Forced lubrication system for cutting speed reducer of tunneller

A technology of forced lubrication and reducer, which is applied in gear lubrication/cooling, cutting machinery, driving devices, etc., can solve the problem that the bearings at the high-speed end or low-speed end of the reducer at the cutting part cannot be lubricated, and achieve heat reduction and seal protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

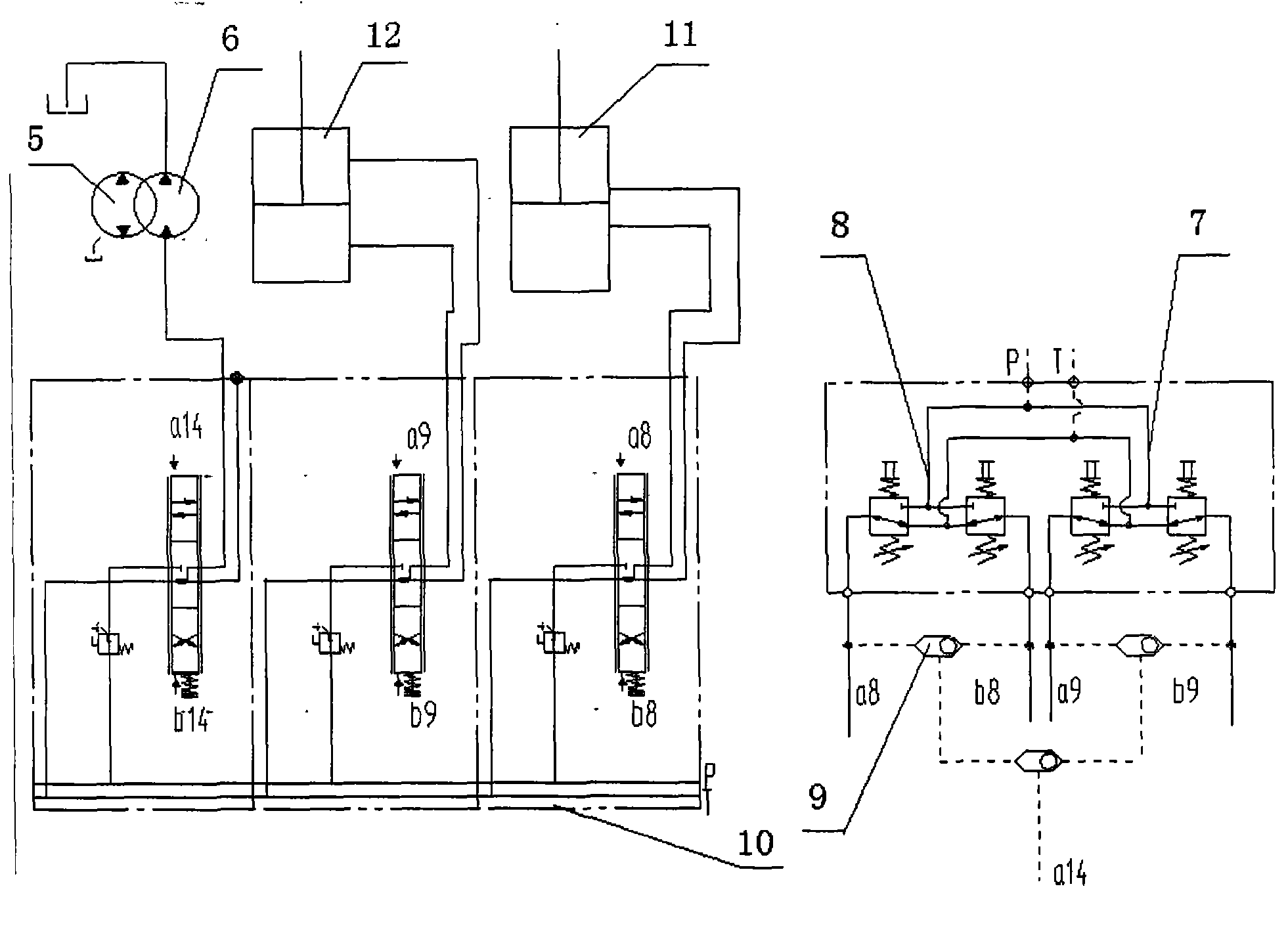

[0016] Such as figure 1 As shown, when the pilot valve 7 of the cutting head rotary cylinder or the pilot valve 8 of the cutting head lifting cylinder is pulled to control the multi-way valve 10 to make the cutting head rotary cylinder 11 or the cutting head lifting cylinder 12 act, the pilot oil passes through the shuttle The valve also controls the multi-way valve 10 to make the lubricating oil circulation pump drive motor 6 work.

