Forging machine with plunger type cylinder unbalance loading resistant structures and assembling and using method thereof

An assembly method and anti-eccentric load technology, which is applied in the field of forging presses, can solve problems such as low seal life, inability to transfer unbalanced loads, oil leakage, etc., and achieve the effects of preventing leakage, enhancing the ability to resist unbalanced loads, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

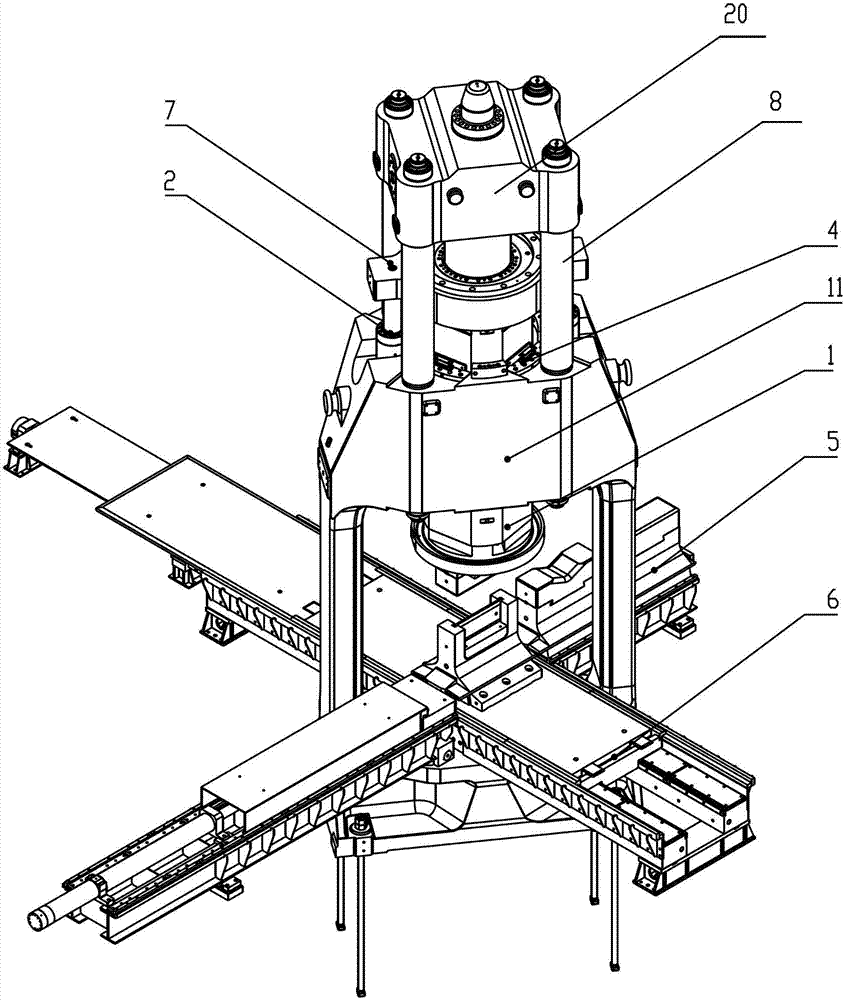

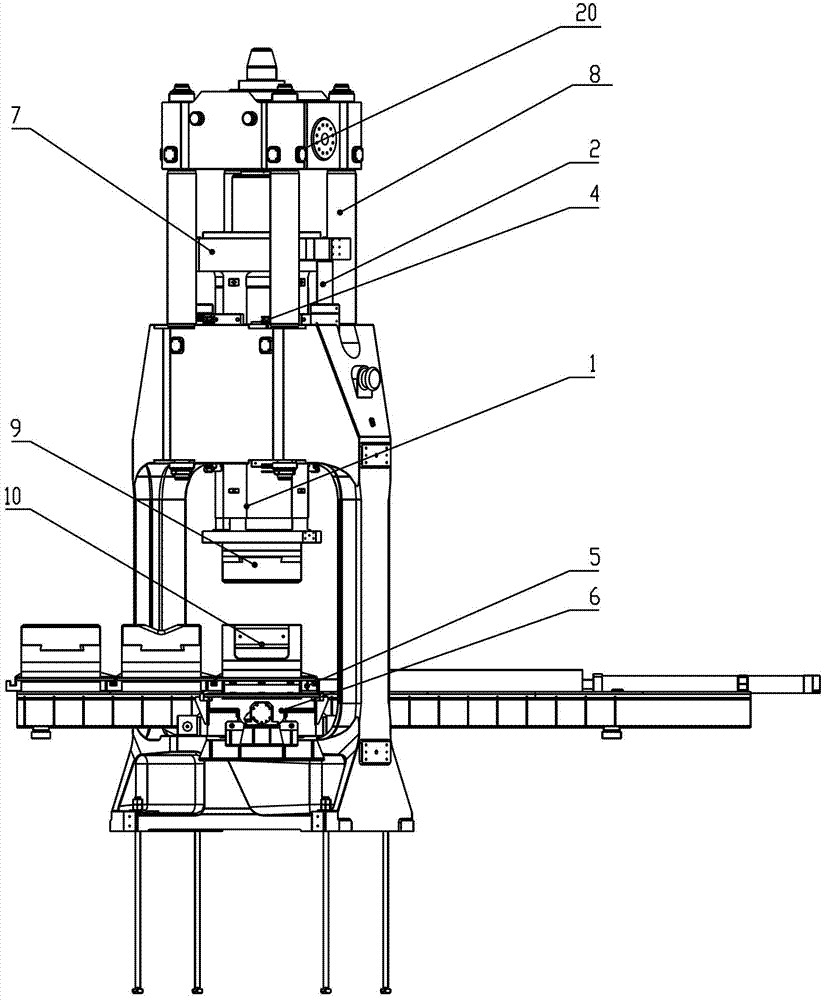

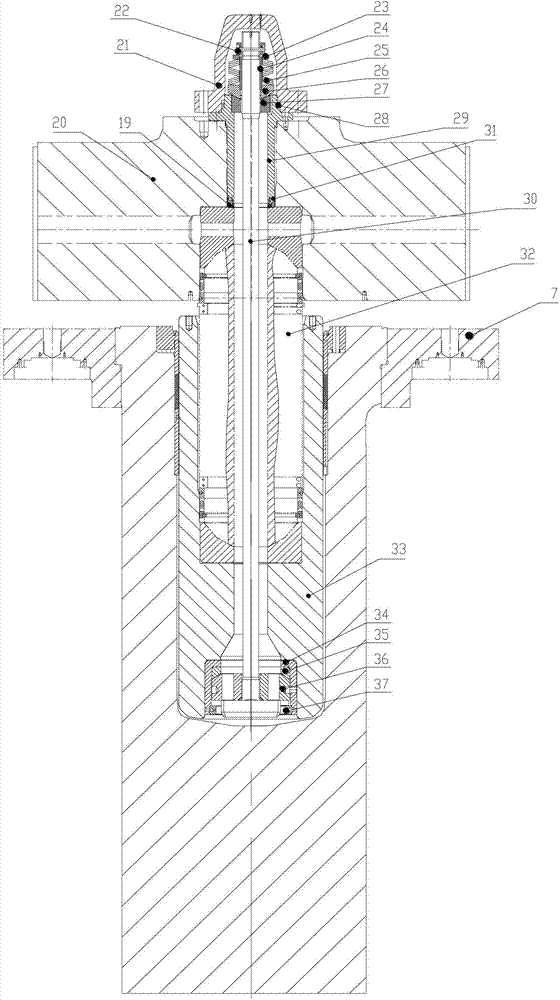

[0034] Such as figure 1 , 2 As shown, a forging press with a plunger cylinder anti-eccentric load structure includes a main frame 11, an upper fixed beam 20, a prestressed tension rod 8, a movable beam 7, a return cylinder 2, a plunger cylinder 1, a guide device 4, a moving Workbench 6, upper anvil 9 and lower anvil 10; the main frame 11 straddles the movable workbench 6 obliquely to carry the plunger cylinder 1 and the return cylinder 2; the upper fixed beam 20 is used to hang the plunger of the plunger cylinder 33. Groups of prestressed tie rods 8 are connected and preloaded between the main frame 11 and the vertical direction of the upper fixed beam 20; the movable beam 7 is arranged between the top of the main frame 11 and the vertical direction of the upper fixed beam 20 and used for connection The driving end of the return cylinder 2 and the cylinder body of the plunger cylinder 1; the cylinder body of the plunger cylinder 1 is connected to the main frame 11 through a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com