Gantry type self-walking roofbolter

A gantry-type self-anchor technology, which is applied to rotary drilling rigs, bolt installation, percussion drilling, etc., can solve the problems of affecting work efficiency and wasting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

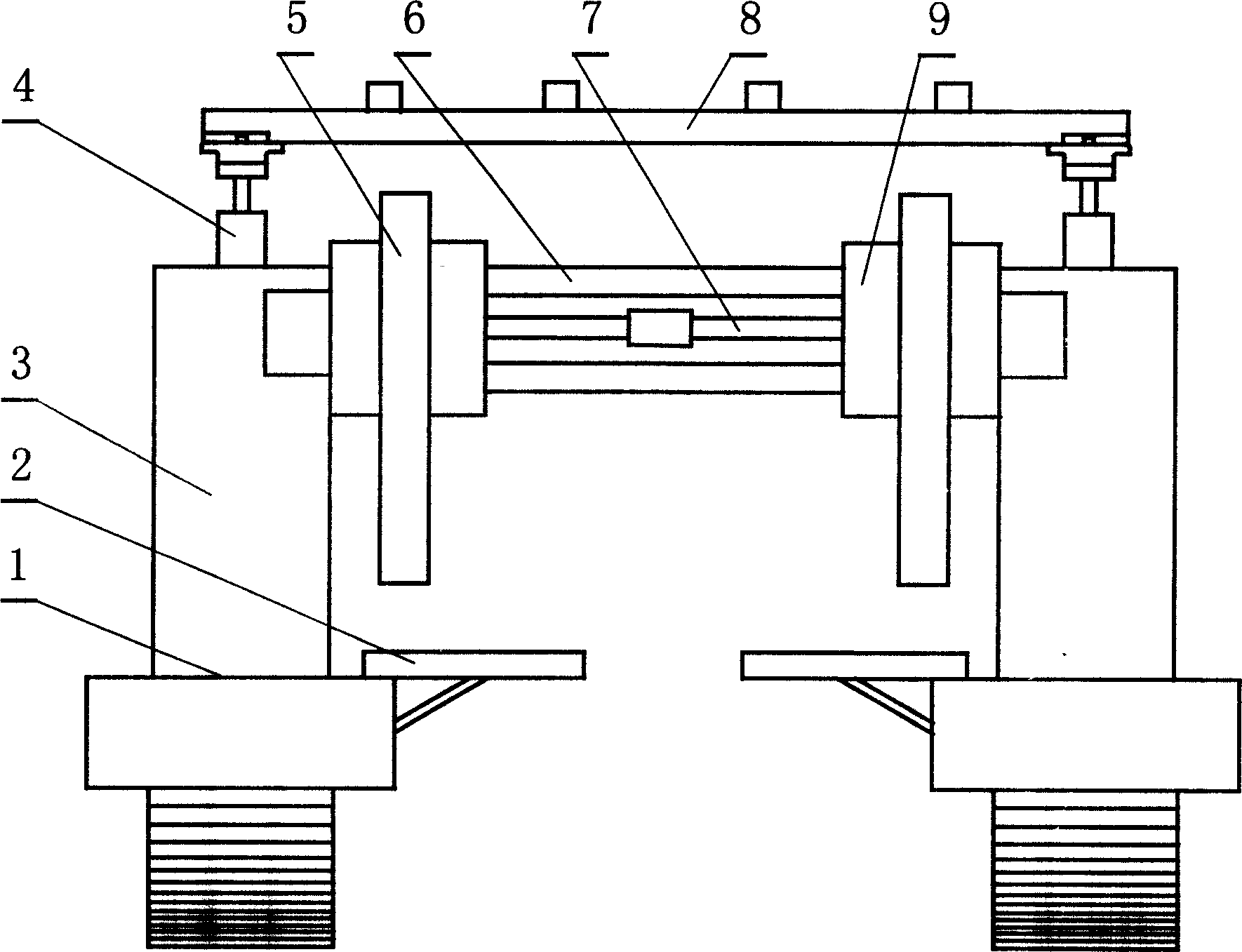

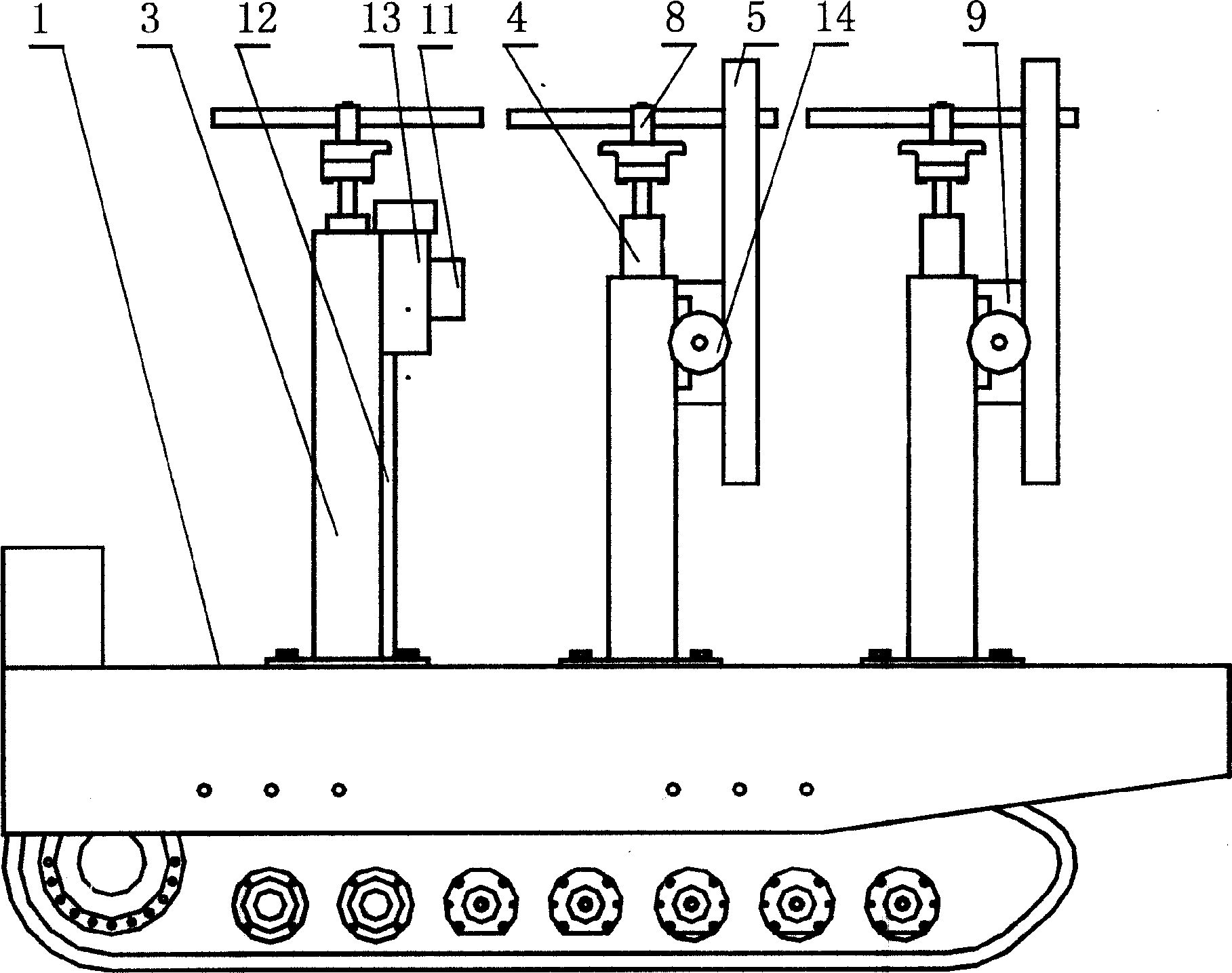

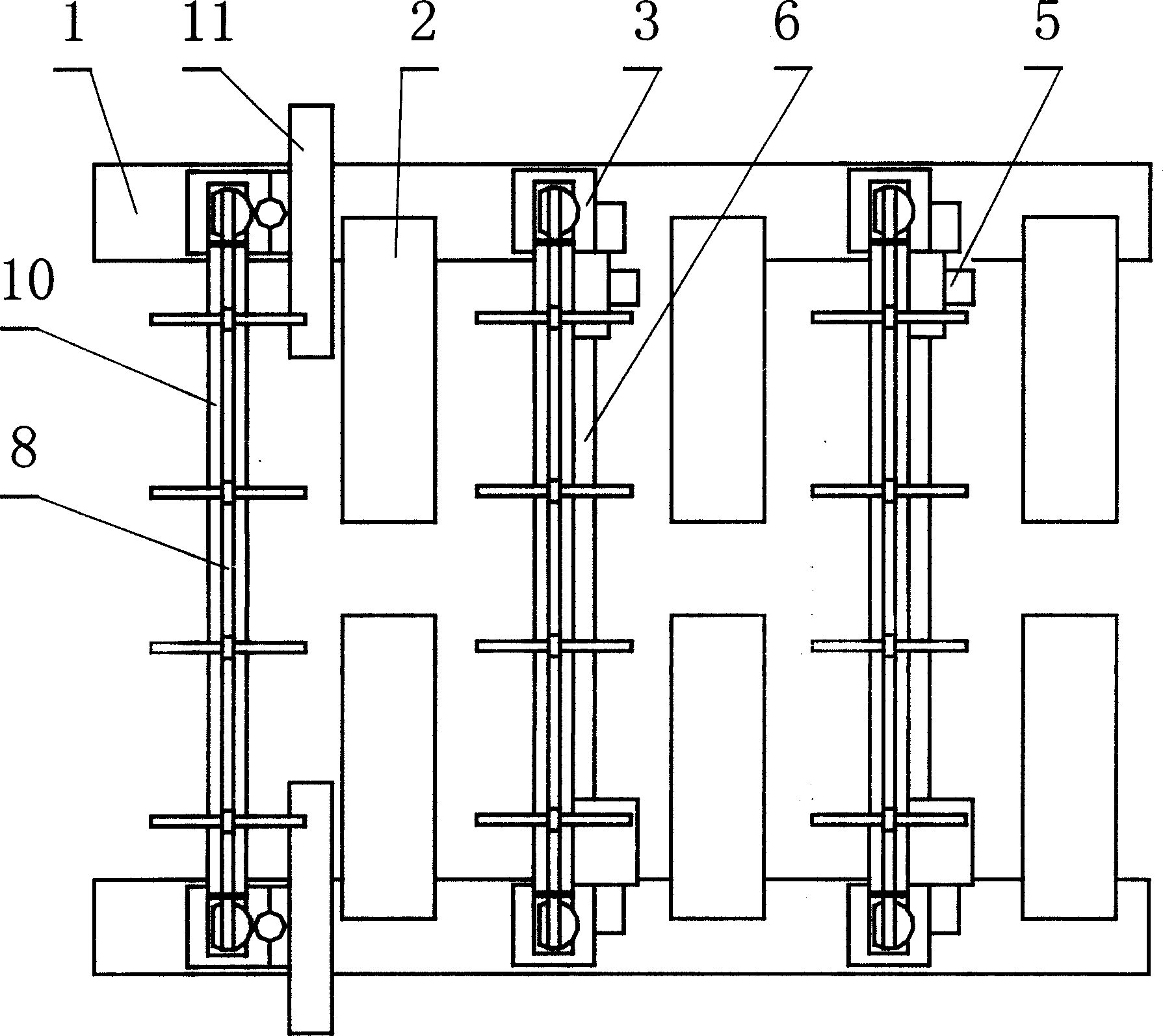

[0018] figure 1 , figure 2 , image 3 As shown, the present invention includes a crawler belt traveling mechanism and a hydraulic system positioned on the crawler belt traveling mechanism, a gantry frame, and a horizontal drilling machine 11 and a longitudinal drilling machine 5 installed on the gantry frame. Described frame is gantry type, and it is made up of two columns 3 and a crossbeam 10 that is fixed on two columns 3. At least one gantry frame straddles the platforms 1 of the two parallel crawler running gears. figure 1 , Figure 4 As shown, the transverse guide rail 6 and the beam screw rod 7 are fixed on the beam 10 of a gantry frame, and the transverse slide plate 9 equipped with the longitudinal drilling machine 5 is set on the transverse guide rail 6, so that the transverse slide plate 9 and the transverse guide rail 6 are slidably matched. Crossbeam screw mandrel 7 engages with the spiral tube engagement on the transverse slide plate 9, and the lateral moveme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com