Method for autocontrolling excavation direction of underground excavator using virtual track

A technology of virtual trajectory and roadheader, which is applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of slow deviation correction process, difficulty in integrating manual control experience, and inability to achieve linear asymptotic performance of deviation correction. The effect of avoiding engineering quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

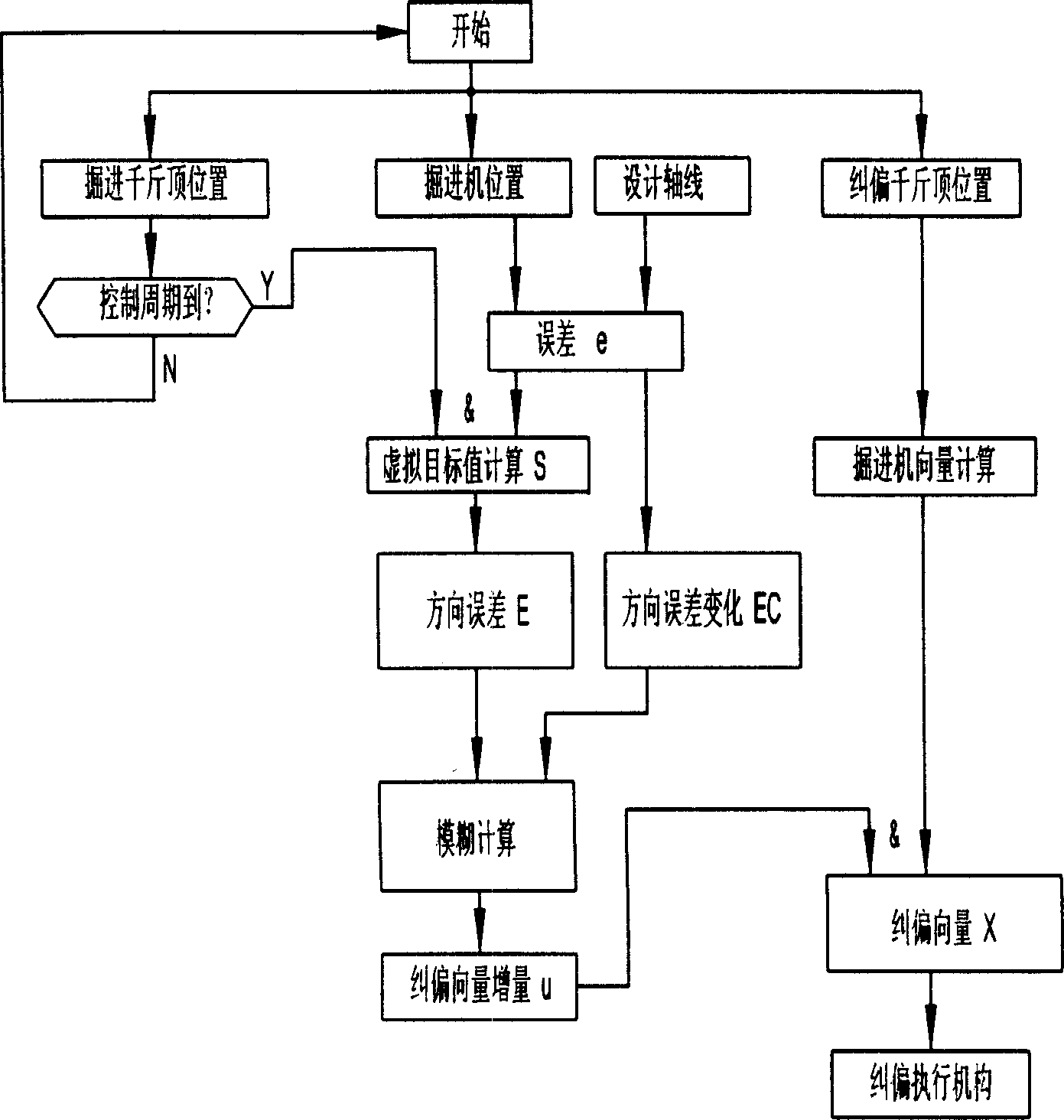

[0065] 1. Calculate the error e of the current control cycle from the parameters of the position and attitude of the roadheader detected by the detection system and the design axis i =23, the error e of the previous control cycle i-1 =25, the error of the first two control cycles: e i-2 = 28.5.

