Construction mode with full cross-section tunneller

A full-face tunnel boring machine and construction method technology, which is applied in the direction of earth square drilling, mining equipment, tunnels, etc., can solve the problems of high installation precision of rubber waterstop, non-compact backfill pea gravel, difficult to repair and difficult to handle, etc., to achieve improvement Grouting effect, low cost, convenient filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

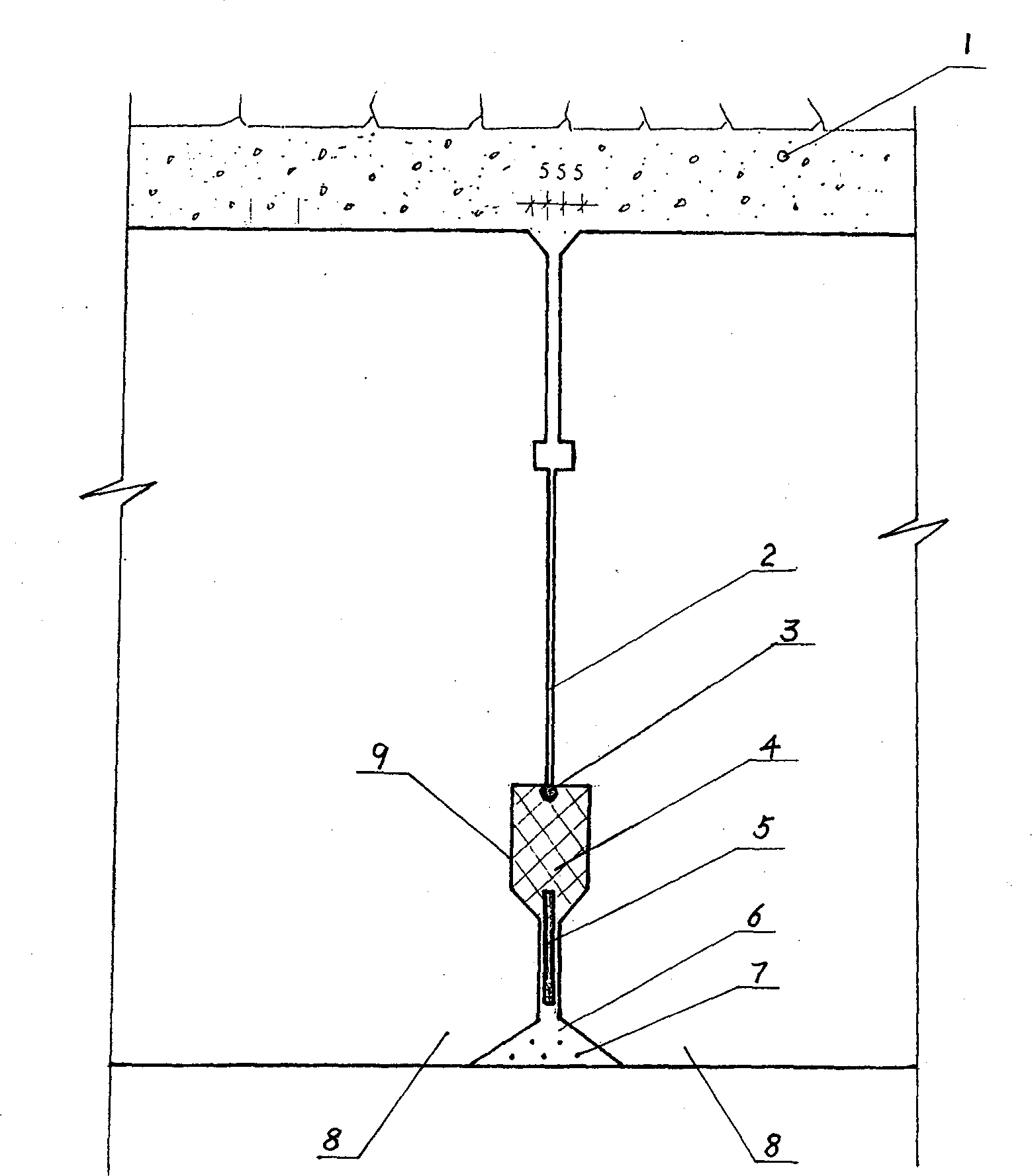

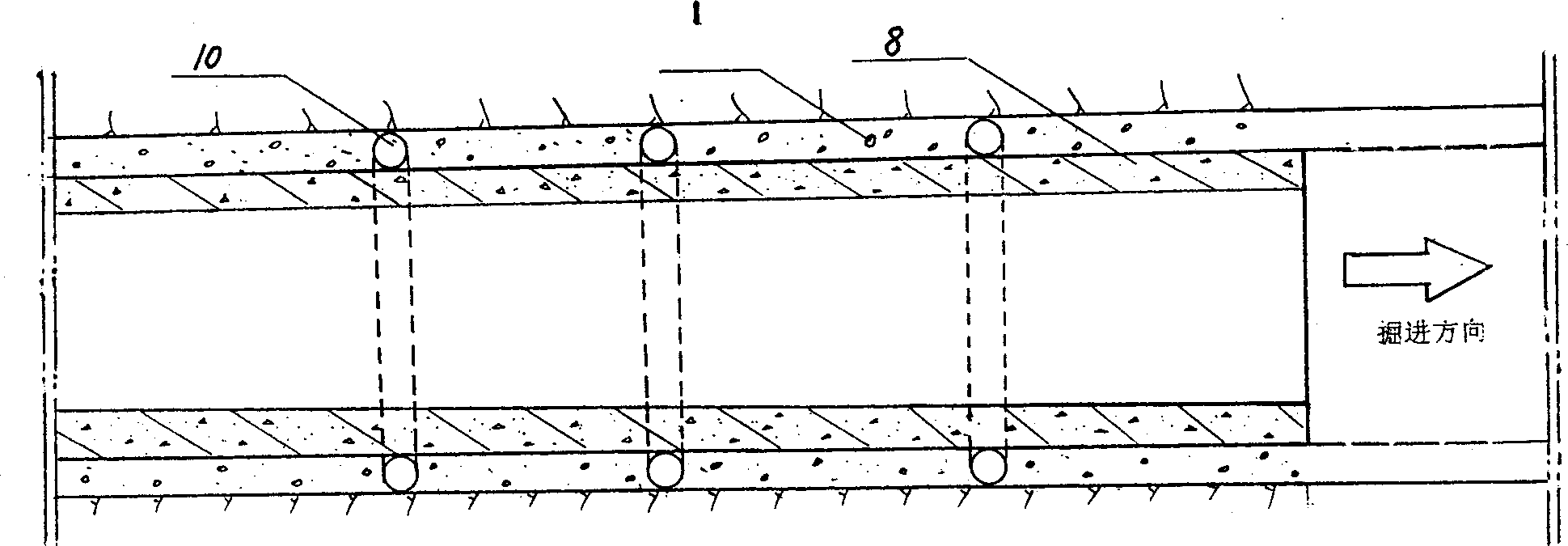

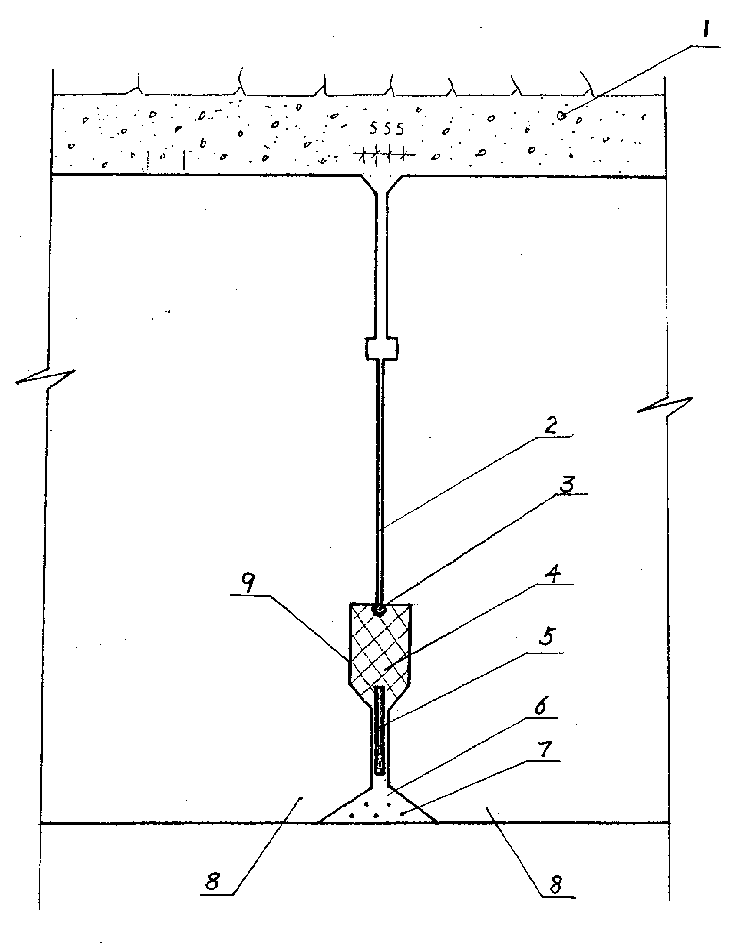

[0021] Such as figure 1 , figure 2 As shown, the construction method of the full-face roadheader in this embodiment includes processes such as cutting rocks and lining segments, among which: it also includes segment water-stop technology, backfilling bean gravel and cement slurry pouring technology; segment stop The water process consists of the following steps:

[0022] 1). Butt the prefabricated reinforced concrete segments 8 according to the design requirements;

[0023] 2) Put the oil-impregnated mineral wool 3 on the butt joint 2 at the bottom of the filling tank 9 formed between the tube pieces 8 to block the butt joint 2 between the two tube pieces 8;

