Patents

Literature

33results about How to "Protective seal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

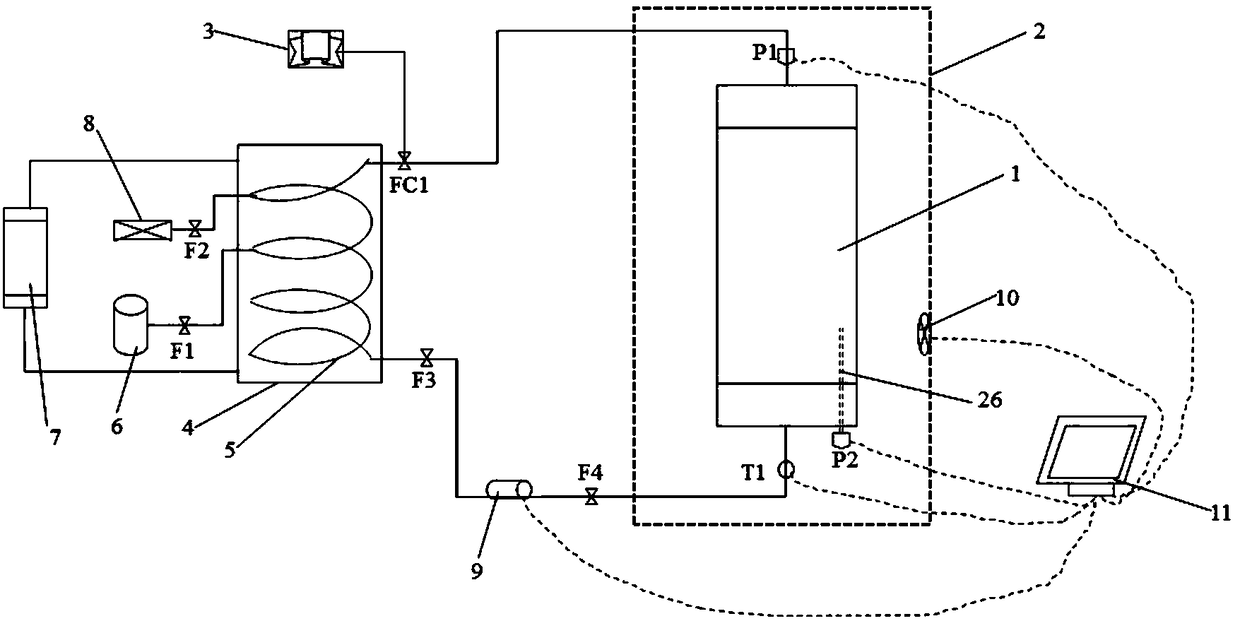

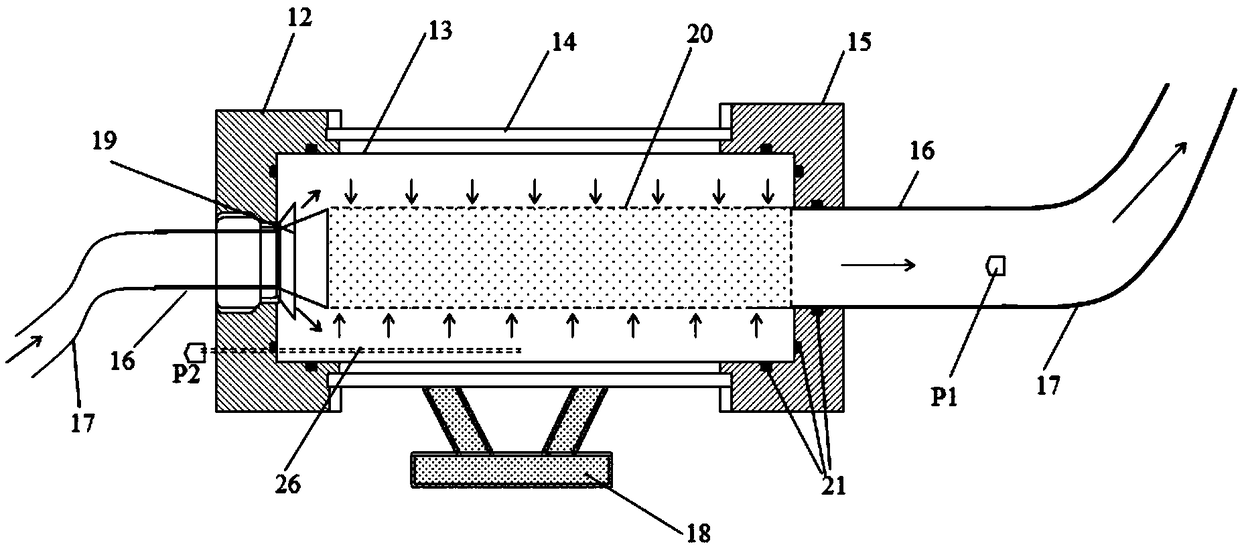

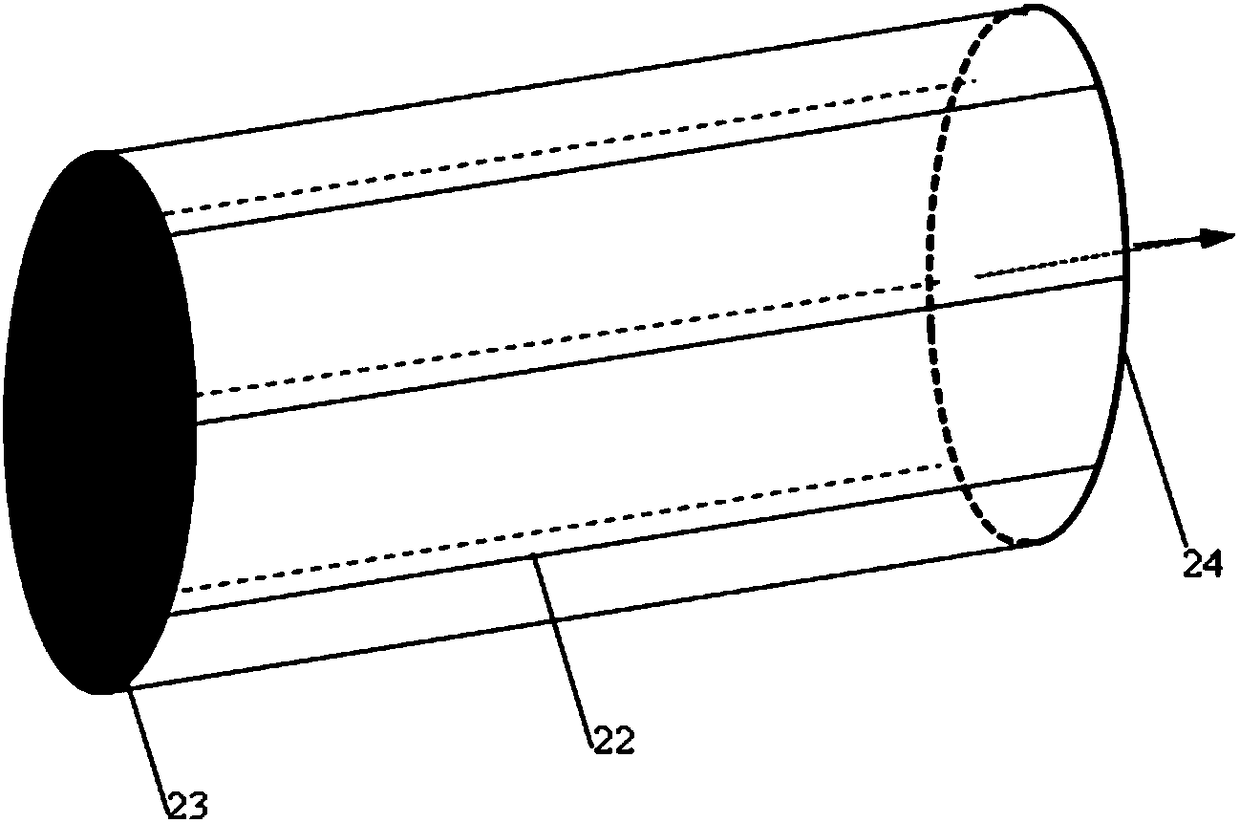

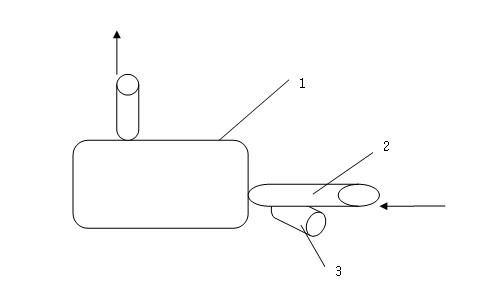

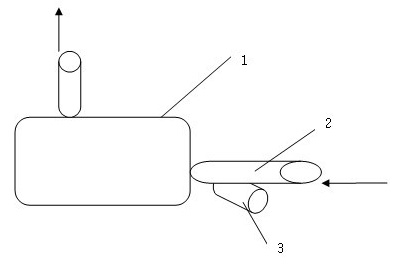

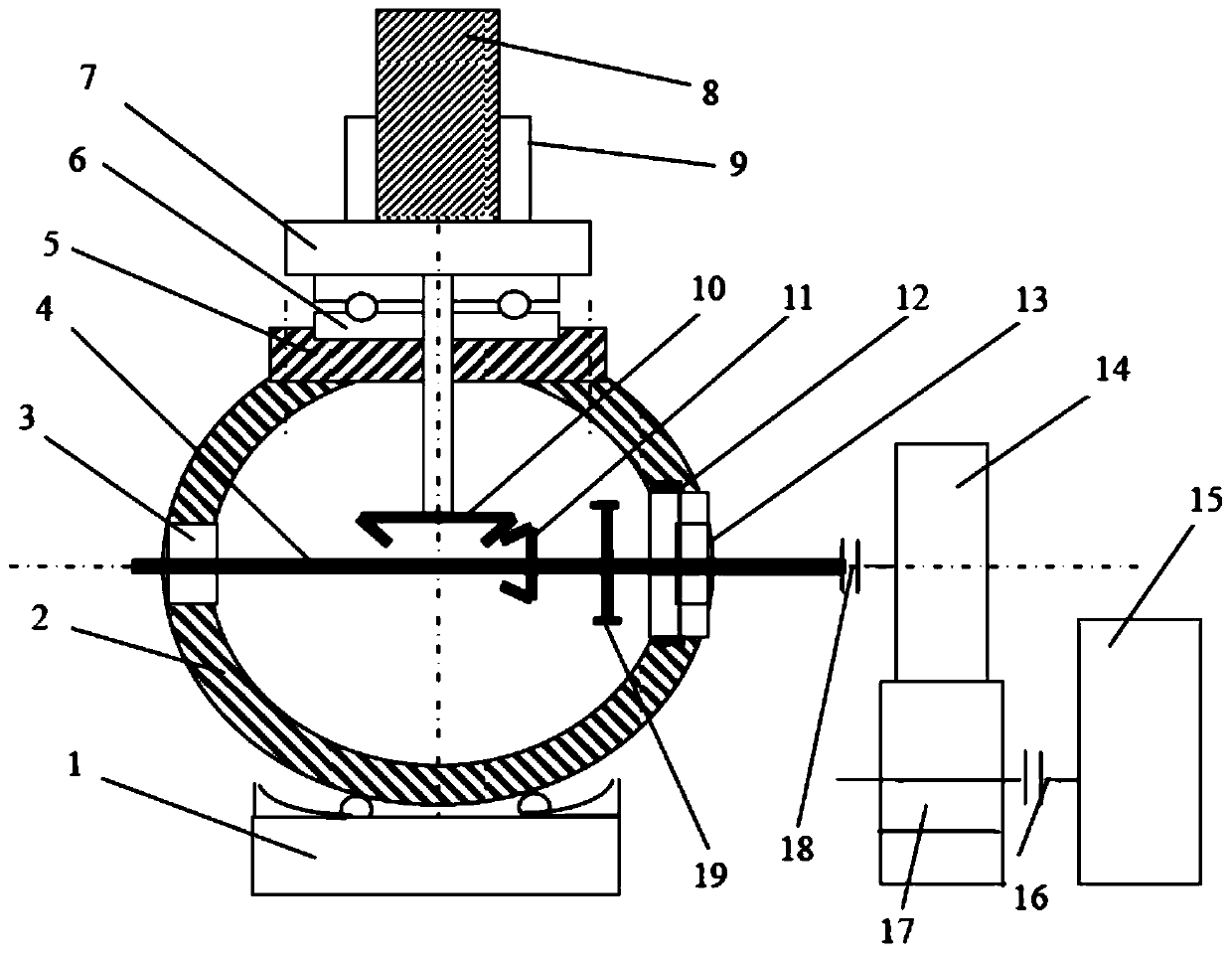

System and method for visually evaluating production and blockage law of hydrate in screen

ActiveCN108226162AAvoid secondary generationAvoiding the Difficulty of Borehole Pressure MeasurementInvestigating moving fluids/granular solidsTemperature controlSkin factor

The invention provides a system for visually evaluating a production and blockage law of hydrate in a screen and a testing method thereof. An experimental system for testing a secondary production, enrichment and blockage law of the hydrate in a screen mesh comprises a reaction kettle, a gas-liquid mixed conveying coil, a high-speed camera, a data acquisition and processing module and the like. The testing method is based on the system, and through adjustment of a cooling mode and control of a temperature and pressure condition and a gas-liquid ratio condition, a three-dimensional chart of thesecondary production and blockage of the hydrate in the screen mesh is simulated; the system can provide basic data for calculation of a well-bottom screen sand control additional skin factor and formulation of a precise pressure-reducing and temperature-controlling scheme under different well body structure conditions (a vertical well, a horizontal well or a multi-branch hole) of a natural gas hydrate production well, and provides a strong support for a sand production management system of the natural gas hydrate production well.

Owner:QINGDAO INST OF MARINE GEOLOGY +1

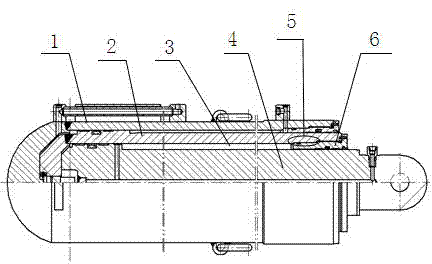

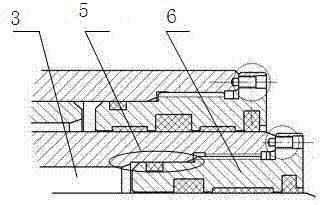

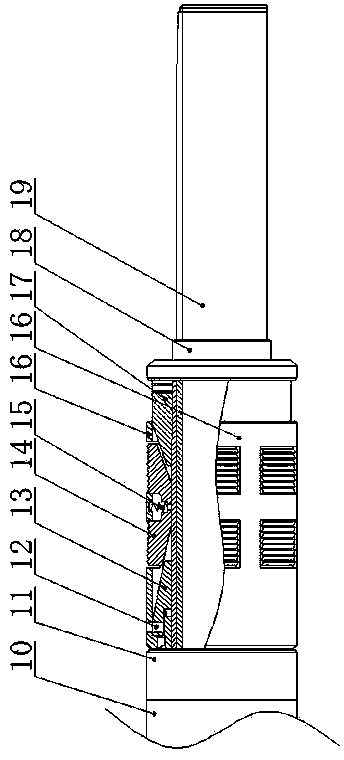

Hydraulic support oil cylinder with inner hole seal part treated by adoption of laser cladding technology

InactiveCN103883587AAvoid corrosionCreate pollutionFluid-pressure actuatorsMine roof supportsCorrosion resistant alloyEngineering

The invention discloses a hydraulic support oil cylinder with an inner hole seal part treated by the adoption of a laser cladding technology. The hydraulic support oil cylinder with the inner hole seal part treated by the adoption of the laser cladding technology comprises an outer cylinder tube, an intermediate cylinder and a movable column, the intermediate cylinder is arranged inside the outer cylinder tube, an inner hole is formed inside the intermediate cylinder, the movable column is inserted into the inner hole inside the intermediate cylinder, and a gap is reserved between a rod body part of the movable column and the wall of the inner hole and filled with emulsified liquid. A guide sleeve is arranged on an opening of the inner hole and seals the gap formed by the rod body part of the movable column and the wall of the inner hole, and an anti-corrosion alloy layer is formed at the inner surface, close to the opening and making contact with the outer wall of the guide sleeve, of the inner hole by the adoption of the laser cladding treatment technology. The device can not pollute the environment at all, a coating can not fall off, the service life is long and can be prolonged substantially, cost for maintaining the oil cylinder is saved for a user, and coal exploitation efficiency is improved.

Owner:CHONGQING JIANGLU LASER TECH

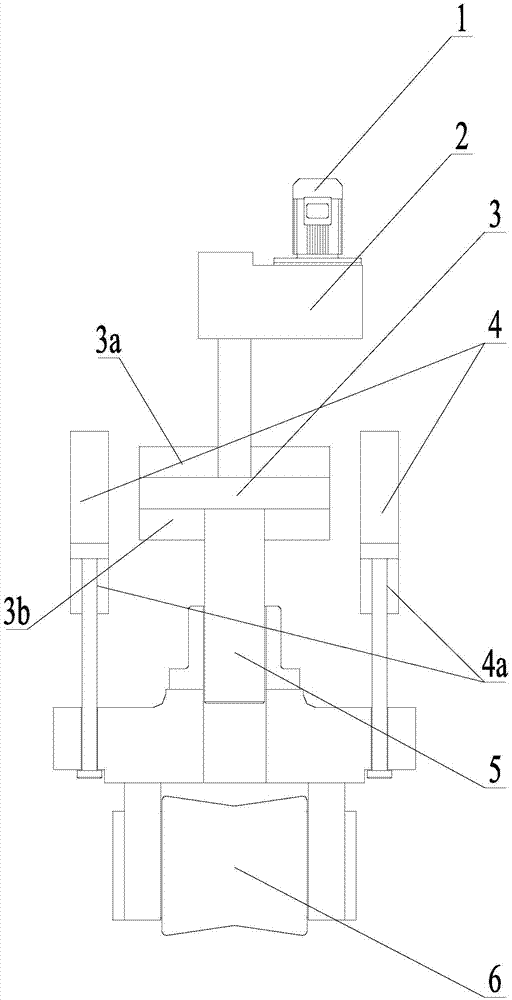

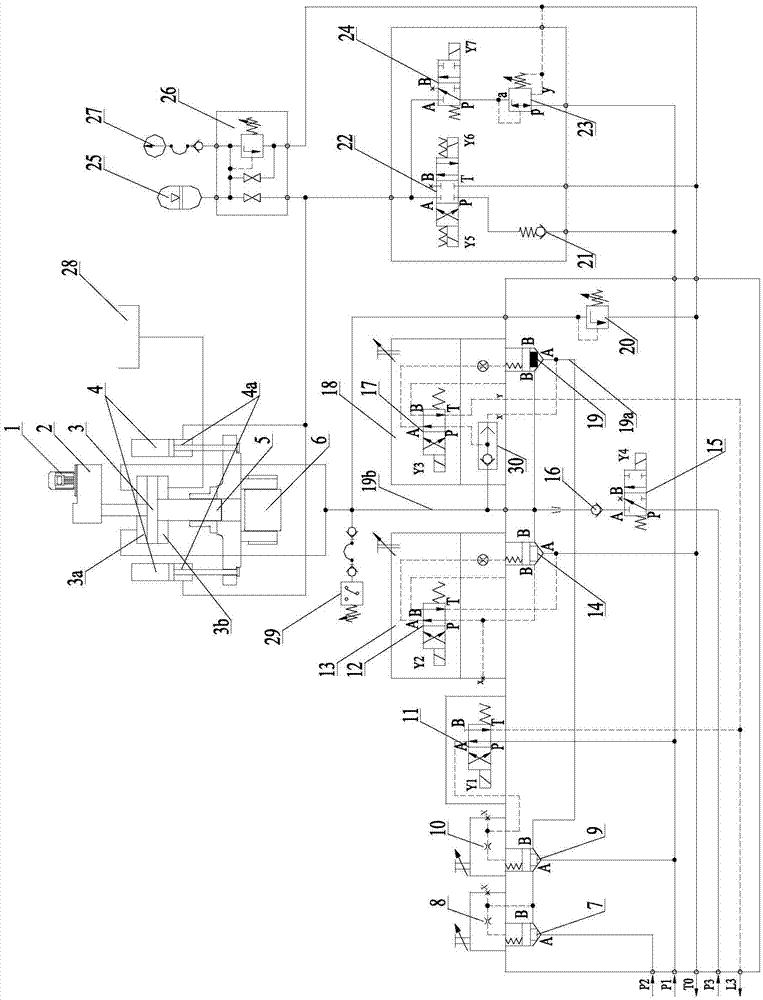

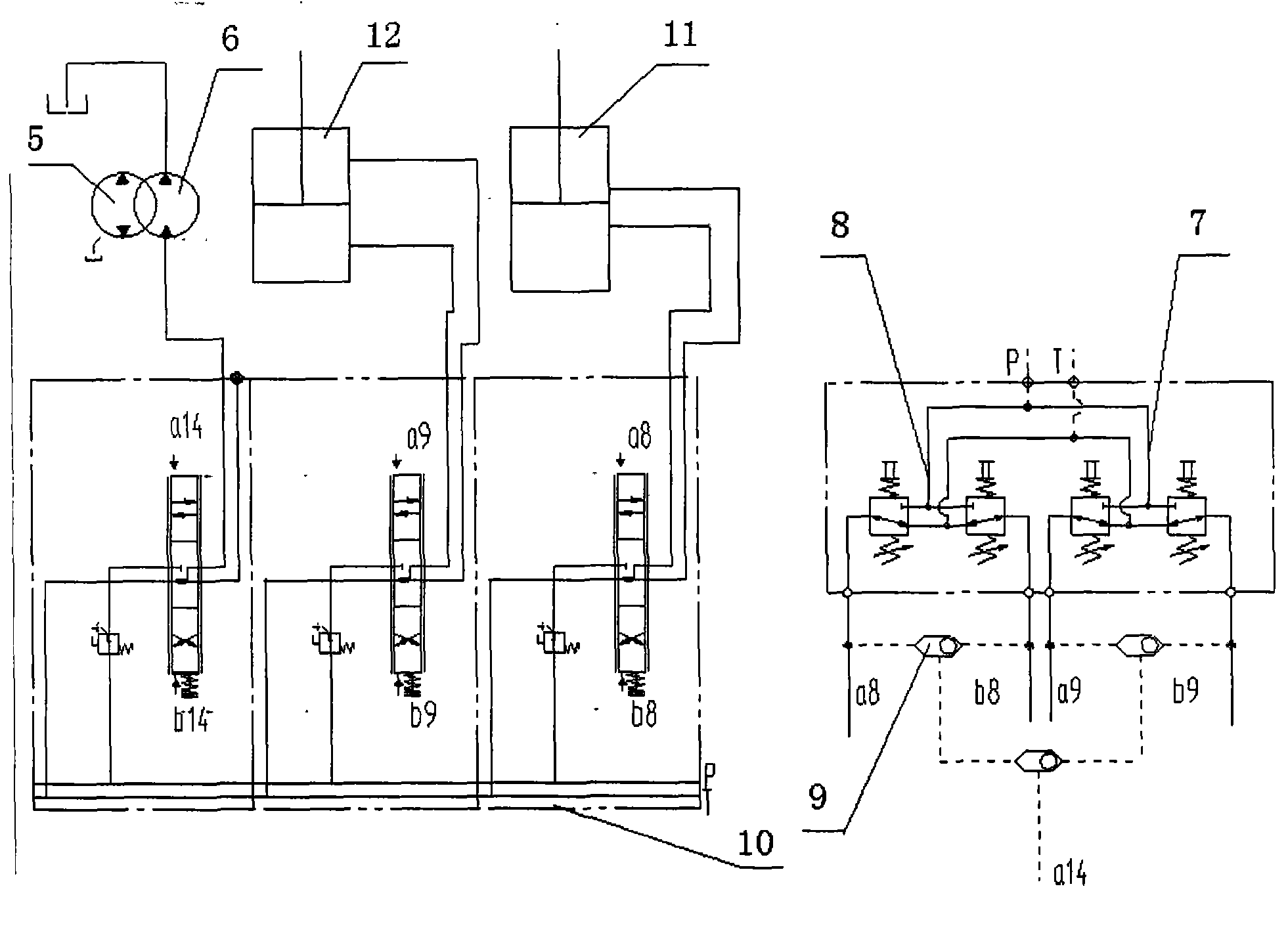

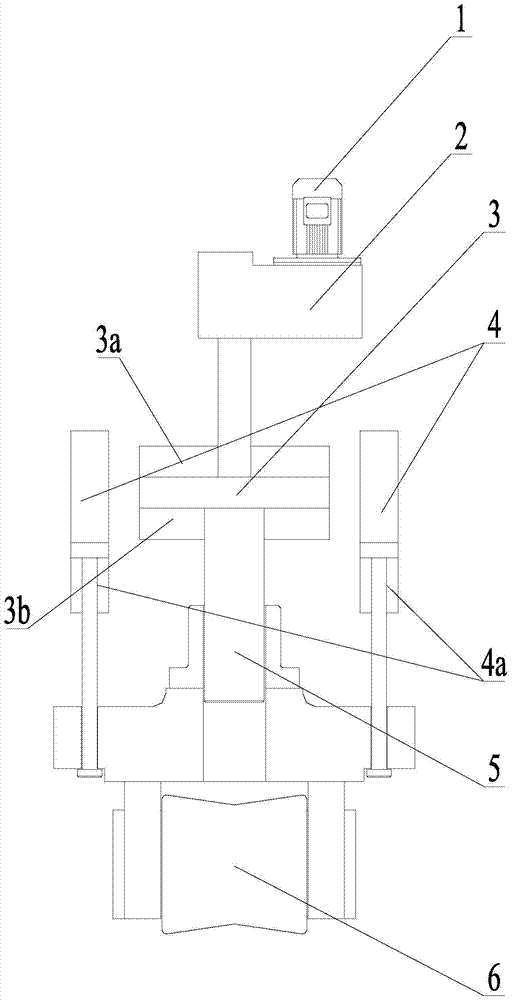

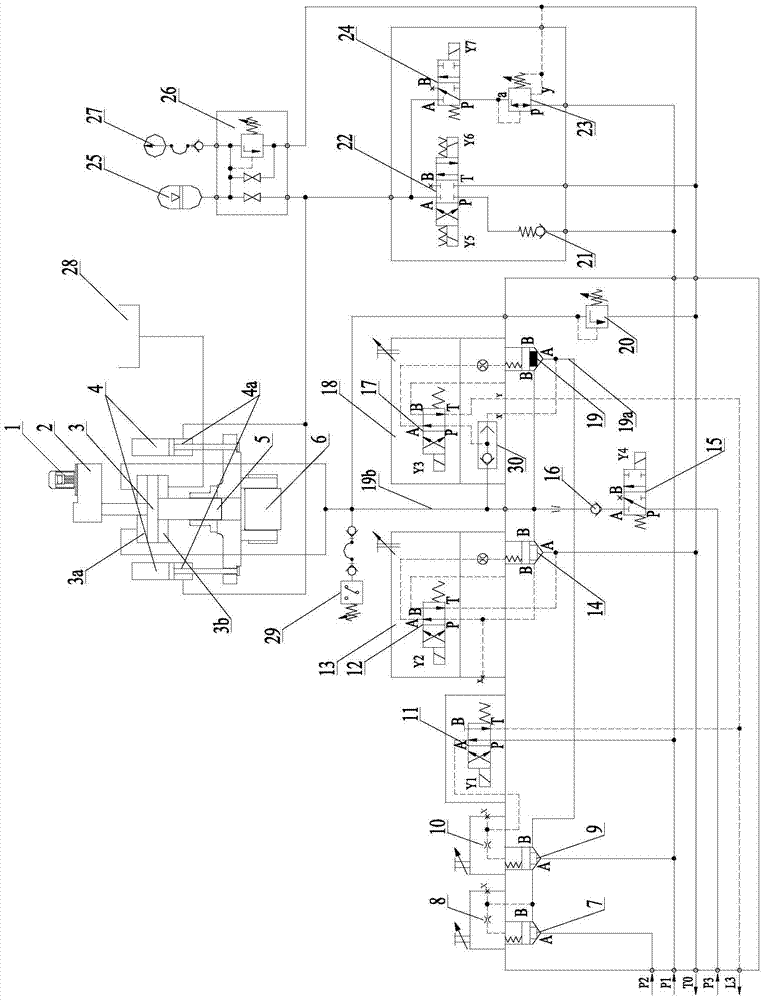

Hydraulic control system for quick opening cylinder and upper roll balance cylinder of steel tube straightening machine

ActiveCN105443466AEliminate hydraulic shockExtended service lifeServomotor componentsServomotorsControl systemHigh pressure

The invention discloses a hydraulic control system for a quick opening cylinder and an upper roll balance cylinder of a steel tube straightening machine. The hydraulic control system comprises a quick opening cylinder hydraulic control loop and an upper roll balance cylinder hydraulic control loop, wherein the quick opening cylinder hydraulic control loop comprises a high-low pressure oil source selecting device, an oil inlet throttling device, a high-pressure compensating device and an oil return throttling device; the upper roll balance cylinder hydraulic control loop comprises a first electromagnetic reserving valve connected to a rod cavity of the upper roll balance cylinder, an energy storage assembly and a three-way pressure relief valve which is selectively communicated to the rod cavity and a high-pressure oil source. The hydraulic control system for the quick opening cylinder and the upper roll balance cylinder of the steel tube straightening machine can effectively eliminate hydraulic impact of the quick opening cylinder, can prolong the service life of the quick opening cylinder, saves energy and reduces consumption, saves cost and effectively protects sealing of the quick opening cylinder.