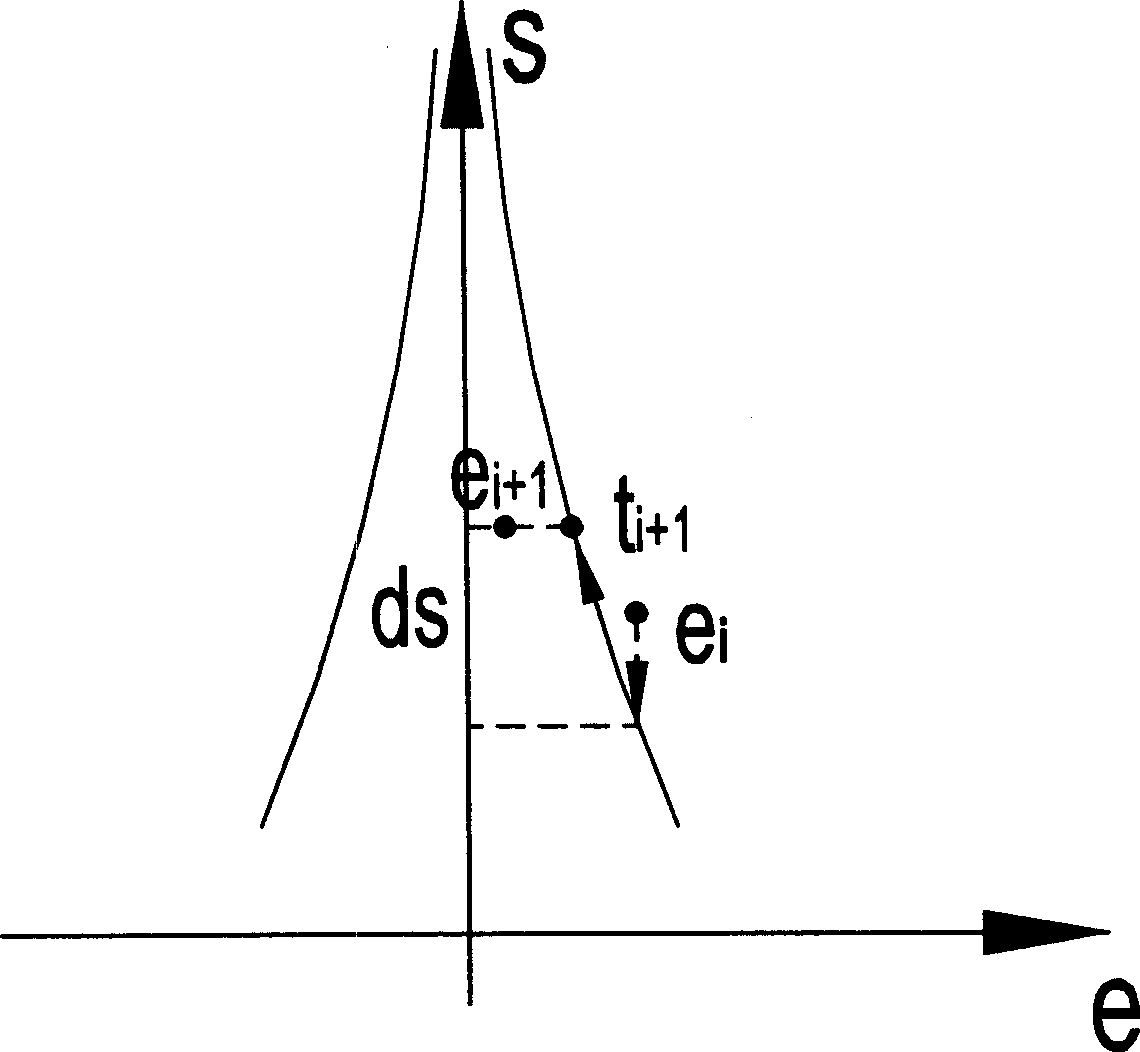

[0066] 2. Set the working condition constant k=1, the axis tolerance value a=50 of the project quality standard, and the control step size dl=20, and the set value t of the control target of the current control cycle can be obtained i+1 = 19.4.

[0067] 3. Calculated: directional error E=-1.6, directional error change: EC=1.5; and E and EC are subjected to fuzzy quantization processing, and the decimals are rounded to obtain e=-2 and ec=2.

[0068] 4. Take e and ec as input for fuzzy control processing, and query the fuzzy membership table:

[0069]

[0070] Finally, the deviation correction signal is output, that is, the deviation correction vector increment u=-2.

[0071] 5. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com