Wet type dust collector for crag lane or half coal crag lane

A wet dust collector and dust collector technology, applied in dust prevention, safety devices, mining equipment, etc., can solve the problems of high viscosity of rock powder, easy to block the filter, and incompetence, so as to control coal dust explosion and improve work efficiency , the effect of preventing pneumoconiosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

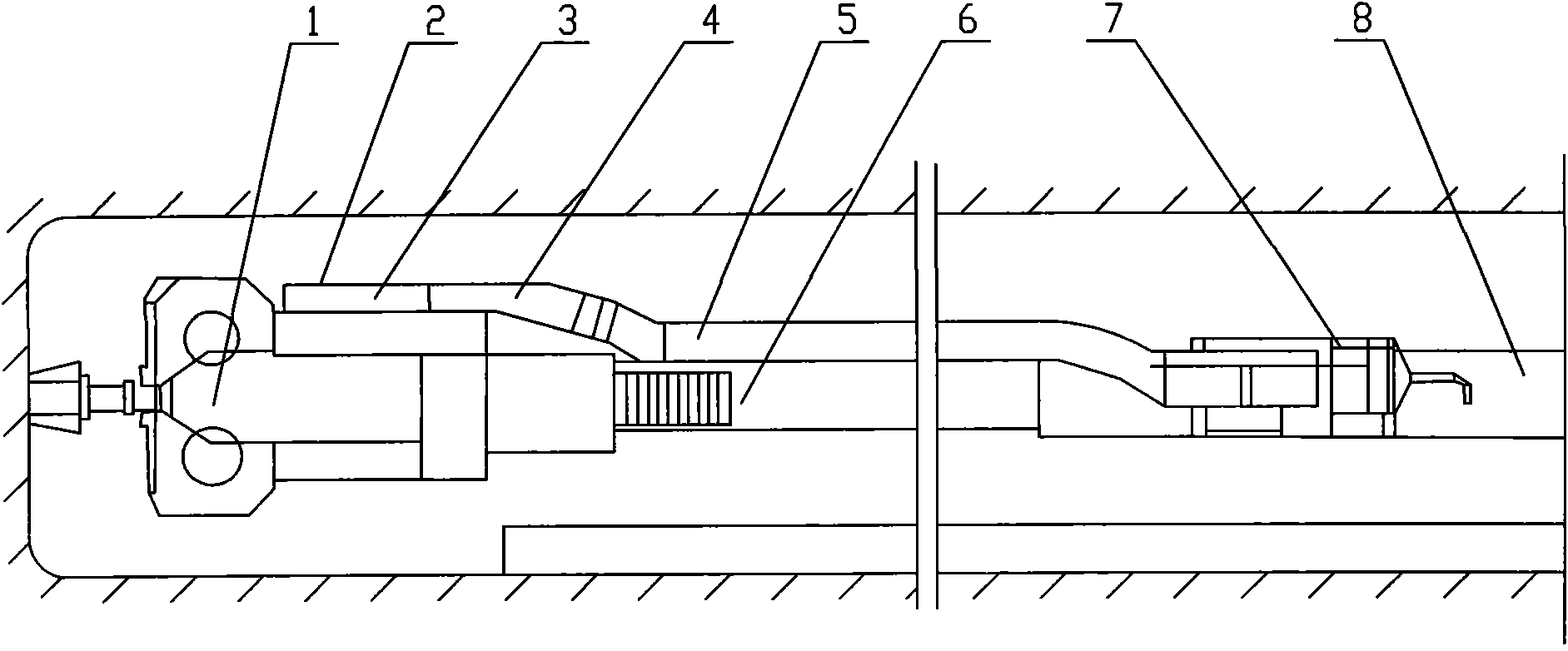

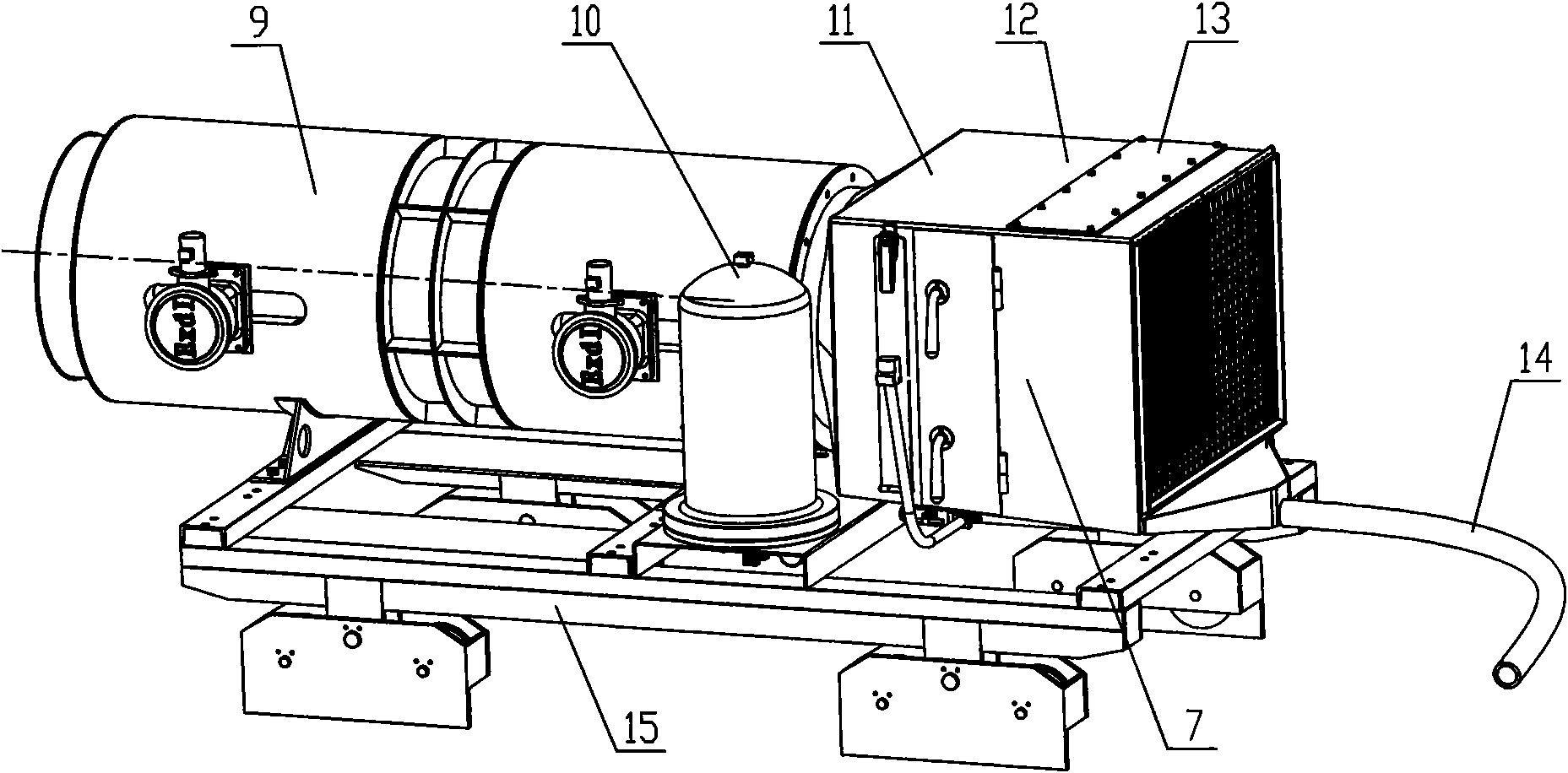

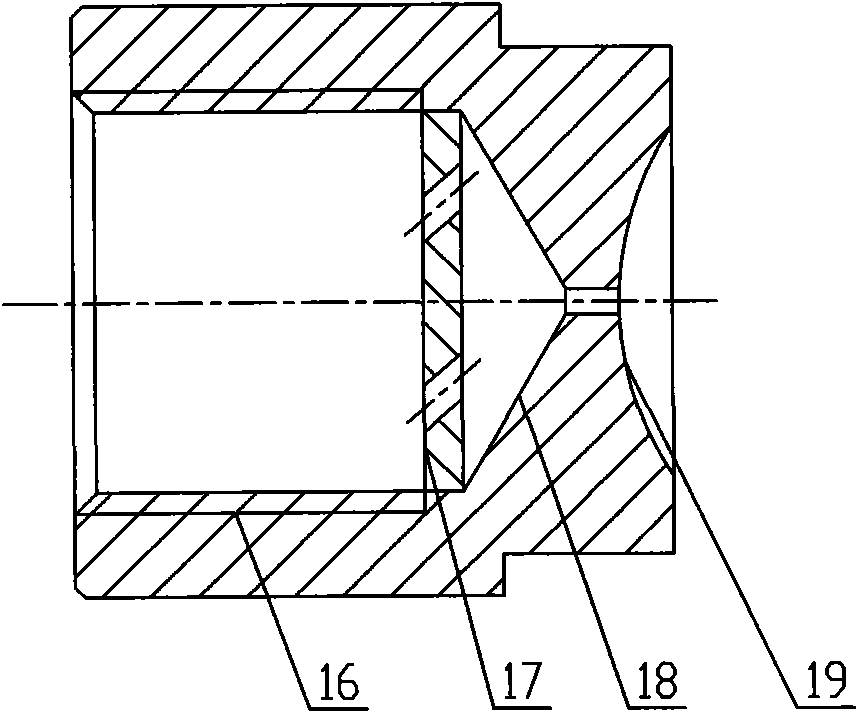

[0022] Further illustrate the present invention below in conjunction with accompanying drawing.

[0023] The present invention is composed of an air inlet assembly, a frame 15, a wet filter dust collector 7, an axial flow fan 9 and a water quality filter 10, the wet filter dust collector 7, an axial flow fan 9, and a water quality filter 10 All are installed on the frame 15, four groups of eight wheels are installed below the frame 15, and are located on the guide rail of the belt conveyor, and the front of the frame is connected with the tail of the transfer machine 6 with a pull rod; The wind pipe I 2, the air inlet pipe II 3, the air inlet square pipe III 4 and the negative pressure air cylinder 5 are composed of the air inlet square pipe I, the air inlet square pipe II, and the air inlet square pipe III, which are connected in sequence and arranged On the side of the roadheader 1, as a suction port for dust, to reduce the dust concentration beside the driver of the roadhea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com