Integrated electric-hydraulic actuator type valve adjusting system for steam turbine

An electro-hydraulic actuator and regulating system technology, applied in the direction of machine/engine, mechanical equipment, engine components, etc., can solve the problems of easy loosening of oil pipeline joints, power oil leakage, complex system, etc., to improve reliability, The effect of protecting sealing and solving external leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

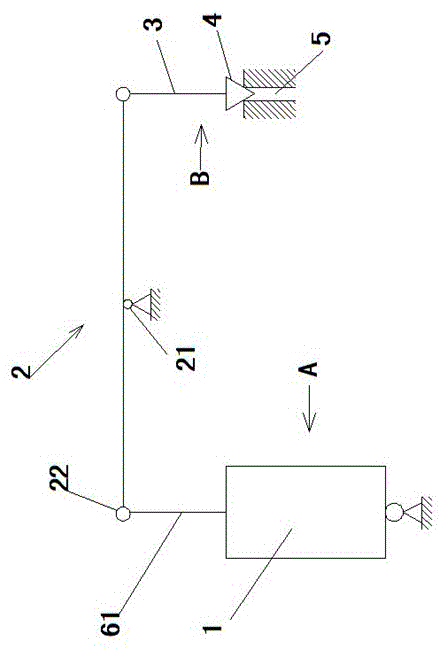

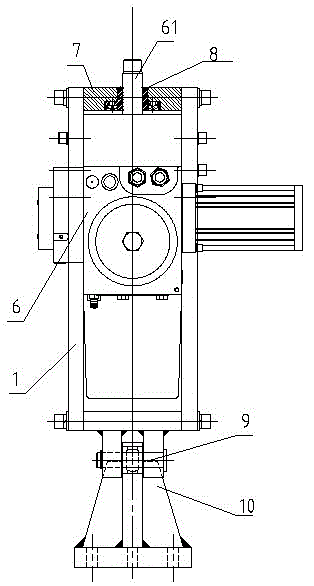

[0012] In order to solve the problem of power oil leakage in the current system, this embodiment uses an integrated electro-hydraulic actuator such as the REXA electro-hydraulic actuator as a lever drive device to replace the oil motor and electro-hydraulic conversion device in the current system. see figure 2 , the REXA electro-hydraulic actuator 6 is fixed in the groove of the trough-shaped bracket 1, the upper port of the bracket is fixed to the guide support plate 7, and the piston rod 61 of the REXA electro-hydraulic actuator passes through the guide hole in the center of the guide support plate. The guide hole is a copper guide hole 8, and the copper guide hole is installed on the guide support plate, and the two are in the structure of the mouth; the lower end of the bracket is installed on the base 10 through the hinge shaft 9,

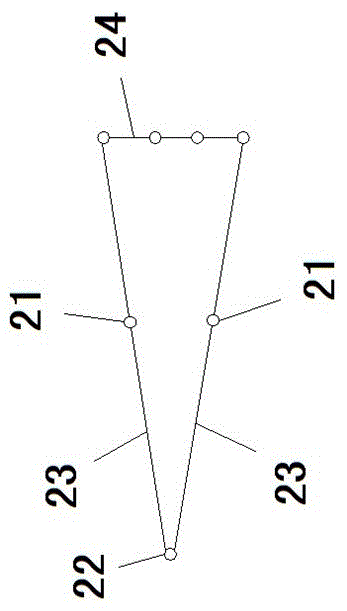

[0013] see figure 1 , 3 -4, the upper end of the piston rod 61 of the REXA electro-hydraulic actuator is hinged with the power point of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com