High-pressure double-screw pump

A twin-screw pump, high-pressure technology, applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve the problems of long research and development time, large capital investment, low service life, etc., to improve reliability and safety, and reduce costs cost, effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

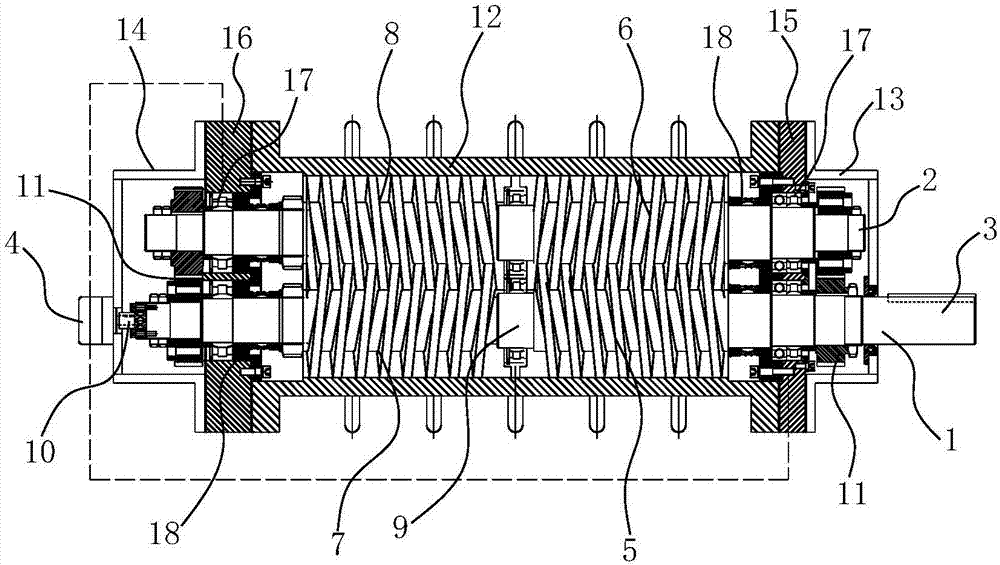

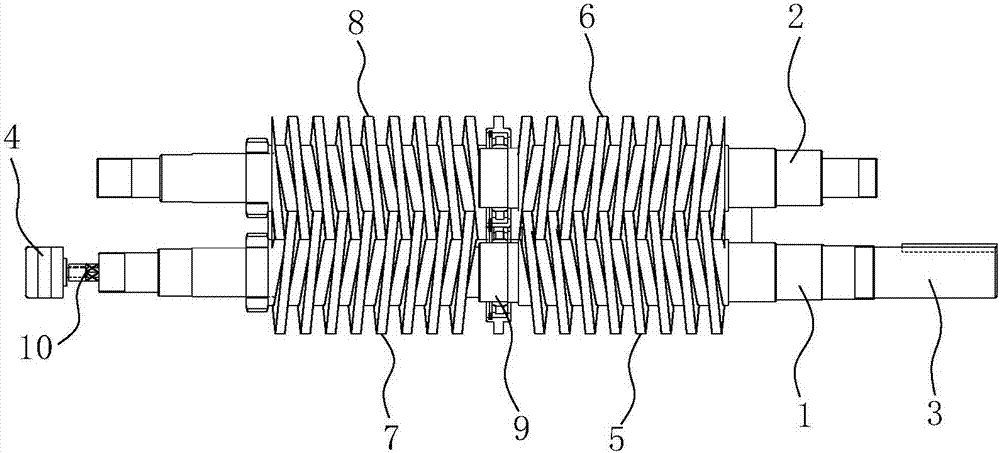

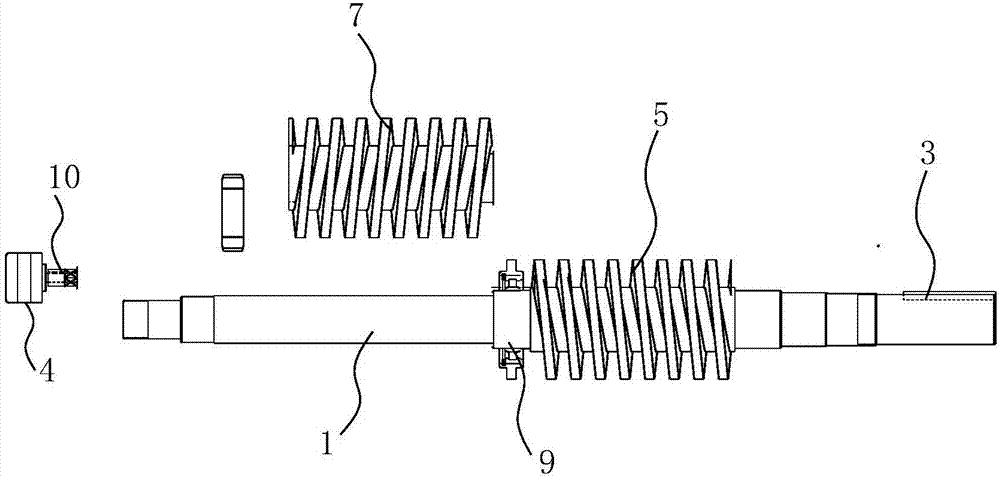

[0020] combine Figure 1-4 A high-pressure twin-screw pump shown includes a driving shaft 1 and a driven shaft 2 arranged in the pump casing. Helical teeth are arranged on the driving shaft 1 and the driven shaft 2 to form a screw. The driving shaft 1 and the driven shaft 2 The transmission connection is formed by connecting gear sets at both ends. Connecting gear set can adopt spur gear set, herringbone gear set etc. But a better way is that the two ends of the driving shaft 1 and the driven shaft 2 form a transmission connection through two sets of helical gears 11 meshing with each other. This can not only increase the bearing load of the connected gear set, but also solve the problems of difficult processing of the herringbone gear set, difficult clearance adjustment, and excessive clearance between the master and slave shafts.

[0021] One end of the drive shaft 1 is a power connection end 3 , and the other end is provided with a lubricating oil pump 4 driven by the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com