Control method for achieving starting and stopping of oil pump motor through opening and closing of grab bucket

A technology of oil pump motor and control method, which is applied in the direction of mechanical equipment, servo meter circuit, load suspension components, etc., can solve problems such as internal leakage of the system, increase of hydraulic oil temperature, and damage to seals, so as to prolong the service life and save energy. Electric energy, the effect of controlling hydraulic oil temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

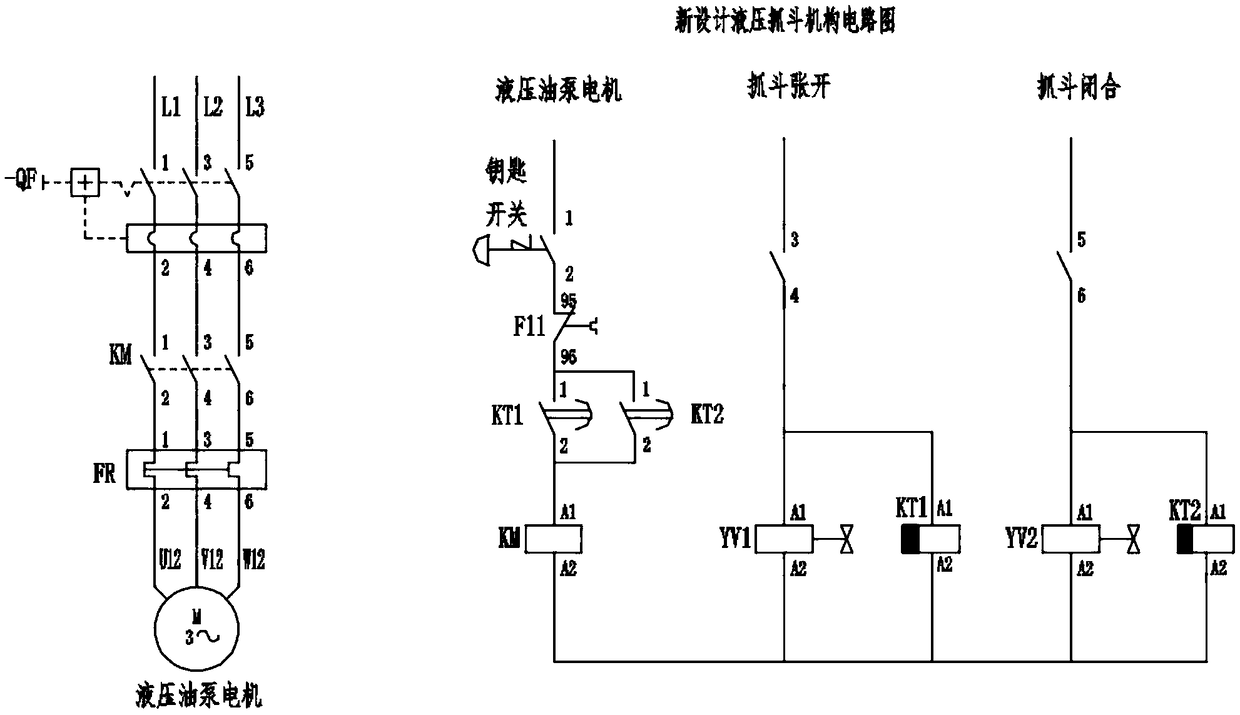

[0010] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the following.

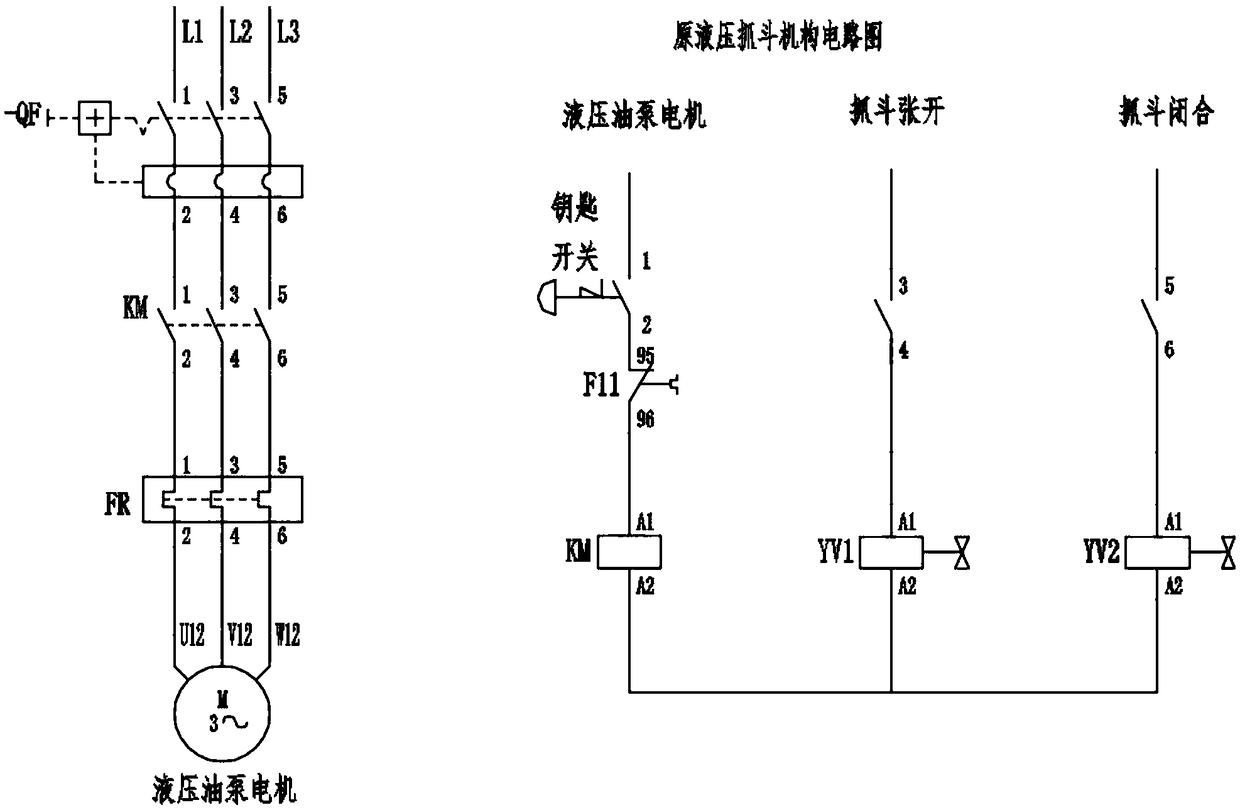

[0011] Such as figure 1 As shown, after operating the key switch on the console, the KM contactor coil is energized, the KM main contact is closed, and the hydraulic oil pump motor starts to work; when the grab is operated on the console to grab materials, the solenoid valve coil YV2 is energized , The hydraulic system drives the clap to complete the closing action; after the bridge crane cart and trolley move to the material stacking position, operate the grab on the console to release the material, the solenoid valve coil YV1 is energized, and the hydraulic system drives the clap to open. Action, the material release is completed. During this process, the hydraulic oil pump motor has been in working condition, and the hydraulic oil overflows back into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com