Owner:TAIYUAN HEAVY IND

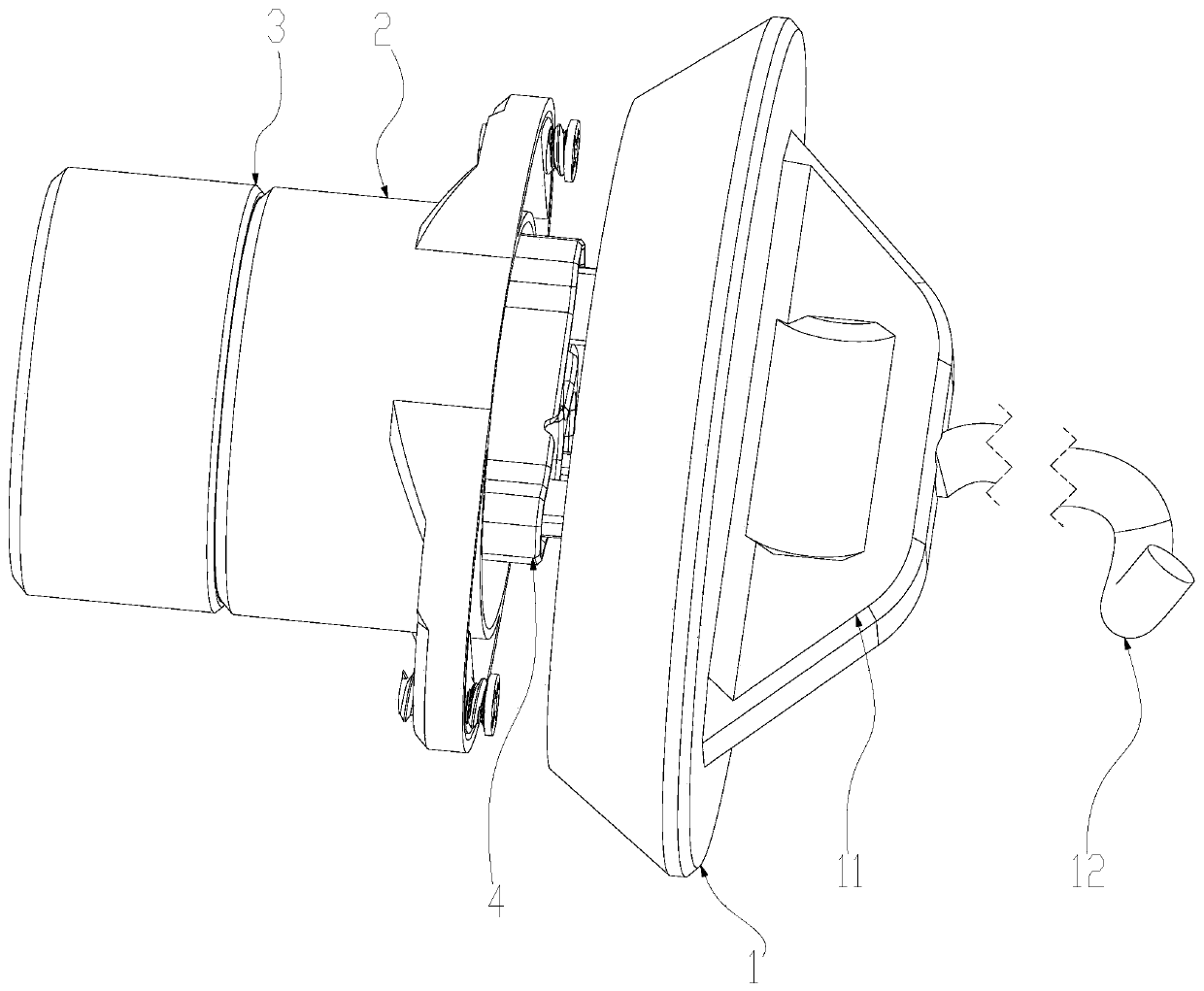

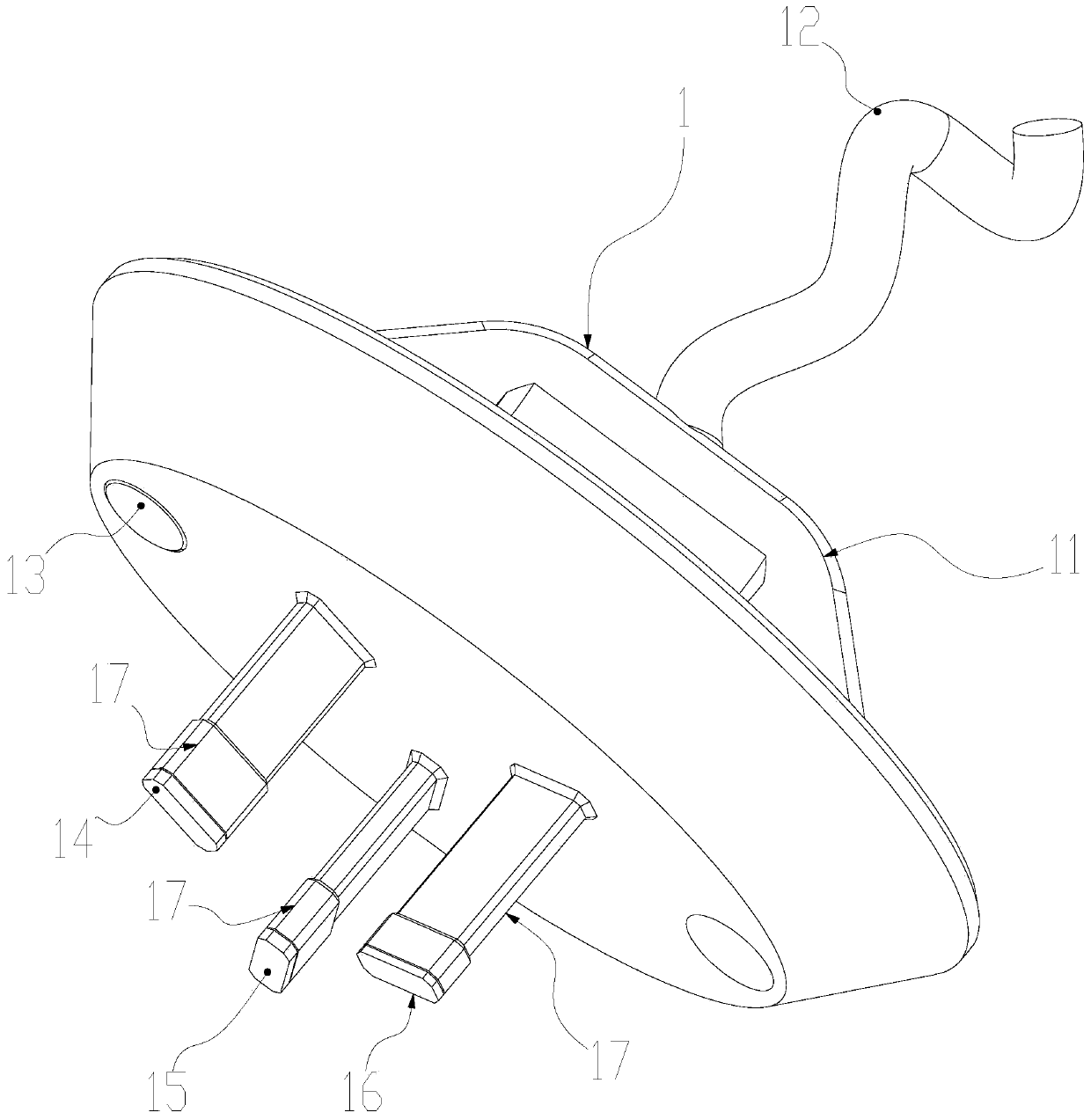

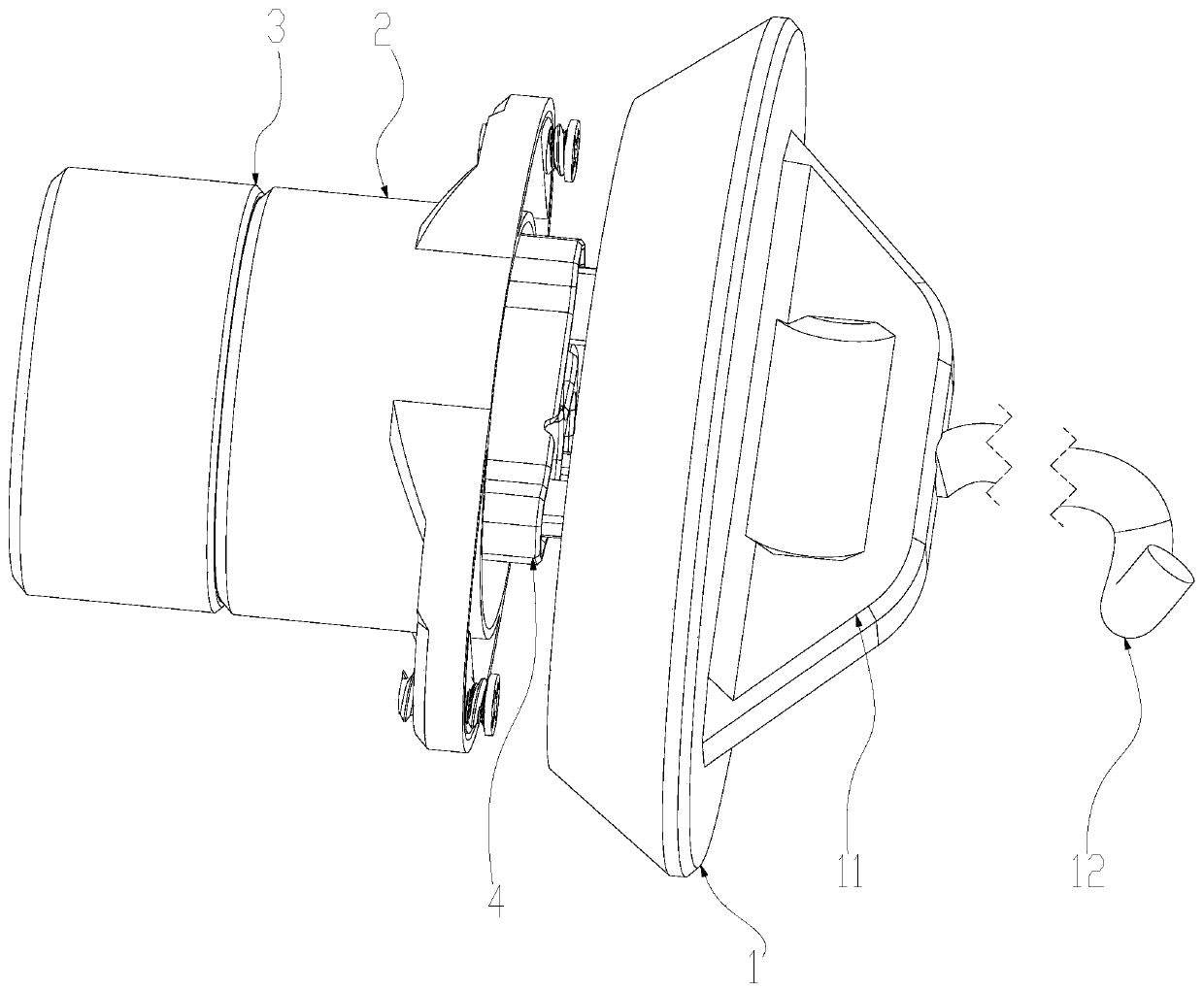

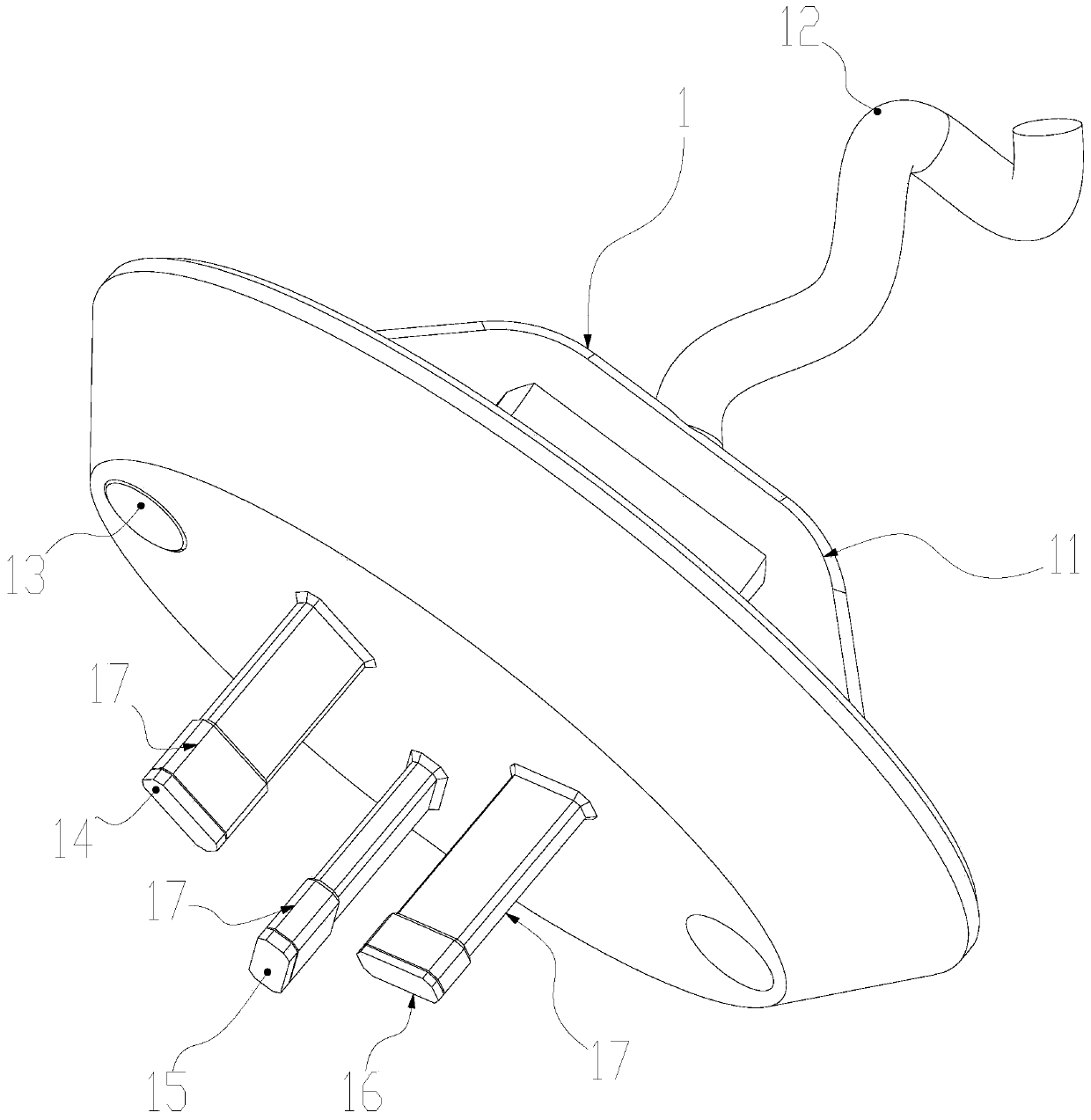

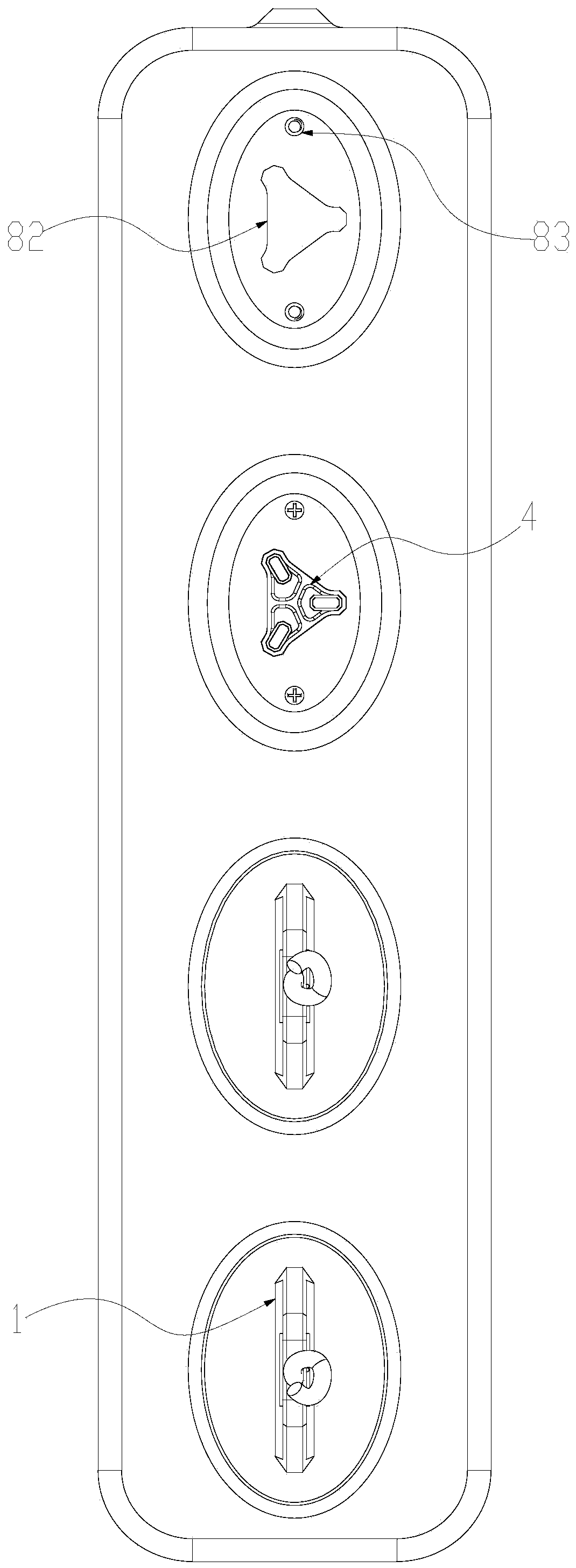

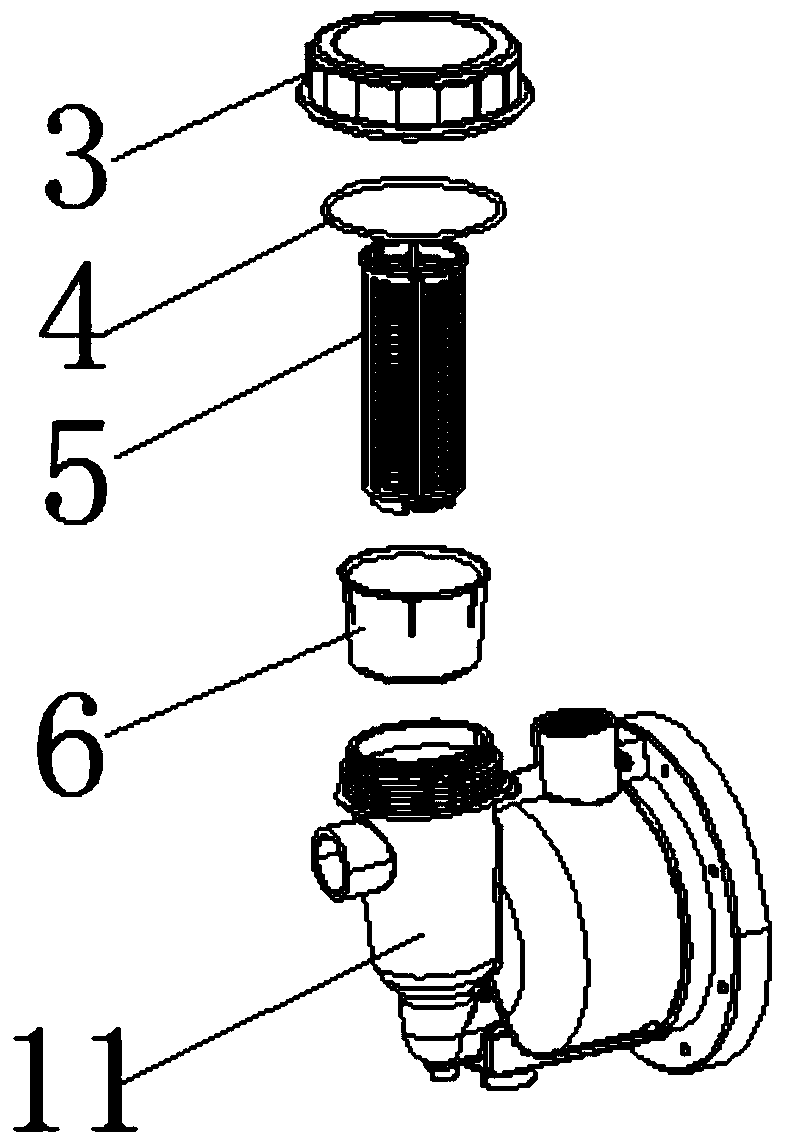

Safety sealing coupling plugging board

ActiveCN109524837AStrong protection sealEase of repair and replacement partsCouplings bases/casesTwo-part coupling devicesModular designElectric shock

The invention relates to a plugging board, more particularly to a safety sealing coupling plugging board comprising a plugging board housing and one or more detachable waterproof sealing coupling devices. The detachable waterproof sealing coupling devices includes external inlaying mounting coupling members and inlaying devices; the external inlaying mounting coupling members are formed by coupling devices and sealing covers; and the coupling devices include ground wire bridge modules, live wire bridge modules, and zero line bridge modules. According to the invention, the plugging board is used directly after being plugged and the operation is completed by one step; the plugging board based on the anti-electric-shock design has the multi-waterproof effect and thus can be used in water; andon the basis of the modular design, the safety sealing coupling plugging board is convenient to maintain and element replacement is also carried out conveniently.

