and the low-speed end of the cutting speed reducer so as to provide forced lubrication for the bearings at the high-speed end and the low-speed end.

Owner:SHENYANG NORTH MINING MACHINERY

Subway tunnel artificial intelligence robot

InactiveCN112810638AReduce work intensityThe detection process is fastPermeability/surface area analysisCarriagesSimulationControl engineering

The invention discloses a subway tunnel artificial intelligence robot, which belongs to the technical field of artificial intelligence equipment. The subway tunnel artificial intelligence robot comprises a base, the bottom of the base is provided with a displacement mechanism, the top of the base is fixedly connected with an upper housing with an opening in the lower end, and the top of the base is fixedly provided with a PLC, a storage battery and a communication device in sequence; and a driving motor b and a driving motor c are fixedly arranged at the inner top of the base. The camera installed on the fixed support is used to shoot the wall in the subway tunnel, then the shot wall is sent to the PLC controller for comparison and identification, the PLC controller is used to determine whether there is water seepage in the subway tunnel, and when water seepage exists, the communication device is used to transmit the positioned and shot water seepage picture to the rear end, in addition, the artificial intelligence robot is used for detecting water seepage of the wall in the subway tunnel instead of manual work, the detection speed is high, the detection efficiency is high, and meanwhile the working intensity of related workers is reduced.

Owner:FUJIAN NORMAL UNIV

Gantry type self-walking roofbolter

InactiveCN100402792CGuaranteed non-interferenceImprove work efficiencyConstructionsRotary drillingEngineeringTunnellers

The invention relates to a tunnel constructing device, especially providing an automatic anchor rod driller for supporting the top plate and side wall, wherein said invention is formed by track walking device, frame and the drilling machine mounted on the frame; said invention can not work with tunneller, to cause low working efficiency. The invention is mainly formed by two separated portable frames mounted on the track walking device; the longitudinal and transverse drilling machines are independently mounted on the beam and upright post of portable frame; the tunneller can move at the middle of portable frame, to improve the working efficiency.

