Near-infrared aircraft attitude and position measurement objective lens system

An aircraft and near-infrared technology, applied in instruments, optics, integrated navigators, etc., can solve the problems of large optical system aperture, difficult processing and detection, and unknown space adaptability, so as to reduce the difficulty of detection and improve the uniformity of imaging illumination , The effect of high reliability in space work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

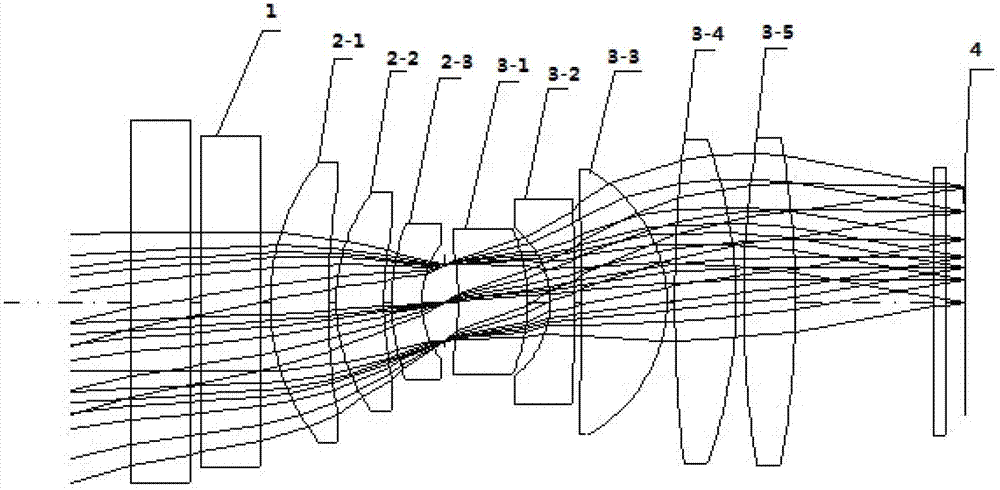

[0039] The air interval between the flat filter 1 and the flat glass on its left side is 0.5mm; the air interval between the first positive meniscus lens 2-1 and the second positive meniscus lens 2-2 in the front lens group 2 is 0.4mm, and the second The air interval between the positive meniscus lens 2-2 and the third negative meniscus lens 2-3 is 0.4mm; the air space between the first positive meniscus lens 3-1 and the second negative meniscus lens 3-2 in the rear mirror group The interval is 1.13mm, the air interval between the second negative meniscus lens 3-2 and the third positive meniscus lens 3-3 is 0.4mm, the air interval between the third positive meniscus lens 3-3 and the first biconvex lens 3-4 The interval is 0.4mm, the air interval between the first lenticular lens 3-4 and the second lenticular lens 3-5 is 0.39mm; the air interval between the flat filter 1 and the first positive meniscus lens 2-1 of the front lens group 2 is 0.5mm mm, the air gap between the thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com