Continuous annealing furnace bottom cover plate quick disassembling and assembling device and disassembling and assembling method

A continuous annealing furnace and cover plate technology, which is applied in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of furnace bottom cover plate jamming, furnace bottom cover plate alignment position is not easy to determine, and hurt people, etc., to achieve shortening Installation time, shortening the time for dismantling the furnace bottom cover, and the effect of protecting the seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

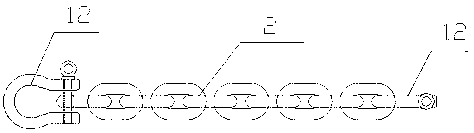

[0026] Refer to attached Figure 1-6 , a continuous annealing furnace furnace bottom cover quick disassembly device, including furnace bottom cover 1, guide chain 2, fixed bracket 3, fastening bolt 5, hook 6, reverse jacking wire 9, card slot 14 and furnace shell 15. Four card slots 14 are evenly fixed around the furnace shell 15, and a fastening bolt 5 is respectively installed on each card slot 14. The fastening bolt 5 includes a screw rod and a bolt head, and the screw thread of the fastening bolt 5 Connected on the card slot 14, the bolt head of the fastening bolt 5 is an inverted U-shaped structure, the bolt head of the fastening bolt 5 is provided with a hook 6, and a guide chain 2 is suspended on the hook 6 of each fastening bolt 5 , the lower end of the guide chain 2 is connected to the fixed bracket 3, the fixed bracket 3 is fixed on the furnace botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com