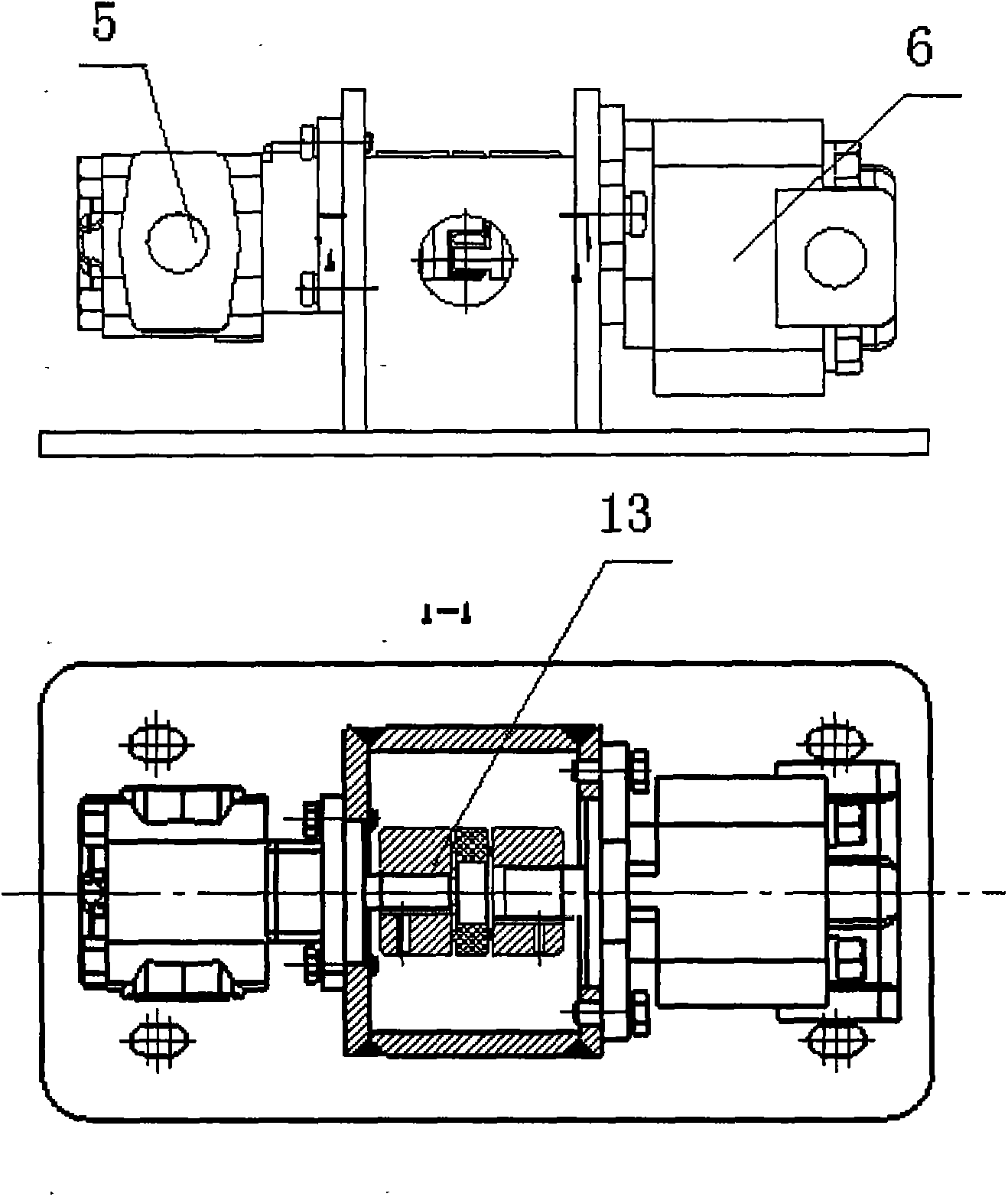

[0017] Such as figure 2 As shown, the lubricating oil circulating pump driving motor 6 drives the lubricating oil circulating pump 5 to work through the coupling 13 .

