Drop-shaft-sinking-based shaft well tunneller and construction method thereof

A technology for roadheaders and shafts, which is applied to shaft equipment, well sinking, earthwork drilling, etc., can solve the problems of low degree of automation, high construction cost, and high risk factor, and achieves the improvement of excavation accuracy and excavation speed, and improves construction. The effect of safety factor and high degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

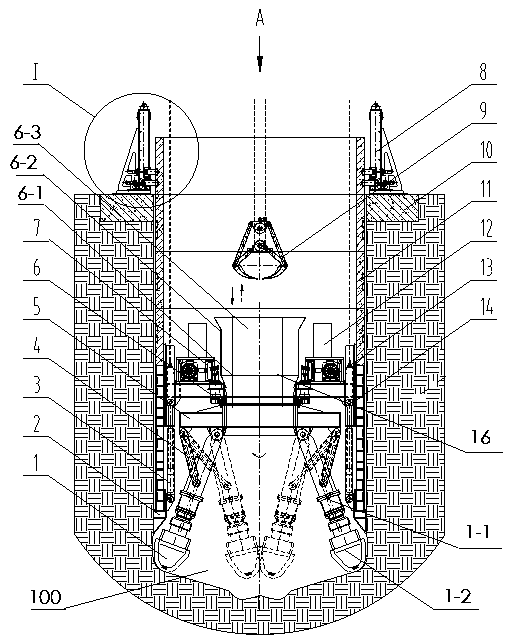

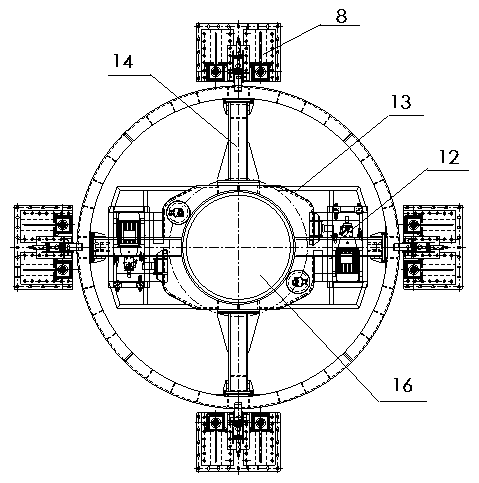

[0033] Example 1, such as Figure 1-2As shown, a caisson shaft tunneling machine includes a tunneling system, a control system and a detection system, and the control system and the detection system are connected with the tunneling system for controlling and detecting the tunneling state. The excavation system includes an excavation device 1 and a well wall pressure lifting device 8. The well wall pressure lifting device 8 is arranged on the wellhead ring beam 10 on the ground, and the well head ring beam 10 is provided with at least two well wall pressure lifting devices. The device 8 and the well wall pressure raising device 8 are equidistantly arranged on the wellhead ring beam 10. The number of the well wall pressure raising device 8 can be set according to the diameter of the wellhead of the originating shaft, whichever can provide a stable support force for the shaft . The excavation device 1 is arranged in the starting shaft 100 and is used for excavating rock and soil...

Embodiment 2

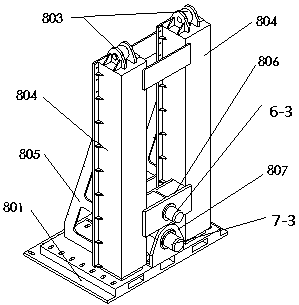

[0036] Example 2, such as Figure 3-4 As shown, a caisson method shaft boring machine, the well wall pressure lifting device 8 includes a bottom plate 801 arranged on the wellhead ring beam 10, two support boxes 802 are arranged on the bottom plate 801, and the inside of the support box 802 is set There is a pressure-lifting oil cylinder 803, which is vertically arranged in the support box, and the pressure-lifting oil cylinder has enough stroke to ensure that the movable bolt has sufficient adjustment space when inserting or pulling out the shaft hole of the segment. The supporting box 802 is provided with a sliding box 804, which cooperates with the supporting box 802. The sliding box is sleeved on the supporting box and slides up and down along the supporting box. The fixed end of the pressure-lifting cylinder 803 is connected with the bottom plate 801 through the cylinder base 805, and the telescopic end of the pressure-lifting cylinder 803 is connected with the slide box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com