Unmanned tunneling system and method of coal mine roadway

A coal mine roadway and roadway technology, applied in the field of coal mine roadway unmanned excavation system, can solve the problems of restricting the development of coal production, the lag of fully mechanized excavation face, and unbalanced excavation, so as to reduce the casualties of coal mines, improve the excavation efficiency, and improve the excavation efficiency. speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

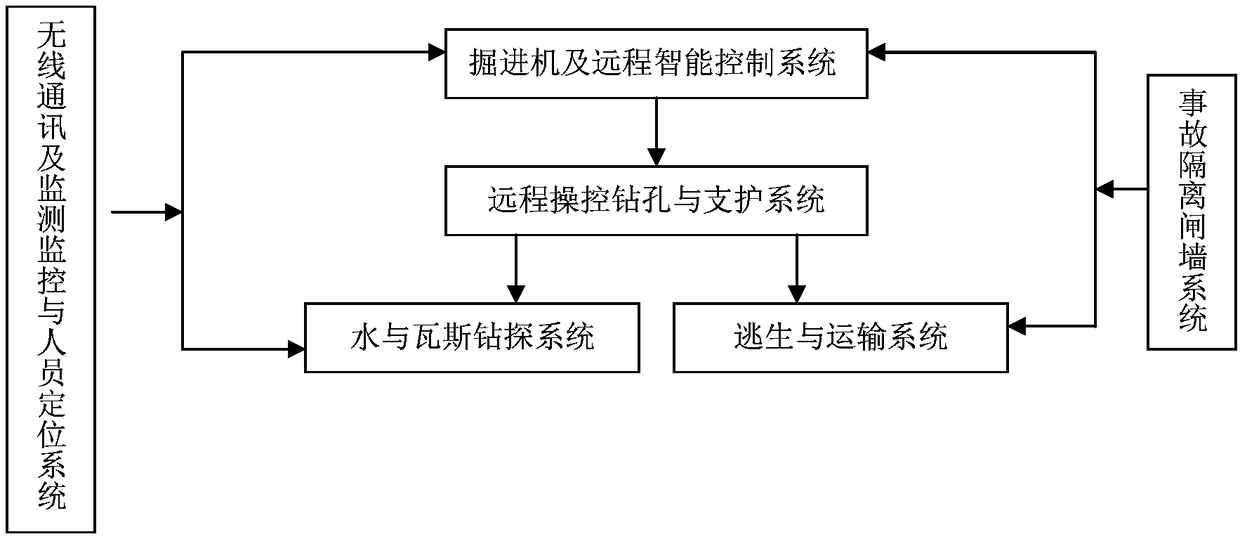

[0058] combine Figure 1 to Figure 5 As shown, the first embodiment provides an unmanned tunneling system for coal mine roadway, which includes: an accident isolation gate wall system, a remote intelligent control system for roadheaders, a remote control drilling and support system, an escape and transportation system, water and gas Drilling system, wireless communication, monitoring and personnel positioning system, the above six systems are coordinated with each other, and signal feedback control can be carried out according to needs.

[0059] In this embodiment, the accident isolation gate wall system is movably installed in the roadway, which isolates the roadway into a 100-meter danger relief area and a normal working area.