Owner:SHANXI DONGHUA MACHINERY

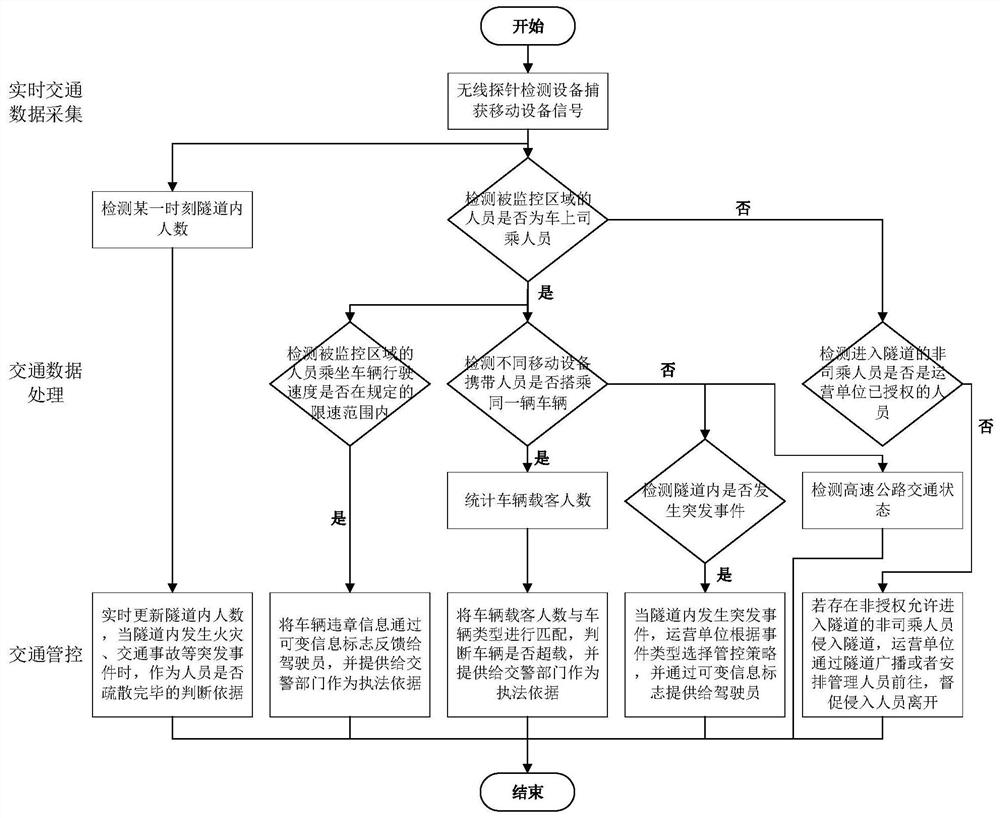

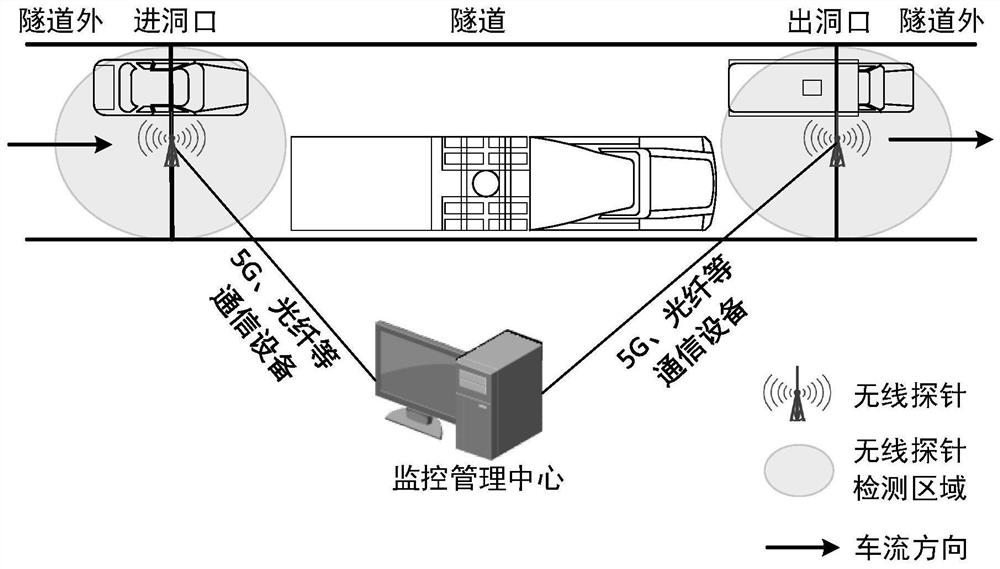

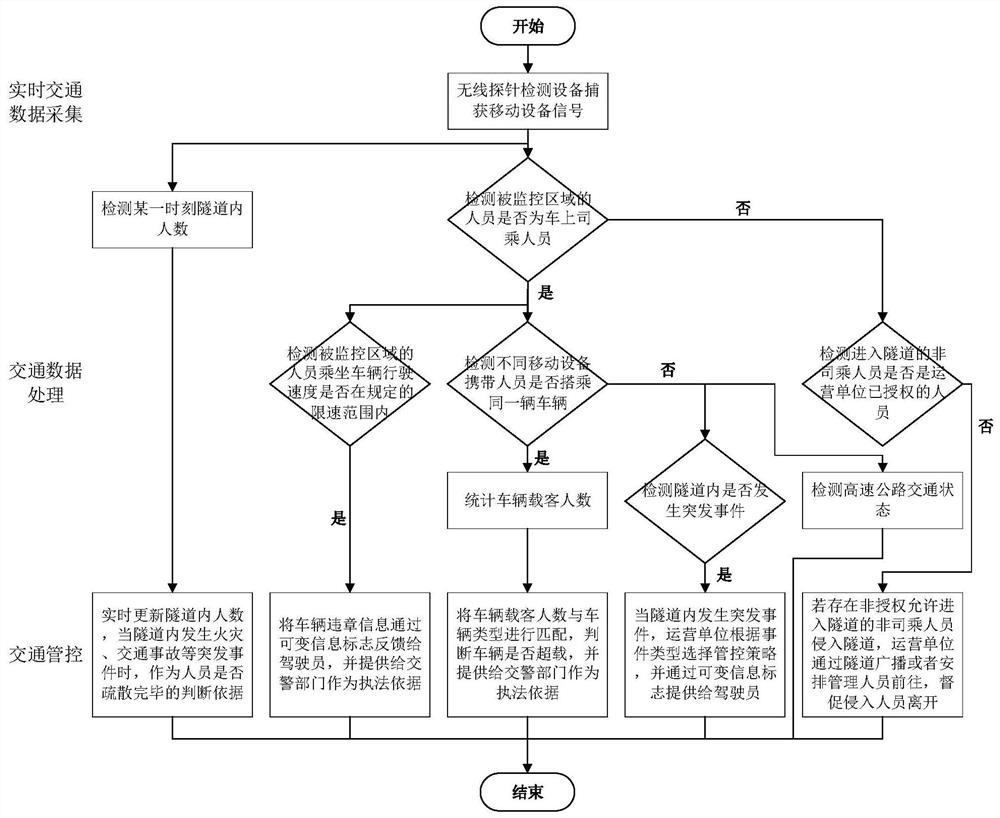

Expressway tunnel personnel monitoring method based on wireless probe

PendingCN113965901AReduce traffic safety risksGuaranteed uptimeParticular environment based servicesDetection of traffic movementTunnellersEmbedded system

The invention relates to an expressway tunnel personnel monitoring method based on a wireless probe, and belongs to the field of intelligent traffic. The method comprises the following steps: S1, capturing a wireless signal sent by a mobile terminal in a detection area through wireless probe detection equipment, recording capturing time and equipment data at the same time, and packaging and sending the data to a monitoring management center; S2, processing the collected data by the monitoring management center, obtaining traffic information, and then carrying out traffic control, wherein the traffic information comprises the number of persons in the tunnel, whether the persons are drivers and conductors in the vehicle, whether the vehicle is driven at a specified speed limit, whether persons carried by different mobile terminals take the same vehicle, a tunnel traffic state, whether emergencies occur in the tunnel, and whether unauthorized persons illegally enter the tunnel. The highway tunnel traffic control capability can be enhanced, and the traffic safety risk can be reduced.