[0024] 3) Insert the plastic water stop material of non-vulcanized butyl rubber (GB) 4 into the filling tank 9 until it is filled;

[0025] 4) Wedge the iron wedge 5 from the top of the filling groove 9 into the plastic water stop material of the non-vulcanized butyl rubber 4 to compress the plastic water stop material;

[...

Embodiment 2

[0035] The construction method of the full-face roadheader in this embodiment includes cutting rock and lining pipe segments, among which: it also includes the pipe segment water-stop technology and the backfilling of pea gravel and the cement slurry pouring technology; the segment water-stop technology consists of The following steps are composed:

[0036] 1). Butt the prefabricated reinforced concrete segments according to the design requirements;

[0037] 2). Arrange the rubber on the butt joint at the bottom of the filling groove formed between the tube pieces to block the butt joint between the two tube pieces;

[0038] 3). Insert the plastic water stop material of the modified asphalt into the filling tank until it is filled;

[0039] 4). Wedge the iron wedge from the top of the filling groove into the modified asphalt plastic water stop material to compact the plastic water stop material;

[0040] 5). Use high-strength cement mortar to backfill the gaps on the surface of th...

Embodiment 3

[0049] The construction method of the full-face roadheader in this embodiment includes cutting rock and lining pipe segments, among which: it also includes the pipe segment water-stop technology and the backfilling of pea gravel and the cement slurry pouring technology; the segment water-stop technology consists of The following steps are composed:

[0050] 1). Butt the prefabricated reinforced concrete segments according to the design requirements;

[0051] 2) The polyester non-woven is arranged on the butt joint at the bottom of the filling groove formed between the tube pieces to block the butt joint between the two tube pieces;

[0052] 3). Insert the plastic water-stop material of elastic polyurethane into the filling tank until it is filled;

[0053] 4) Wedge the iron wedge from the top of the filling groove into the elastic polyurethane plastic material to compress the plastic water stop material;

[0054] 5). Use high-strength cement mortar to backfill the gaps on the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com