Owner:温州市鹿城区渊龙电器科技有限公司

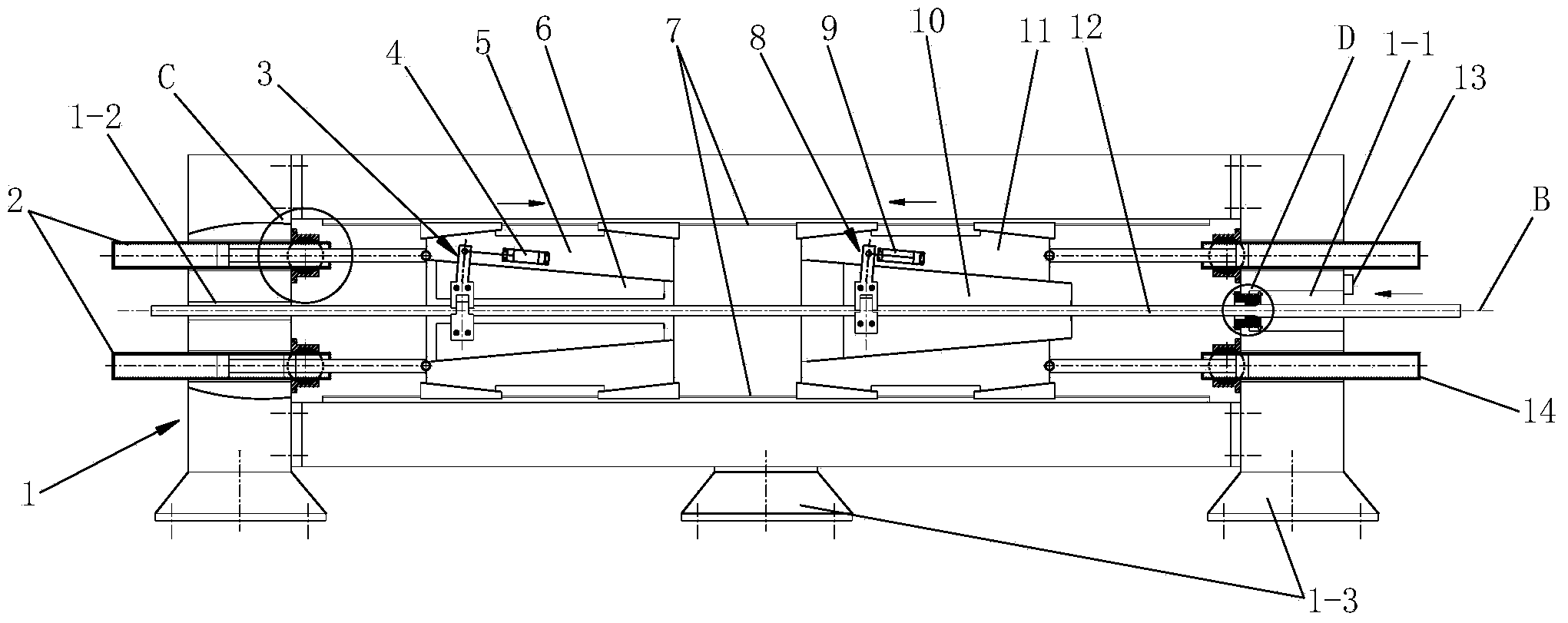

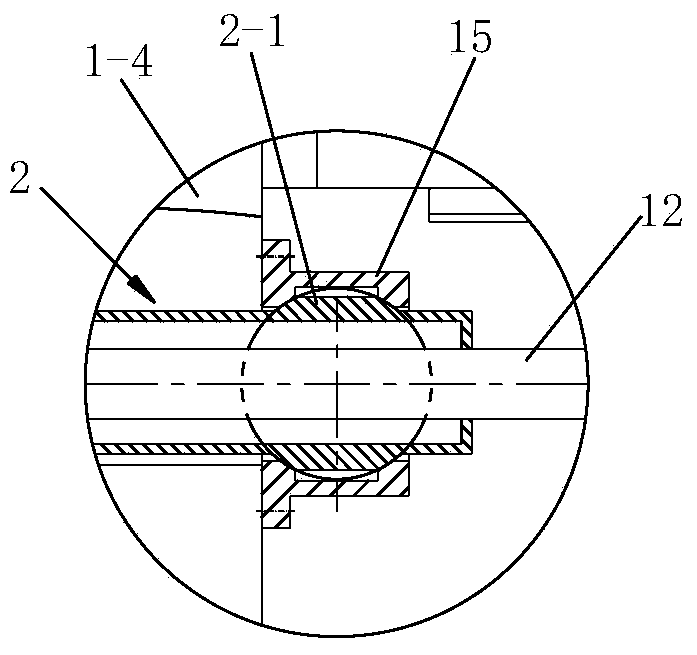

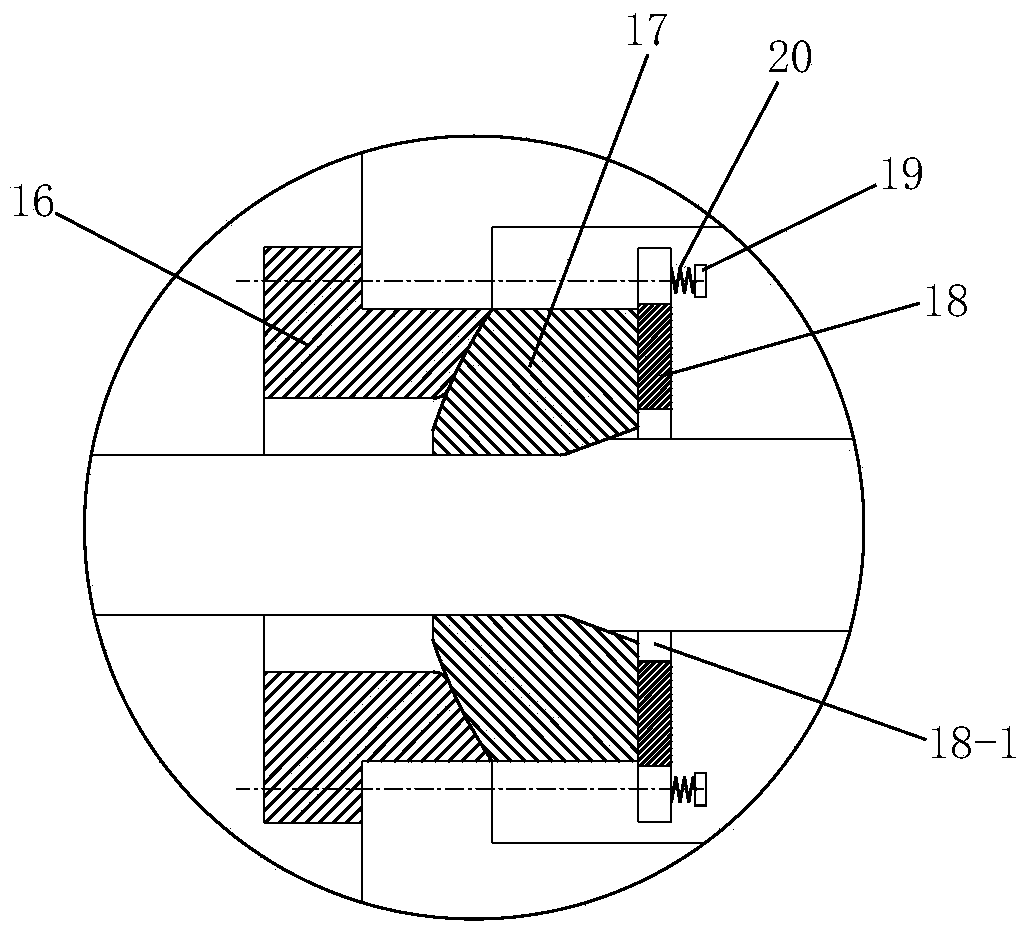

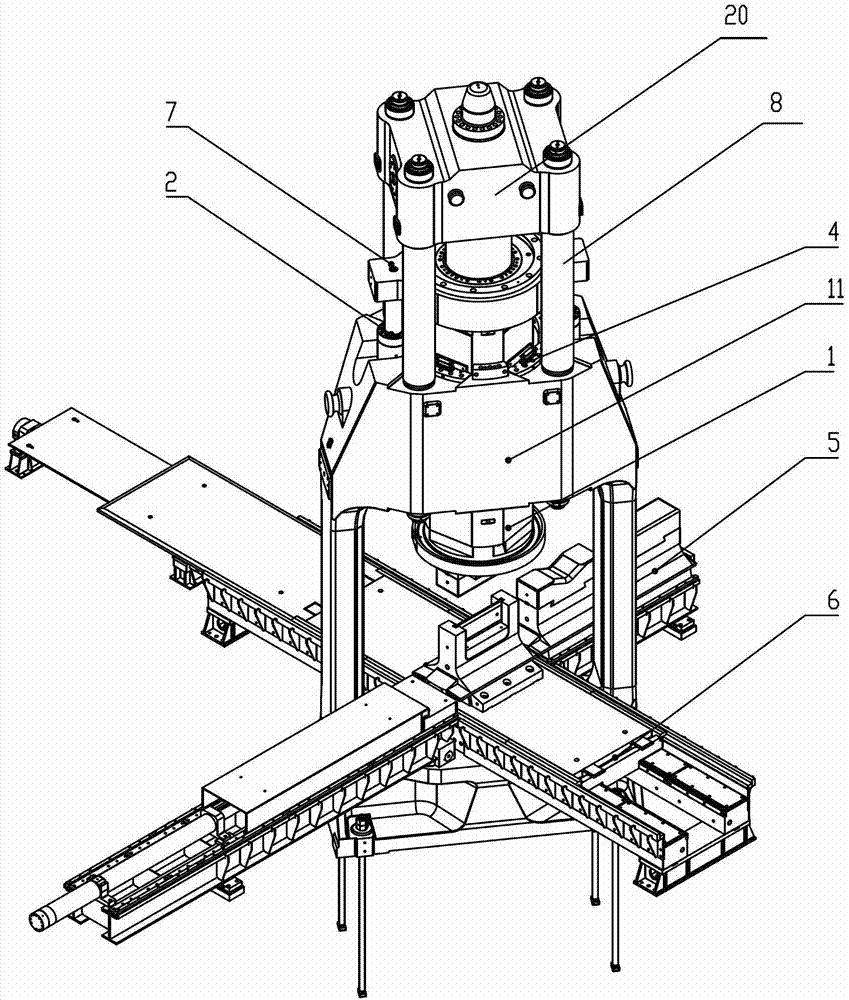

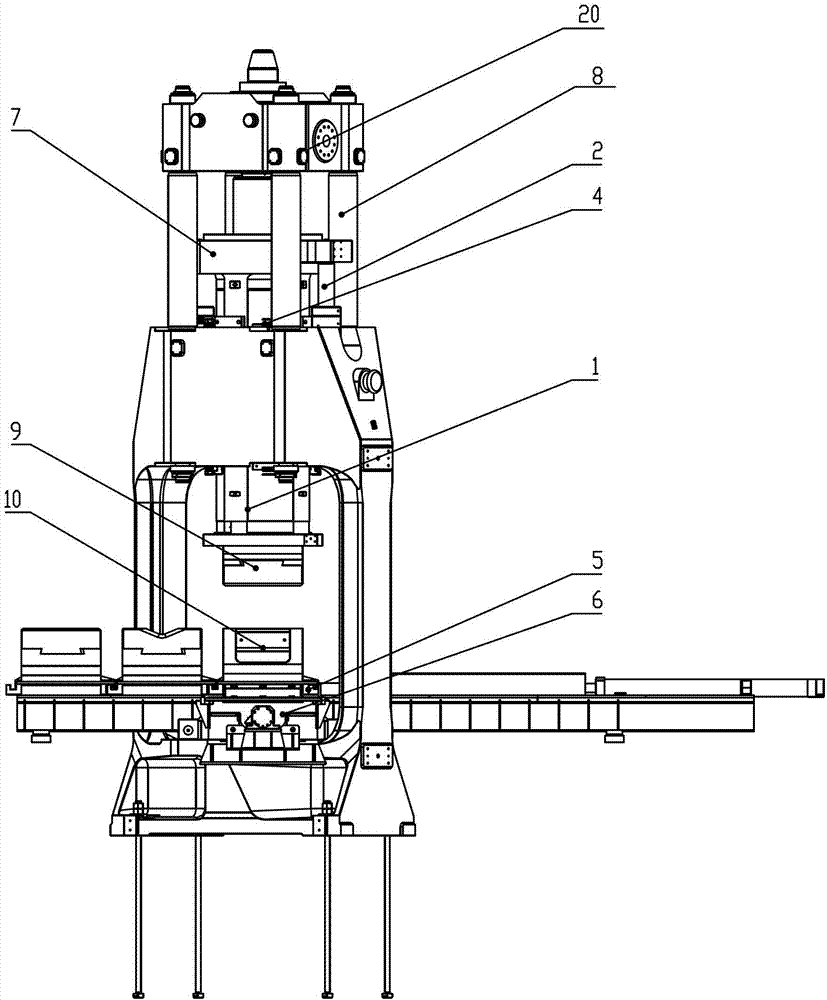

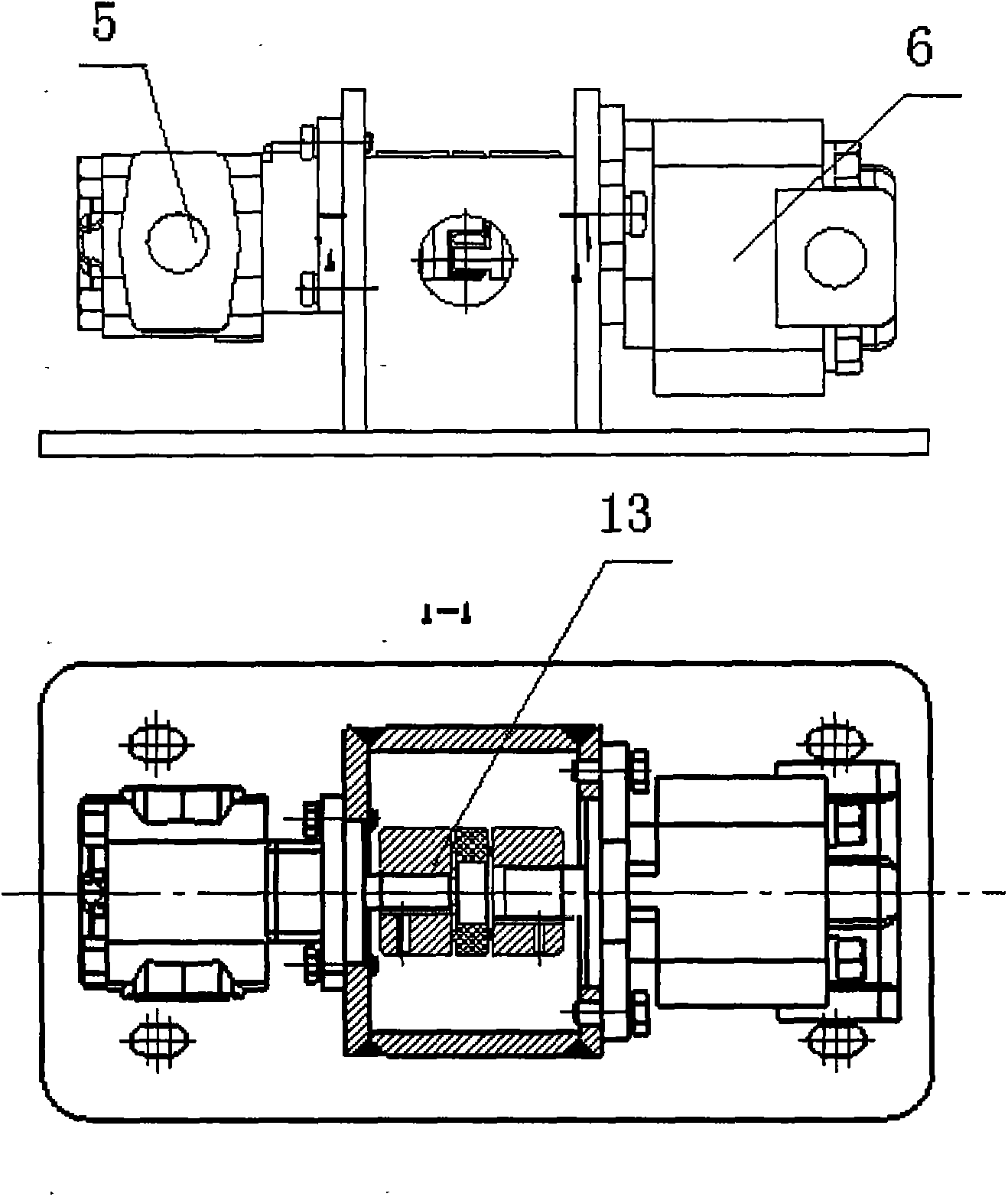

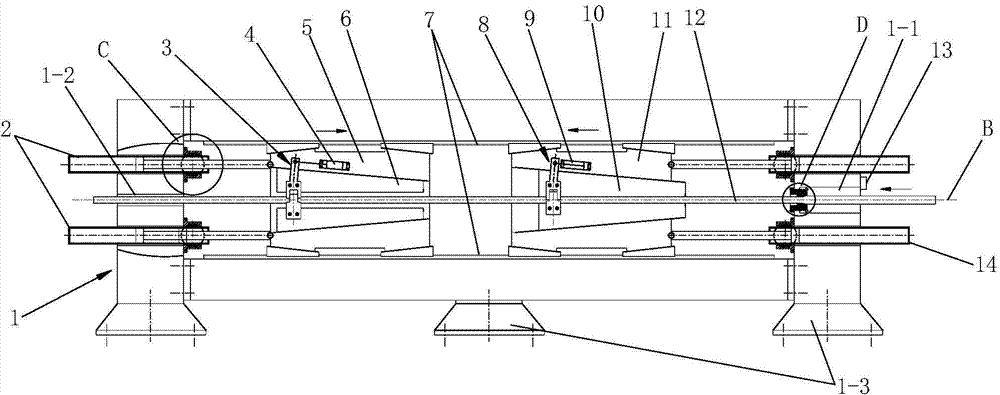

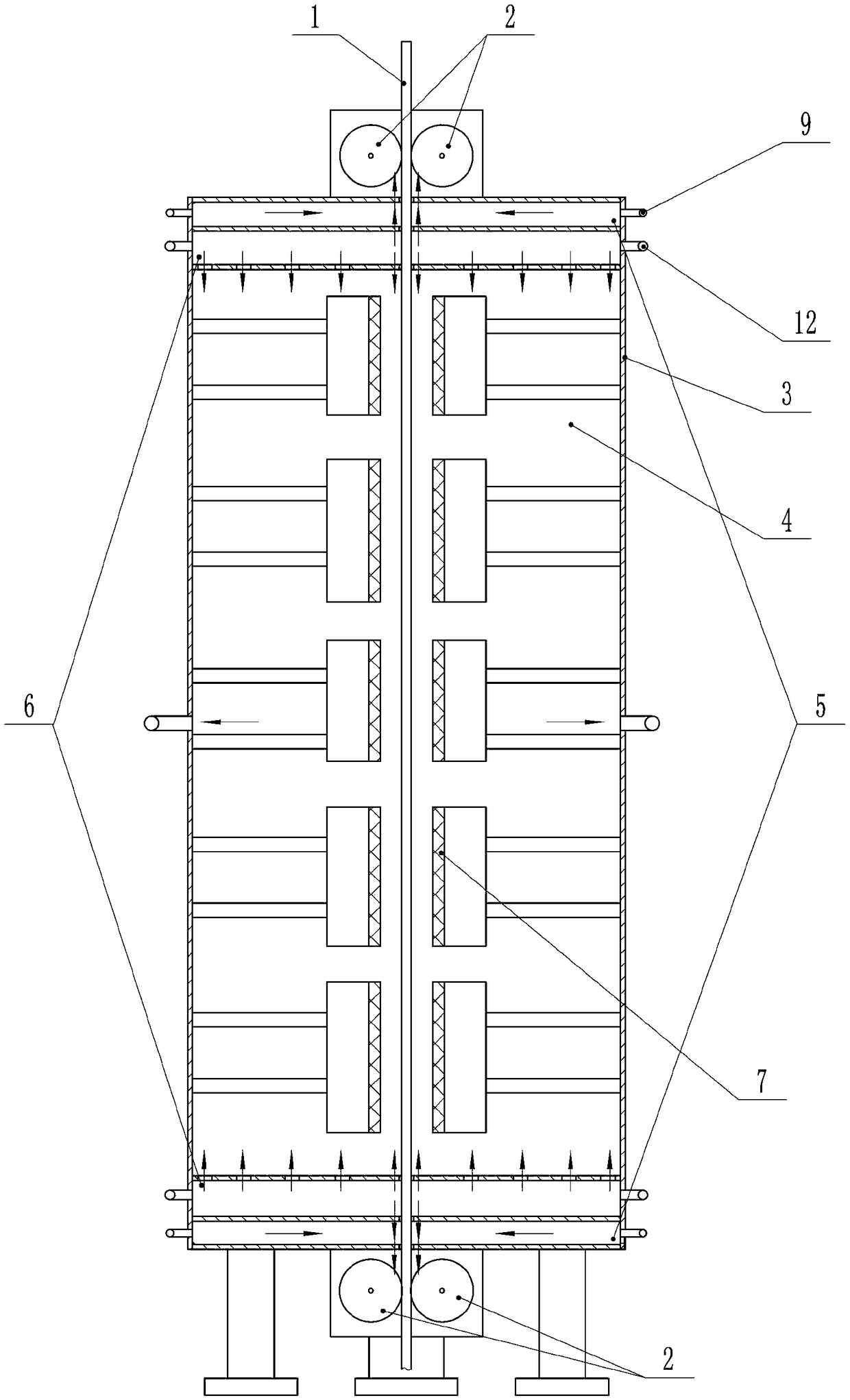

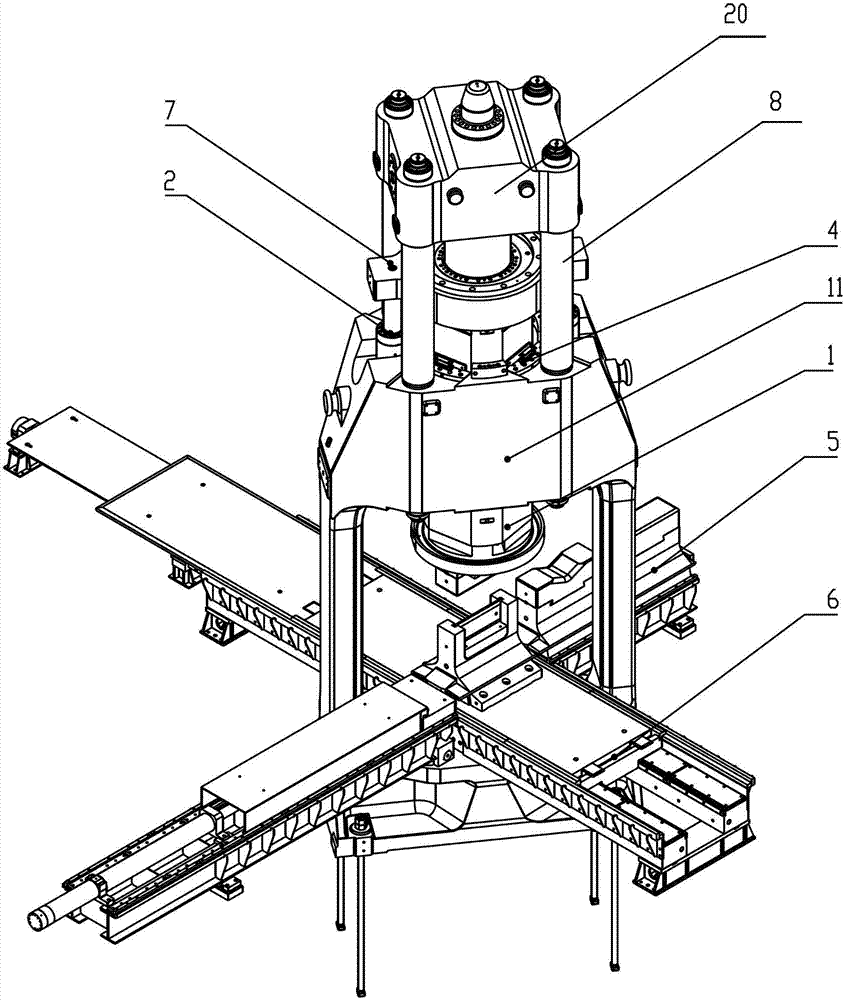

Hydraulic continuous drawing machine

ActiveCN103447327ASimple structureNovel and reasonable designDrawing diesHydraulic cylinderEngineering

The invention discloses a hydraulic continuous drawing machine. The hydraulic continuous drawing machine comprises a framework, a left trolley, a right trolley, two left drawing hydraulic cylinders and two right drawing hydraulic cylinders, wherein the framework is of a vertical structure and is provided with a feeding channel and a discharging channel; the feeding channel is provided with a product drawing mould; each left drawing hydraulic cylinder body is mounted on the left part of the framework; each right drawing hydraulic cylinder body is mounted on the right part of the framework; the left trolley is internally provided with a left clamp; each of the upper part and the lower part of the left clamp is in a wedged shape and is in sliding fit with the left trolley; the left trolley is provided with a left pressing hydraulic cylinder; the right trolley is internally provided with a right clamp; each of the upper part and the lower part of the right clamp is in a wedged shape and is in the sliding fit with the right trolley; the right trolley is provided with a right pressing hydraulic cylinder; the framework is internally provided with public guide rails. According to the hydraulic continuous drawing machine, the framework is of a vertical structure, so that a product is vertically clamped by the left clamp and the right clamp and the machining quality is guaranteed.

Owner:XIAN METALWK HYDRAUMATIC MACHINERY

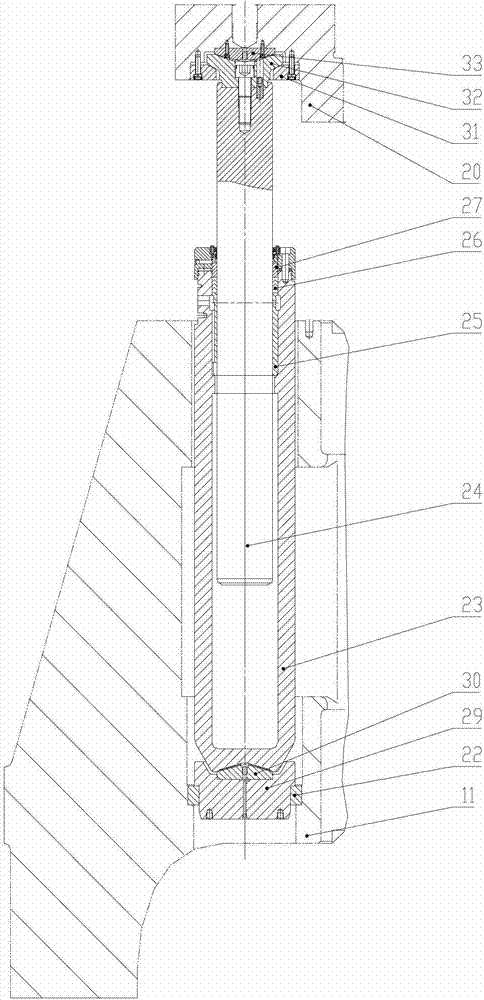

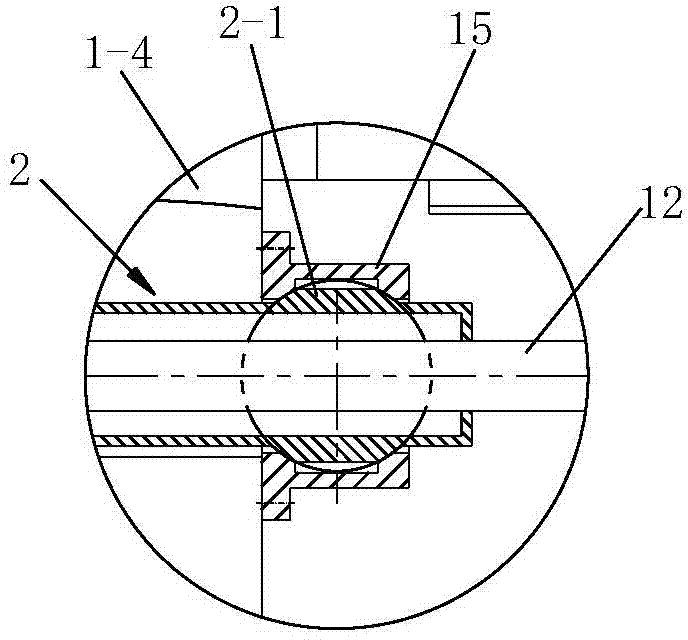

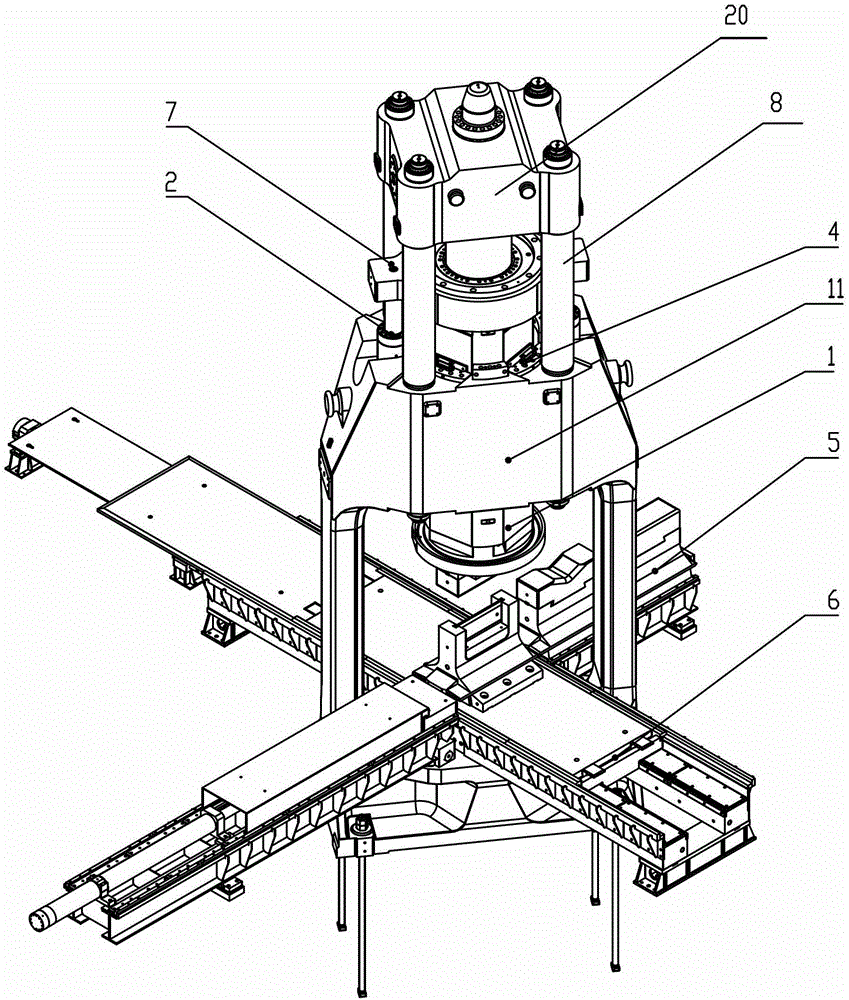

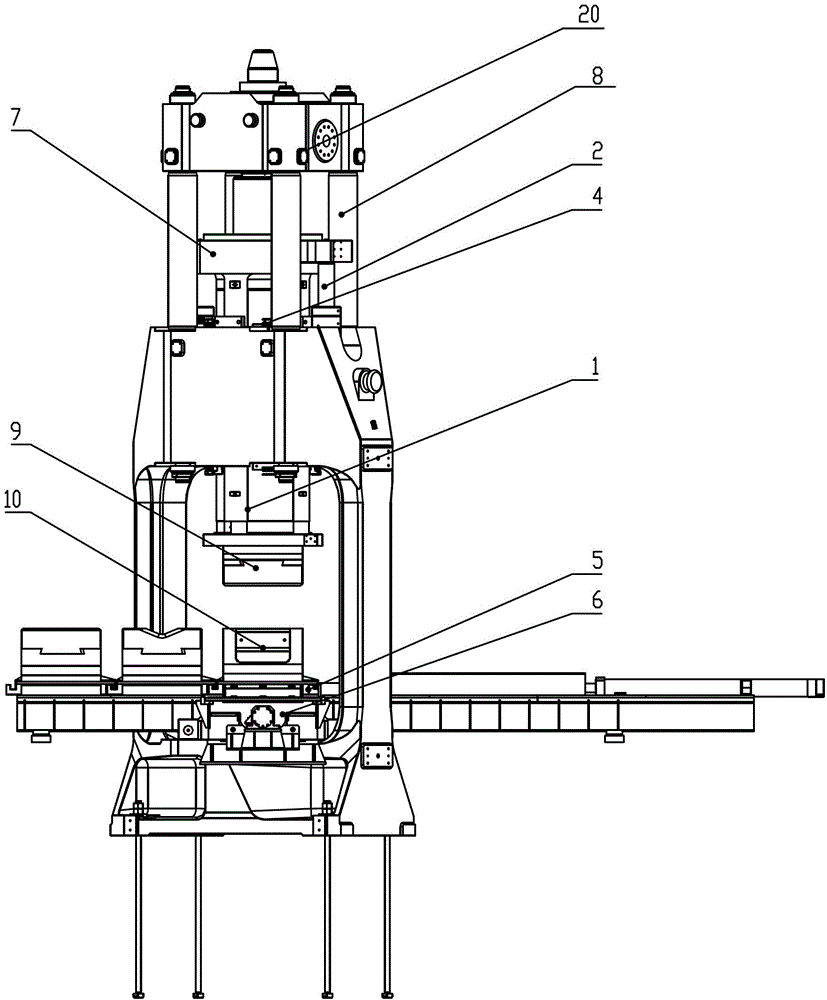

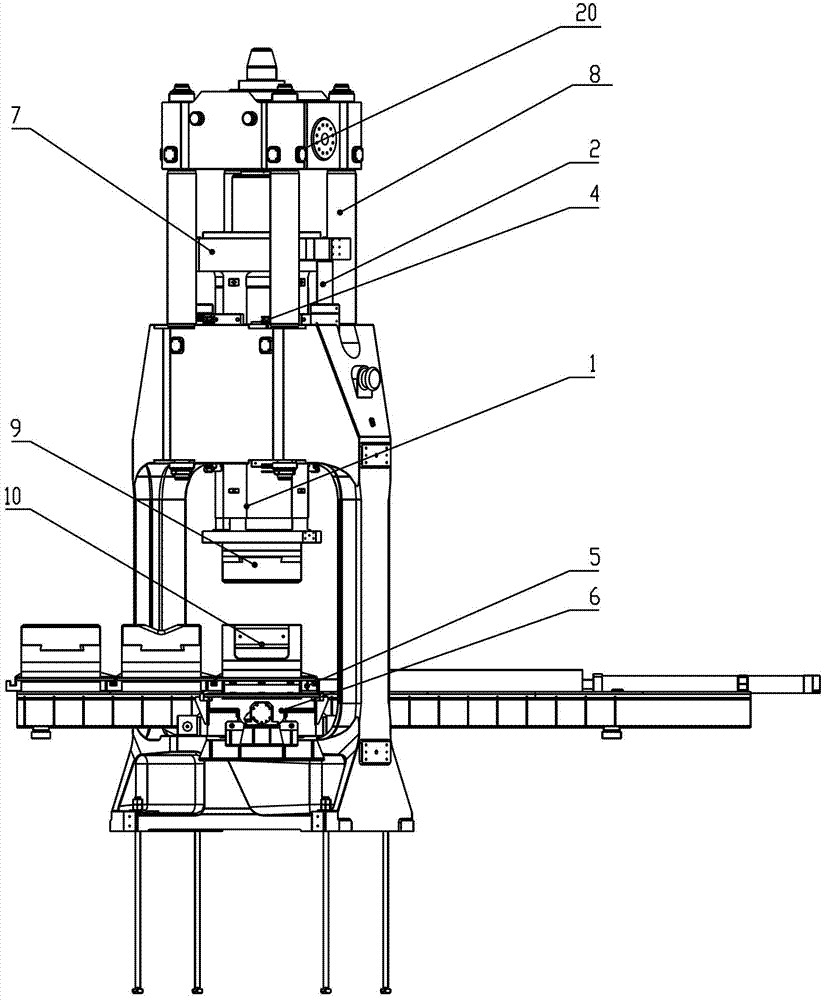

Forging machine with return cylinder anti-unbalance-loading mechanisms and assembling method and using method thereof

ActiveCN103111573AExtended service lifeExtend your lifeFluid-pressure actuatorsForging press drivesPre stressingPiston cylinder

The invention relates to a forging machine with return cylinder anti-unbalance-loading mechanisms and an assembling method and a using method of the forging machine. The forging machine comprises a main machine frame, an upper fixed beam, a pre-stressed pull rod, a movable beam, a return cylinder, a plunger piston cylinder, a guiding device, a mobile working table, a transverse moving anvil, an upper anvil and a lower anvil. The return cylinder comprises a return cylinder body and a return cylinder plunger piston, wherein the return cylinder body and the return cylinder plunger piston are matched with each other. The anti-unbalance-loading mechanisms are respectively arranged between the upper end of the return cylinder plunger piston and the upper fixed beam and between the lower end of the return cylinder body and the main machine frame, wherein spherical surfaces of the anti-unbalance-loading mechanisms contact each other, and the anti-unbalance-loading mechanisms are displaced relatively. The forging machine with the return cylinder anti-unbalance-loading mechanisms and the assembling method and the using method of the forging machine have the advantages that the upper end and the lower end of the return cylinder are both provided with the anti-unbalance-loading mechanisms, and therefore when the return cylinder receives unbalance loading, the return cylinder plunger piston is guaranteed to move freely and cannot suppress strength, and the service life of the return cylinder plunger piston is prolonged. The return cylinder plunger piston sealing and each part of sealing inside an inner cavity are protected, and the service life of a sealing element and a copper bush is prolonged. The anti-unbalance-loading capacity of a return cylinder plunger piston structure is strengthened, and the stationarity of forging machine running is strengthened.

