Bearing chamber suitable for rolling bearing

A technology for rolling bearings and bearing chambers, which is applied to the rigid support of bearing components, bearing elements, shafts and bearings, etc., which can solve the problems of providing lubricating and cooling conditions for bearings, increasing the volume of the bearing body, and limited heat dissipation efficiency, etc., to achieve good cooling effect , High cooling efficiency, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

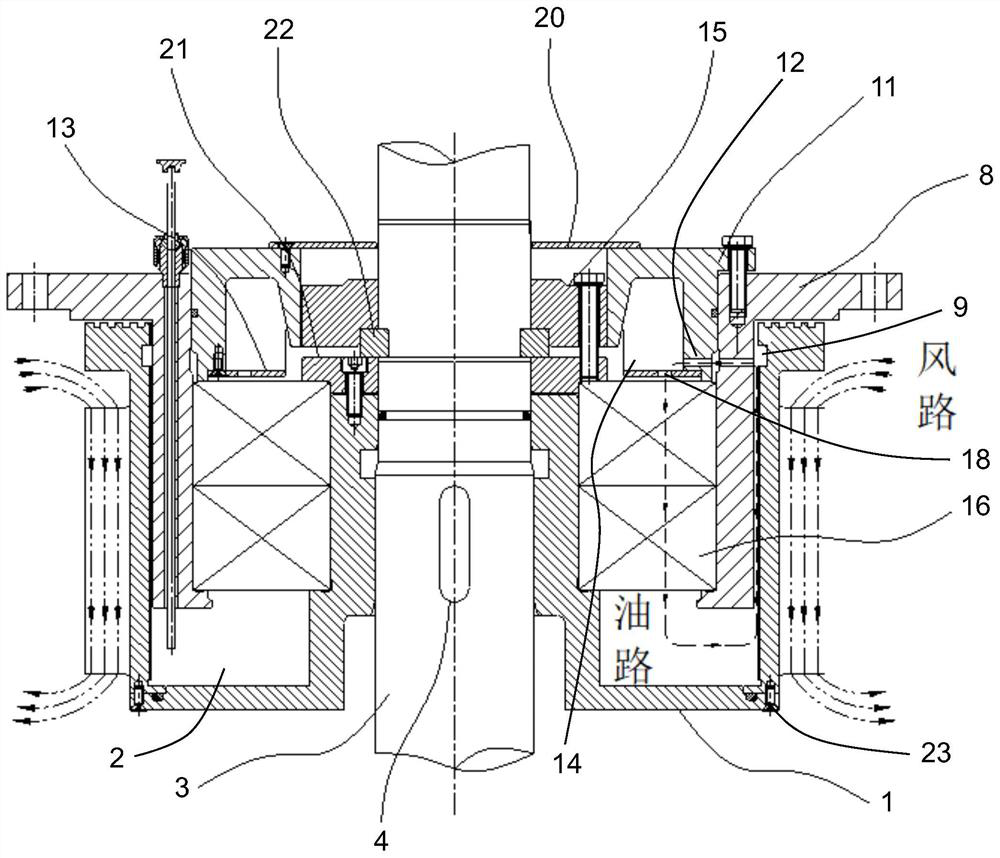

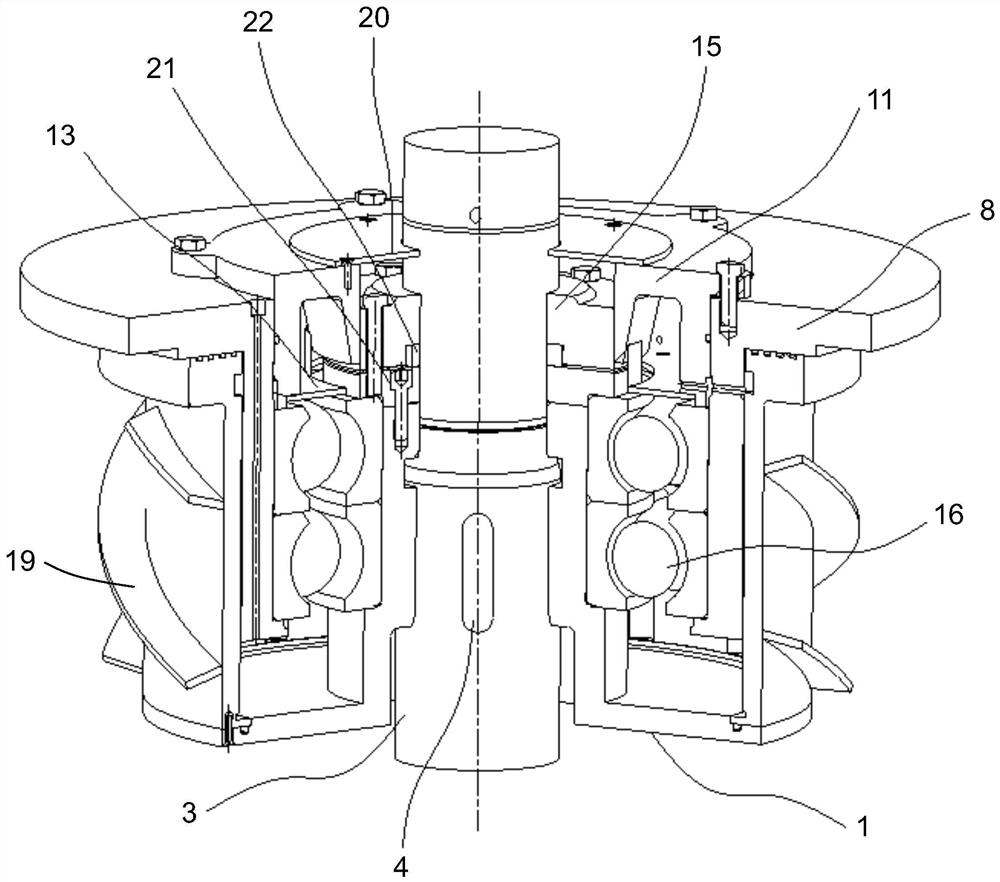

[0037] In order to better understand the above-mentioned technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the drawings and embodiments.