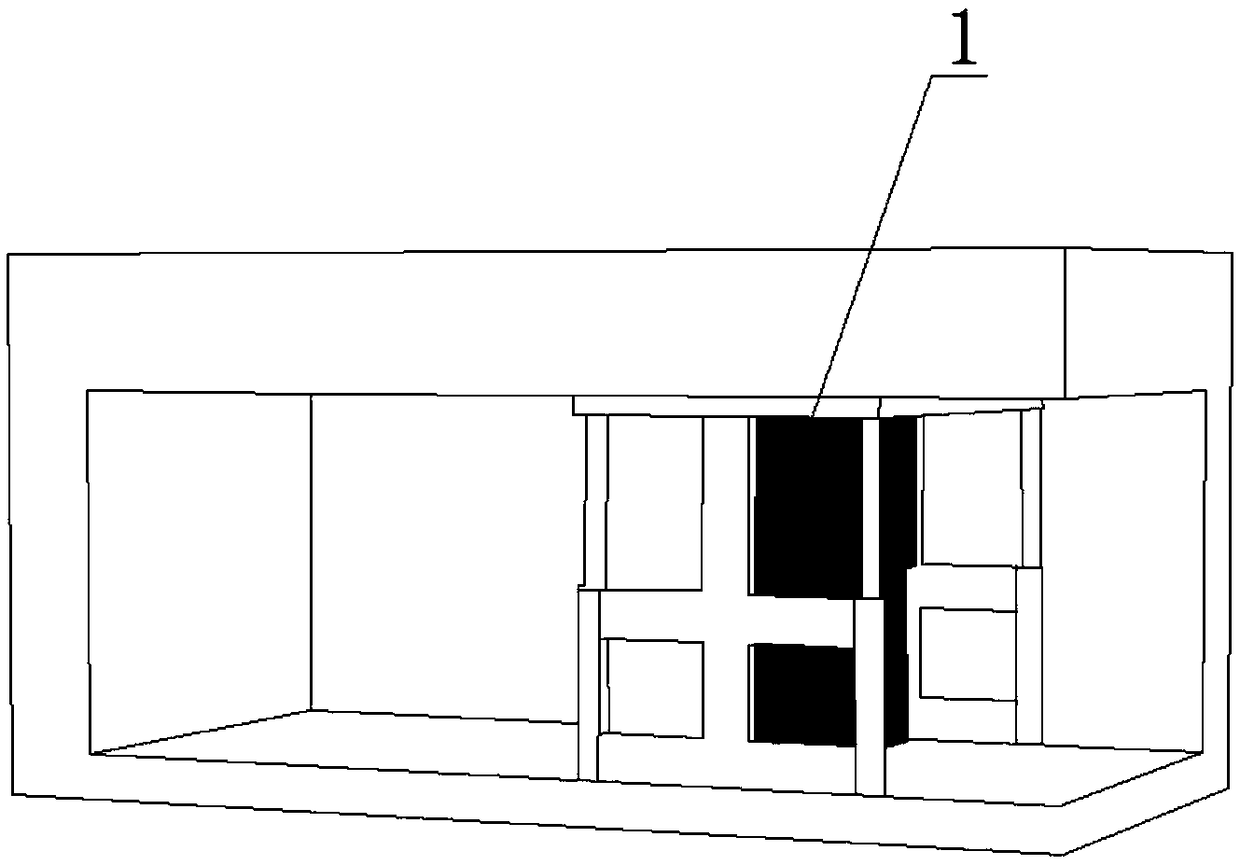

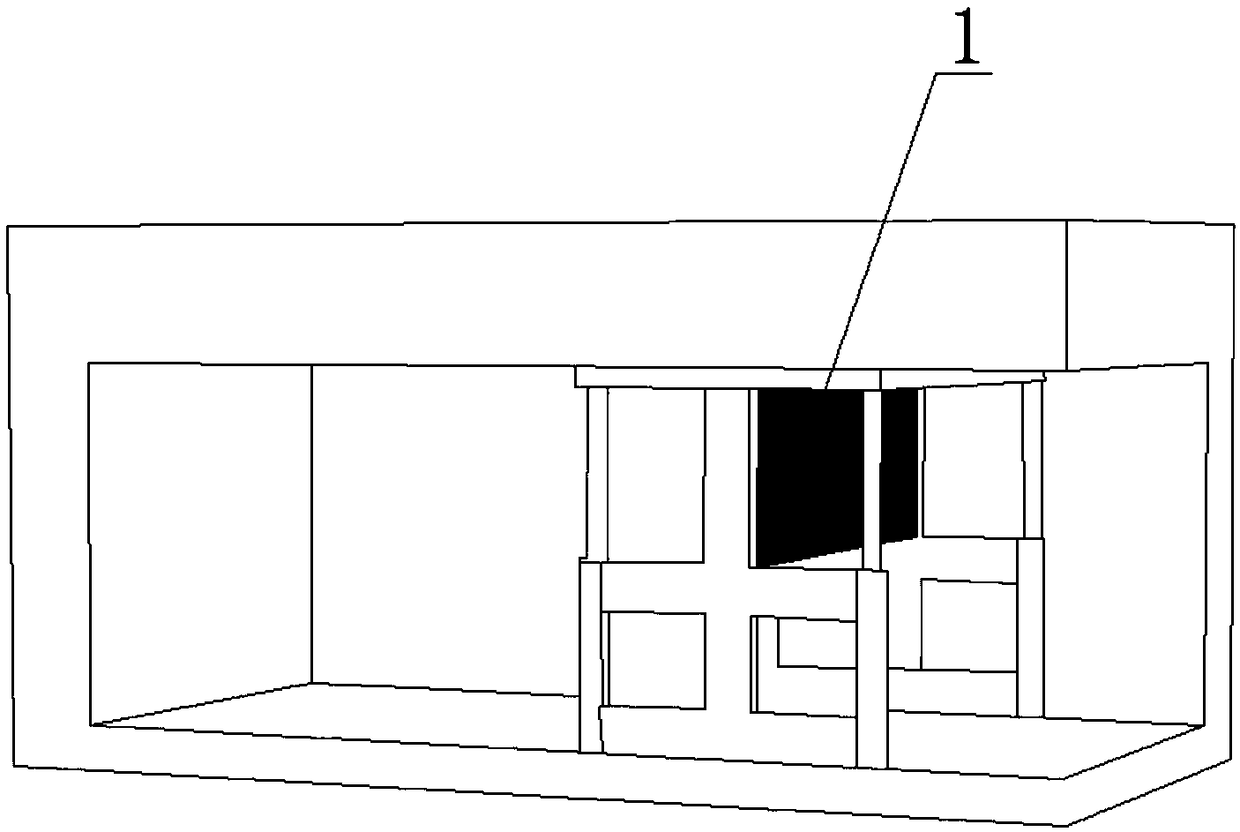

[0060] Preferably, the accident isolation wall system 1 includes: at least one self-moving disaster isolation gate wall 11; the self-moving disaster isolation gate wall 11 is arranged between the 100-meter danger relief area and the normal working ar...

Embodiment 2

[0131] The second embodiment provides a method for the coal mine roadway unmanned excavation system according to the first embodiment above, which includes the following steps:

[0132] The roadway is separated into a 100-meter danger relief area and a normal working area through the accident isolation gate wall system;

[0133] Among them, when the roadway is normally excavated, the accident isolation gate wall system is on standby, and the remote intelligent control system of the roadheader remotely controls the roadheader to carry out excavation operations in the 100-meter danger-relief area, and remotely controls the drilling and support system to remotely control the drilling rig The assembly performs support operations in the 100-meter danger-relief area, and the escape and transportation system assists in the transportation of materials. The water and gas drilling system can detect water and gas in the 100-meter-de-emergency relief area, and de-risk coal by drilling. To...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com