Owner:青岛海德马克智能装备有限公司

Chemical pump filter device

The invention discloses a chemical pump filter device, which comprises a pump body and an inlet pipeline, wherein the inlet pipeline is connected on the inlet of the pump body, and a filter is arranged on the inlet pipeline. The filter is a filter bag, the filter bag is arranged below the inlet pipeline through an interface, and one end of the filter bag extends into the inlet pipeline. The filter with the simple structure in the device can effectively filter impurities in liquid so that the impurities do not enter the chemical pump, the service life of an impeller is prolonged, the seal is protected and the perfectness rate of the chemical pump is improved.

Owner:JIANGSU LINGFEI CHEM

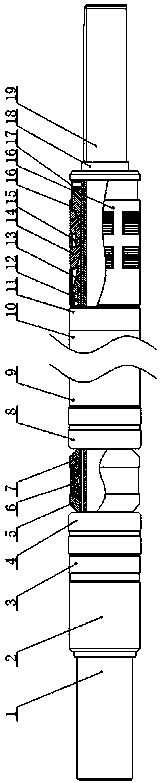

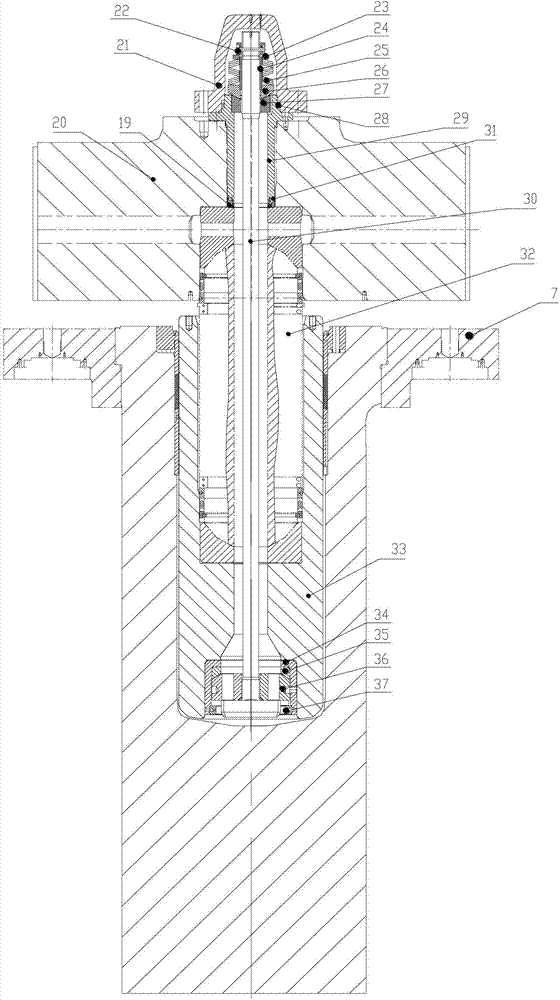

High-temperature high-pressure large-drift-diameter hydraulic sleeve packer

InactiveCN103590780AProtective sealImprove pressure bearing capacitySealing/packingHigh pressureTemperature resistance

The invention relates to a high-temperature high-pressure large-drift-diameter hydraulic sleeve packer which comprises an inner central tube, a combined sealing rubber cylinder part, a setting piston part, a locking part, a slip set and an outer central tube, wherein the combined sealing rubber cylinder part, the setting piston part, the locking part, the slip set and the outer central tube are connected to the inner central tube in a sleeved mode. The front end of the inner central tube is connected with an upper connector in a screwed mode, a release sleeve is connected to the outer side of the upper connector, and the lower portion of the release sleeve is connected with a balancing connector in a screwed mode. A core sleeve is sleeved with the combined sealing rubber cylinder part, the inner central tube is sleeved with the core sleeve, and the upper end of the core sleeve is connected with the balancing connector in a screwed mode. The combined sealing rubber cylinder part comprises a rubber cylinder and a metal net, an upper guide ring and a lower guide ring butt against the upper side of the combined sealing rubber cylinder part and the lower side of the combined sealing rubber cylinder part, the upper guide ring is connected with the balancing connector in a screwed mode, the lower guide ring is connected with an oil drainage sleeve in a screwed mode, and the lower portion of the oil drainage sleeve is sequentially connected with a cylinder sleeve, the locking part and the slip set in a screwed mode. The setting piston part is arranged in the cylinder sleeve, the slip set is fixed into a slip sleeve through an upper cone and a lower cone, and the outer central tube is sleeved with the slip set in a wrapping mode. The high-temperature high-pressure large-drift-diameter hydraulic sleeve packer is high in pressure bearing capacity, high in temperature resistance, large in drift diameter, high in overall stability and long in effective separation time.

Owner:CHINA PETROLEUM & CHEM CORP

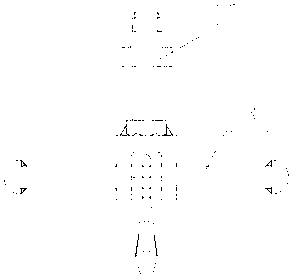

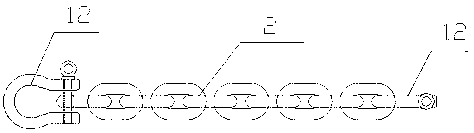

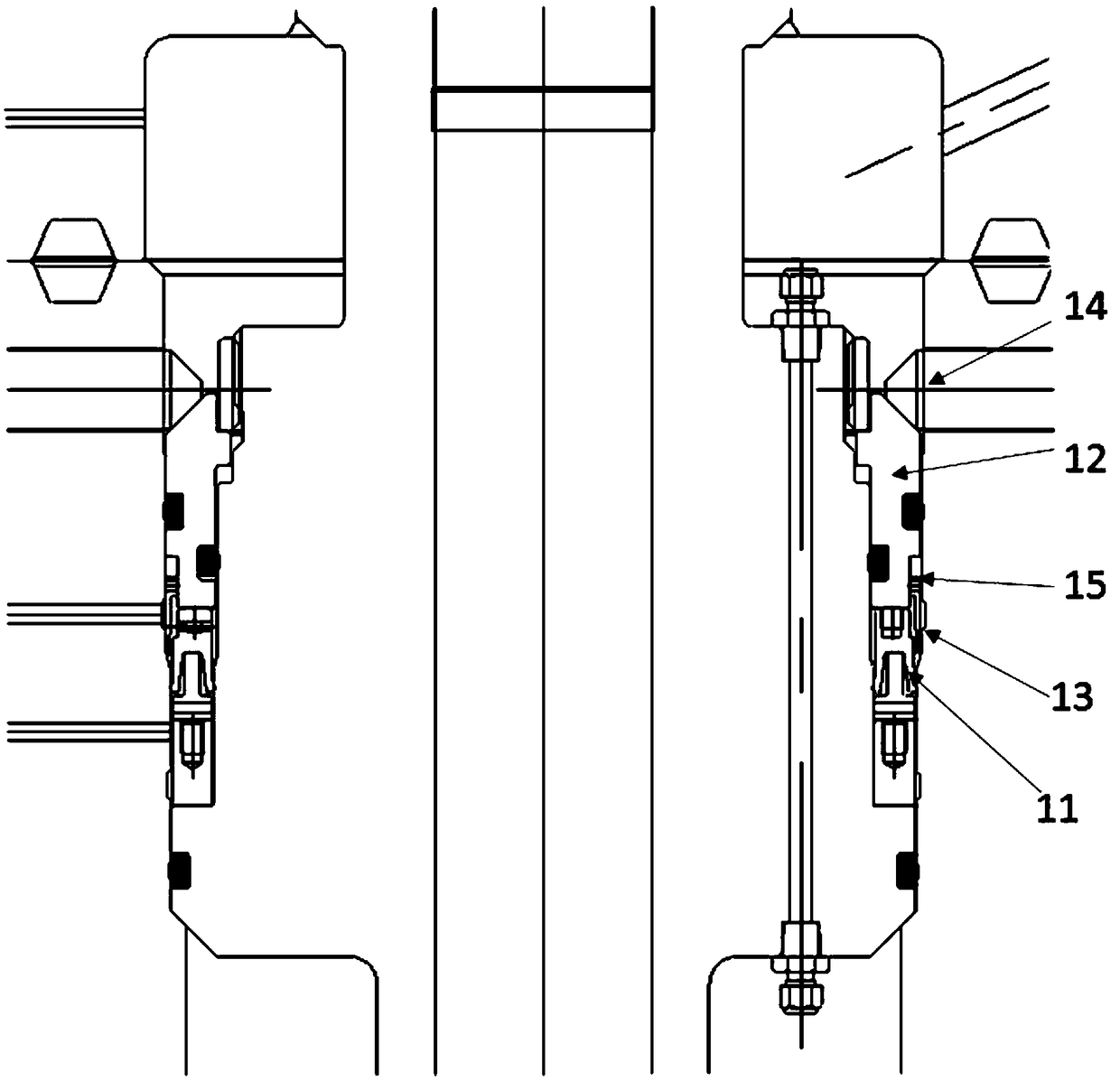

Continuous annealing furnace bottom cover plate quick disassembling and assembling device and disassembling and assembling method

ActiveCN110923436ASave installation timeControl the tightening forceFurnace typesProcess efficiency improvementJackscrewStrip steel

The invention relates to a continuous annealing furnace bottom cover plate quick disassembling and assembling device and disassembling and assembling method, and belongs to the technical field of cold-rolling strip steel production equipment in the metallurgical industry. According to the technical scheme, the periphery of a furnace shell (15) is fixedly and uniformly provided with four clamping grooves (14), each clamping groove (14) is provided with a corresponding fastening bolt (5), a corresponding screw of each fastening bolt (5) is in threaded connection with the corresponding clamping groove (14), hooks (6) are arranged on the bolt heads of the fastening bolts (5) correspondingly, a corresponding guide chain (2) is hung on the corresponding hook (6) of each fastening bolt (5), the lower ends of the guide chains (2) are connected to a fixing support (3), the fixing support (3) is fixed to a furnace bottom cover plate (1), and a reverse jackscrew (9) is in threaded connection withthe furnace shell (15) close to the furnace bottom cover plate (1). The device has the beneficial effects that the furnace bottom cover plate can be quickly disassembled and assembled, the time losscaused by furnace bottom cover plate disassembling and assembling is reduced, and the accident or maintenance treating time is shortened.

Owner:HANDAN IRON & STEEL GROUP +1

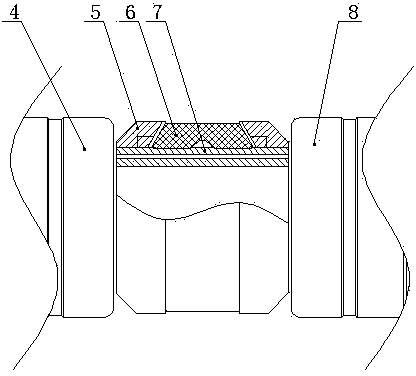

Seal assembly and slewing bearing using same

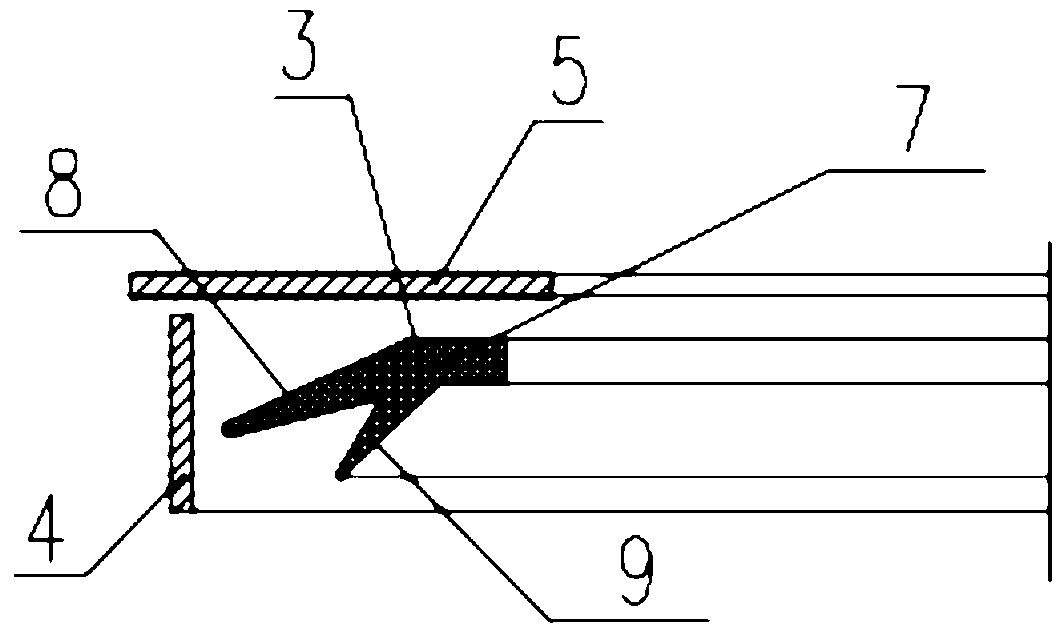

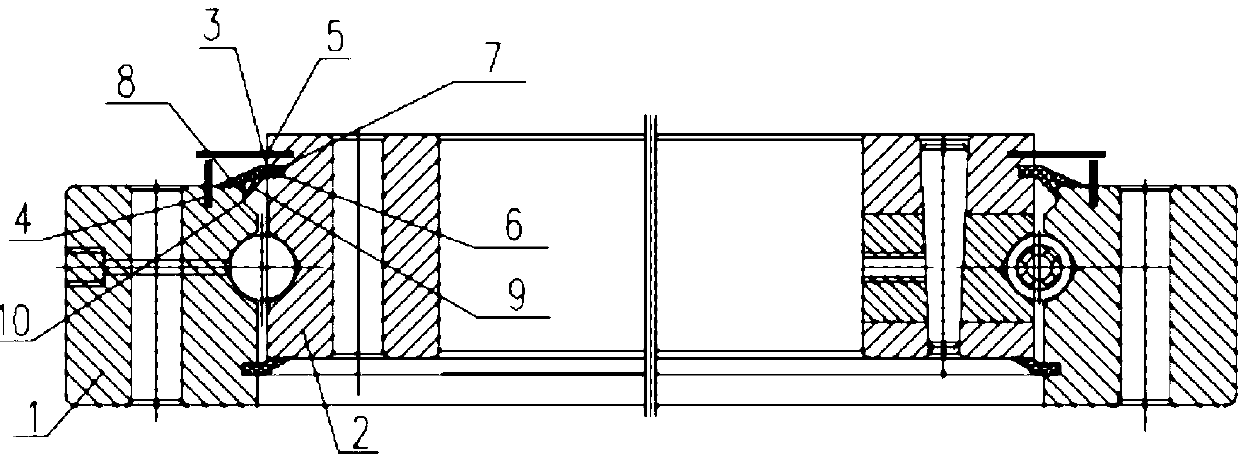

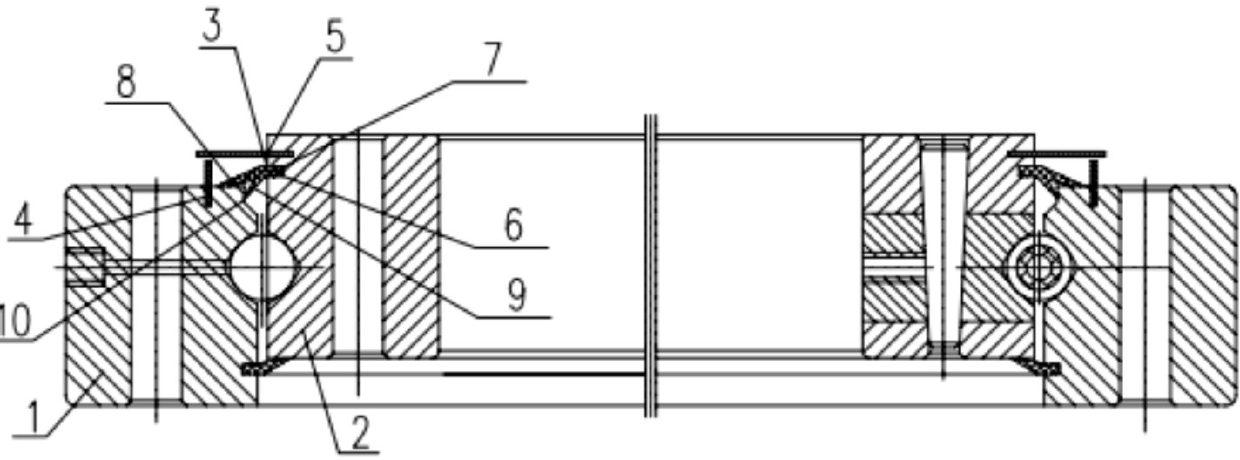

InactiveCN102705514AImprove sealingProtective sealEngine sealsBearing componentsEngineeringSlewing bearing

The invention discloses a seal assembly. The seal assembly is characterized by comprising a rubber seal (3) and a dust board, wherein the dust board and the rubber seal are arranged in a separated manner; the rubber seal comprises an inner oil lip and an outer oil lip, the inner oil lip and the outer oil lip are divergent and arranged in a'Y' shape; the outer oil lip (8) is thick and large and is arranged outside; the inner oil lip (9) is small and thin and is arranged inside; and the inner oil lip and the outer oil lip are connected to a rubber seal base (7). The dust board is arranged outside the rubber seal, better dustproof effect can be realized, and the rubber seal can be protected. The invention also discloses a slewing bearing applying the seal assembly. The outer oil lip of the rubber seal clings to the end face of an outer ring of the slewing bearing, and the inner oil lip is clings to an annular slope groove of an outer ring, thus sealing effect is enhanced.

Owner:LUOYANG LONGDA BEARING

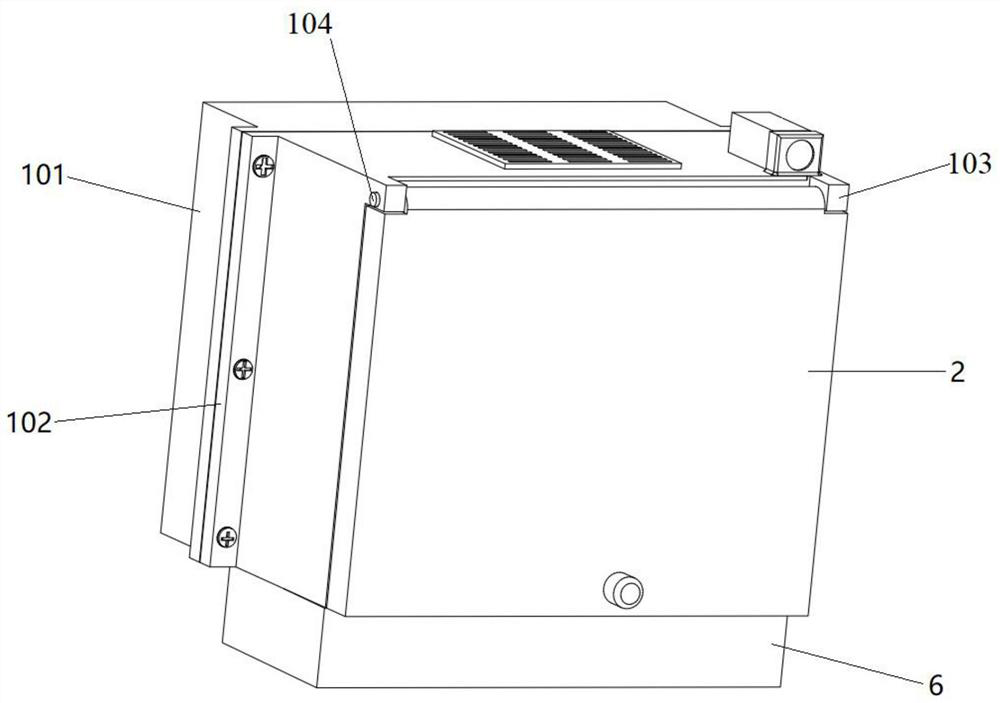

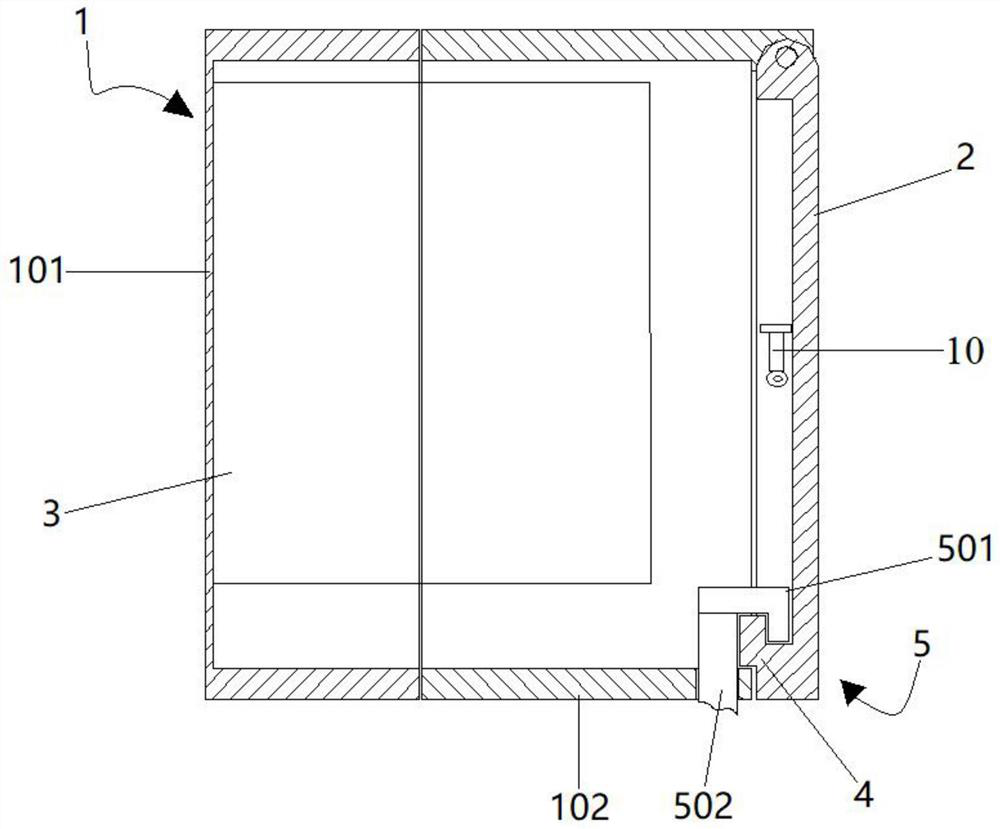

Circuit breaker with high safety

ActiveCN112201543AImprove the safety of useProtective sealProtective switch detailsElectric switchesPressure transmissionRemote control

The invention discloses a high-safety circuit breaker, which comprises a protection box body, a cover plate, a circuit breaker main body, lock hooks, lock catches and a control box, wherein the coverplate is used for sealing the protection box body, the circuit breaker main body is installed in the protection box body, a group of lock catches sliding in the protection box body is used for the lock hooks on the cover plate to cooperate, an air pressure transmission system used for driving the lock catches to slide is arranged in the control box, a remote control system used for remotely controlling the air pressure transmission system is arranged in the control box, the air pressure transmission system comprises a double-acting air cylinder, an electromagnetic reversing valve and an air pump, and the remote control system comprises a remote communication module, a mobile terminal and a control module. According to the technical scheme provided by the invention, the lock hooks on the cover plate are matched with the lock catches on the protection box body to realize the sealing of the protection box body so as to protect the internal circuit breaker main body, and a manager needs tosend an unlocking instruction through the mobile terminal to open the cover plate, so that the serious safety problem caused by randomly touching the circuit breaker by non-professionals is avoided,and the use safety of the circuit breaker is improved.

