Efficient rapid rock drift tunneller

A roadheader and fast technology, which is applied to mining equipment, earthwork drilling, tunnels, etc., can solve the problems of high labor intensity, low efficiency of rock tunneling, and many safety hazards, so as to improve cutting stability and improve tunneling High efficiency and high molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

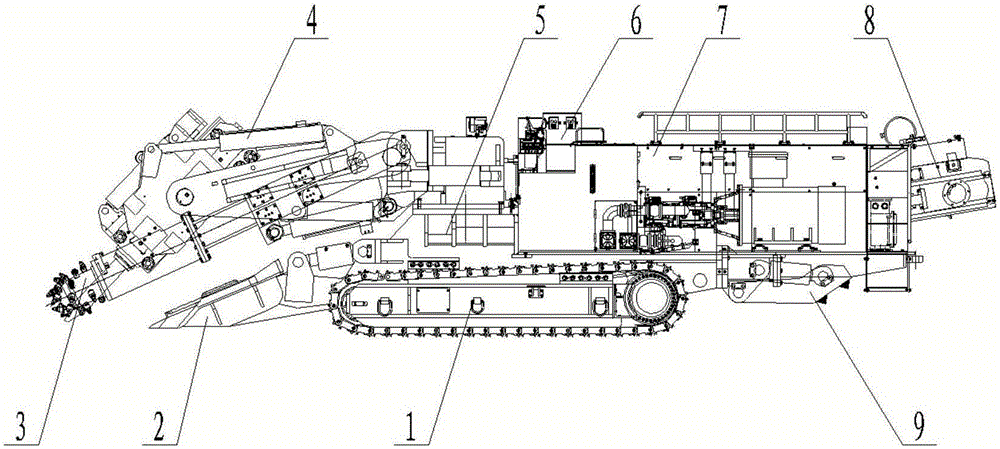

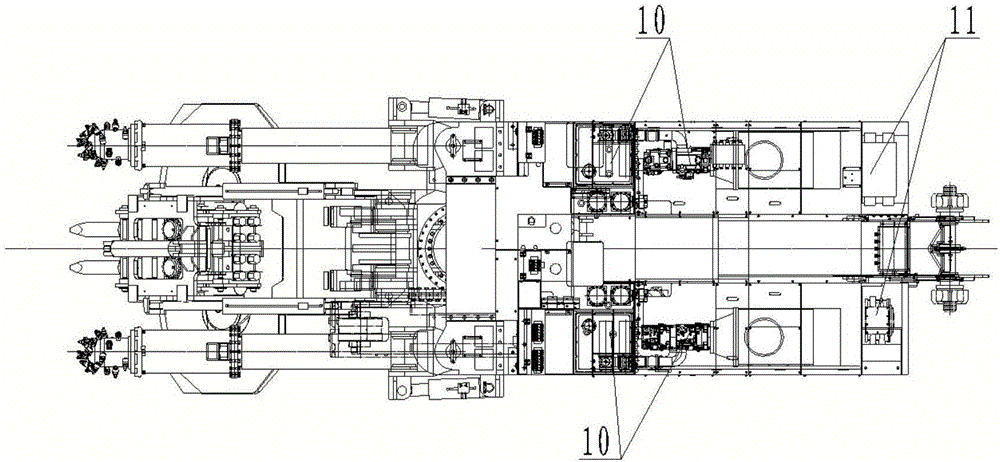

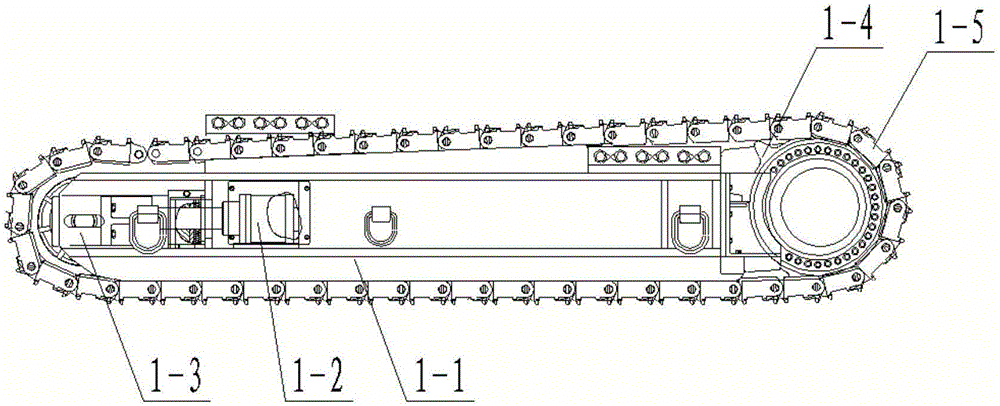

[0033] A high-efficiency and fast rock roadway boring machine, such as figure 1 and figure 2 As shown, it includes a walking part 1, a shovel part 2, two cutting arms 3, a telescopic part 4, a body part 5, a manipulation part 6, a guard part 7, a conveying part 8, a rear support part 9, and two hydraulic systems. 10 and electrical system 11 are composed of eleven parts, the walking part 1 is arranged under the body part 5, the shovel part 2 is hinged at the front end of the body part 5, the telescopic part 4 is arranged at the middle position above the front and upper part of the body part 5, and the two cutting arms 3 It is symmetrically arranged on the front, upper, left and right sides of the body part 5, the conveying part 8 is arranged in the middle of the body part 5, the rear support part 9 is installed behind the body part 5, and two hydraulic systems 10 are symmetrically arranged on the left and right sides of the body part 5 middle part. The part 6 is installed abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com