Device for testing force transmission characteristics of tunnellers

A technology of transmission characteristics and test device, which is applied in the direction of measuring device, testing of machine/structural components, and hydraulic/pneumatic force measurement, etc., and can solve the problem that there is no report on the force transmission test device of roadheader.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

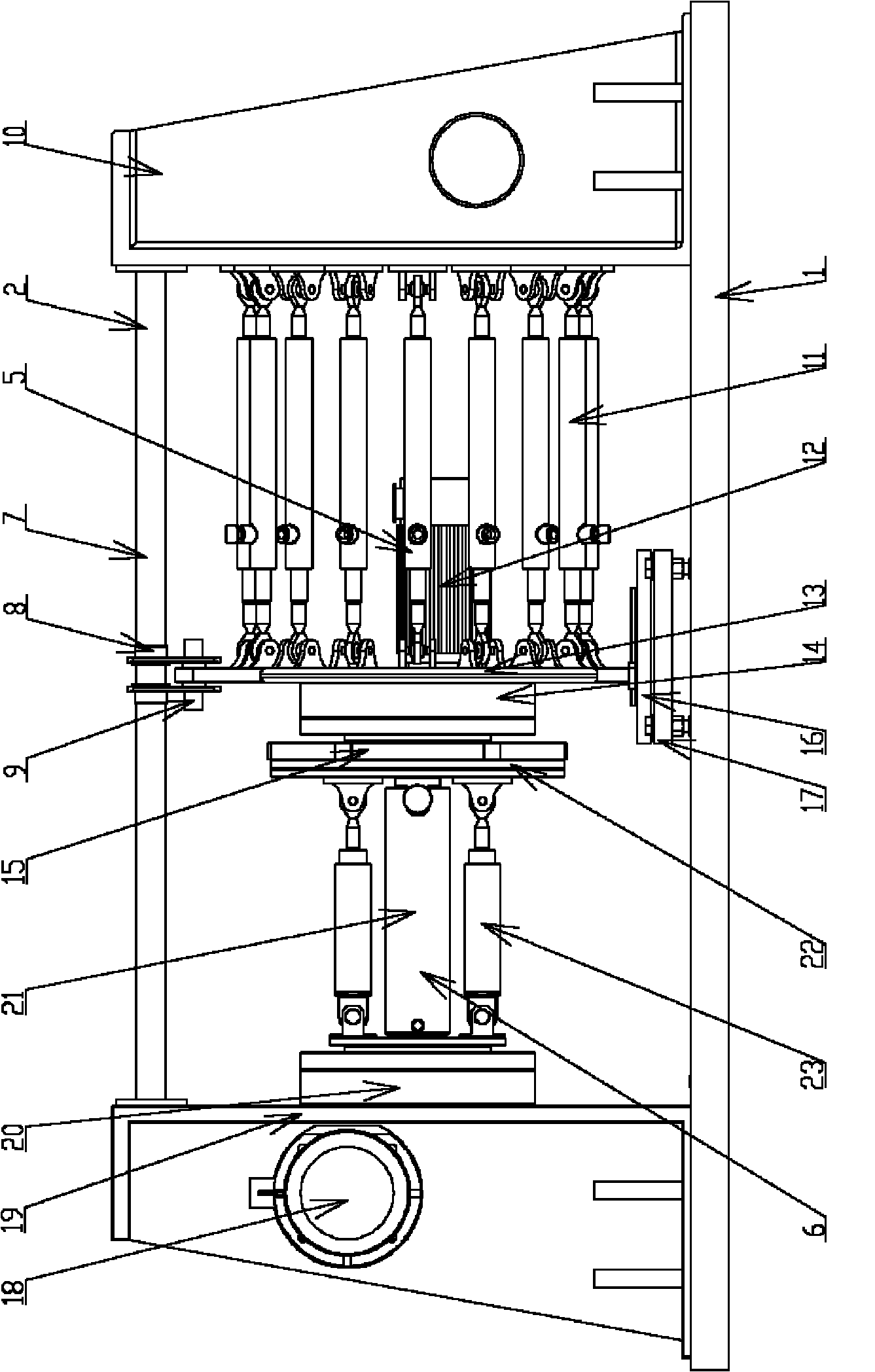

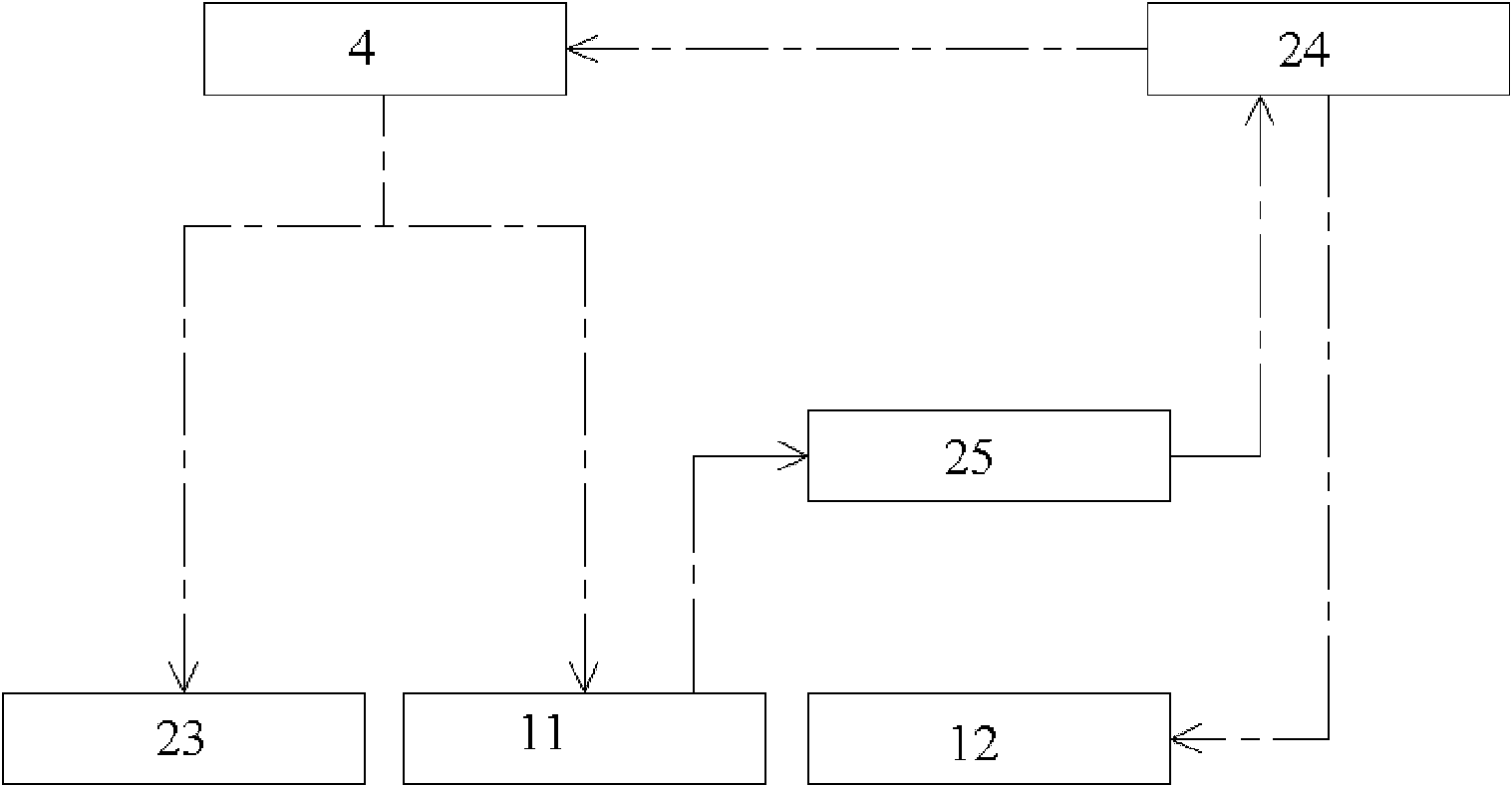

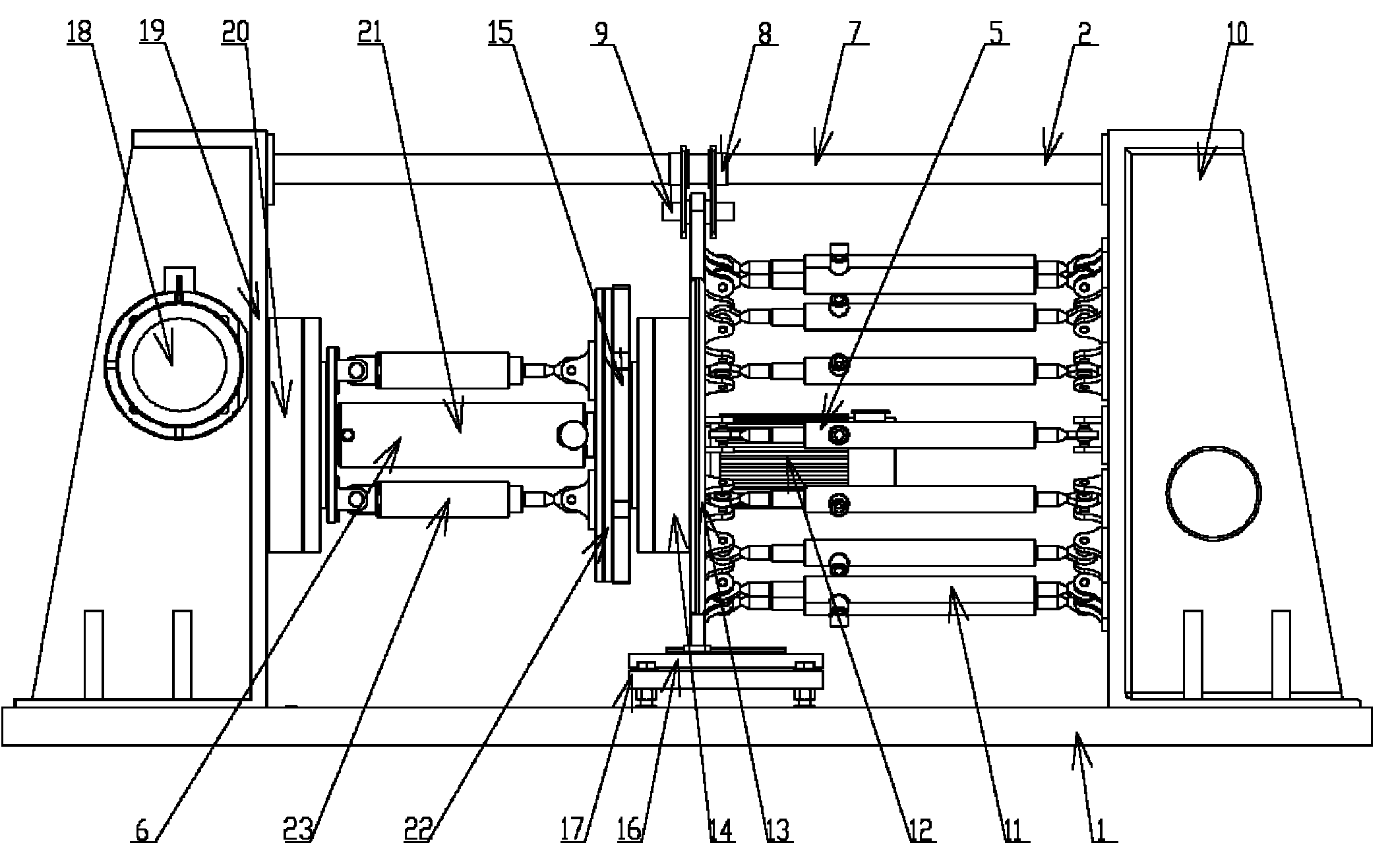

[0024] Such as figure 1 As shown, this embodiment includes: base 1, main top mechanism 2, control mechanism 3, hydraulic mechanism 4, shield simulation mechanism 5 and load simulation mechanism 6, wherein: base 1 is provided with shield simulation mechanism 5 and load simulation mechanism 6 , the main top mechanism 2 is connected with the shield simulation mechanism 5 and the load simulation mechanism 6 respectively, the control mechanism 3 is connected with the shield simulation mechanism 