Owner:HXXN ELECTRICITY

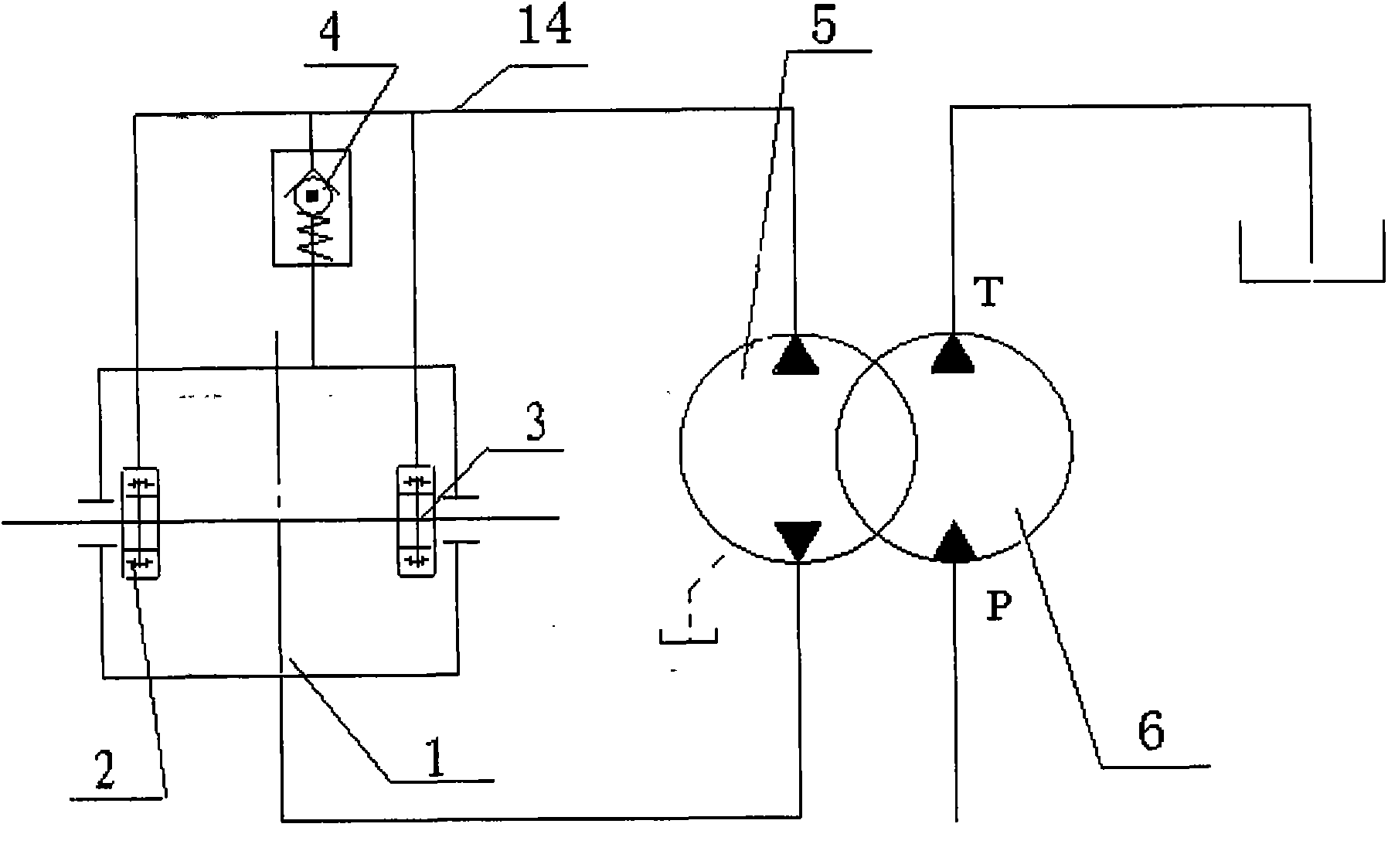

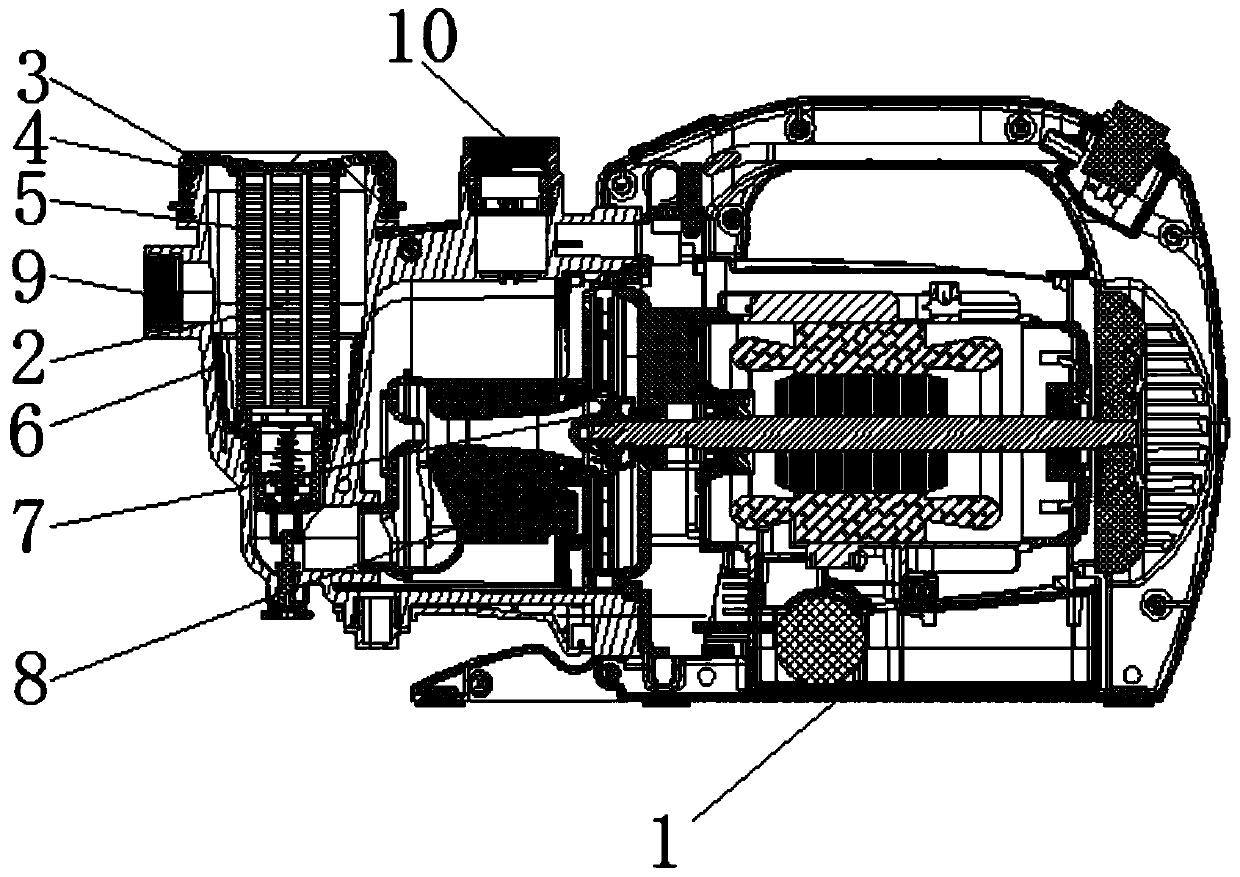

Forced lubrication system for cutting speed reducer of tunneller

InactiveCN103670403ALubrication mandatoryRealize forced lubricationGear lubrication/coolingDriving meansHydraulic motorLow speed

The invention relates to excavating and mining of large-slope coal mine tunnels, in particular to a forced lubrication system for the cutting speed reducer of a tunneller and solves the problem that when a traditional tunneller works at a slope of above 23 degrees, the bearing at the high-speed end or the low-speed end of the cutting speed reducer cannot be lubricated. Through the adoption of the forced lubrication system, the bearing at the high-speed end or the low-speed end of the cutting speed reducer can be lubricated above the level of lubricating oil. In a large-slope tunnel, when the tunneller goes up a slope to cut a roof, the bearing at the low-speed end of the cutting speed reducer is below the level of lubricating oil and thus cannot be lubricated; when the tunneller goes down the slope and the cutting head performs bottom sweeping, the bearing at the high-speed end of the cutting speed reducer is below the level of the lubricating oil and thus cannot be lubricated. A lubricating pump is driven by the hydraulic motor of a hydraulic system; when a cutting arm goes up and down, or rotates, lubricating oil at the bottom of the cutting speed reducer is pumped to the bearing cavities at the high-speed end and the low-speed end of the cutting speed reducer so as to provide forced lubrication for the bearings at the high-speed end and the low-speed end.

Owner:SHENYANG NORTH MINING MACHINERY

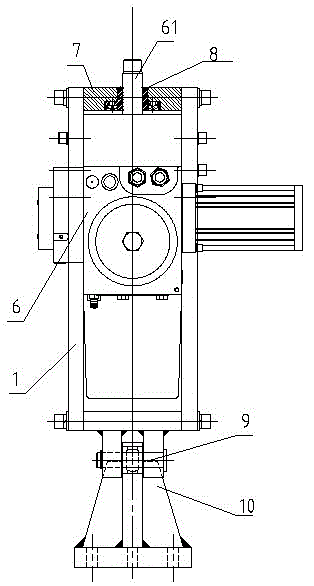

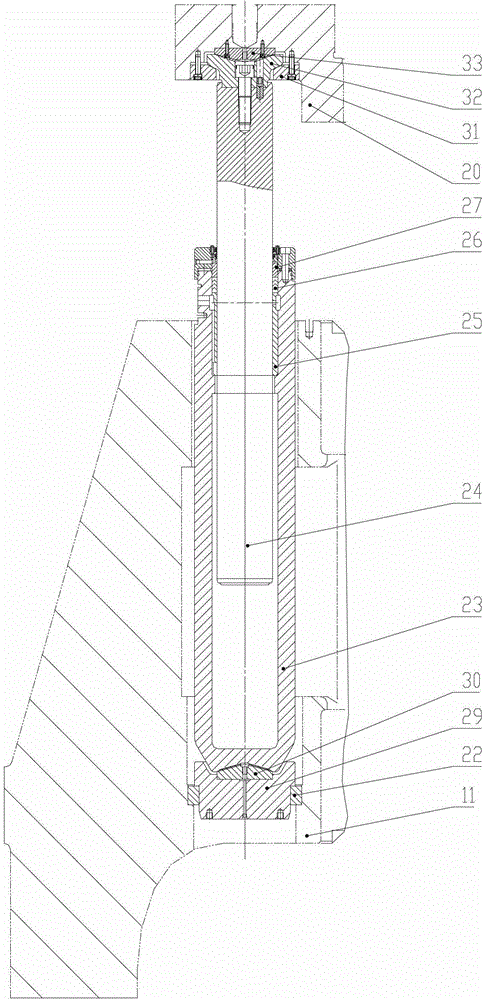

Integrated electric-hydraulic actuator type valve adjusting system for steam turbine

ActiveCN105041390AImprove reliabilitySolve the leakMachines/enginesEngine componentsActuatorControl theory

The invention provides an integrated electric-hydraulic actuator type valve adjusting system for a steam turbine. The valve adjusting system is characterized by comprising a lever, a valve and an integrated electric-hydraulic actuator, wherein the integrated electric-hydraulic actuator is fixed in a support, a guide supporting plate is fixed to an upper end opening of the support, a piston rod of the integrated electric-hydraulic actuator penetrates through a guide hole in the center of the guide supporting plate, the lower end of the support is installed on a base through a hinge shaft, the upper end of the piston rod of the integrated electric-hydraulic actuator is hinged to a power point of the lever, and all hinge shafts are in the same direction. The integrated electric-hydraulic actuator type valve adjusting system has the advantages that the integrated electric-hydraulic actuator serves as an electric-hydraulic conversion device, external power oil is not needed, and in this way, the problem that an original system leaks power oil is solved; the piston rod is protected and sealed, and therefore the reliability of the integrated electric-hydraulic actuator and the whole system is improved.

Owner:SHENYANG NORTHEAST ELECTRIC POWER CONTROL

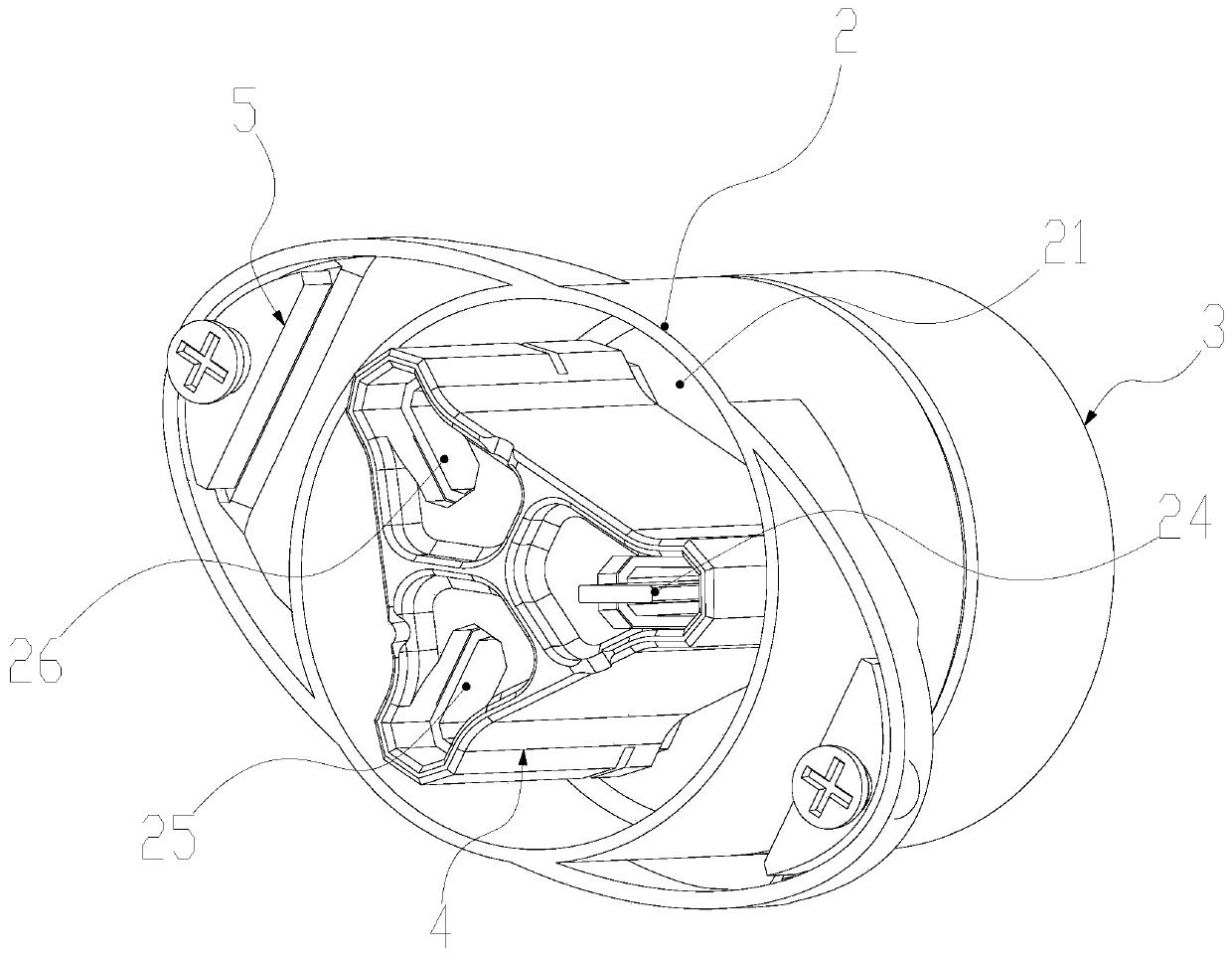

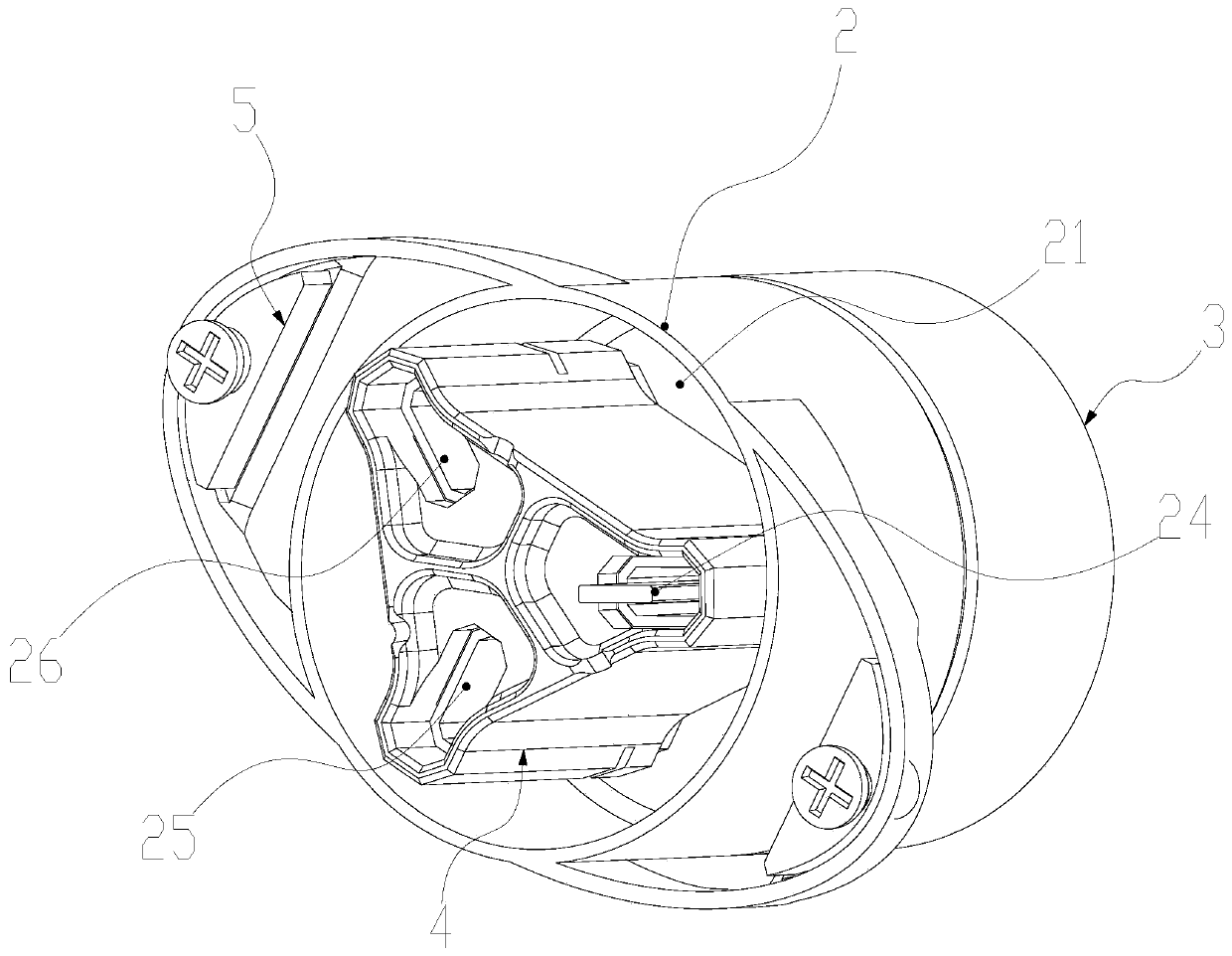

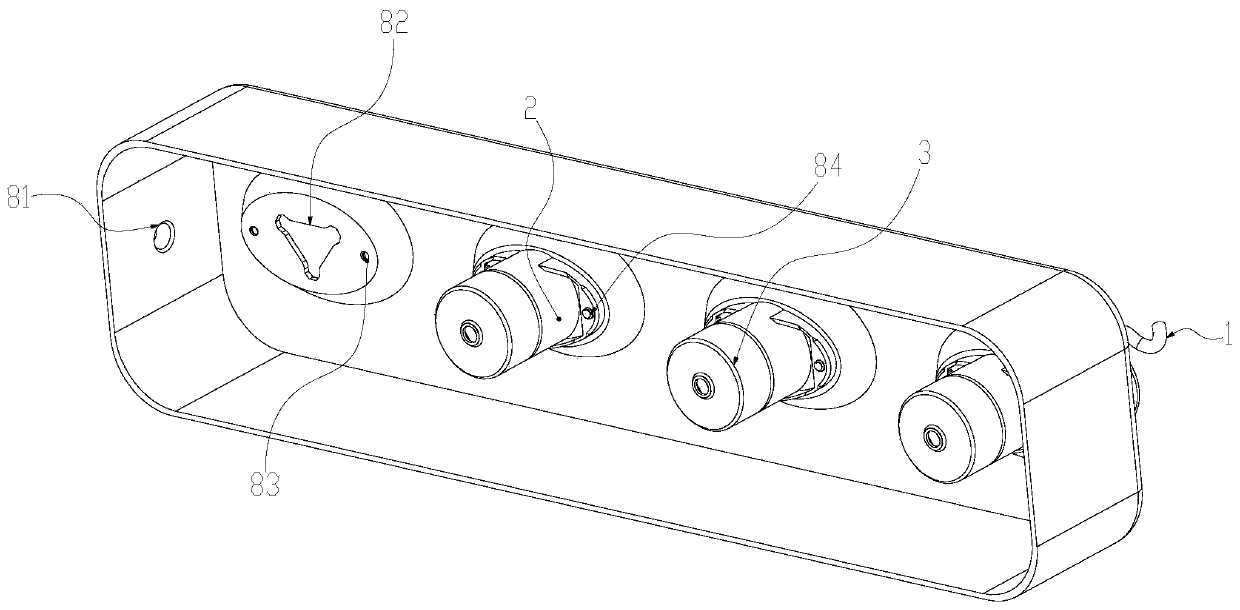

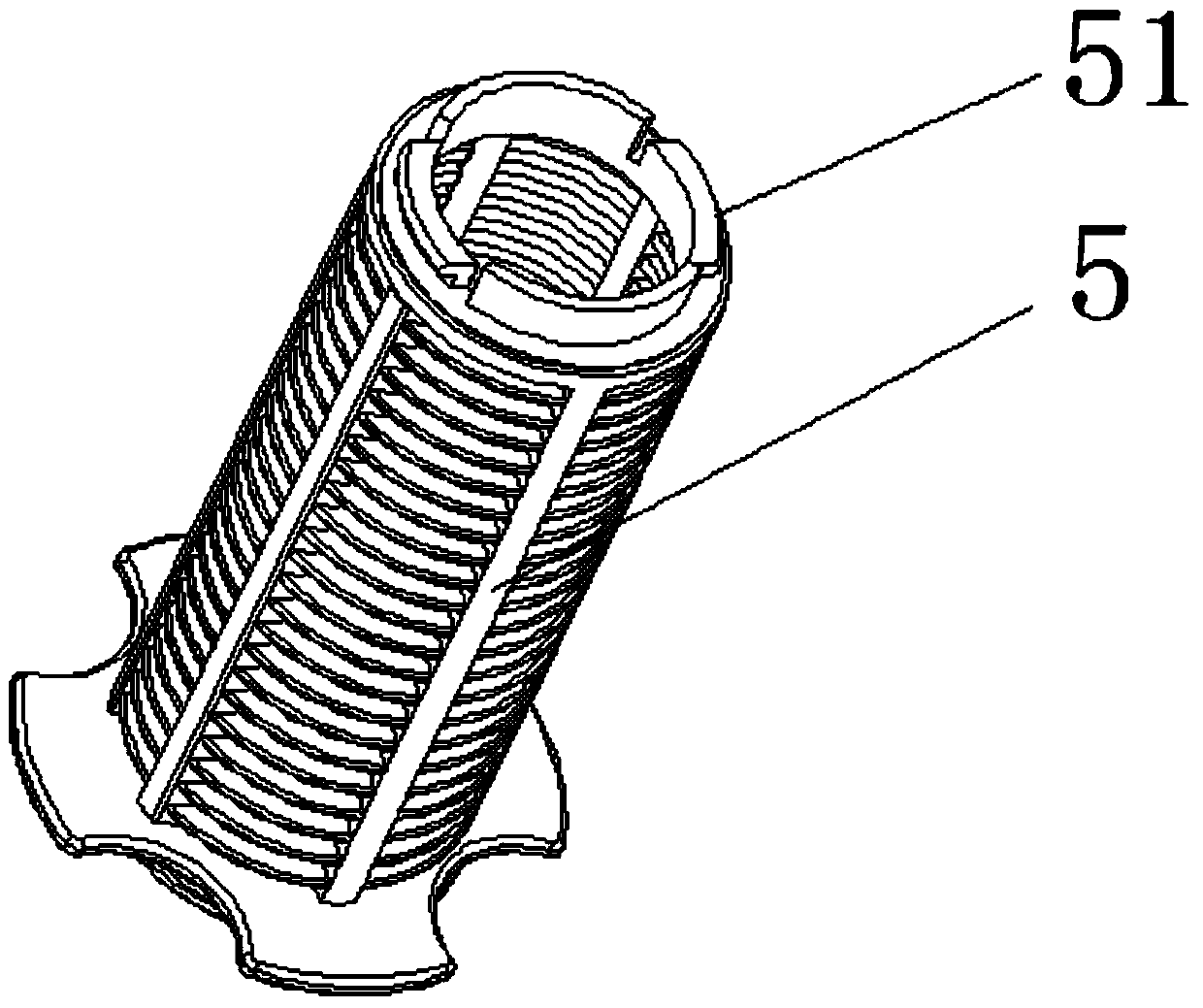

A waterproof coupling device

ActiveCN109462099BWith anti-shock designProtective sealOptical fibre/cable installationCouplings bases/casesCouplingModular design

The present invention relates to a coupling device, in particular to a waterproof coupling device, comprising an inserter, a coupler, a sealing cover, a data bridge module, a live wire bridge module and a neutral bridge module, and the inserter is provided with a live wire insert The input terminal, the neutral line insertion terminal, the data insertion terminal and the insulating layer covering the outer surface of the live wire insertion terminal, the neutral line insertion terminal and the data insertion terminal; the coupler is divided into a coupling chamber and a sealed cavity The external matching thread outside the chamber and the sealing chamber, the coupling chamber and the sealing chamber are separated by a barrier layer provided in the coupler, and the barrier layer is provided with a live wire coupling sleeve, a neutral wire coupling sleeve, a data Coupling sleeve, data through hole, live line through hole, neutral line through hole and sliding sleeve cooperate with the extension sleeve; the invention can be used immediately after insertion, one step in place, with anti-shock design; has multiple waterproof effects, can be used in water, and adopts Modular design for easy repair and replacement parts.

Owner:温州市鹿城区渊龙电器科技有限公司

Hydraulic continuous drawing machine

ActiveCN103447327BSimple structureNovel and reasonable designDrawing diesHydraulic cylinderEngineering

The invention discloses a hydraulic continuous drawing machine. The hydraulic continuous drawing machine comprises a framework, a left trolley, a right trolley, two left drawing hydraulic cylinders and two right drawing hydraulic cylinders, wherein the framework is of a vertical structure and is provided with a feeding channel and a discharging channel; the feeding channel is provided with a product drawing mould; each left drawing hydraulic cylinder body is mounted on the left part of the framework; each right drawing hydraulic cylinder body is mounted on the right part of the framework; the left trolley is internally provided with a left clamp; each of the upper part and the lower part of the left clamp is in a wedged shape and is in sliding fit with the left trolley; the left trolley is provided with a left pressing hydraulic cylinder; the right trolley is internally provided with a right clamp; each of the upper part and the lower part of the right clamp is in a wedged shape and is in the sliding fit with the right trolley; the right trolley is provided with a right pressing hydraulic cylinder; the framework is internally provided with public guide rails. According to the hydraulic continuous drawing machine, the framework is of a vertical structure, so that a product is vertically clamped by the left clamp and the right clamp and the machining quality is guaranteed.