[0038] to combine Figure 1 to Figure 4 As shown, the present invention provides a bearing chamber suitable for rolling bearings. The annular cavity below the inside of the bushing 1 serves as the oil chamber 2 of the bearing chamber of the present invention, and lubricating oil is stored in the oil chamber 2 . When the unit works normally, the shaft sleeve 1 installed on the main shaft 3 rotates together with the rotation of the main shaft 3 through the key 4 .

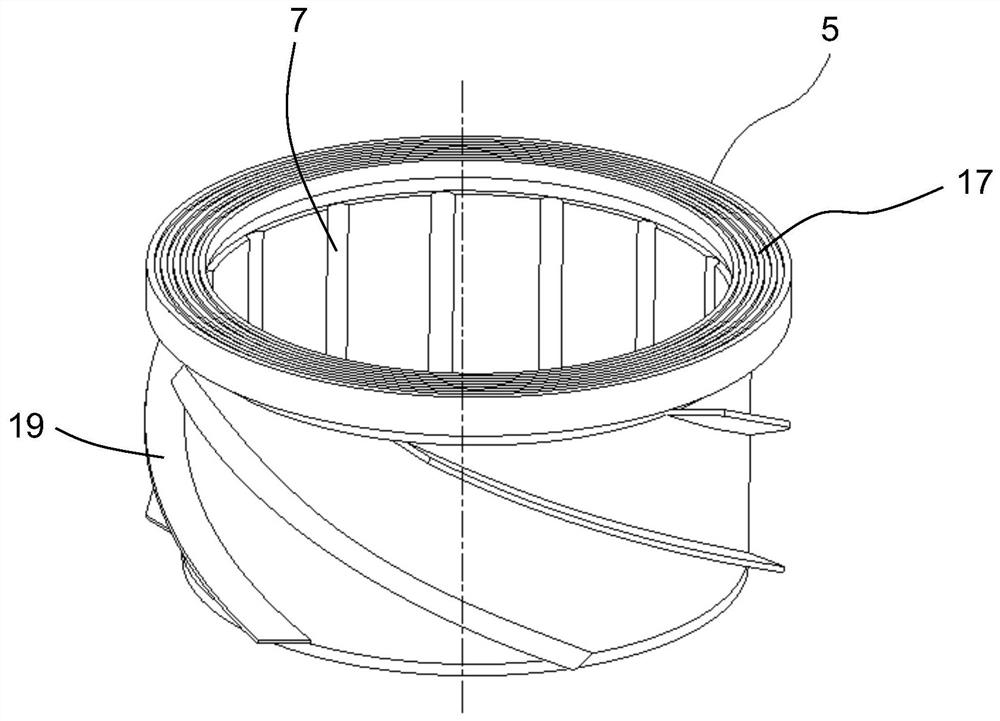

[0039] The shaft sleeve 1 includes the shaft sleeve outer ring 5 and the shaft sleeve inner ring 6. A plurality of oil delivery grooves 7 are processed on the inner wall of the shaft sleeve outer ring 5. When the main shaft 3 rotates, it has the function of pumping lubricating oil upward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com