Processing method of bracket holes of tunneller type asynchronous motor

A processing method and electric motor technology, which is applied in the manufacture of motor generators, electromechanical devices, electric components, etc., can solve the problems of difficult realization of the production process, and achieve the effects of saving manufacturing costs, reducing labor intensity, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

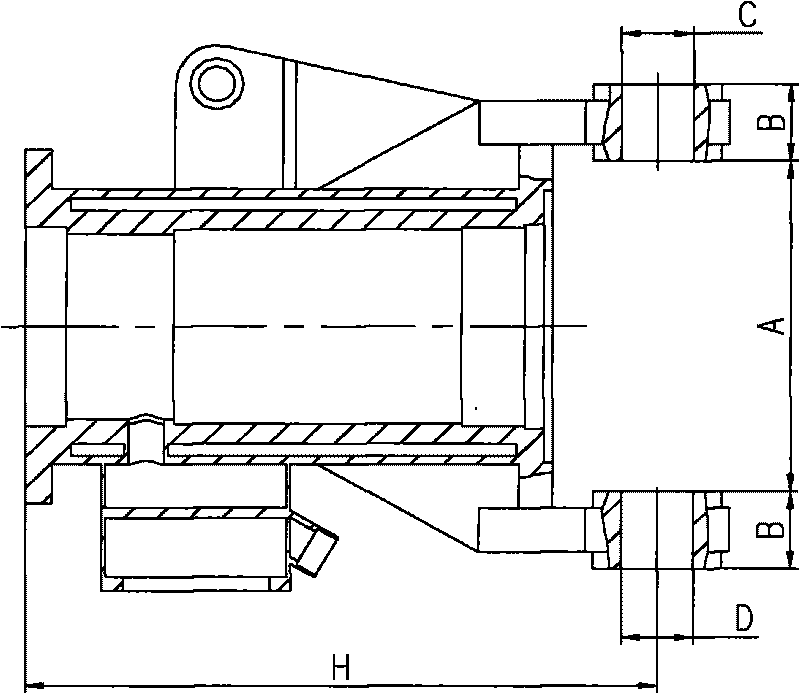

[0018] Such as figure 1 The motor bracket holes shown are machined as follows:

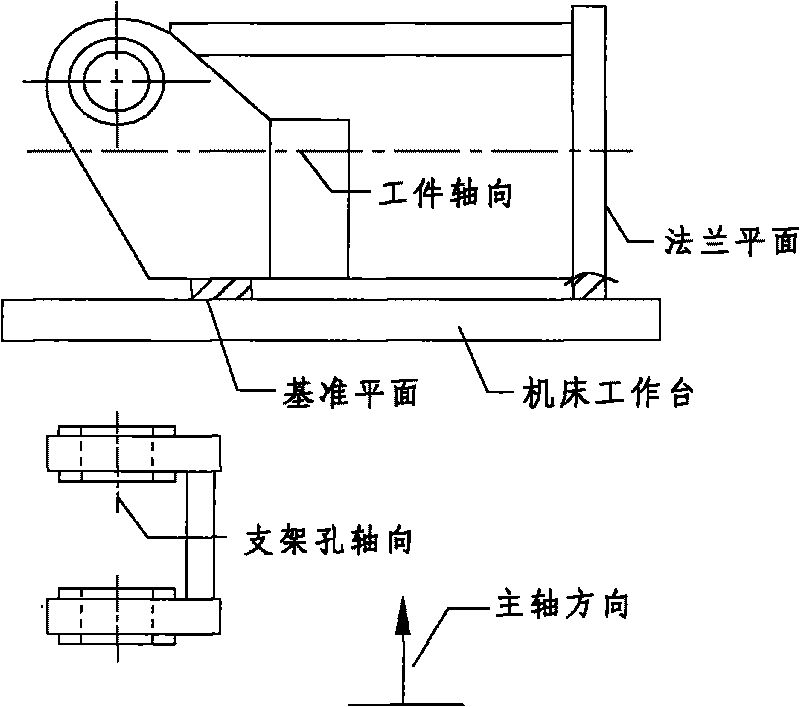

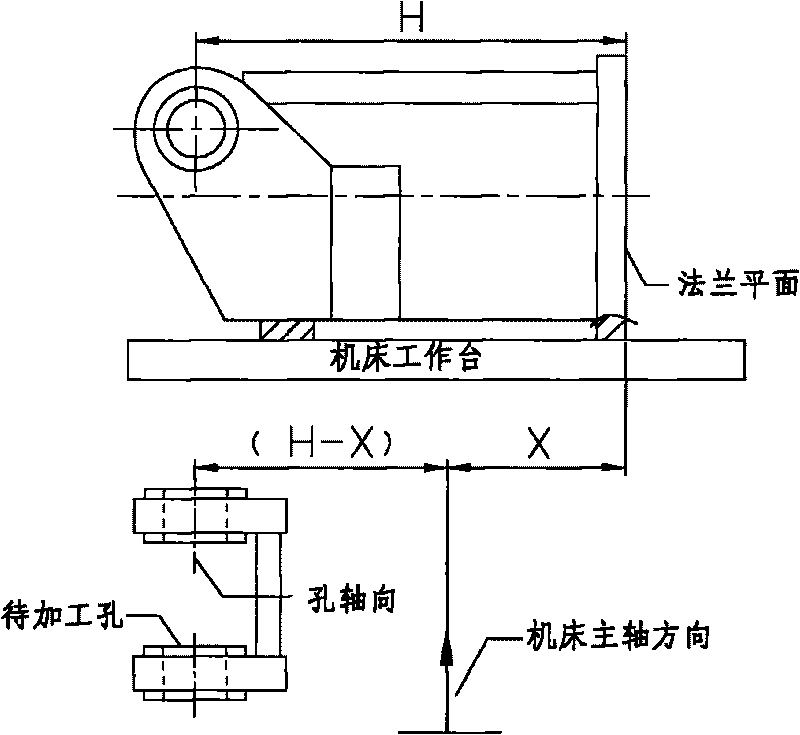

[0019] Firstly, align the center of the machine tool table, and then process a datum plane on the same side of the left and right ends of the workpiece to be processed as the subsequent alignment datum. Facing the workbench of the machine tool with this datum surface, place the workpiece to be processed flat on the workbench, align and press it so that the axis of the workpiece is parallel to the workbench, the flange plane at the left end of the workpiece is perpendicular to the workbench, and the axial direction of the two bracket holes Parallel to the direction of the spindle of the machine tool, one of the bracket holes is adjacent to the spindle. After pressing the workpiece, take the center point of the worktable as the origin, and use coordinate translation to find the distance X from the flange plane of the workpiece to the origin (the center of the workbench). Since the left and right e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com