Owner:XIAN METALWK HYDRAUMATIC MACHINERY

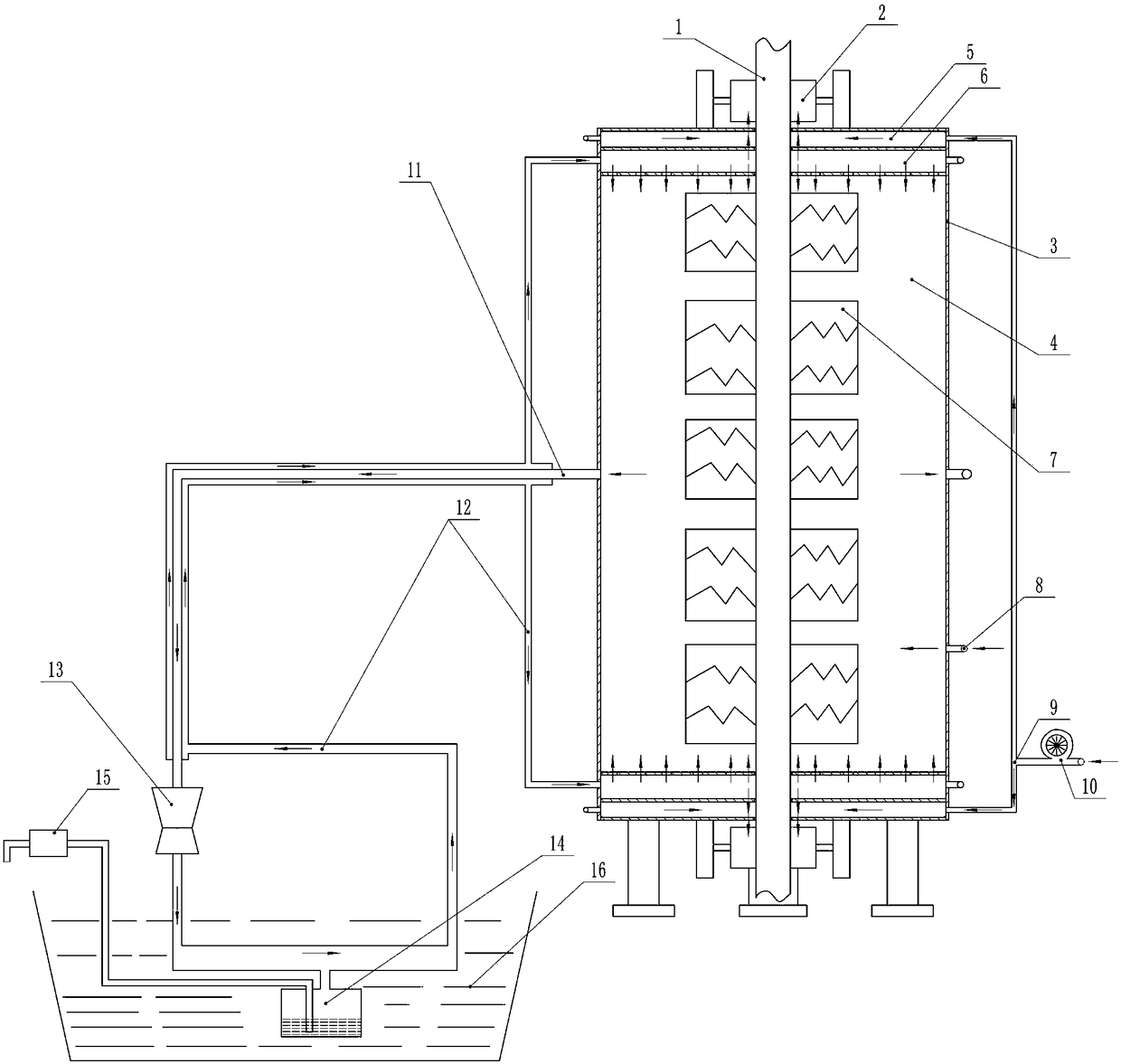

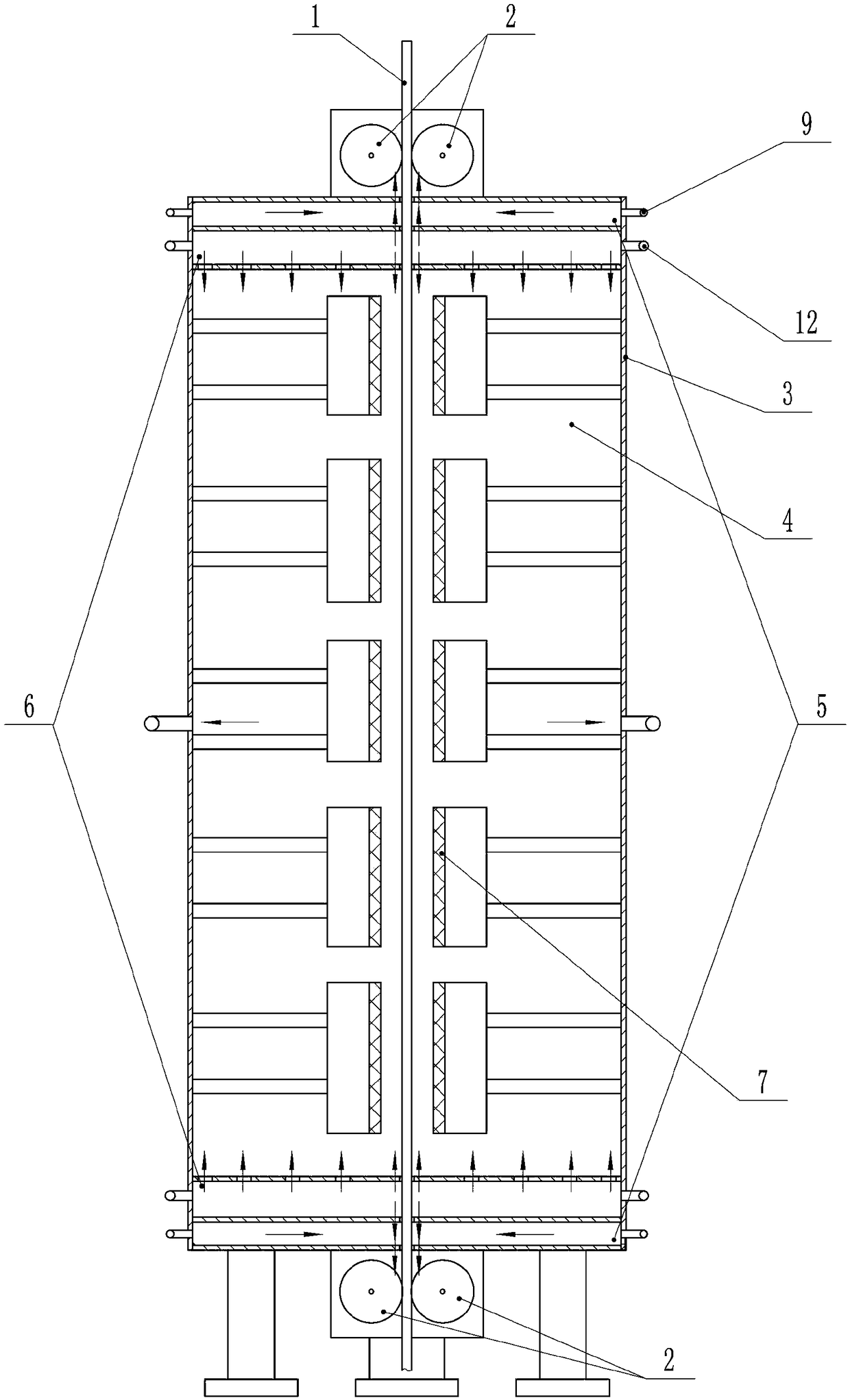

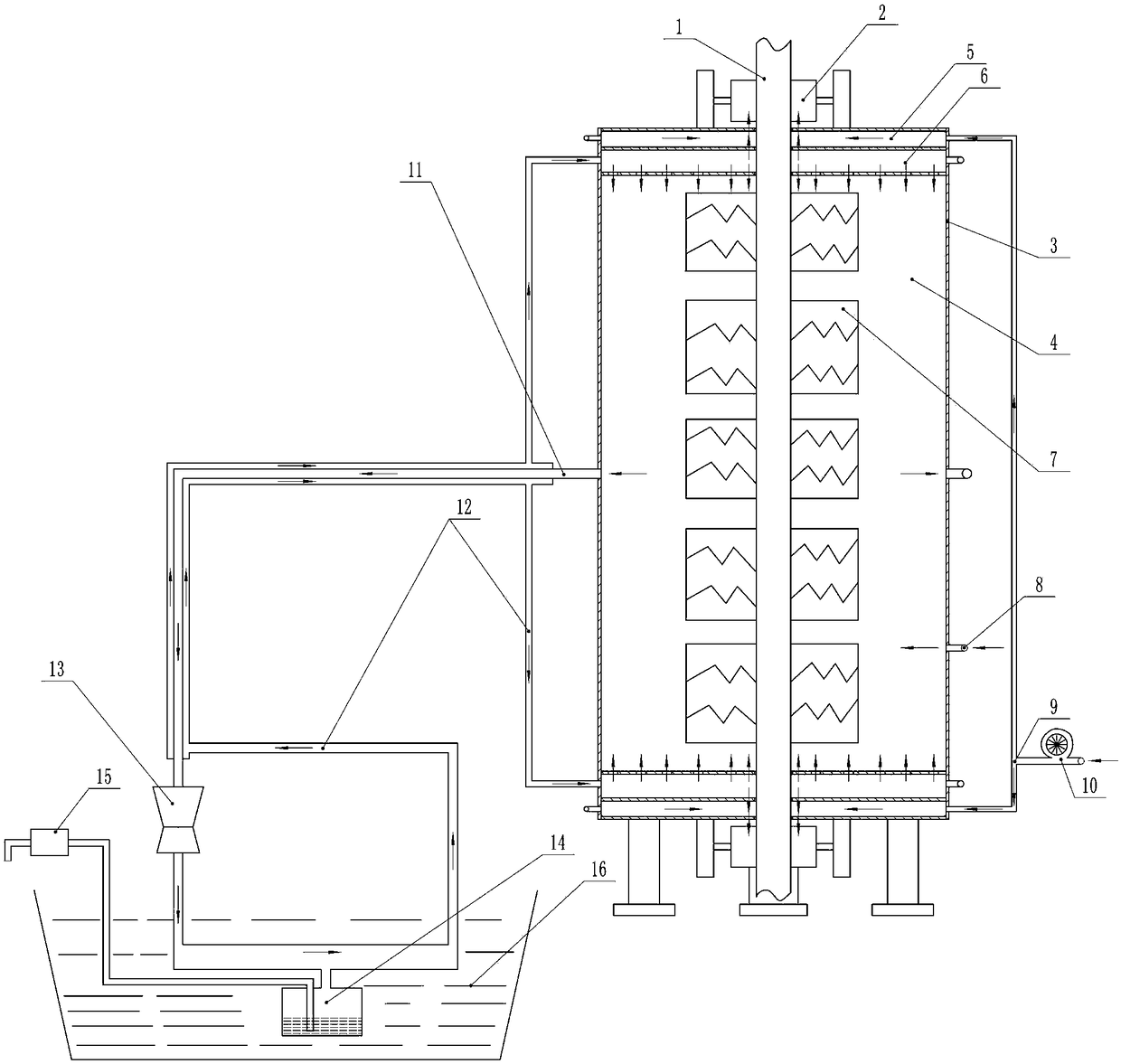

Nickel iron battery pulp belt drying device and method

ActiveCN108489233AAchieve sealingAchieving a protective seal over theFinal product manufactureDrying gas arrangementsShielding gasPulp and paper industry

The invention discloses a nickel iron battery pulp belt drying device which comprises a drying oven. A pulp belt penetrates through the drying oven; a protective gas balance chamber is arranged at anintersection part of the drying oven and the pulp belt, and communicates with the drying oven; and a circulating fan is arranged. The pulp belt penetrates through the balance chamber; an air sealing cavity is arranged at an intersection part of the balance chamber and the pulp belt, and communicates with the outside; and a sealing fan is arranged. The invention further provides a drying method based on the drying device. When the circulating fan works, a protective gas sequentially passes through a circulating pipeline, the balance chamber, and a gap at the intersection part of the drying ovenand the pulp belt from a drying oven chamber, and then re-enters the drying oven chamber so as to form protective gas circulation. The purpose is to provide the nickel iron battery pulp belt drying device and the nickel iron battery pulp belt drying method aiming at solving the problem that an existing drying oven cannot meet the requirement for continuously drying a battery pulp belt in the protective gas. According to the drying device and the drying method, the battery pulp belt can be continuously dried in the protective gas.

Owner:SICHUAN UNIV +1

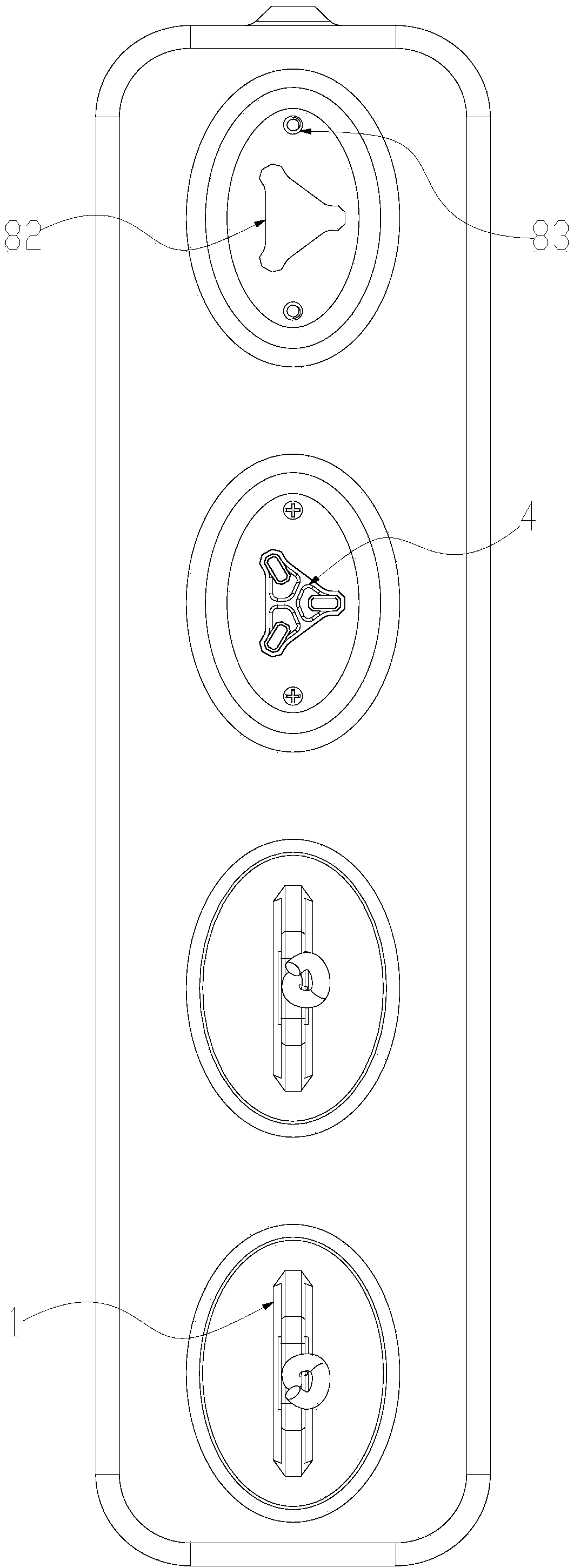

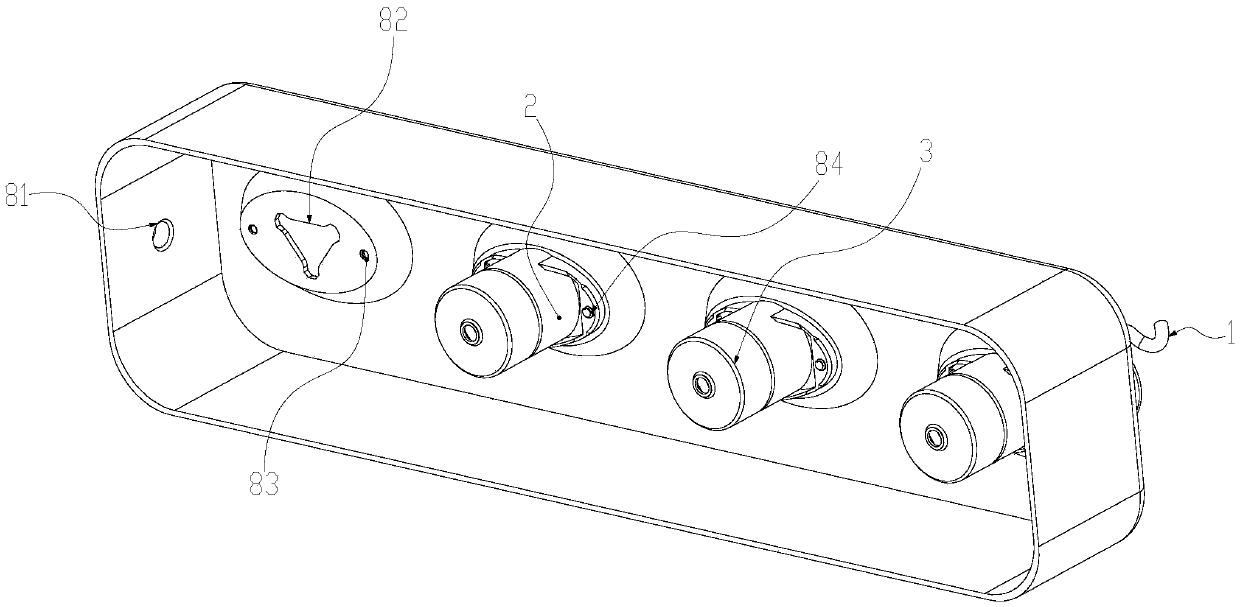

Waterproof coupling device

ActiveCN111175924AWith anti-shock designProtective sealOptical fibre/cable installationCouplingSoftware engineering

The invention relates to a coupling device. The waterproof coupling device comprises an inlaying device, a coupler, a sealing cover, a data bridging module, a live wire bridging module and a zero linebridging module, wherein the inlaying device is provided with a live wire inlaying end, a zero line inlaying end, a data inlaying end and insulating layers covering outer surfaces of the live wire inlaying end, the zero line inlaying end and the data inlaying end, the coupler is divided into a coupling chamber, a sealing chamber and an external matching thread outside the sealing chamber, the coupling cavity and the sealing cavity are separated through a blocking layer arranged in the coupler, and the blocking layer is provided with a live wire coupling sleeve, a zero line coupling sleeve, adata coupling sleeve, a data through hole, a live wire through hole, a zero line through hole and a sliding cylinder matching extension sleeve. The waterproof coupling device is advantaged in that thewaterproof coupling device can be used after being inserted in one step, and has an anti-electric shock design, the waterproof device has multiple waterproof effects, can be used in the water, adoptsa modular design, and is convenient to maintain and replace parts.

Owner:余成威

A device and method for drying iron-nickel battery slurry tape

ActiveCN108489233BAchieve sealingAchieving a protective seal over theFinal product manufactureDrying gas arrangementsElectrical batteryShielding gas

The application discloses a continuous drying device for iron-nickel battery slurry belt, which includes a drying furnace, the slurry belt runs through the drying furnace, and a protective gas equalization room is arranged at the intersection of the drying furnace and the slurry belt; the gas equalization room is connected with the drying furnace The dry furnace is connected and equipped with a circulating fan. The pulp belt runs through the equalization chamber, and an air-tight cavity is provided at the intersection of the equalization chamber and the pulp belt. The sealed cavity communicates with the outside world and is provided with a sealing fan. And a drying method based on the above-mentioned drying device. When the circulating fan is working, the protective gas passes through the circulation pipe, the equalization chamber, the gap between the drying furnace and the pulp belt in sequence from the drying furnace chamber, and then enters the drying furnace again. Dry the furnace chamber to create a protective gas circulation. The object of the present invention is to provide a continuous drying device and method for iron-nickel battery slurry belts in order to solve the problem that the existing drying ovens cannot meet the requirements of continuous drying of battery slurry belts in a protective gas. The drying device and method can continuously dry the battery slurry in the protective gas.

