Construction mode with full cross-section tunneller

A technology of a full-section roadheader and a construction method, which is used in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of high installation accuracy of rubber water-stops, incompact backfilling of peas and gravels, difficult to repair and difficult to handle, etc. Grouting effect, low cost, convenient filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

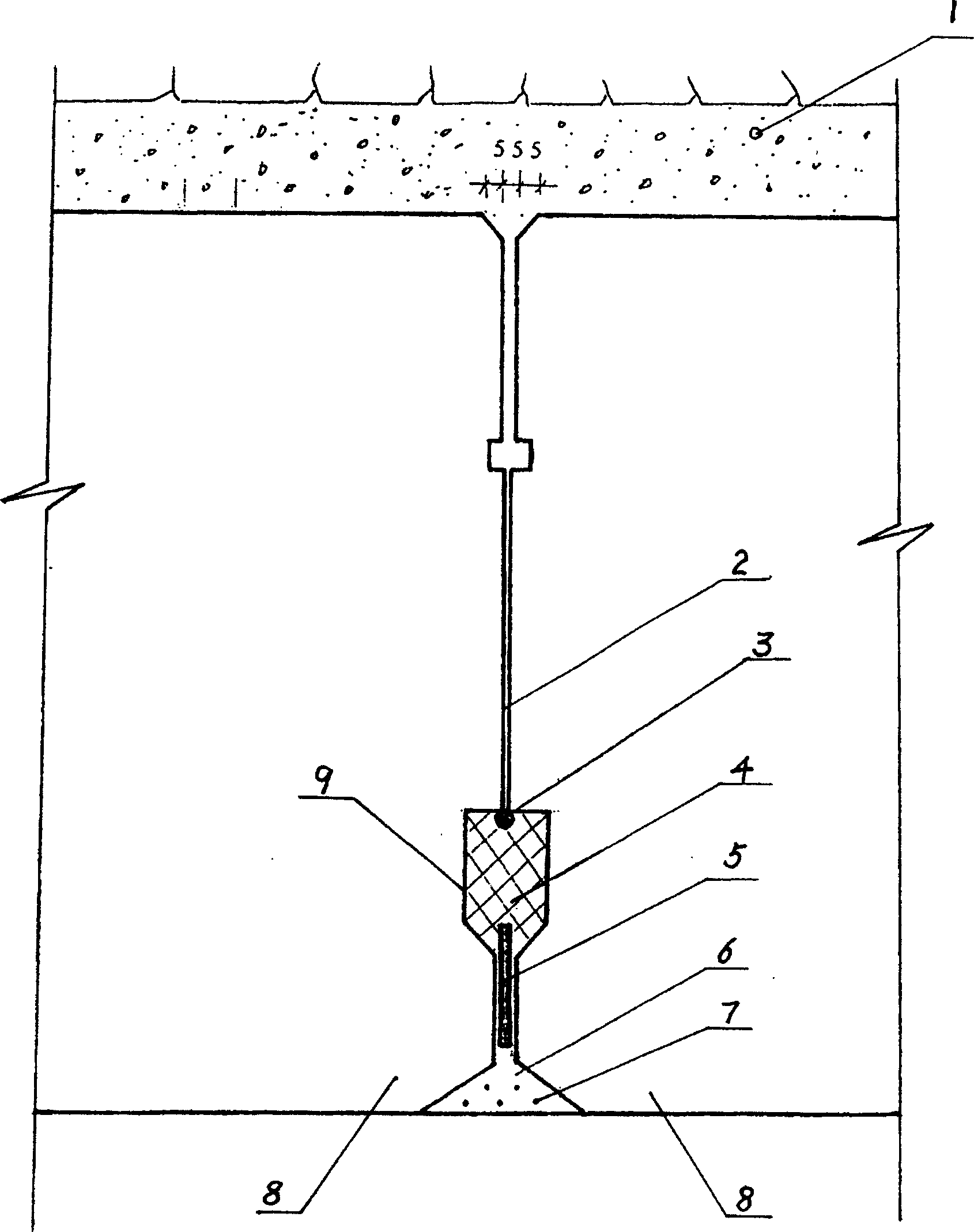

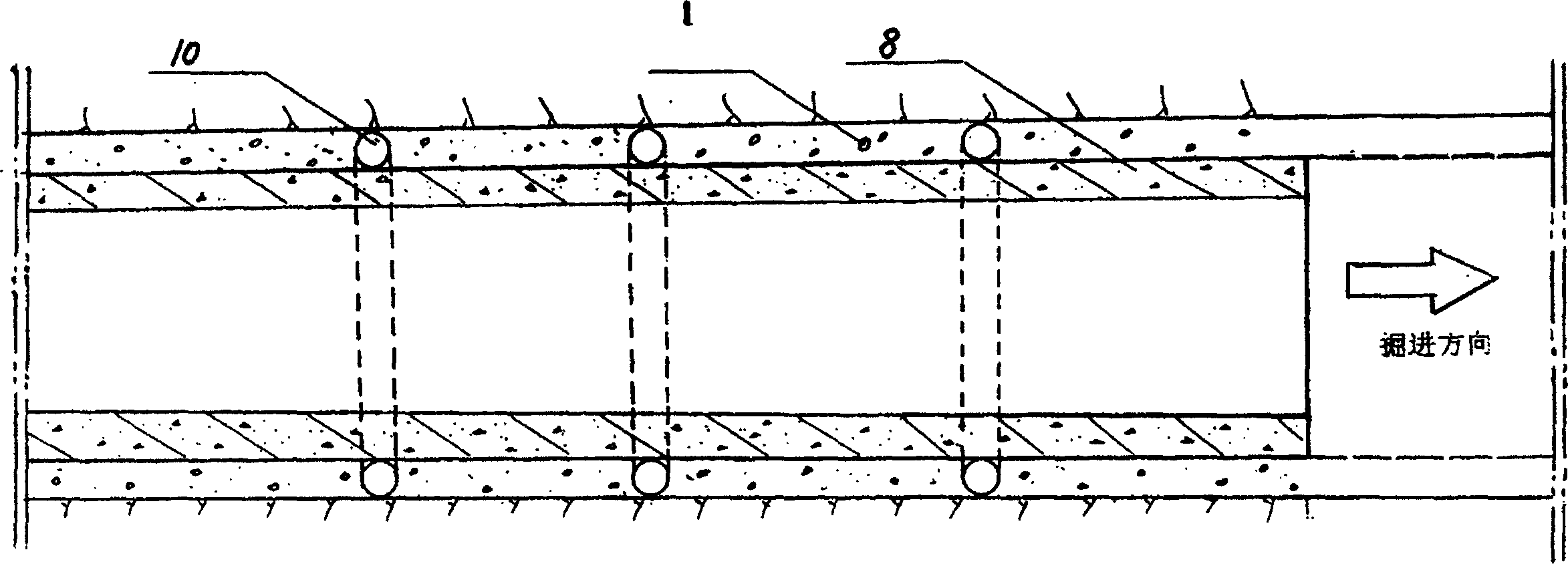

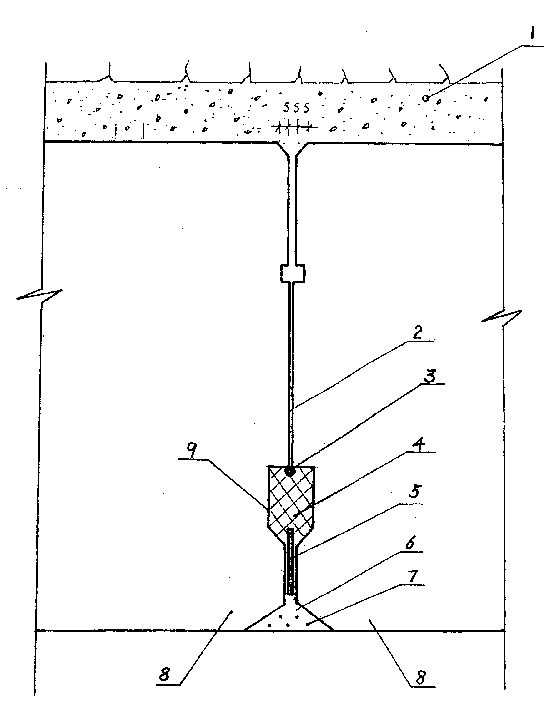

[0021] Such as figure 1 , figure 2 As shown, the construction method of the full-face roadheader in this embodiment includes processes such as cutting rocks and lining segments, wherein: it also includes segment water-stopping technology, backfilling pea gravel and pouring cement slurry technology; The water process consists of the following steps:

[0022] 1), butt the prefabricated reinforced concrete segments 8 according to the design requirements;

[0023] 2), the oil-impregnated mineral wool 3 is placed on the butt joint 2 at the bottom of the filling groove 9 formed between the segments 8, so as to block the butt joint 2 between the two segments 8;

[0024] 3) Insert the plastic water-stop material of non-vulcanized butyl rubber (GB) 4 into the filling groove 9 until it is filled;

[0025] 4) Wedge the iron wedge 5 into the plastic water-stop material of non-vulcanized butyl rubber 4 from the top of the filling groove 9 to compress the plastic water-stop material;

...

Embodiment 2

[0035] The construction method of the full-face roadheader in this embodiment includes processes such as cutting rocks and lining segments, wherein: it also includes the segment water-stopping process and backfilling pea gravel and pouring cement slurry processes; the segment water-stopping process consists of Consists of the following steps:

[0036] 1) Butt the prefabricated reinforced concrete segments according to the design requirements;

[0037] 2) Arrange the rubber on the butt joint at the bottom of the filling groove formed between the segments to block the butt joint between the two segments;

[0038] 3) Insert the plastic water-stop material of modified asphalt into the filling tank until it is full;

[0039] 4) Wedge the iron wedge into the modified asphalt plastic water-stop material from the top of the filling tank to compress the plastic water-stop material;

[0040] 5) Backfill the gap between the surface of the segment with high-strength cement mortar, and c...

Embodiment 3

[0049] The construction method of the full-face roadheader in this embodiment includes processes such as cutting rocks and lining segments, wherein: it also includes the segment water-stopping process and backfilling pea gravel and pouring cement slurry processes; the segment water-stopping process consists of Consists of the following steps:

[0050] 1) Butt the prefabricated reinforced concrete segments according to the design requirements;

[0051] 2), the polyester non-woven is arranged on the butt joint at the bottom of the filling tank formed between the segments to block the butt joint between the two segments;

[0052] 3) Insert the plastic water-stop material of elastic polyurethane into the filling tank until it is filled;

[0053] 4) Wedge the iron wedge into the elastic polyurethane plastic material from the top of the filling tank to compress the plastic water-stop material;

[0054] 5) Backfill the butt joint gap on the surface of the segment with high-strength c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com