Compressor piston

A technology for compressors and pistons, which is applied in the field of pistons for compressors, and can solve problems such as lack of oil in the crankshaft cavity and insufficient lubricating oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

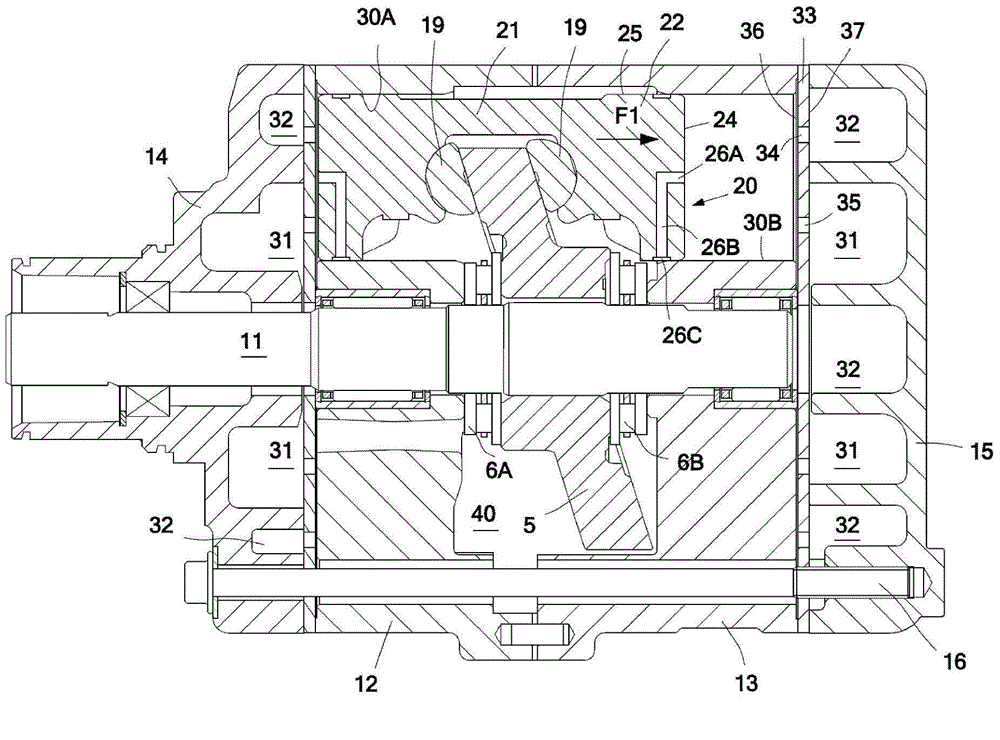

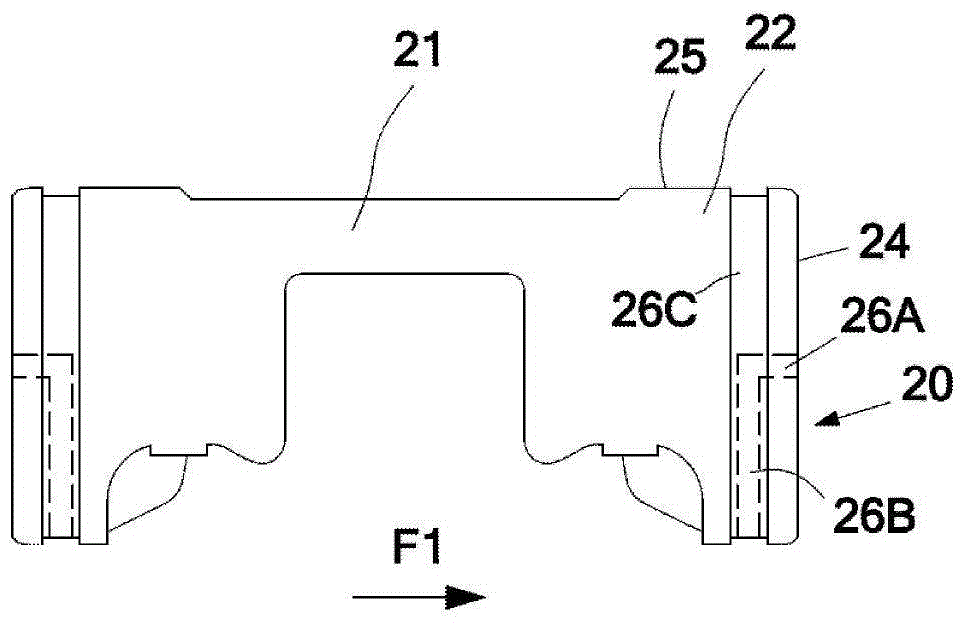

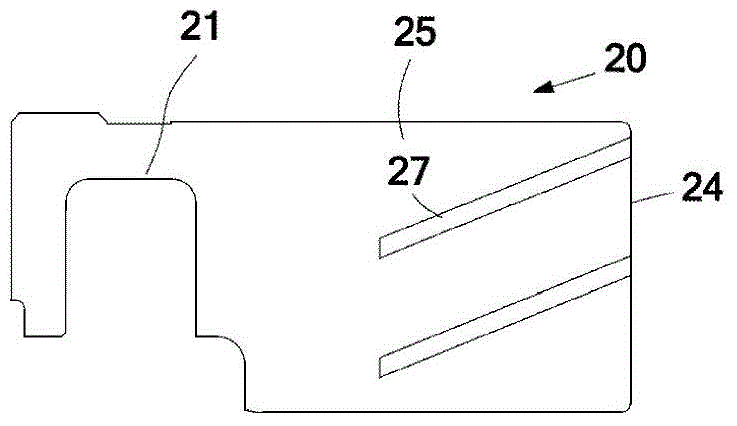

[0021] Figure 1 to Figure 2 An embodiment of the present invention is shown, and it should be noted that these and other subsequent drawings are only examples, they are not drawn in isometric conditions, and should not be taken as protection for the actual requirements of the present invention Scope constitutes a limitation.

[0022] like figure 1 Shown is a cross-sectional view of a bidirectional swash plate compressor used in a vehicle air conditioner. The bidirectional swash plate type compressor has a pair of front cylinder blocks 12 and rear cylinder blocks 13 , and bolts 16 fasten the front cylinder block 12 and the rear cylinder block 13 together to form a swash plate cavity 40 . The drive shaft 11 penetrates the swash plate 5 , the front thrust bearing 6A, and the rear thrust bearing 6B, and the front thrust bearing 6A and the rear thrust bearing 6B are respectively supported by the front cylinder block 12 and the rear cylinder block 13 . The front and rear covers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com