System and method for predicting fault of working arm reducer of tunneller.

A technology of fault prediction and reducer, applied to instruments, measuring devices, etc., to achieve the effects of wide application range, lower configuration requirements, and less unplanned maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

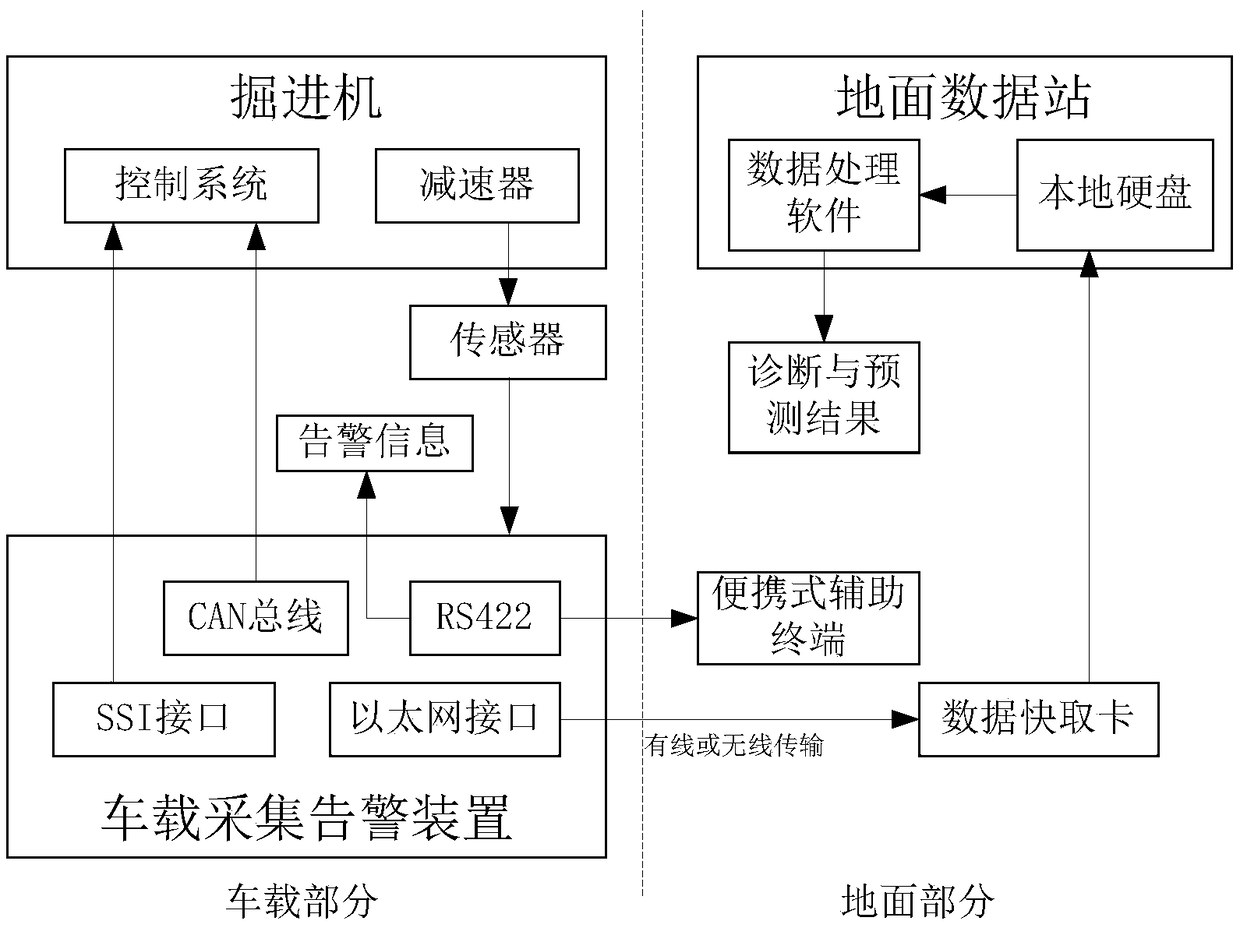

[0065] like figure 1 As shown, the failure prediction system of the working arm reducer of the roadheader in the present invention is composed of the vehicle part (vehicle acquisition and alarm processing device, sensor, cache card) and the ground part (ground data hard disk, ground data processing software).

