Dust removal device

A technology of dust removal device and box, which is applied in combination devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of easy clogging of the filter layer, large working resistance, inconvenient management, etc., and achieves light weight and reduces maintenance frequency. , the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

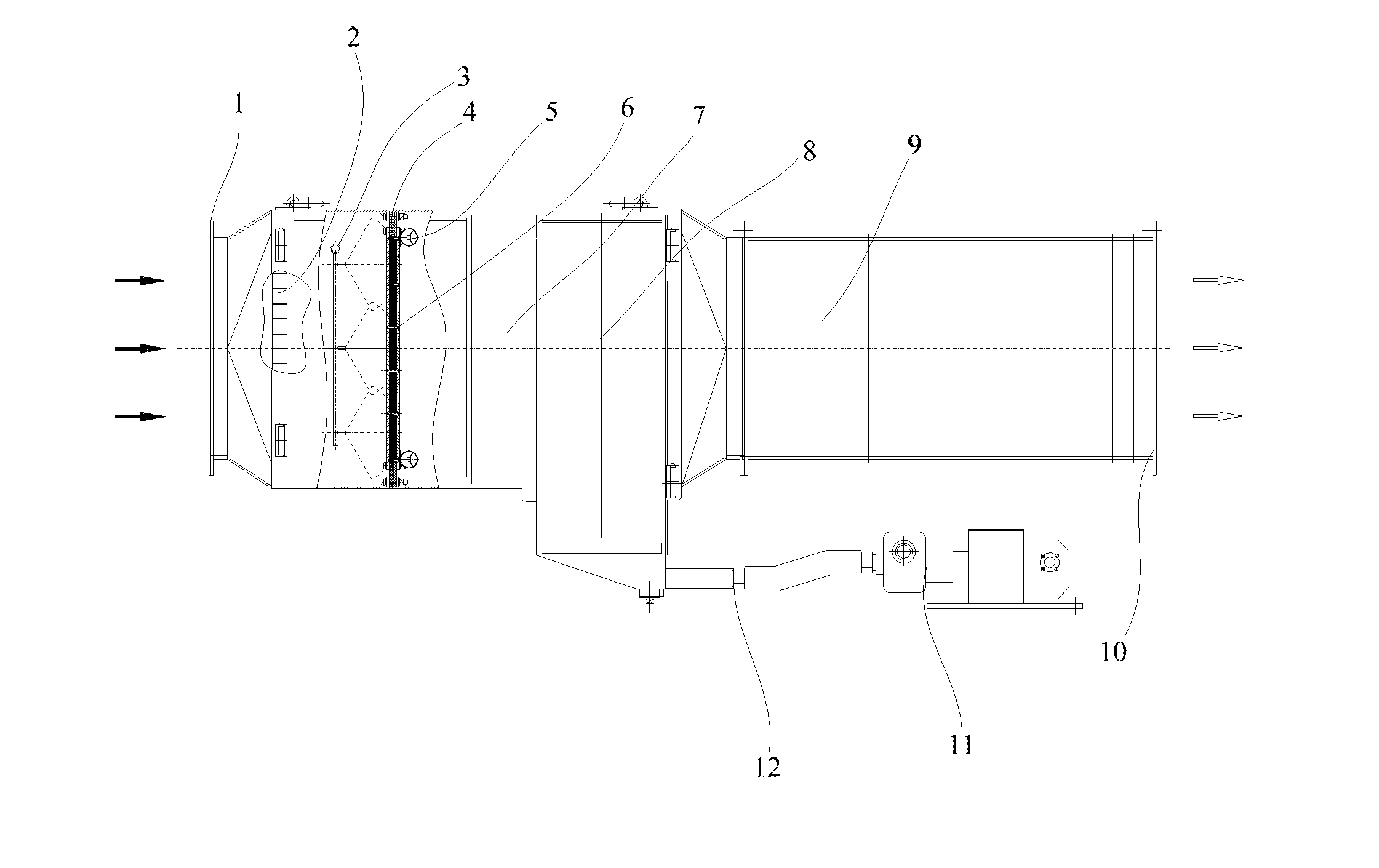

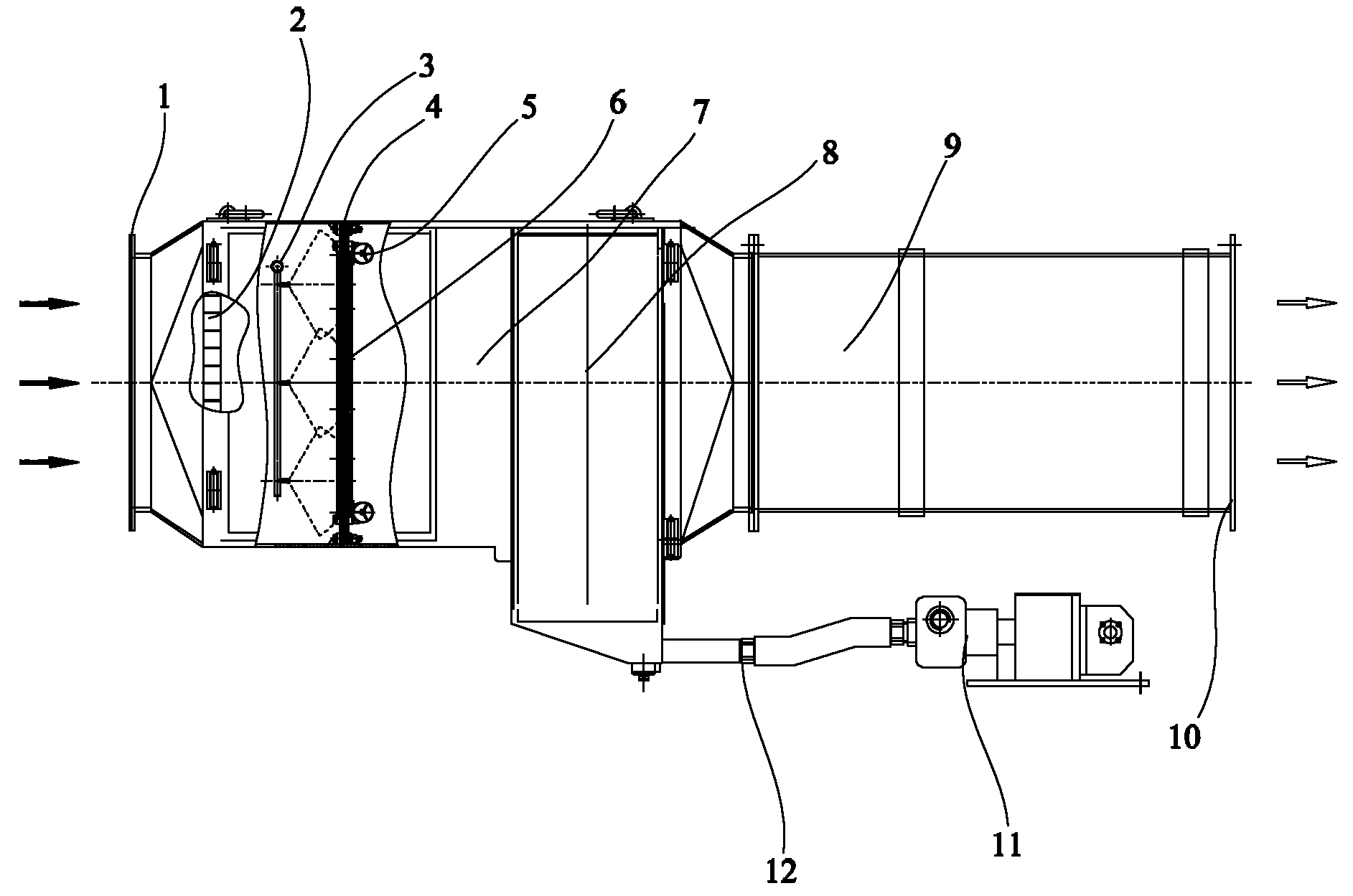

[0023] figure 1 A schematic structural view of a dust removal device according to an embodiment of the present invention is shown.

[0024] One embodiment of the present invention provides a dust removal device, such as figure 1 As shown, it includes a dust removal box 7 placed horizontally. The inner cavity of the dust removal box 7 is a gas flow channel. One end of the dust removal box 7 is provided with an air inlet 1, and the other end is connected to a fan 9. The rear of the fan is It is an air outlet 10, and some nozzles 3 for spraying water are arranged in the dust removal box 7, and a filter layer 6 is arranged behind the nozzle 3, and a vibration motor 5 is installed at the rear of the filter layer. After 6, a dehydrator 8 is arranged. In this embodiment, the fan can be an axial fan, a centrifugal fan, or other fans; the vibration motor can be one or more, so as to achieve the vibration effect that best meets the actual needs. should. In this technical solution, s...

