Onboard dust removing tunneller

A technology of roadheader and dust removal device, which is applied in the direction of cutting machinery, slitting machinery, earthwork drilling and mining, etc., which can solve the problems of inability to inhale dust and unsatisfactory dust removal effect, and achieve the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

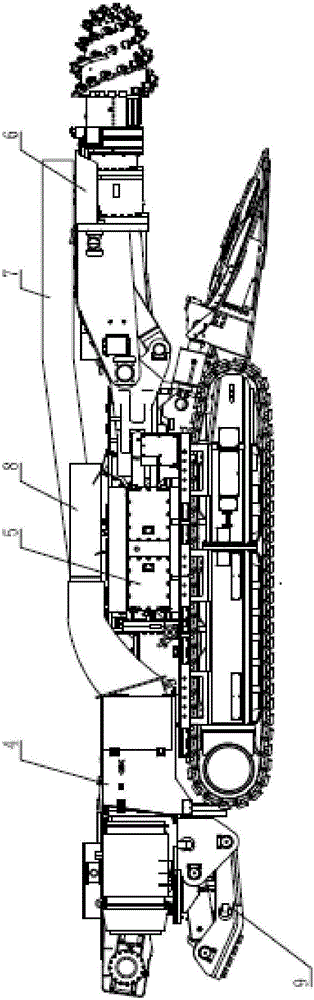

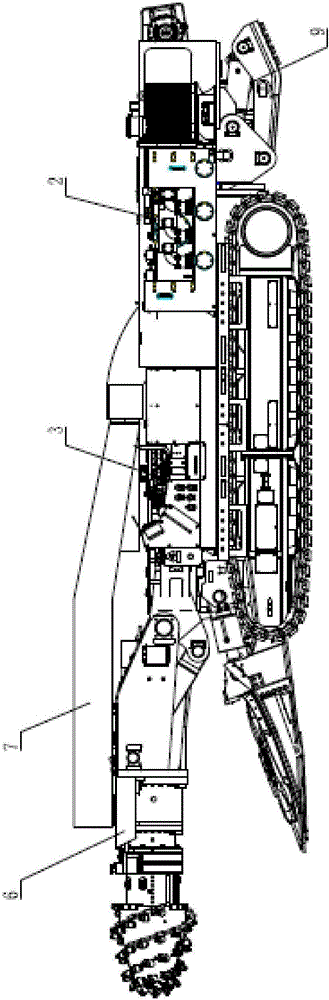

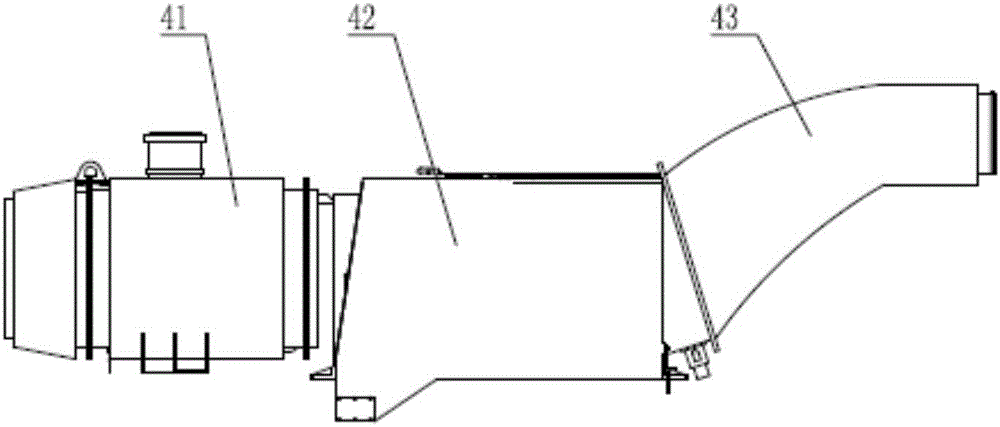

[0022] Such as figure 1 and figure 2 The airborne dust removal roadheader shown includes a fuselage 1, and the two sides of the fuselage 1 are respectively equipped with a hydraulic system 2, an operating console 3, an airborne dust removal device 4 and an electric control box 5, and the front end of the fuselage 1 is provided with a cutting Part 6. The hydraulic system 2 may include a fuel tank and a pump station. The cutting part 6 provides the power for turning and lifting. The operation table 3 is the position where workers operate the roadheader. The electric control box 5 supplies power for the operation of various parts of the roadheader. The device 4 is used to absorb and filter the dust generated by the excavation face.

[0023] The airborne dust removal device 4 is connected with an air inlet pipe 7 , the inlet of the air inlet pipe 7 extends to the cutting part 6 and is linked with the cutting part 6 . During the excavation process, the cutting part 6 will lift ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com