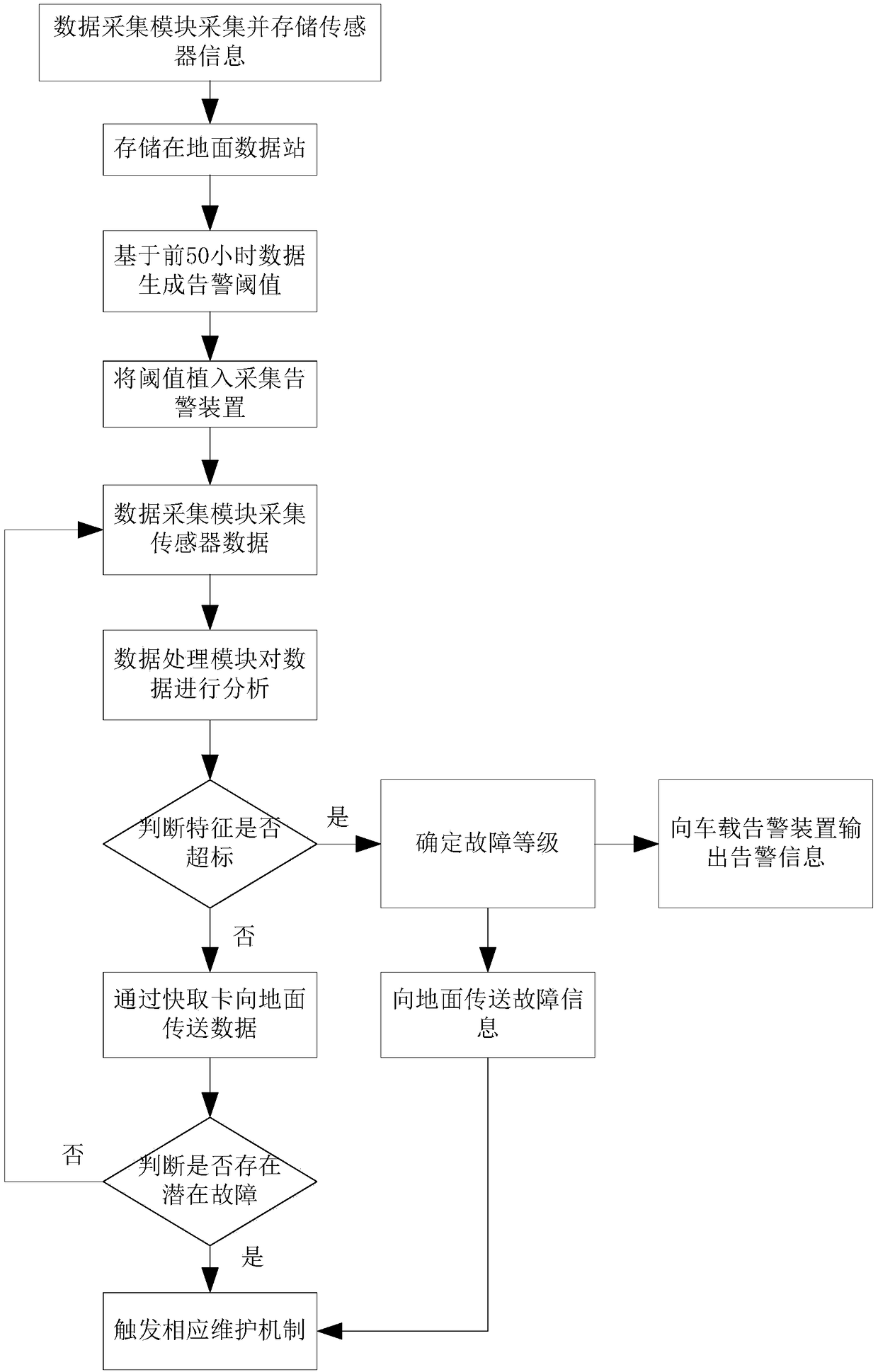

[0066] like figure 2 As shown, the specific implementation of the method of the present invention based on the system structure comprises the following steps:

[0067] S1: The on-board collection and alarm processing device collects 50 hours of data in advance and stores them in the ground data station, and uses data processing software to generate an initial threshold, which is updated every 500 hours thereafter.

[0068] S2: The on-board collection and alarm processing device conducts real-time analysis and processing of the state parameter information transmitted by the sensor, and judges whether the current health characteristics of the reducer exceed the standard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com