Embodiment 2

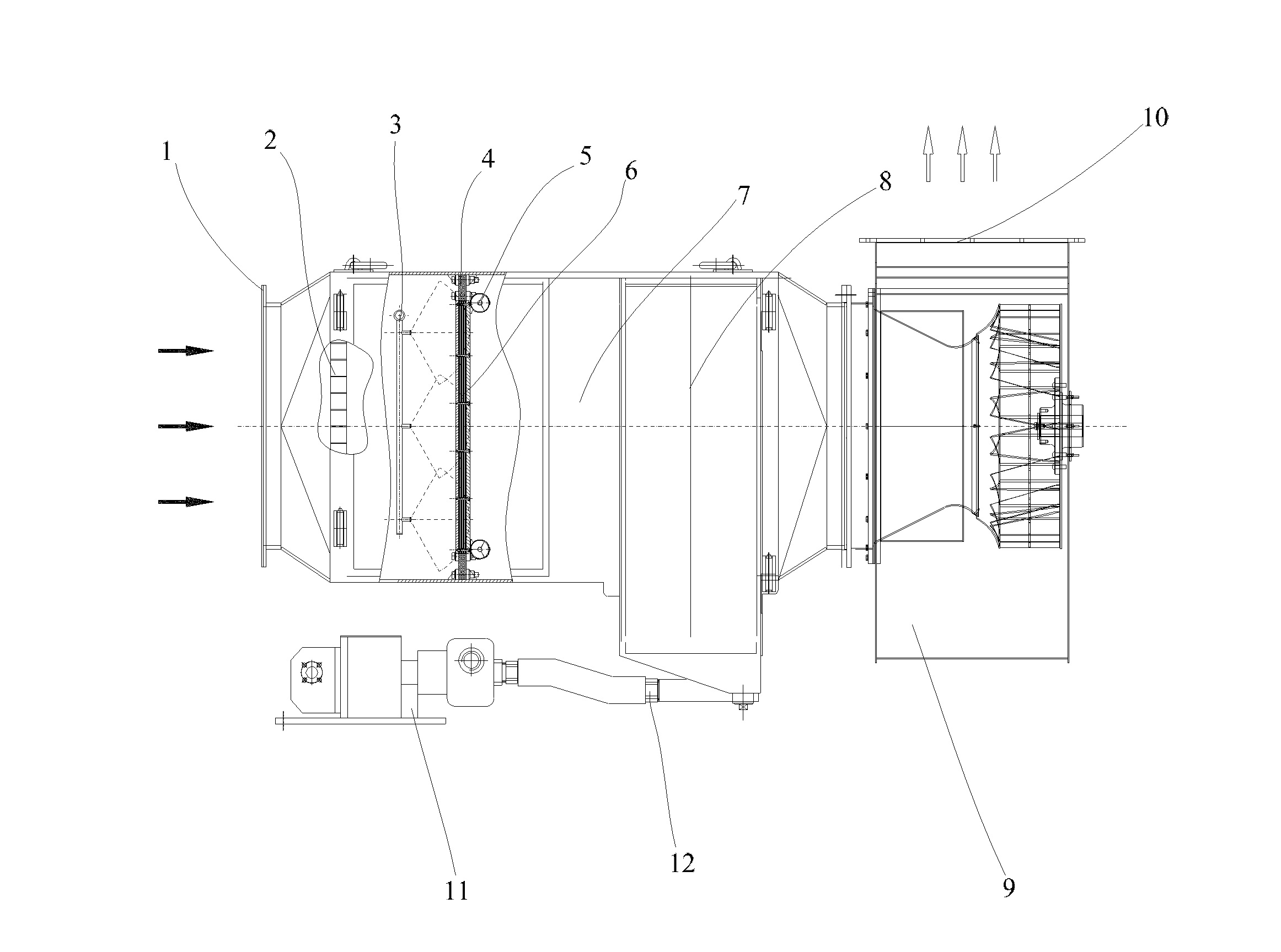

[0035] figure 2 A schematic structural view of a dust removal device according to another embodiment of the present invention is shown.

[0036] like figure 2 As shown, in this embodiment, the difference from that in Embodiment 1 is that the fan 9 is a centrifugal fan, and the inlet of the centrifugal fan 9 is provided with a collector.

[0037] like figure 2 As shown, in the above technical solution, optionally, a second protective lining is provided between the impeller of the centrifugal fan 9 and the collector, and the second protective lining is processed by copper or plastic. The inlet of the centrifugal fan is provided with a collector, and a second protective lining is provided between the impeller of the centrifugal fan and the collector, and the second protective lining is made of copper or plastic, so that the impeller and the collector The sparks produced by the impact of the protective lining meet the safety performance requirements of the friction spark tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com