Auxiliary pushing mechanism for tunneller

A technology for auxiliary propulsion and roadheader, which is applied in mining equipment, earth-moving drilling, tunnels, etc., and can solve problems such as insufficient power, personnel safety and slippage affecting the working condition of the whole machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

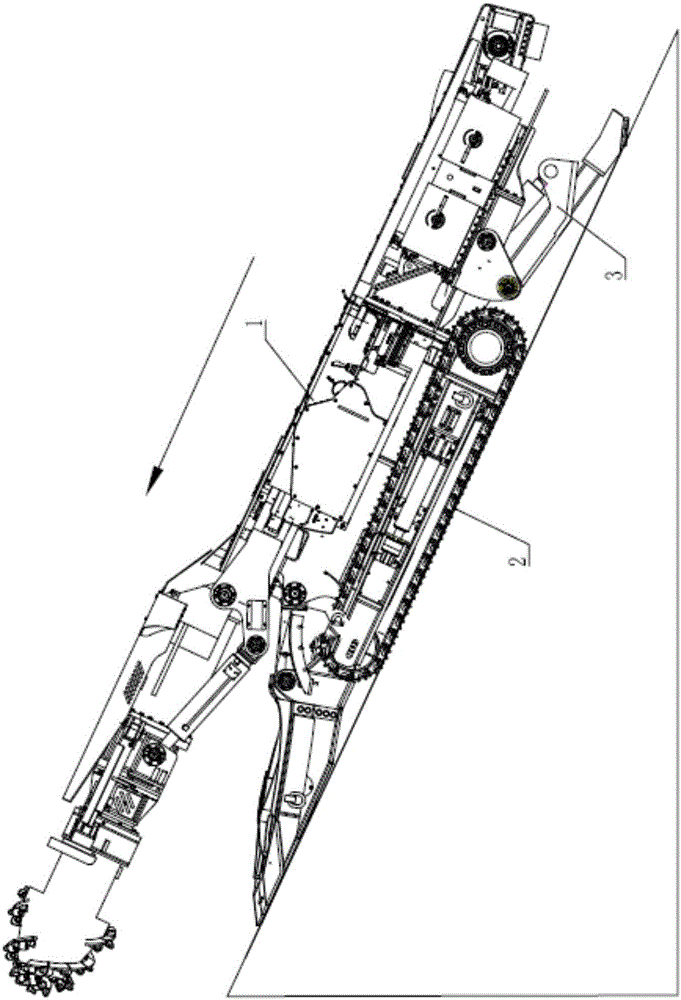

[0018] Such as figure 1 The roadheader shown walks forward along the direction of the arrow on a slope, and it includes a fuselage 1, a walking track 2 is provided at the bottom of the fuselage 1, an auxiliary propulsion mechanism 3 is installed at the bottom of the tail of the fuselage 1, and The auxiliary propulsion mechanism 3 is located behind the crawler belt 2 .

[0019] Generally speaking, roadheaders traveling on slopes will encounter the problem of insufficient uphill power, causing slippage and other phenomena, which seriously affect the safety of staff. The auxiliary propulsion mechanism 3 in the embodiment can provide additional auxiliary thrust for the advancement of the roadheader. After the auxiliary thrust is superimposed with the power of the roadheader itself, it can ensure that the roadheader can move forward stably without slipping backwards.

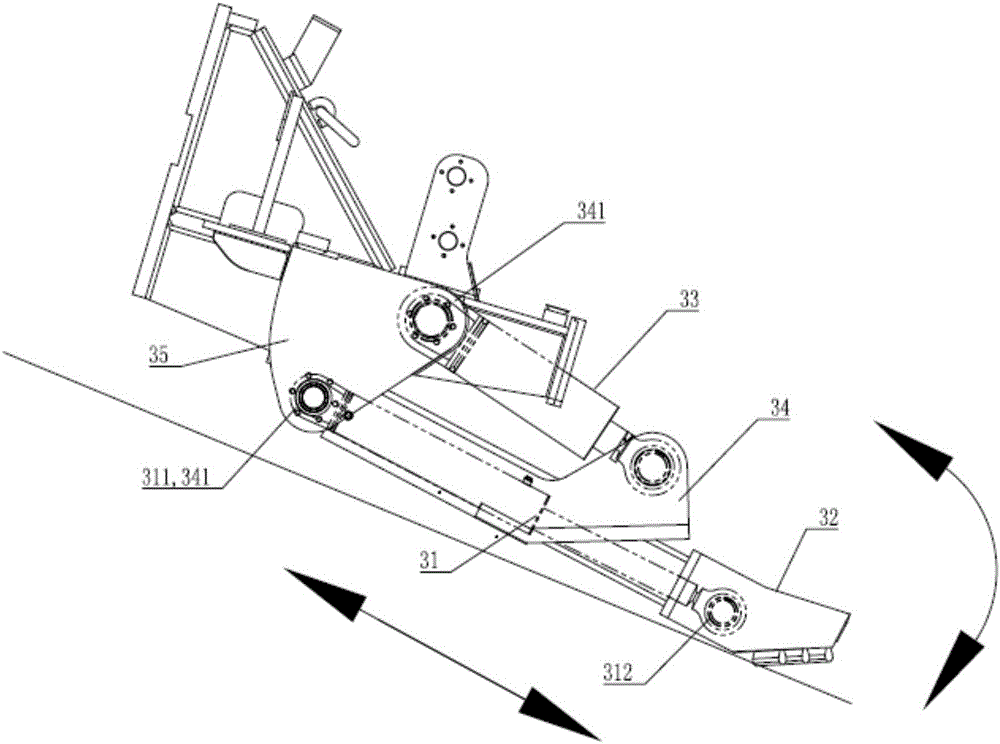

[0020] Such as figure 2 As shown, the auxiliary propulsion mechanism at least includes a telescopic part and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com