5 and the hydraulic mechanism 4 respectively, and the hydraulic mechanism 4 is connected with the load simulation mechanism 6 and the shield simulation mechanism 5 respectively.

[0025] The main top mechanism 2 includes: two parallel guide rails 7, linear bearings 8 and movable pins 9, wherein: the ends of the guide rails 7 are connected to the linear bearings 8, and the movable pins 9 are movable on the guide rails 7.

[0026] The shield simulation mechanism 5 is a parallel mechanism of 16...

Embodiment 2

[0041] The other implementations of this embodiment are the same as in Embodiment 1, the geological condition is 60% soft soil, the excavation process of the hydraulic propulsion cylinder 11 is divided into five groups, and only the hydraulic oil in the hydraulic mechanism 4 needs to be fully unloaded, by changing the hydraulic propulsion cylinder 11 and For the quick oil joint connection between the hydraulic mechanisms 4, the grouping was changed into five groups, and then the steps of Example 1 were repeated for testing.

Embodiment 3

[0043] The other implementations of this embodiment are the same as in Embodiment 1. The geological conditions are changed from 60% soft soil to 40% soft soil during the excavation process. Taking the hydraulic propulsion cylinder 11 as an example in four groups, in the process of steady propulsion, it can be adjusted The proportional overflow valve of the hydraulic mechanism 4 is used to change the pressure of the hydraulic loading cylinder 23, thereby increasing the bending moment, and realizing the sudden change of the address condition in the process of simulating the excavation.

[0044] This test device can simulate the excavation process of different groups of hydraulic propulsion cylinders with constant geological conditions, the excavation process of the same group of propulsion cylinders with constant geological conditions, the excavation process of different groups with sudden changes in the same geological conditions, and the same sudden change in different geologica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com