Method for controlling deformation of coal seam floor rock stratum through underground grouting slurry filling sleeve

A technology for controlling coal seam and coal seam floor, which can be used in fillings, shaft equipment, shaft lining, etc., and can solve problems such as floor deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings, but are not limited thereto. Any modification or equivalent replacement of the technical solutions of the present invention without departing from the spirit and scope of the technical solutions of the present invention shall be included in the present invention. within the scope of protection.

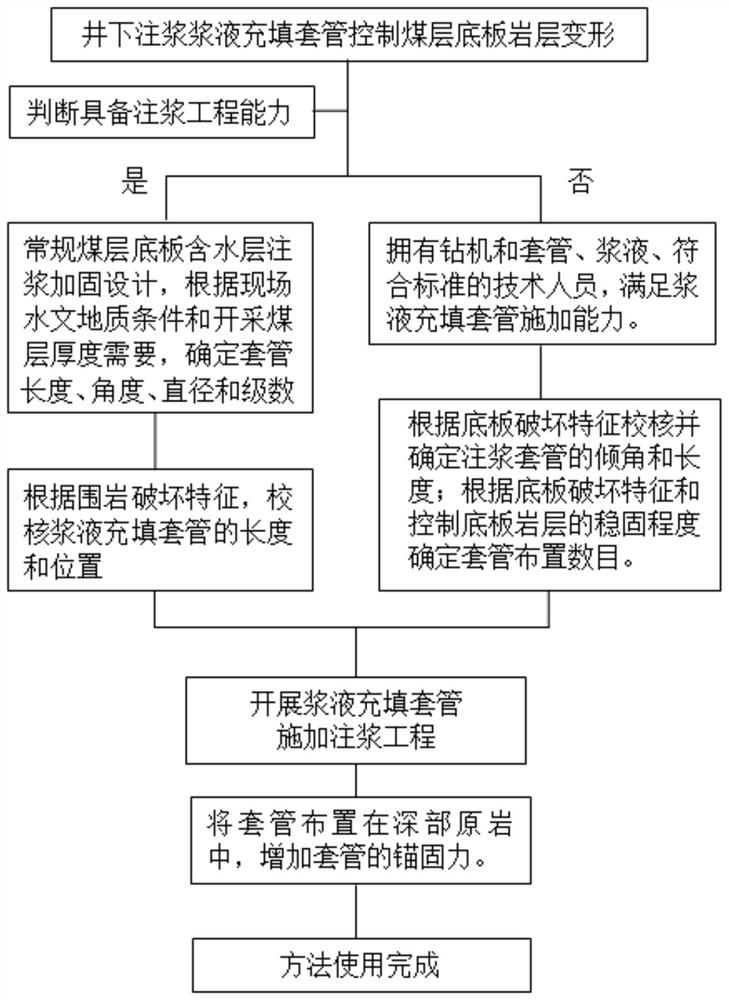

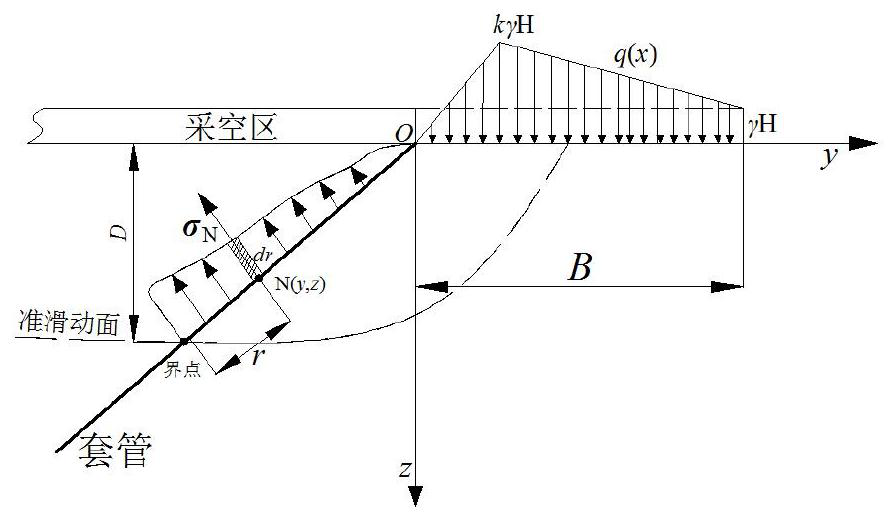

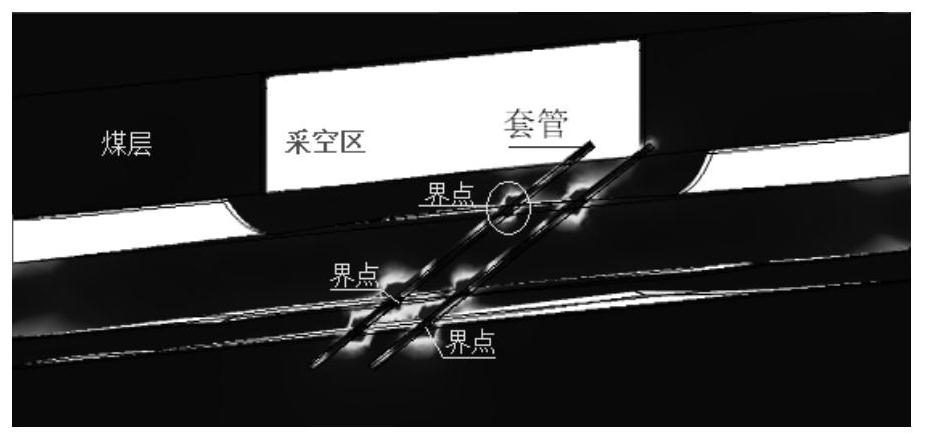

[0038] The invention provides a method for downhole grouting slurry filling casing to control the deformation of coal seam floor rock formation. The method gives full play to the mechanical properties of the slurry filling casing, and based on its ability to resist rock formation deformation caused by uneven deformation in the axial direction, through Determine the geological characteristics and scope of the space to be reinforced, and determine the stable fixed end of the surrounding rock. According to the spatial force characteristics of the slurry-fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com