Design method for forced lubrication system of inverted-triangle rotor engine

A rotor engine, forced lubrication technology, applied in the direction of engine lubrication, combustion engine, engine components, etc., can solve the problems of emission pollution, lubricating oil consumption, increasing lubricating oil consumption, etc., to reduce emission pollution, improve lubrication effect, reduce The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

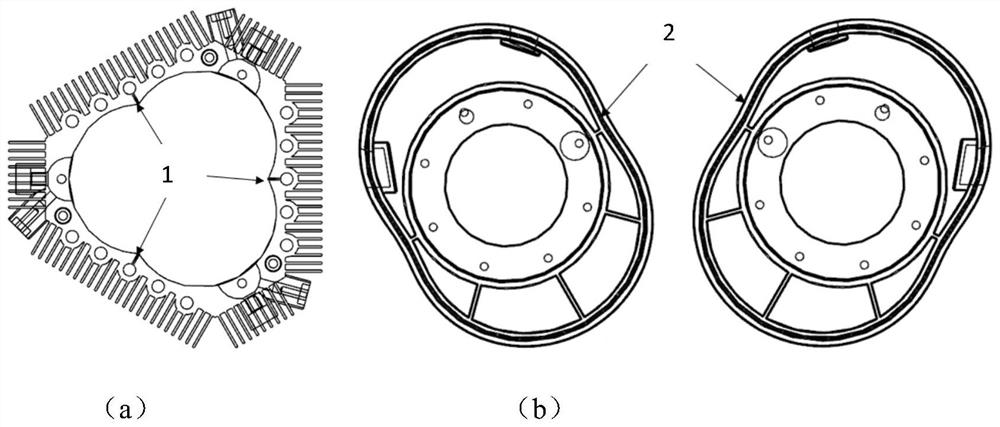

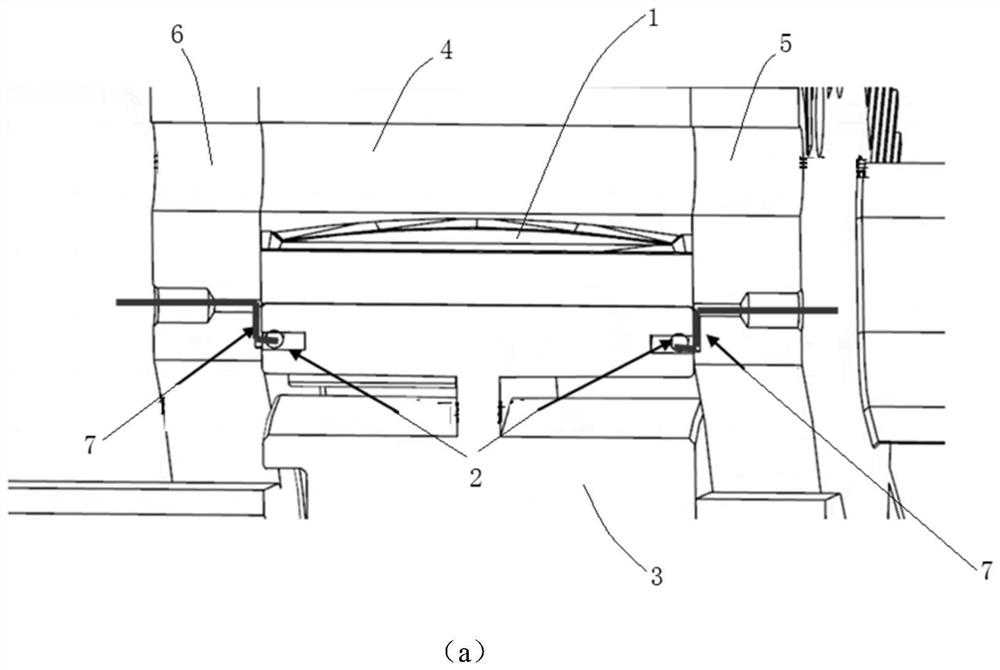

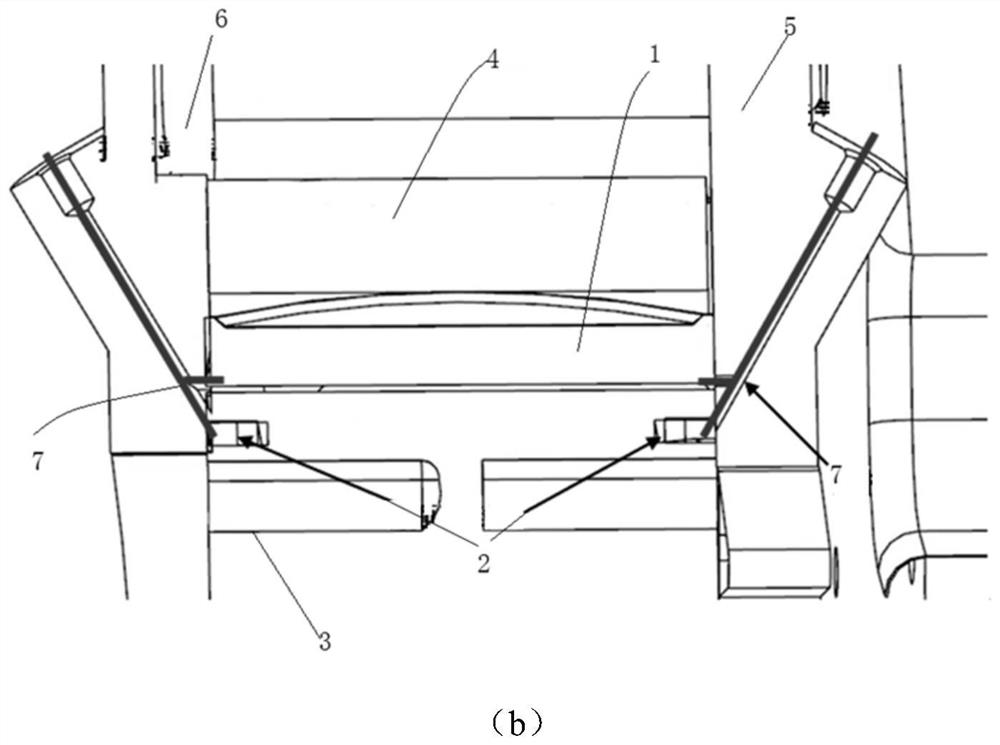

[0022] In order to realize the forced lubrication of each friction surface, it is necessary to combine the structural characteristics of the anti-triangular rotor engine and the movement rules of the rotor, etc., to carry out the lubrication system of the anti-triangular rotor engine, including the lubrication of radial seals and end face seals, the lubrication of bearings and The design of the oil storage chamber is designed in a targeted manner.

[0023] In the reverse triangular rotor engine, the radial sealing sheet 1 is installed on the fixed cylinder body, and the sealing sheet can be forcibly lubricated through the setting of the oil passage; The relationship with the position of the cylinder is through forced lubrication. In this way, the lubricating effect on each friction surface can be improved, the consumption of expensive lubricating oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com