Discharge valve for slurry bed residual oil hydrogenation device

A technology of hydrogenation unit and bed residue oil, which is applied in valve unit, valve operation/release unit, lift valve, etc., can solve the problem of affecting the overall working condition, medium retention, and no slurry bed residue oil hydrogenation unit valve and other problems to achieve the effect of ensuring the flow of the medium, preventing the medium from staying, and protecting the packing seal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

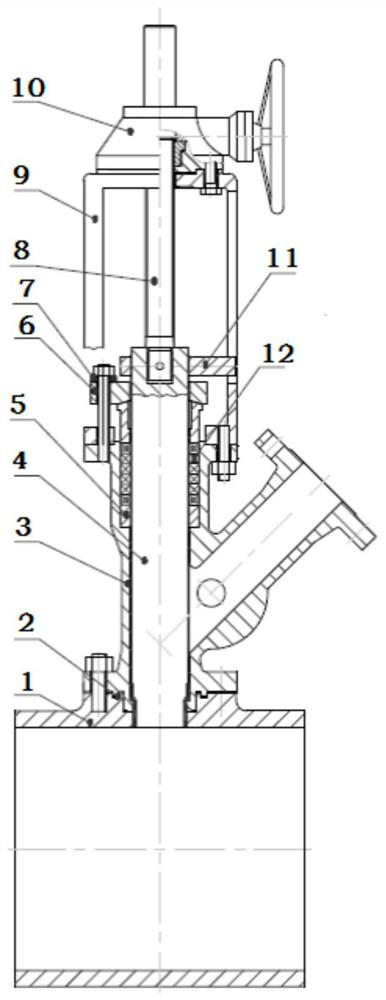

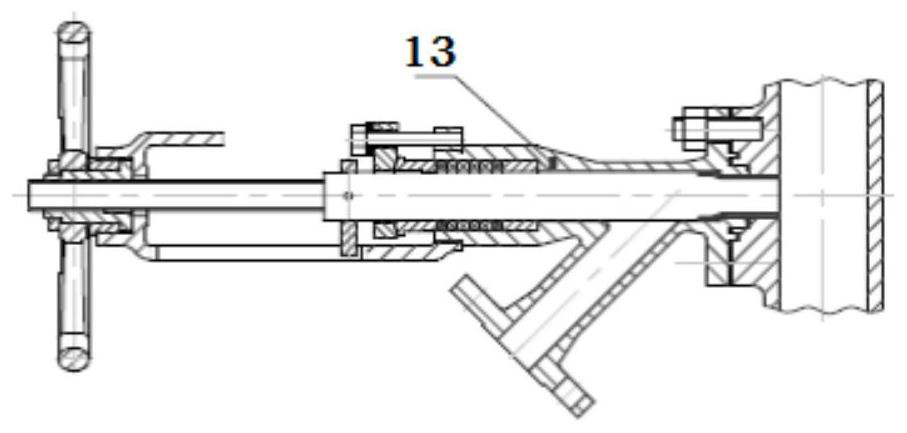

[0018] Disclosed is a discharge valve for a slurry bed residual oil hydrogenation unit. The main pipeline of the valve 1 is connected with the valve body by a discharge flange in the middle; the sealing gasket 2 is provided with two seals to improve the sealing performance between the main pipeline and the valve body; Flange connection, and a cemented carbide sealing surface is set at the bottom of the middle cavity channel, and the Y-shaped outlet channel is provided with a flushing port near the middle cavity channel, and connected to the Y-line flushing valve; plunger 4, installed in the middle cavity channel of the valve body Inside, move up and down along the middle cavity channel, the arc shape of the plunger head is the same as the radius of the main pipe, and the head is surfacing with STL hard alloy; the oil scraper ring 5 is placed at the bottom of the packing to prevent the medium residue from entering the packing; the plunger packing The sealing mechanism 6 is load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com