Owner:SHANDONG HI SPEED COMPANY

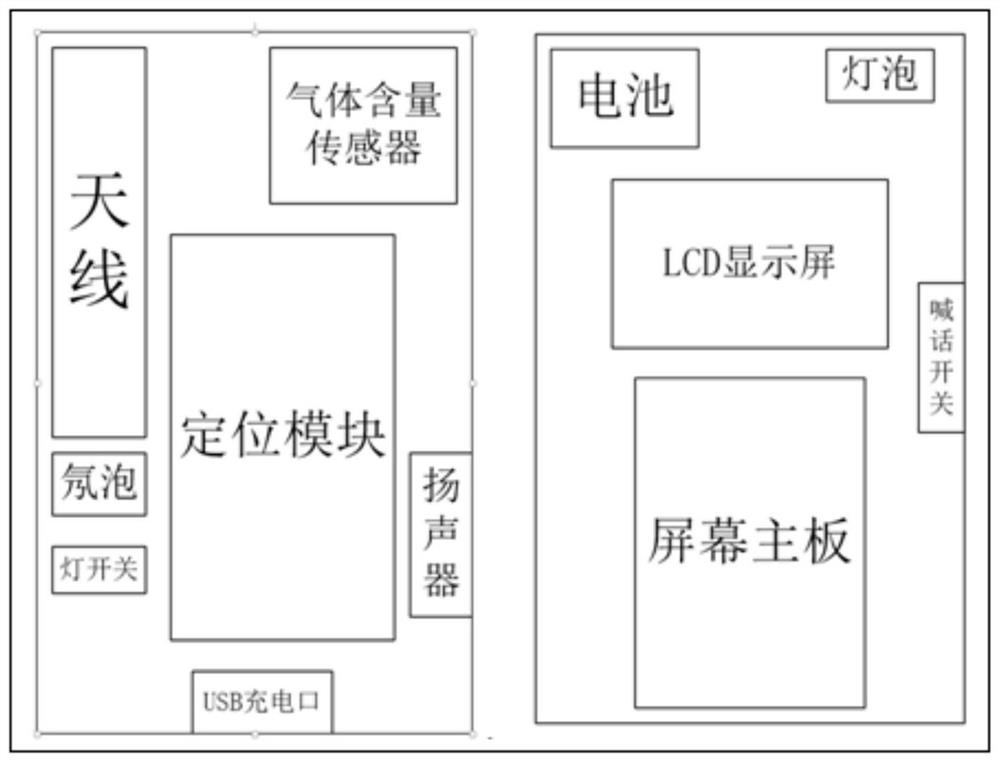

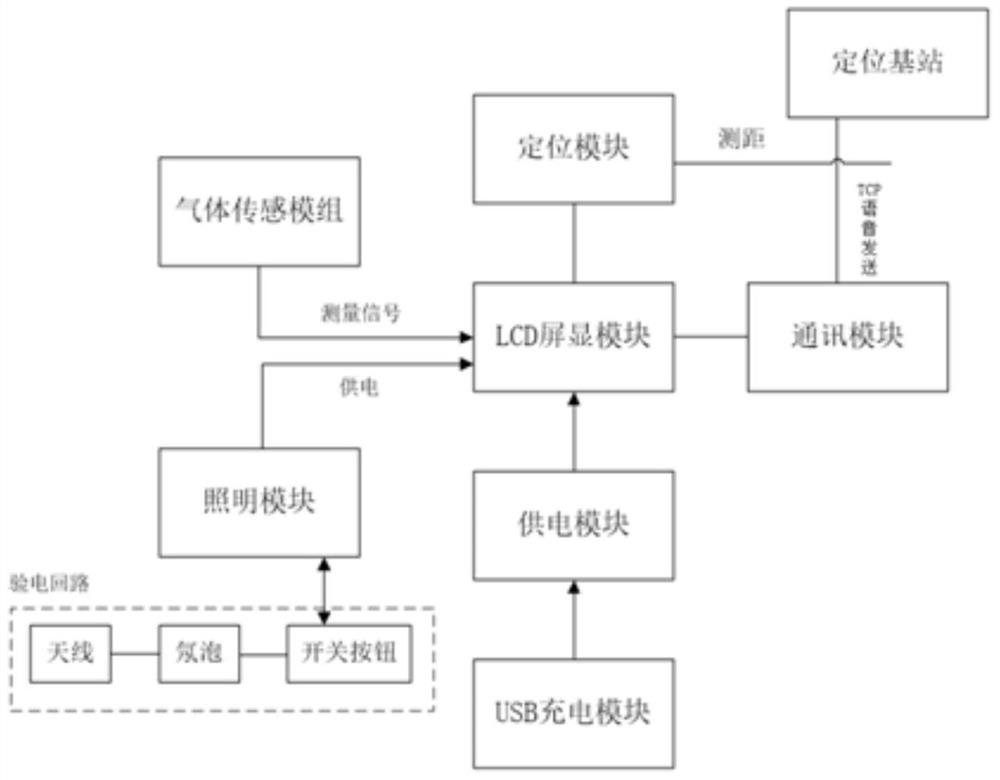

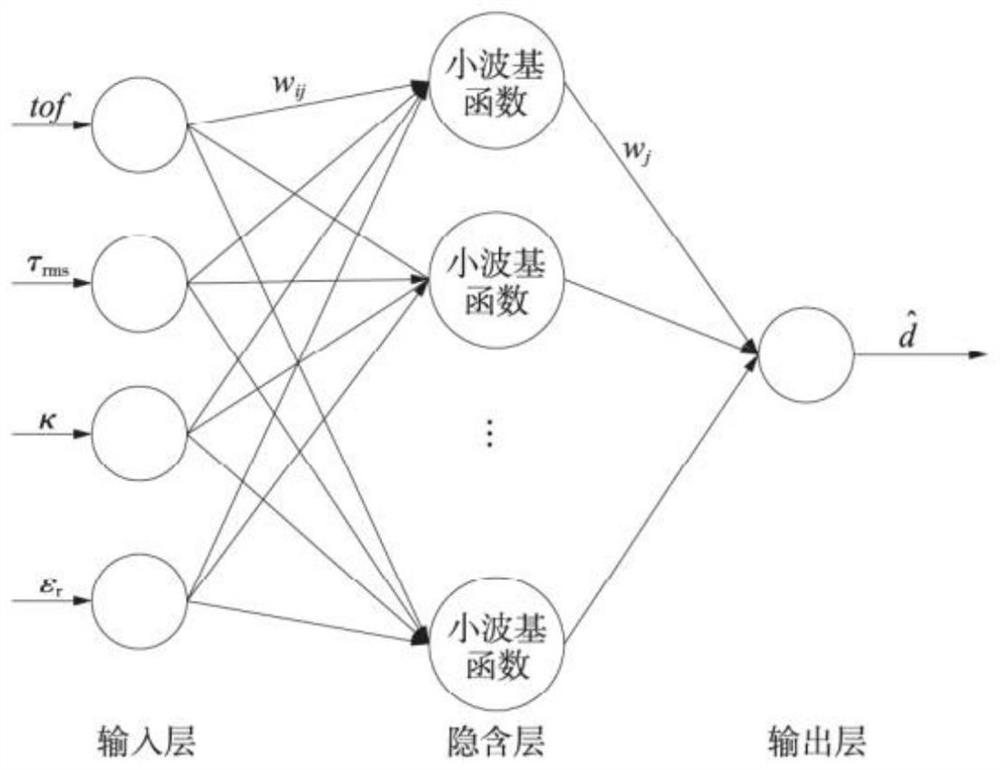

Multifunctional positioning device based on neural network

PendingCN114697860AGuarantee personal safetyEasy to carryParticular environment based servicesGas analyser construction detailsPrimary stationVoice communication

The invention discloses a multifunctional positioning device based on a neural network. The multifunctional positioning device comprises a positioning module, a communication module, a gas sensing module, a lighting module, an LCD screen display module, an electricity measuring module, a power supply module, a USB charging module and a positioning base station. The LCD screen display module is respectively connected with the positioning module, the communication module, the gas sensing module, the lighting module and the power supply module, the electricity measuring module is connected with the lighting module, the USB charging module is connected with the power supply module, and the positioning base station is respectively connected with the positioning module and the communication module; the positioning module is internally provided with a neural network model. The system integrates multiple functions of positioning, voice communication, environmental gas monitoring, illumination, electricity measurement and the like, is internally provided with a positioning module optimized by a neural network model algorithm, improves the positioning precision, guarantees the advantages of small equipment size and low power consumption, is convenient for a user to carry, achieves the mastering of the comprehensive information of tunnel personnel by a monitoring main station, and improves the working efficiency. The occurrence rate of tunnel safety accidents is greatly reduced, and the personal safety of users in the tunnel is guaranteed.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

Construction mode with full cross-section tunneller

The full-section entry-driving machine construction method includes the following processes of cutting rock, lining pipe-sheet, pipe-sheet water-stopping, backfilling gravel and pouring cement slurry, in which the pipe-sheet water-stopping process includes the following steps: butt-jointing pipe-sheets, placing the filling strip on the butt joint of bottom of filling groove, inserting the plastic water-stopping material into filling groove, wedging iron wedge from top of filling groove and backfilling high-strength cement slurry into butt-joint seam is pipe-sheet surface, and the process of backfilling gravel and pouring cement slurry includes the following steps: sectionalizing periphery of pipe-sheet, placing rubber hose along the periphery of pipe-sheet, air-inflating hose, backfilling gravel, pouring cement slurry, finally releasing air from hose and pouring cement slurry.

Owner:刘丽萍

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com