Owner:SICHUAN UNIV +1

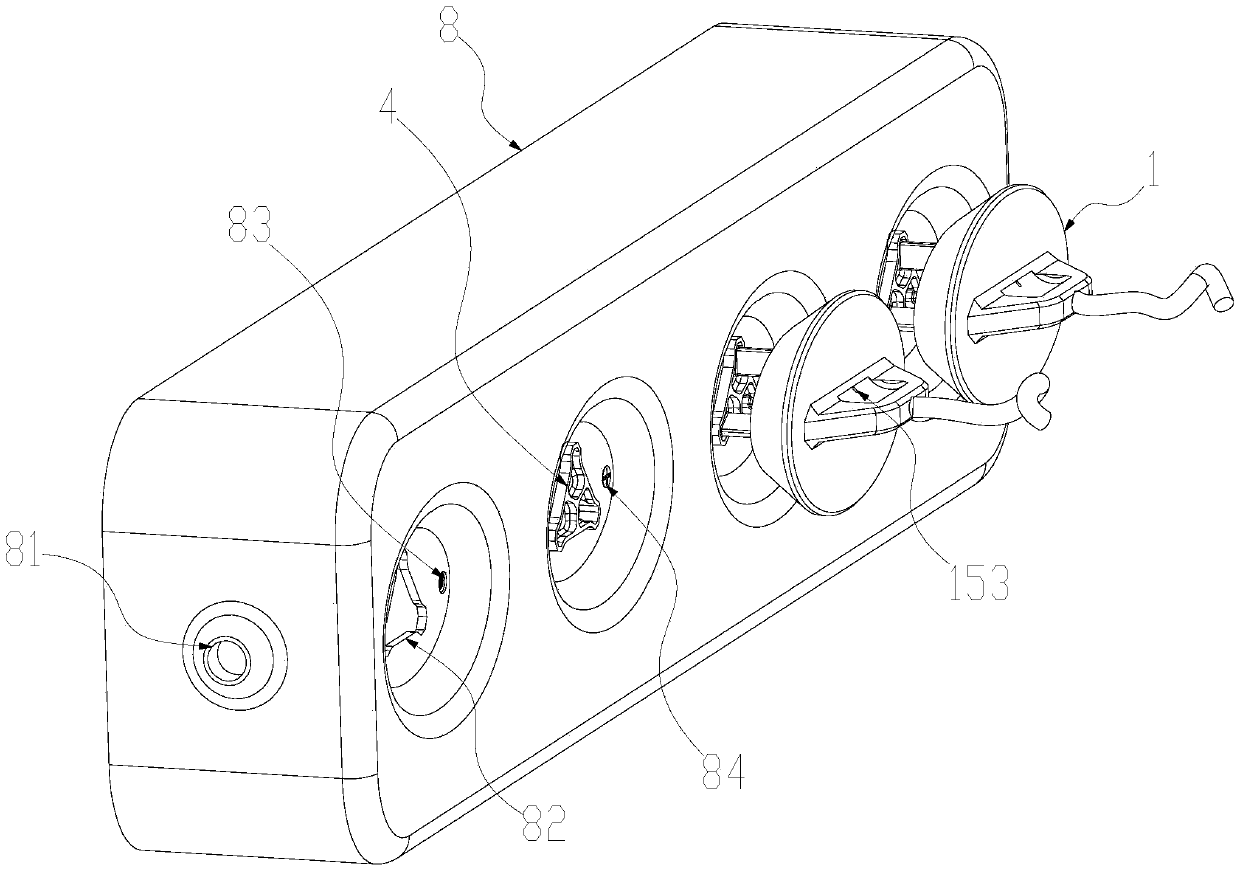

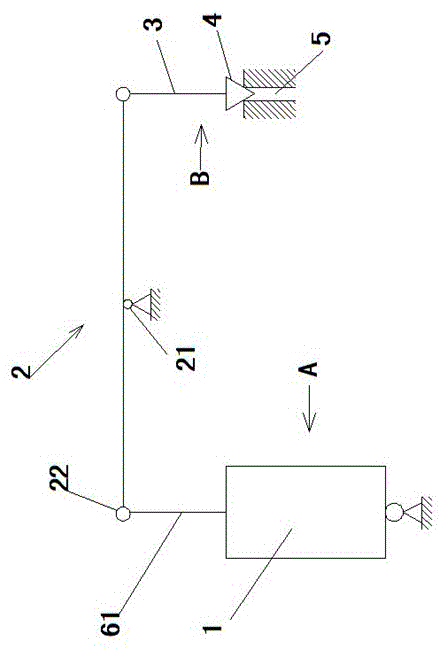

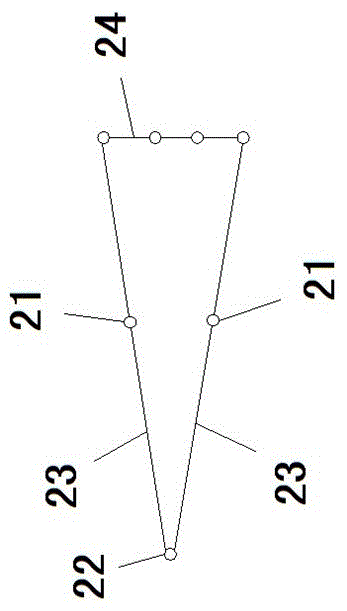

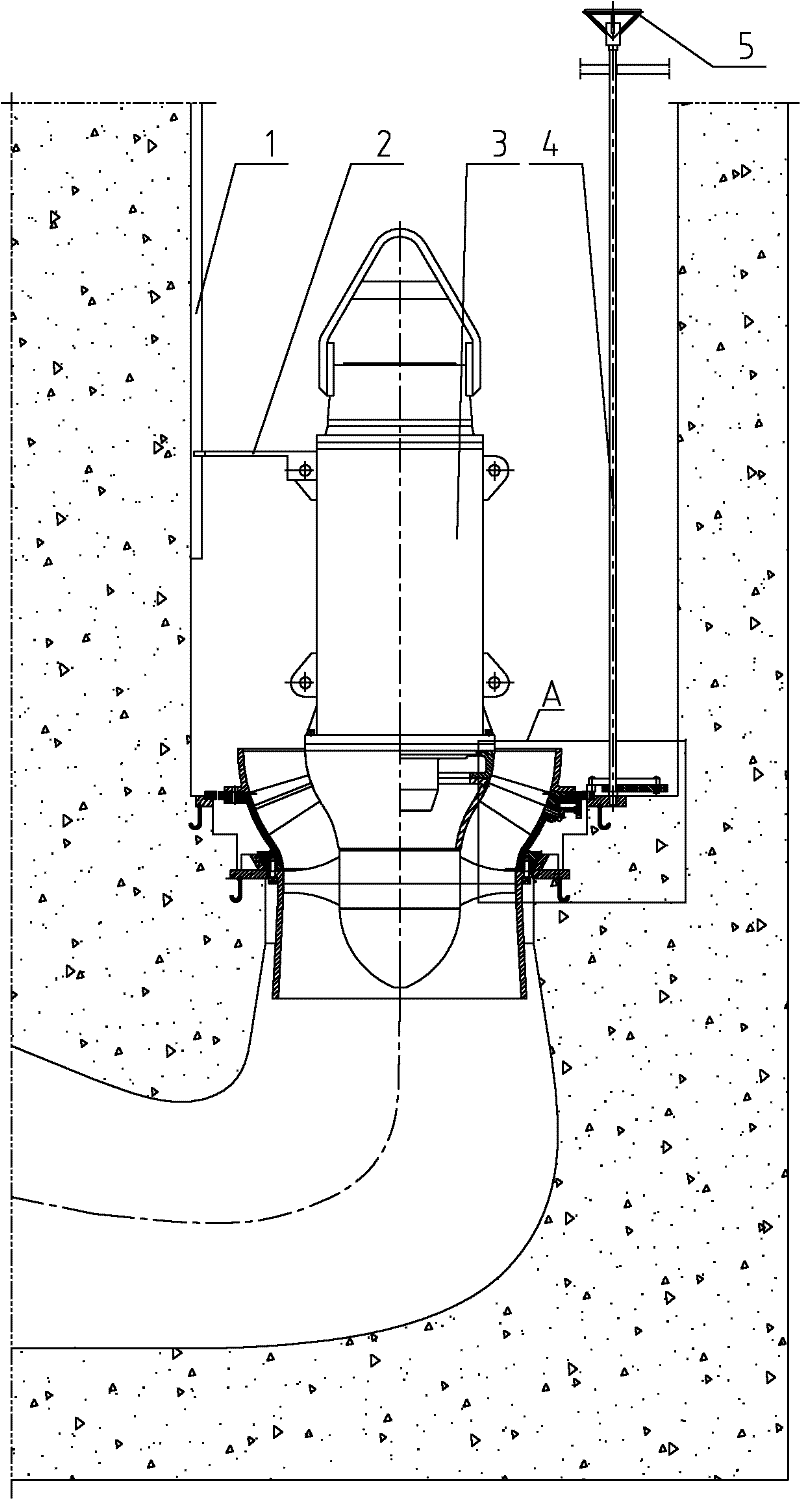

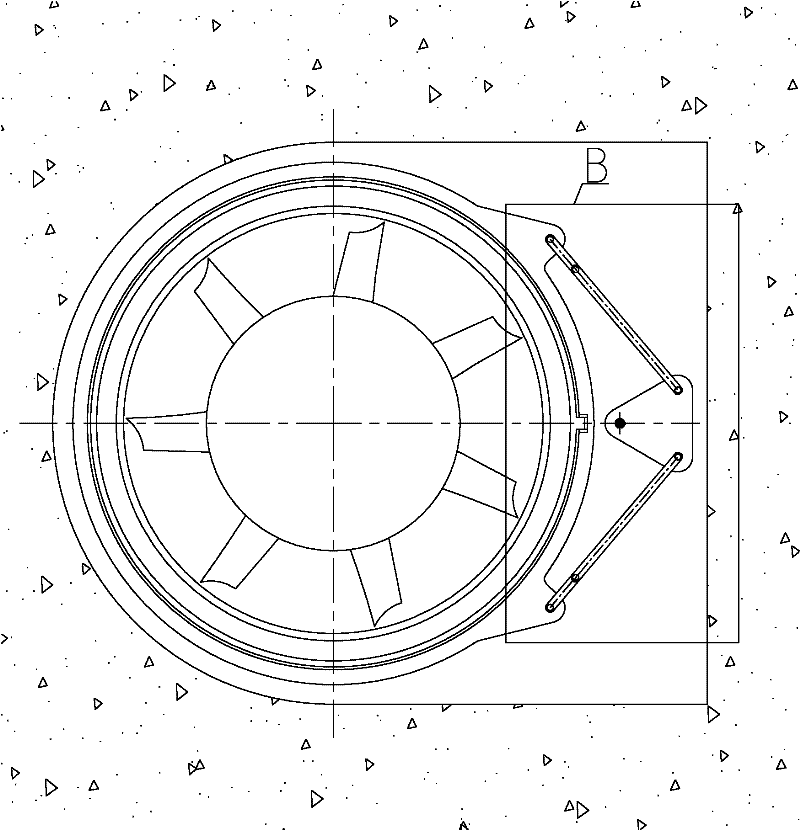

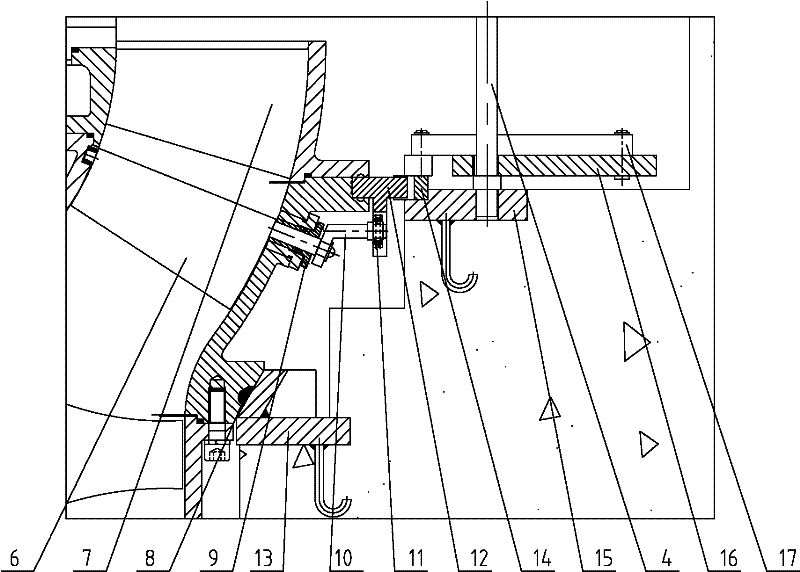

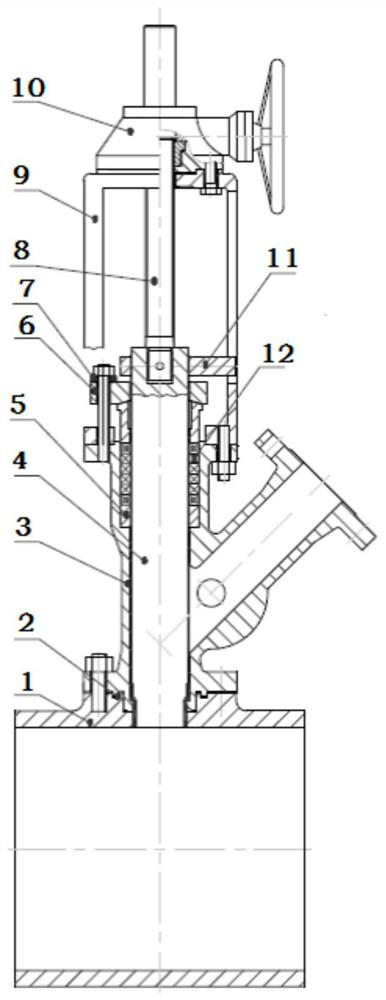

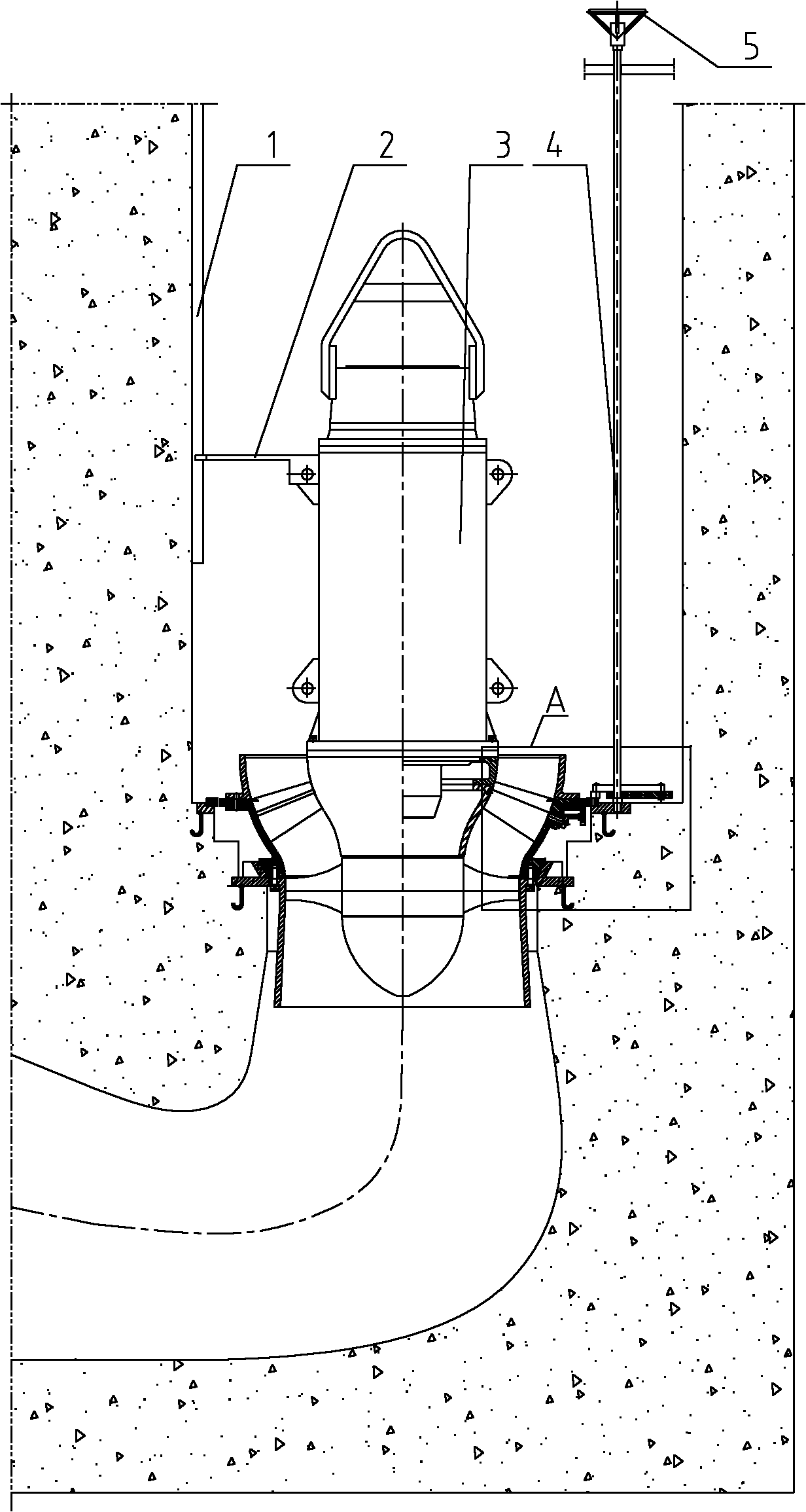

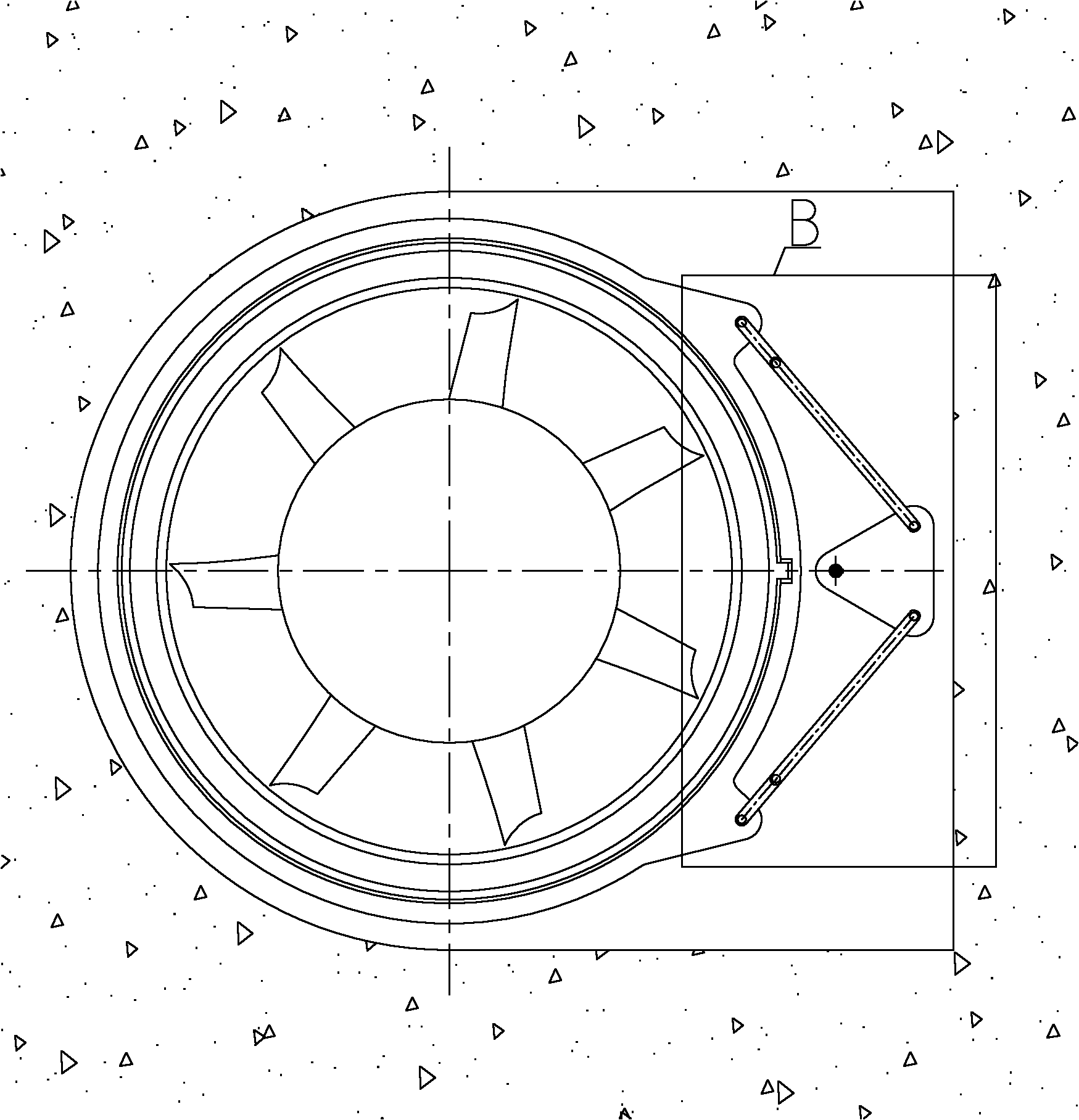

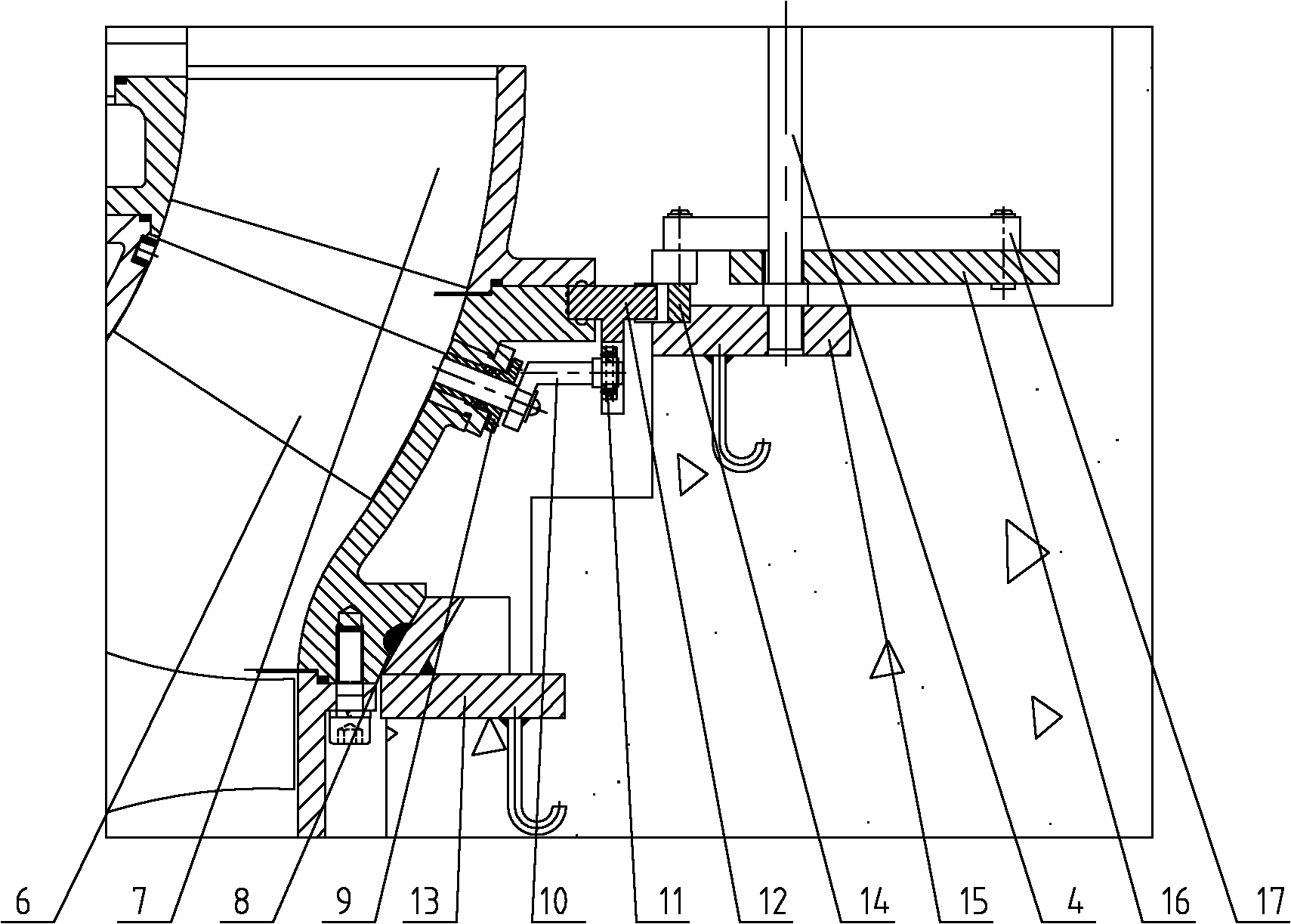

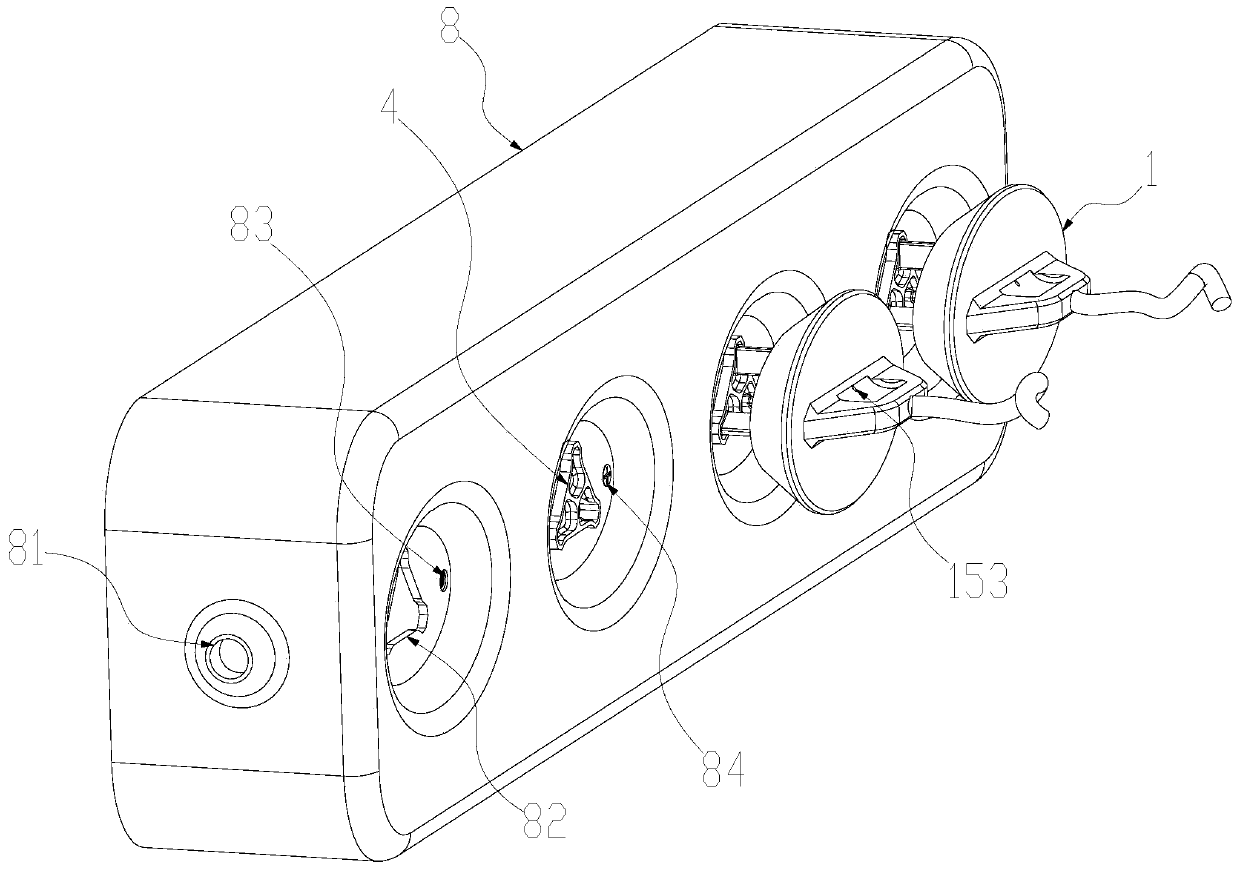

Guide vane angle regulating device for submersible pump

ActiveCN102022375BDoes not affect the main structureProtective sealPump componentsPumpsEngineeringSubmersible pump

The invention discloses a guide vane angle regulating device for submersible pumps, which is convenient to regulate the guide vane angle. The guide vane angle regulating device comprises a crank, a driven ring, a driving ring and a drive plate, wherein the driven ring and the driving ring are bonded and connected, one end of the crank is connected with the driven ring in a rotating mode, the other end of the crank is used for connecting and regulating the guide vane angle, a connecting mechanism for connecting the driving ring and the drive plate is arranged between the driving ring and the drive plate, and the drive plate is connected with a drive link. The guide vane angle regulating device can be used for regulating underground or underwater guide vane angle by ground operation. In theinvention, by means of the triangular drive plate and a connecting link device, the guide vane can be freely driven to rotate clockwise or anticlockwise. Meanwhile, the application of the crank ensures that the guide vane angle can be greatly changed only when the driving ring and the driven ring rotate by small distance.

Owner:LANSHEN GRP CORP LTD

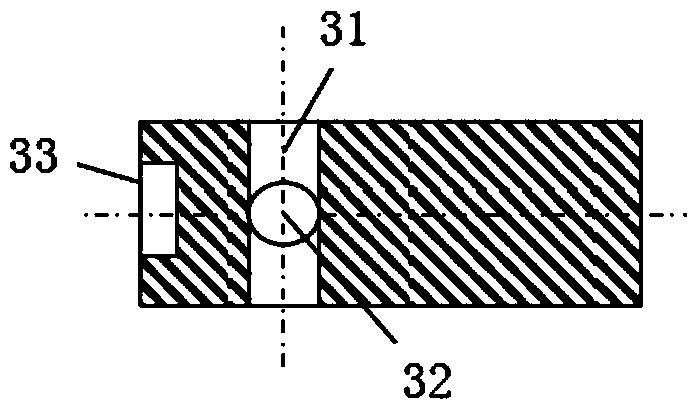

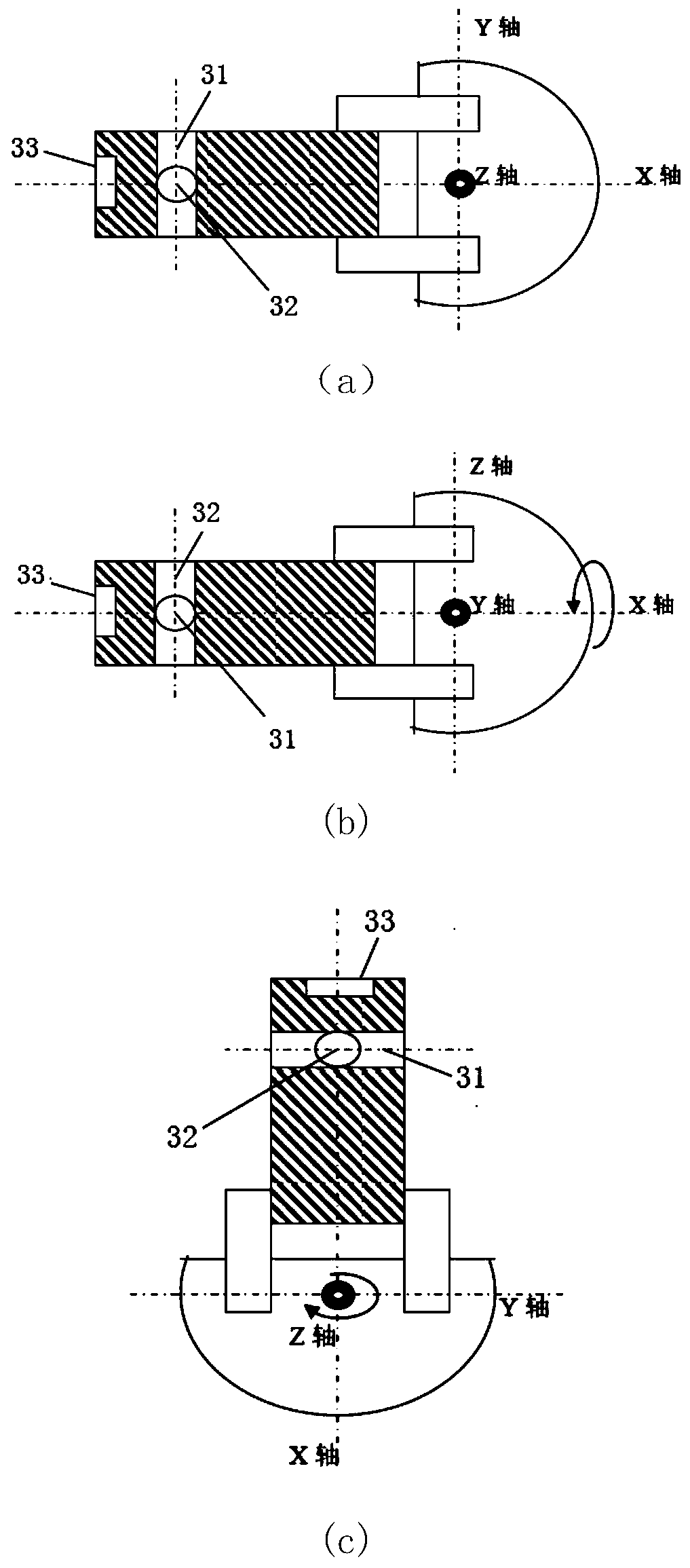

Bench vise with dual axis position adjustment and control

Owner:SHANGHAI INST OF TECH

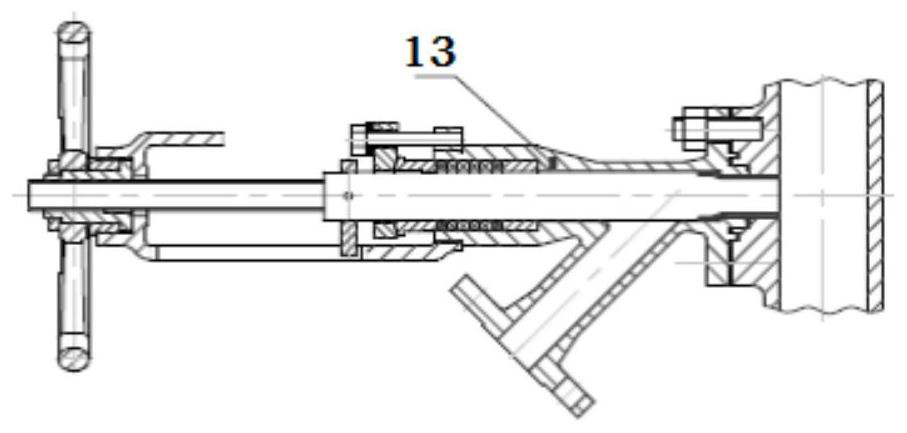

Discharge valve for slurry bed residual oil hydrogenation device

PendingCN114110187APrevent lingeringAvoid damageSpindle sealingsOperating means/releasing devices for valvesSlurryMechanical engineering

The invention belongs to discharge valves for dissimilar materials, and particularly relates to a discharge valve for a slurry bed residual oil hydrogenation device. A discharge valve for a slurry bed residual oil hydrogenation device comprises a valve body communicated with a main pipeline, a valve rod assembly is arranged in the valve body, the valve rod assembly is connected with a manual device at the top end and can be driven by the manual device to move up and down, and the valve body is provided with a hard alloy sealing face at the bottom of a middle cavity channel. A flushing opening is formed in the position, close to the middle cavity channel, of the Y-shaped outlet channel of the valve body, and a Y-shaped flushing valve is arranged at the position. The invention has the advantages that: the medium flows smoothly without residence; hard particles in the medium are prevented from damaging the plunger; medium residual oil is prevented from entering the filler; and reliable sealing of the plunger is ensured.

Owner:SUFA TECH IND CNNC

Steel pipe straightening machine hydraulic control system for quick opening cylinder and upper roll balance cylinder

ActiveCN105443466BEliminate hydraulic shockExtended service lifeServomotor componentsServomotorsControl systemHigh pressure

The invention discloses a hydraulic control system for a quick opening cylinder and an upper roll balance cylinder of a steel tube straightening machine. The hydraulic control system comprises a quick opening cylinder hydraulic control loop and an upper roll balance cylinder hydraulic control loop, wherein the quick opening cylinder hydraulic control loop comprises a high-low pressure oil source selecting device, an oil inlet throttling device, a high-pressure compensating device and an oil return throttling device; the upper roll balance cylinder hydraulic control loop comprises a first electromagnetic reserving valve connected to a rod cavity of the upper roll balance cylinder, an energy storage assembly and a three-way pressure relief valve which is selectively communicated to the rod cavity and a high-pressure oil source. The hydraulic control system for the quick opening cylinder and the upper roll balance cylinder of the steel tube straightening machine can effectively eliminate hydraulic impact of the quick opening cylinder, can prolong the service life of the quick opening cylinder, saves energy and reduces consumption, saves cost and effectively protects sealing of the quick opening cylinder.

Owner:TAIYUAN HEAVY IND

Novel high-pressure metal sealing component

The invention discloses a novel high-pressure metal sealing component. The metal sealing component is mounted on a high-pressure gas recovery wellhead device, and comprises a metal seal, a sealing pressure ring arranged on the upper side of the metal seal, and a sealing surface guard ring arranged on the side face of the metal seal; a cavity is reserved in the upper side of the sealing pressure ring, and the pressure is applied into the cavity to press the sealing pressure ring. The novel high-pressure metal sealing component has the advantages that the sealing pressure ring is designed separately, compression in the axial direction is achieved through pressure application, and the stress is uniform; the sealing surface guard ring is designed to protect the metal seal in the descending process of the metal seal.

