Bench vise with dual axis position adjustment and control

A technology of bench vise and bearing group, applied in the field of bench vise, can solve the problem of high operation difficulty, achieve the effect of ensuring the position accuracy, preventing the deviation of the set position, and reducing the overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

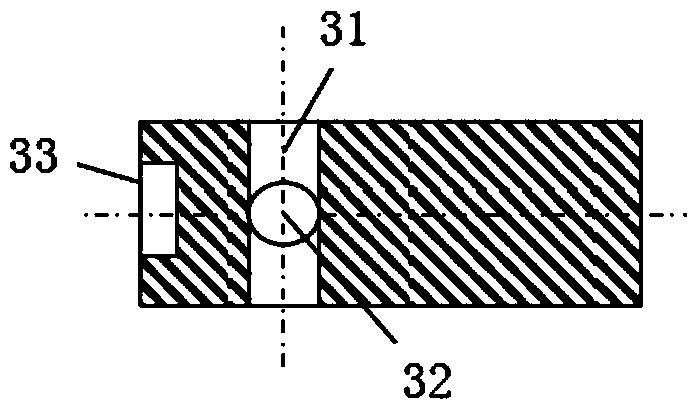

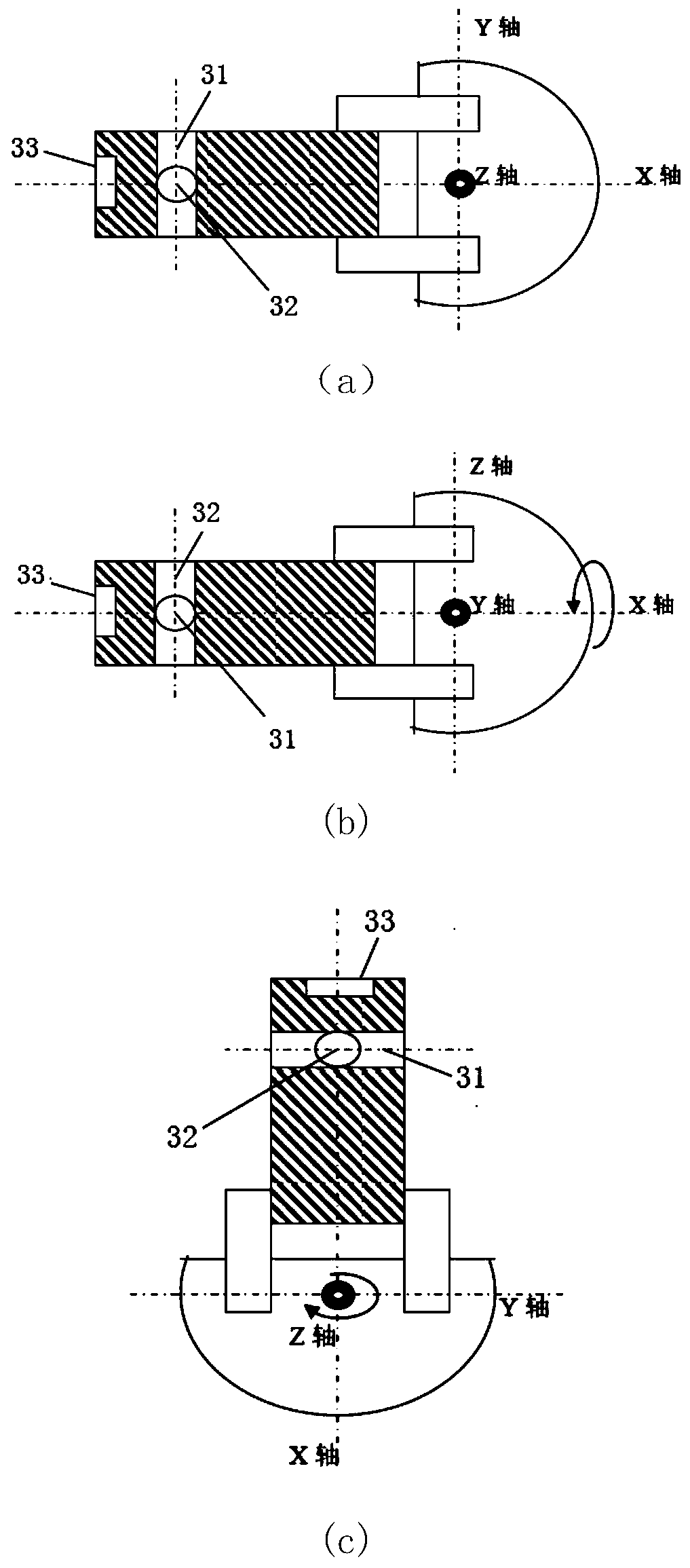

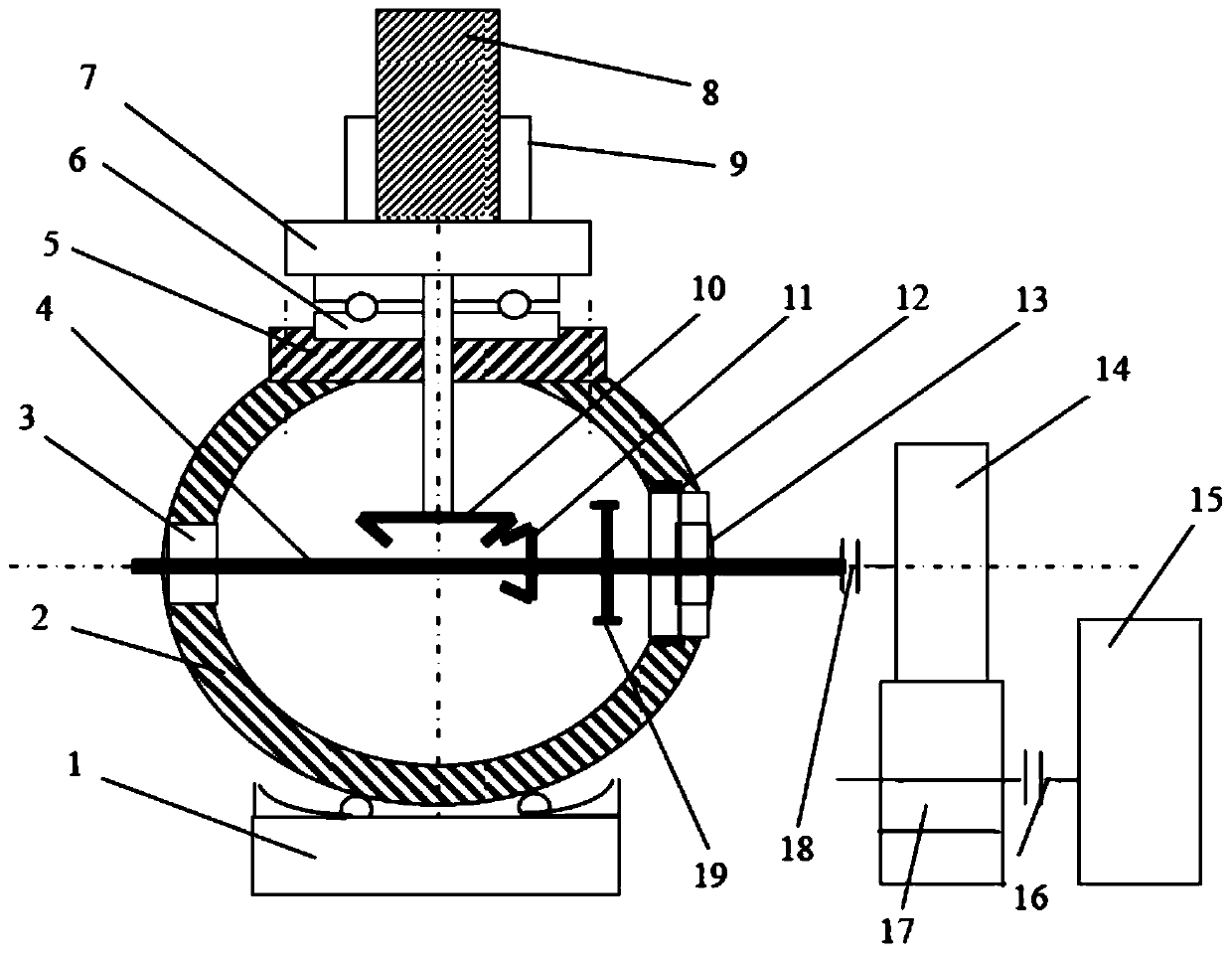

[0054] Such as image 3 , shown in 4, a multi-degree-of-freedom bench vise for adjusting position and direction, including a machine base 1, a spherical shell 2, a bearing group a3, a main drive shaft 4, a cover 5, a plane bearing 6, a fixture base 7, and a workpiece 8. Fixture assembly 9, large bevel gear 10, small bevel gear 11, inner ring gear 12, bearing group b 13, drive motor assembly 14, feed system 15, coupling one 16, lead screw and nut assembly 17, coupling Shaft device two 18, spur gear 19.

[0055] A spherical shell 2 is installed on the base 1, and the arc groove on the top of the base 1 matches the spherical shell 2, and balls are arranged at the joint between the arc groove on the top of the base 1 and the spherical shell 2. The upper end of the spherical shell 2 is fixedly connected to the cover 5, and the main transmission shaft 4 arranged horizontally is housed inside. The main transmission shaft 4 is equipped with a small bevel gear 11 and a spur gear 19. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com