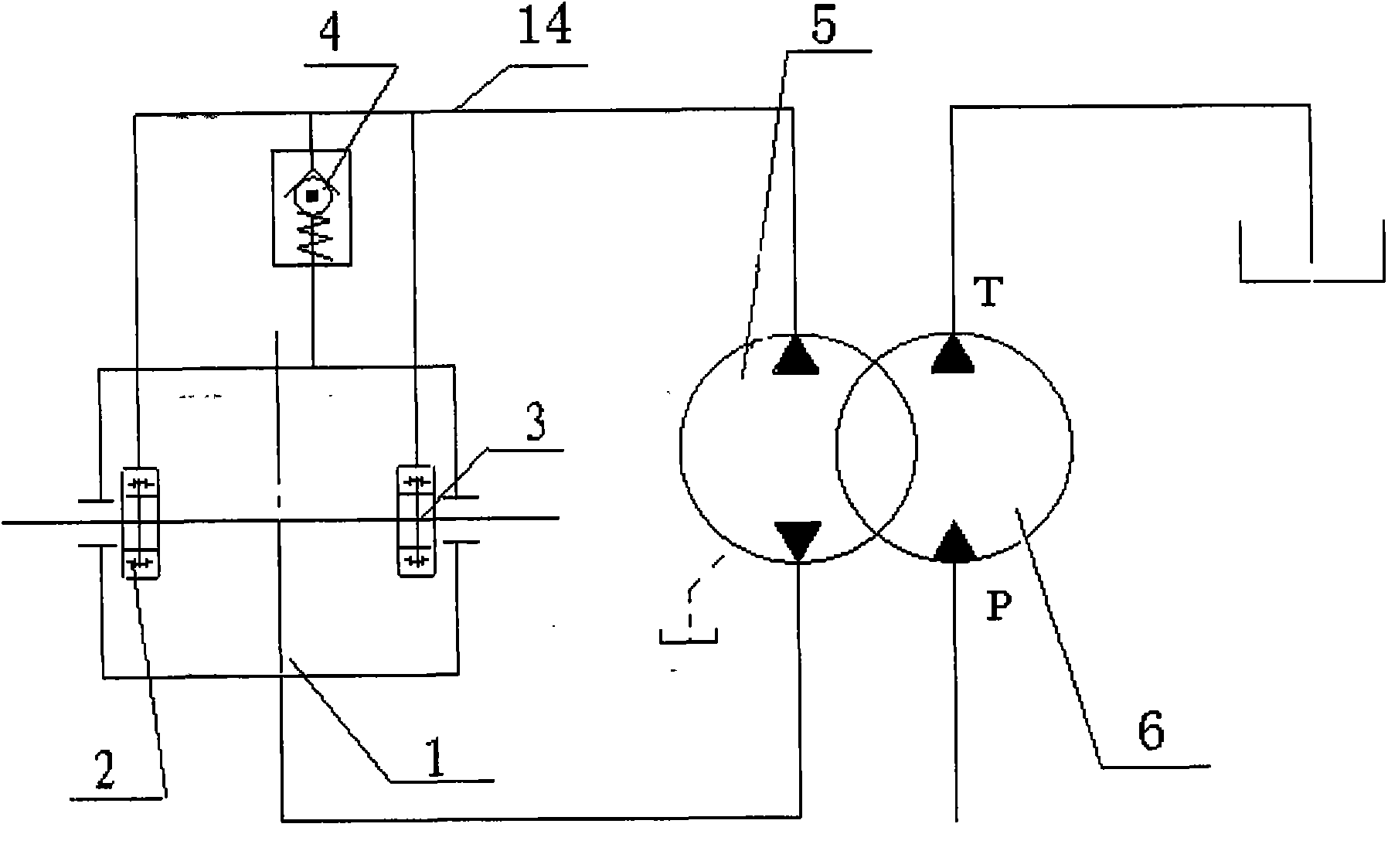

[0018] Such as image 3 As shown, the lubricating oil circulation pump 5 circulates the lubricating oil from the bottom of the cutting reducer 1 through the lubricating pipeline 14 to the bearing chambers of the low-speed end bearing 2 of the reducer and the high-speed end bearing 3 of the reducer for lubrication, and passes through the check valve Make the excess lubricating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com