Owner:MEIZUAN SHENHAI ENERGY TECH RES & DEV SHANGHAI CO LTD +1

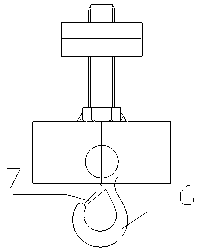

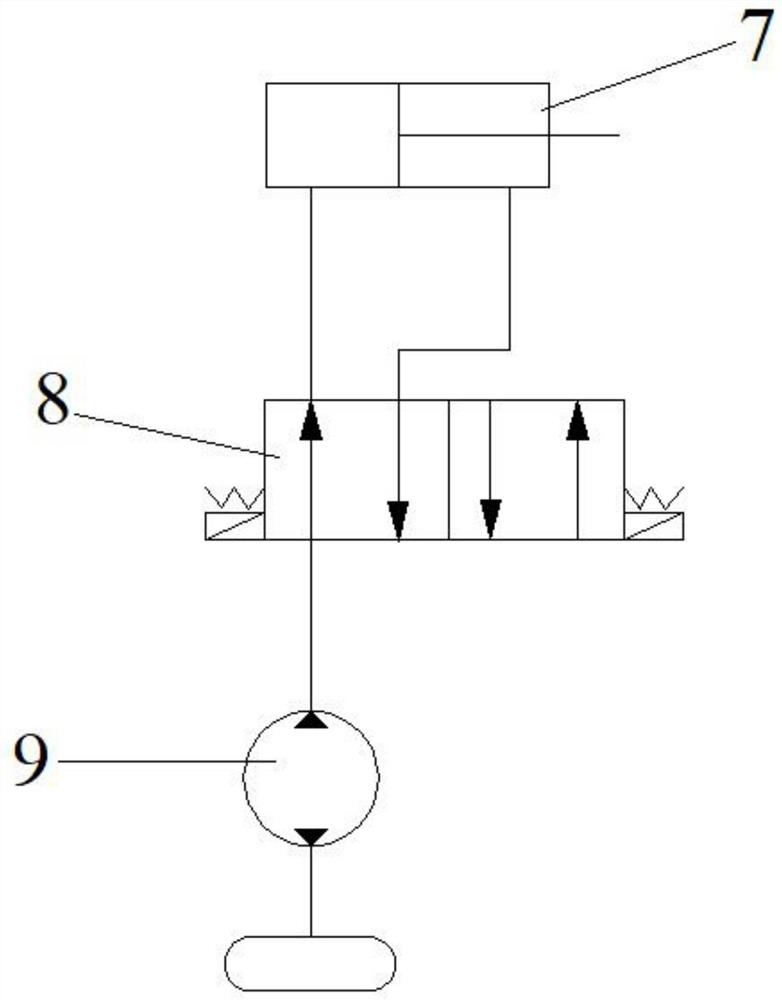

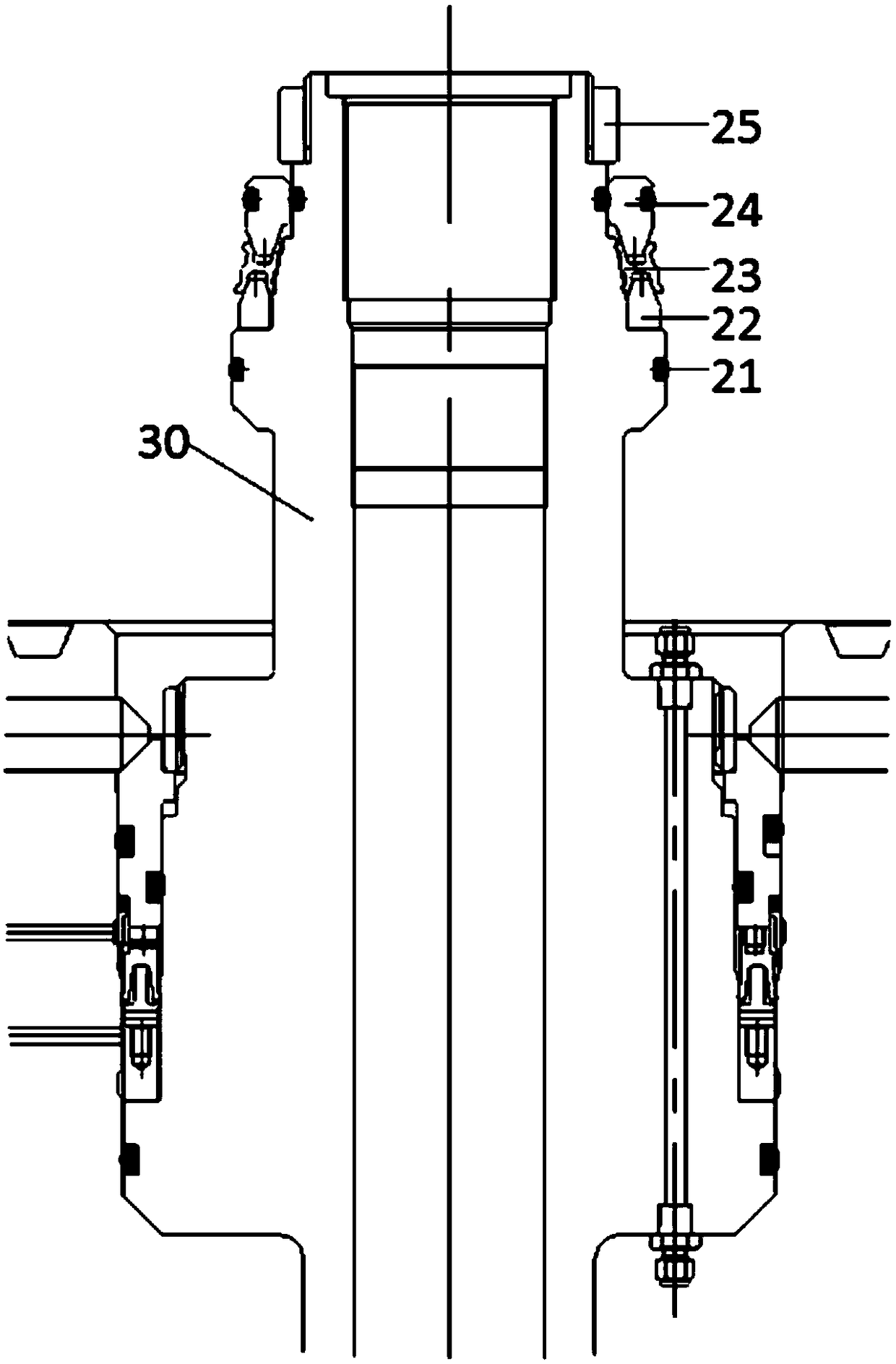

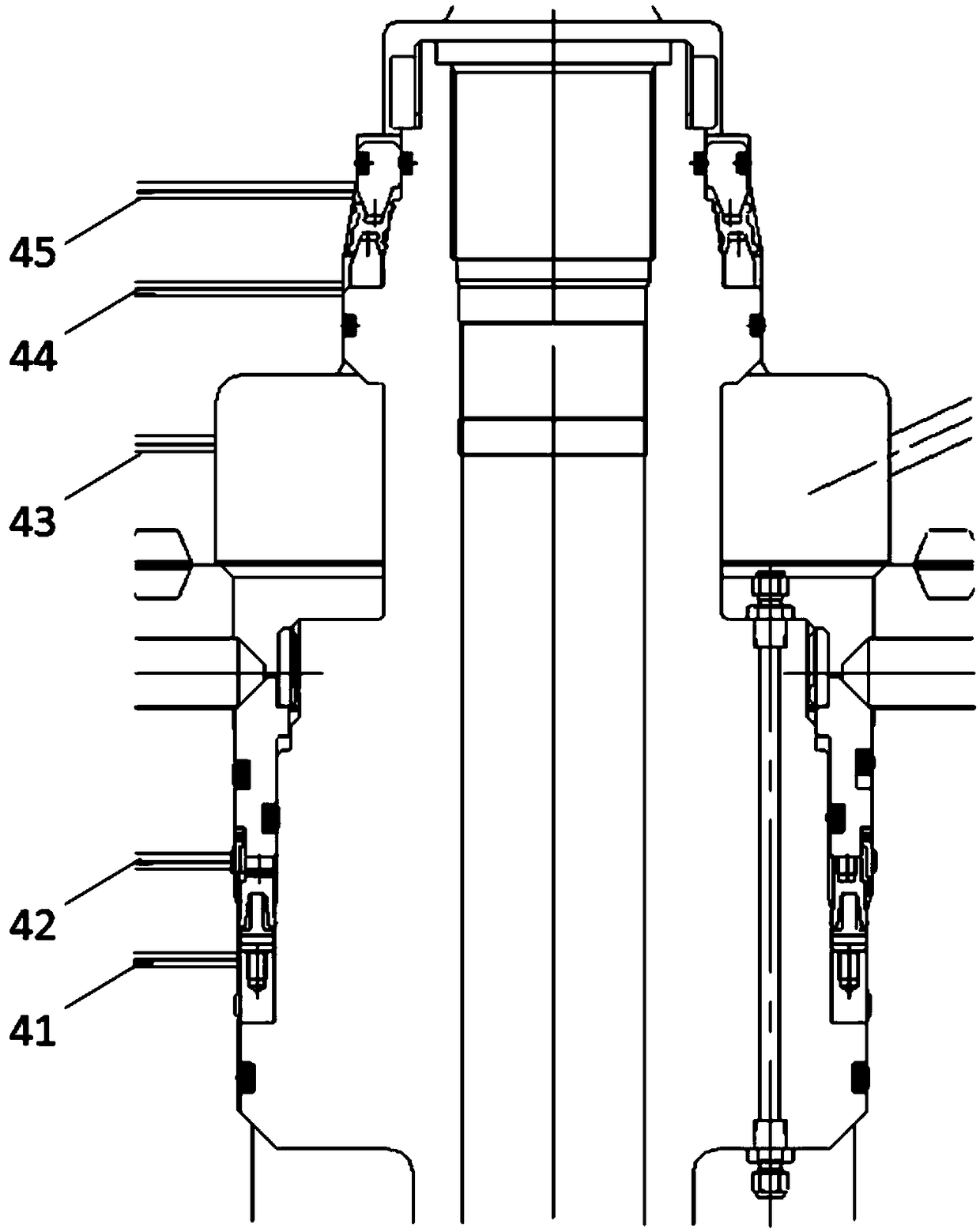

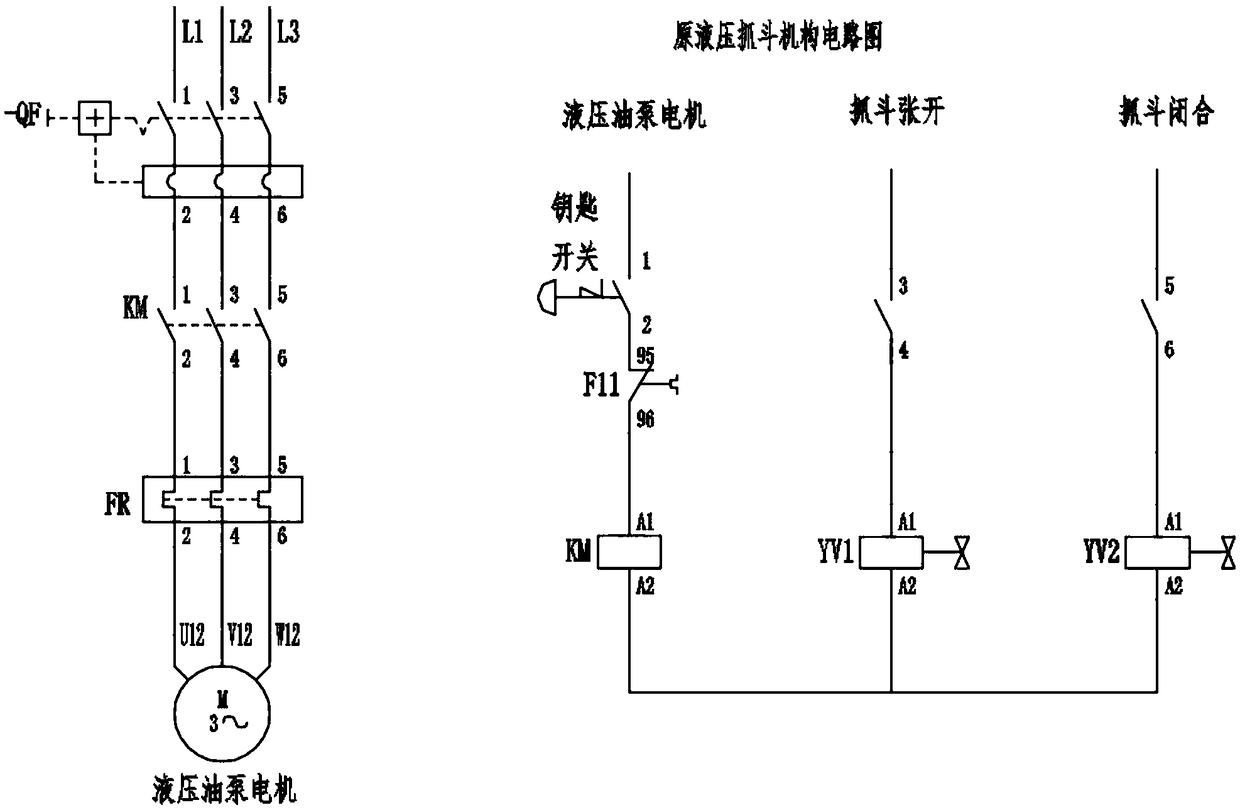

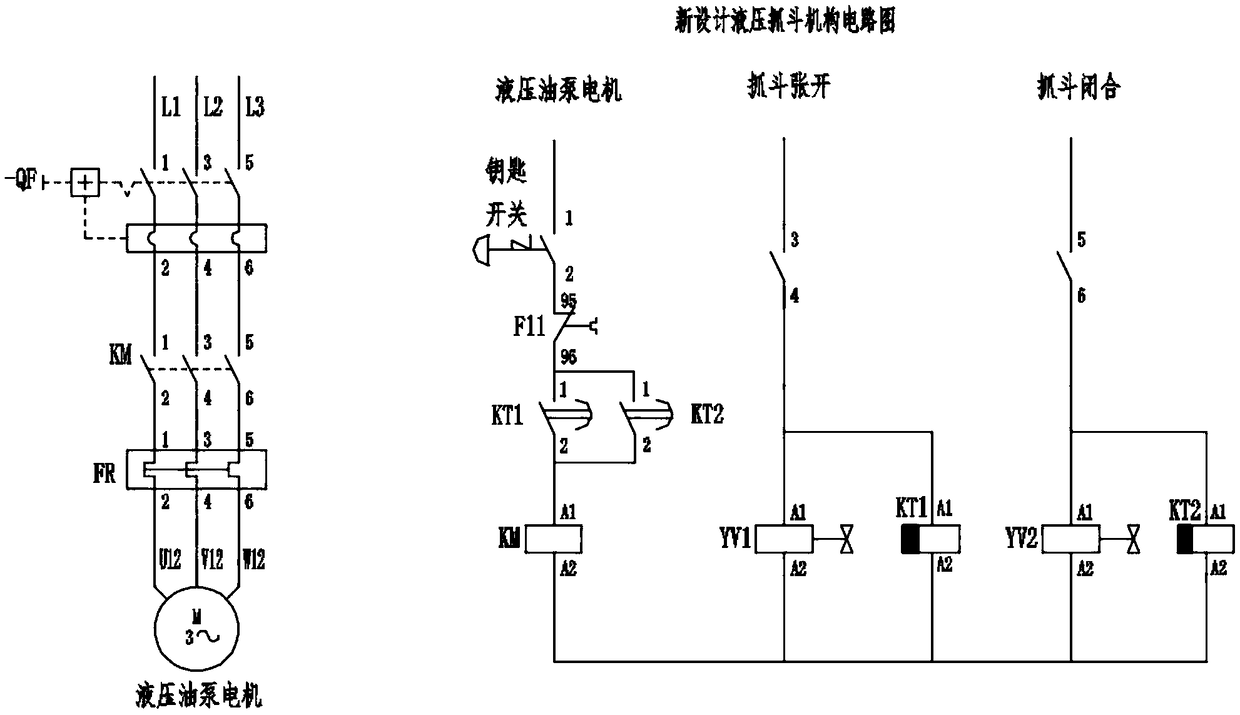

Control method for achieving starting and stopping of oil pump motor through opening and closing of grab bucket

InactiveCN108946486ASave time at workProtective sealServometer circuitsLoad-engaging elementsStart stopTime delays

The invention discloses a control method for achieving starting and stopping of an oil pump motor through opening and closing of a grab bucket. The positions of coils of three-position four-way solenoid valve sets for hydraulic system control are connected with time-delay relays in parallel, and outage time-delay contacts of the time-delay relays are connected into a starting-stopping loop of theoil pump motor in series. The starting and stopping of an oil pump are controlled through the opening and closing of the grab bucket. According to the control method, due to the fact that the time-delay relays are additionally arranged, the starting and stopping of the oil pump motor and the opening and closing of the grab bucket are interlocked, and the working time of the oil pump is shortened;and electric energy is saved, the hydraulic oil temperature is controlled, hydraulic system seal is protected, and the service life of hydraulic components is prolonged.

Owner:CHENGDU XINGRONG RENEWABLE ENERGY CO LTD

Guide vane angle regulating device for submersible pump

ActiveCN102022375AReduced installation and repair timeFit tightly and reliablyPump componentsPumpsSubmersible pumpEngineering

The invention discloses a guide vane angle regulating device for submersible pumps, which is convenient to regulate the guide vane angle. The guide vane angle regulating device comprises a crank, a driven ring, a driving ring and a drive plate, wherein the driven ring and the driving ring are bonded and connected, one end of the crank is connected with the driven ring in a rotating mode, the other end of the crank is used for connecting and regulating the guide vane angle, a connecting mechanism for connecting the driving ring and the drive plate is arranged between the driving ring and the drive plate, and the drive plate is connected with a drive link. The guide vane angle regulating device can be used for regulating underground or underwater guide vane angle by ground operation. In the invention, by means of the triangular drive plate and a connecting link device, the guide vane can be freely driven to rotate clockwise or anticlockwise. Meanwhile, the application of the crank ensures that the guide vane angle can be greatly changed only when the driving ring and the driven ring rotate by small distance.

Owner:LANSHEN GRP CORP LTD

A safety sealed coupling board

ActiveCN109524837BWith anti-shock designProtective sealCouplings bases/casesTwo-part coupling devicesModular designEngineering

The invention relates to a plugboard, in particular to a safety sealing coupling plugboard, which comprises a plugboard shell and one or more detachable waterproof sealing coupling devices, and is characterized in that each detachable waterproof sealing coupling device consists of an embedded installation coupling kit and an embedded device; the embedded installation coupling kit is composed of acoupler and a sealing cover. The coupler is composed of a ground wire bridging module, a live wire bridging module and a zero wire bridging module. The plugboard can be used after being inserted in one step, and has an anti-electric shock design; the waterproof device has multiple waterproof effects, can be used in water, adopts a modular design, and is convenient to maintain and replace parts.

Owner:温州市鹿城区渊龙电器科技有限公司

Forging machine with return cylinder anti-unbalance-loading mechanisms and assembling method and using method thereof

ActiveCN103111573BImprove stabilityFreedom of movementFluid-pressure actuatorsForging press drivesPre stressPre stressing

The invention relates to a forging machine with return cylinder anti-unbalance-loading mechanisms and an assembling method and a using method of the forging machine. The forging machine comprises a main machine frame, an upper fixed beam, a pre-stressed pull rod, a movable beam, a return cylinder, a plunger piston cylinder, a guiding device, a mobile working table, a transverse moving anvil, an upper anvil and a lower anvil. The return cylinder comprises a return cylinder body and a return cylinder plunger piston, wherein the return cylinder body and the return cylinder plunger piston are matched with each other. The anti-unbalance-loading mechanisms are respectively arranged between the upper end of the return cylinder plunger piston and the upper fixed beam and between the lower end of the return cylinder body and the main machine frame, wherein spherical surfaces of the anti-unbalance-loading mechanisms contact each other, and the anti-unbalance-loading mechanisms are displaced relatively. The forging machine with the return cylinder anti-unbalance-loading mechanisms and the assembling method and the using method of the forging machine have the advantages that the upper end and the lower end of the return cylinder are both provided with the anti-unbalance-loading mechanisms, and therefore when the return cylinder receives unbalance loading, the return cylinder plunger piston is guaranteed to move freely and cannot suppress strength, and the service life of the return cylinder plunger piston is prolonged. The return cylinder plunger piston sealing and each part of sealing inside an inner cavity are protected, and the service life of a sealing element and a copper bush is prolonged. The anti-unbalance-loading capacity of a return cylinder plunger piston structure is strengthened, and the stationarity of forging machine running is strengthened.

Owner:青岛海德马克智能装备有限公司

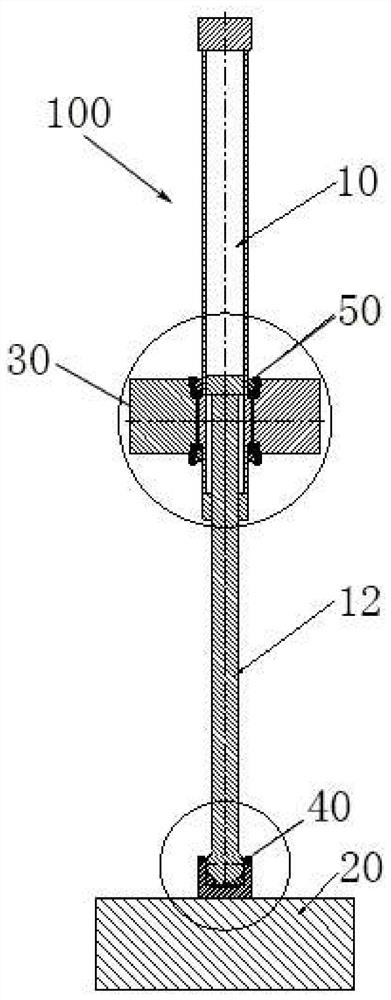

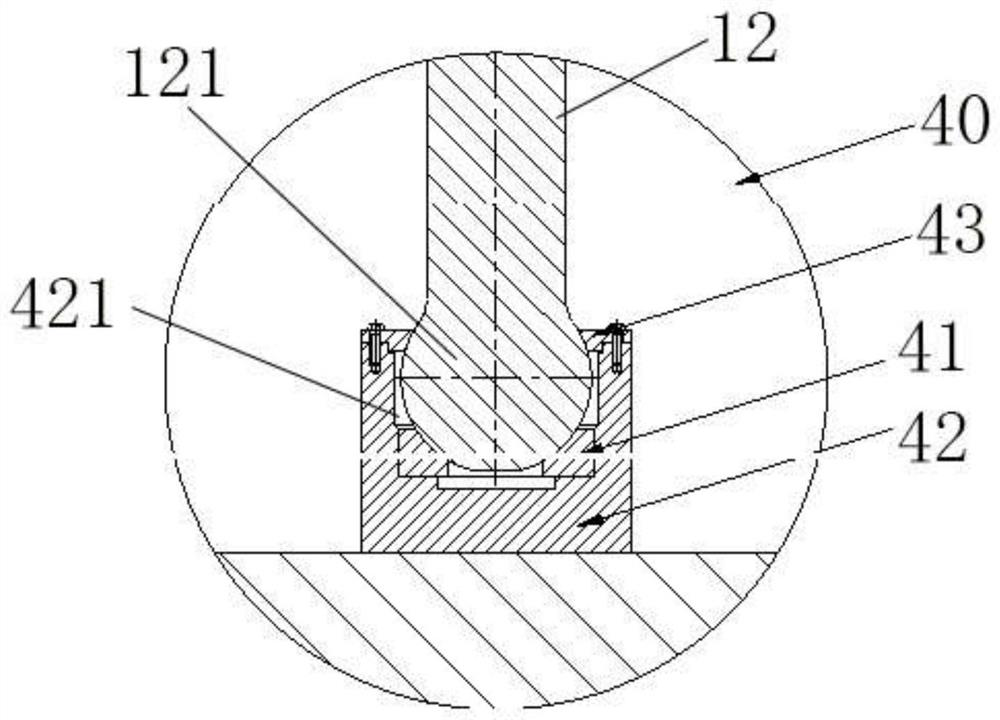

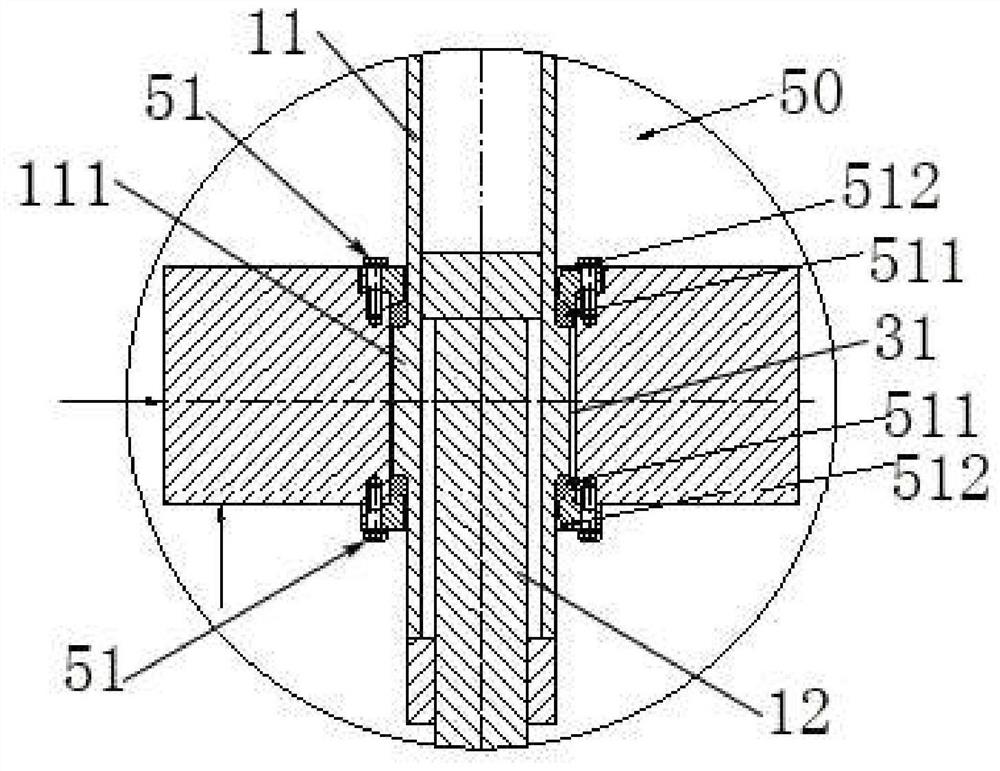

Structure for preventing oil cylinder from unbalance loading

InactiveCN113202836AAvoid unbalanced loadProtective sealFluid-pressure actuatorsStructural engineeringMechanical engineering

The invention provides a structure for preventing an oil cylinder from unbalance loading, and relates to the technical field of hydraulic oil cylinders. The oil cylinder is fixed to a base and can push a load to reciprocate, the structure for preventing the oil cylinder from unbalance loading comprises a first unbalance loading prevention assembly and a second unbalance loading prevention assembly, the first unbalance loading prevention assembly is arranged between the oil cylinder and the base, and the second unbalance loading prevention assembly is arranged between the oil cylinder and the load. The structure for preventing the oil cylinder from unbalance loading can effectively prevent the oil cylinder from unbalance loading, and oil cylinder sealing is protected.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

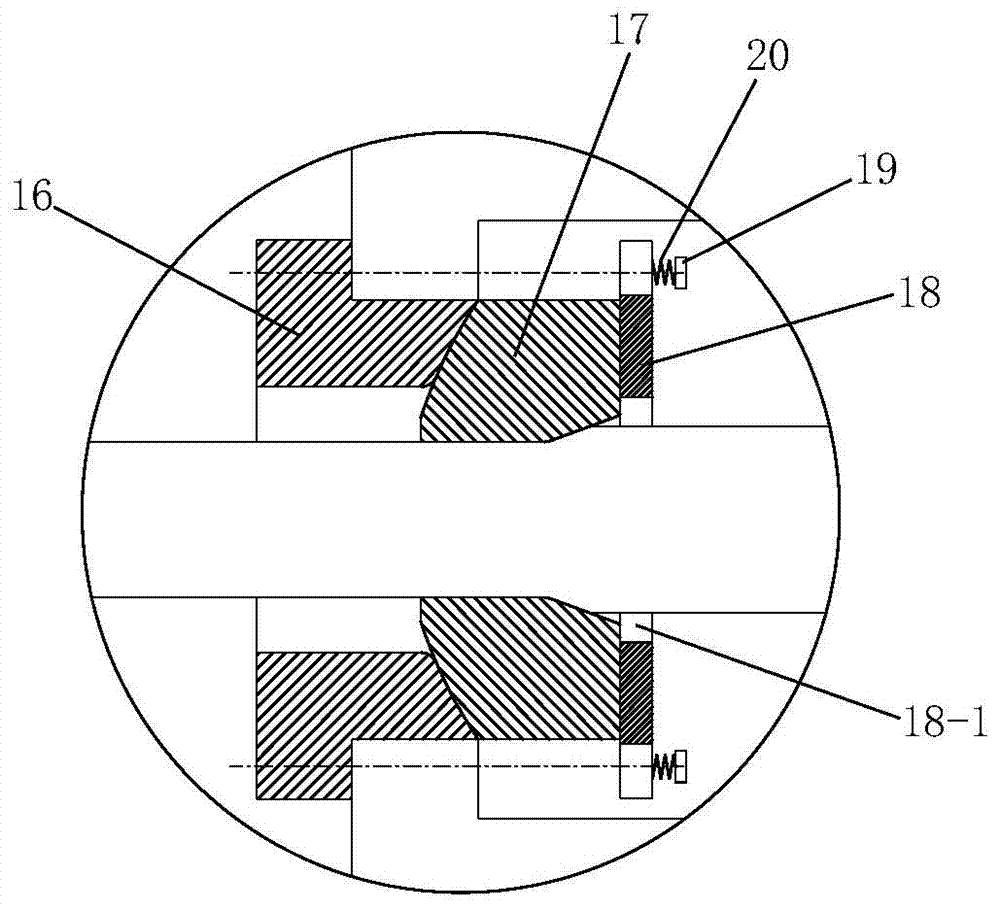

Forging machine with plunger type cylinder unbalance loading resistant structures and assembling and using method thereof

ActiveCN103100629BImprove stabilityExtended service lifeForging press detailsRelative displacementMaster cylinder

The invention discloses a forging machine with plunger type cylinder unbalance loading resistant structures. The forging machine with the plunger type unbalance loading resistant structures comprises a main rack, an upper fixed beam, a prestress draw bar, a movable cross beam, a plunger type cylinder, a guide device and a movable workbench, and is characterized in that the plunger in the plunger type cylinder is fixed on the upper fixed cross beam through a T-shaped draw bar in a hanging mode, and unbalance loading resistance structures with spherical surfaces contacted with each other and shifting relatively are arranged between the upper end of the upper fixed beam and the tail end of the T-shaped draw bar and between the bottom portion of the plunger and the T-shaped head of the T-shaped draw bar. The forging machine with the plunger type cylinder unbalance loading resistance structures has the advantages that when a main cylinder bears unbalance loading force, the two unbalance loading structures with the spherical surfaces contacted with each other and shifting relatively can eliminate the unbalance loading acting on the cylinder body of the plunger type cylinder, the plunger of the plunger type cylinder is enabled not to be blocked, the service life of the plunger is prolonged, a seal is protected, the service lives of the seal and a copper sleeve are prolonged, the unbalance loading capacity of the plunger type cylinder is enhanced, and working efficiency is improved.

Owner:青岛海德马克智能装备有限公司

A self-priming water pump with filter device

ActiveCN105443449BExtended service lifeAvoid destructionPump componentsPriming pumpDrop outWaste management

The invention discloses a self-priming water pump with a filter device. The self-priming water pump comprises a water pump body, wherein a water inlet is formed in one side of the water pump body, and a water outlet is formed in the top of the water pump body; the filter device is arranged on one side of the water inlet and comprises a filter cover, and a sealing ring is arranged in the filter cover; a filter, a filter cup and a water outlet connecting piece are successively arranged at the bottom of the filter cover, and a buckling groove and a buckling hook are respectively arranged the bottom of the filter and the top of the filter cup and are matched with each other. As the self-priming water pump is provided with the filter cup, in the process that a worker cleans the filter, sand cannot drop out from the surface of the filter to enter an impeller again so as to damage a sealing piece, and the service life of the water pump is prolonged. The filter cup with a simple structure can effectively prevent sand from entering the impeller and protect the sealing of the water pump, and the service life of the self-priming water pump is prolonged.

Owner:SUZHOU MEDAS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com