Method for cleaning polymer on side wall of etching chamber and contact hole forming method

A technology for etching cavity and polymer, applied in cleaning methods and appliances, chemical instruments and methods, electrical components, etc., can solve problems such as small contact hole line width and failure to reach the target size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

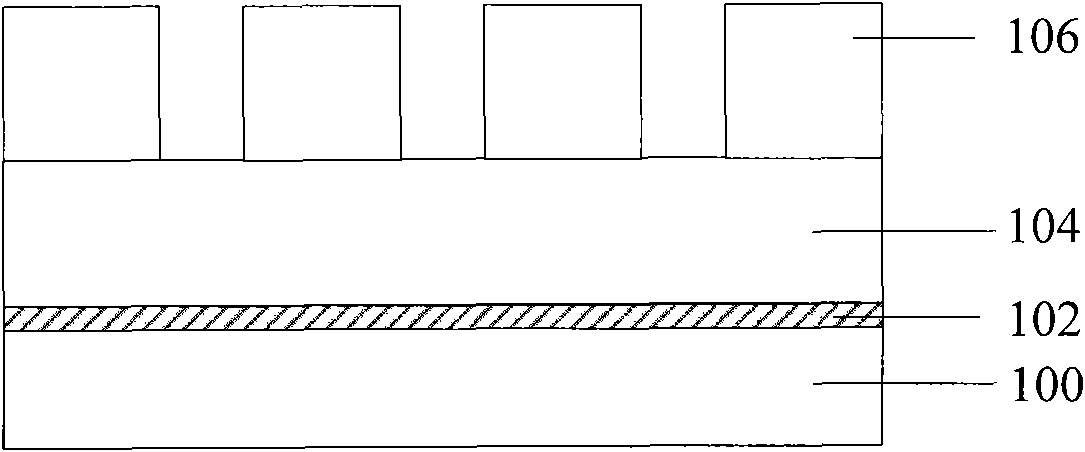

[0024] In the prior art, in the process of etching the insulating dielectric layer to form a contact hole, because too much polymer remains on the side wall of the etching chamber, when the contact hole is formed by subsequent etching, the polymerization formed on the side wall of the etching chamber will Excessive accumulation of particles will cause excessive particles on the surface of the wafer, resulting in incomplete etching of contact holes or short circuits. However, if the polymer on the side wall of the etching chamber is cleaned and there is too little residue, the line width after subsequent contact hole etching will be too small and the target size will not be reached.

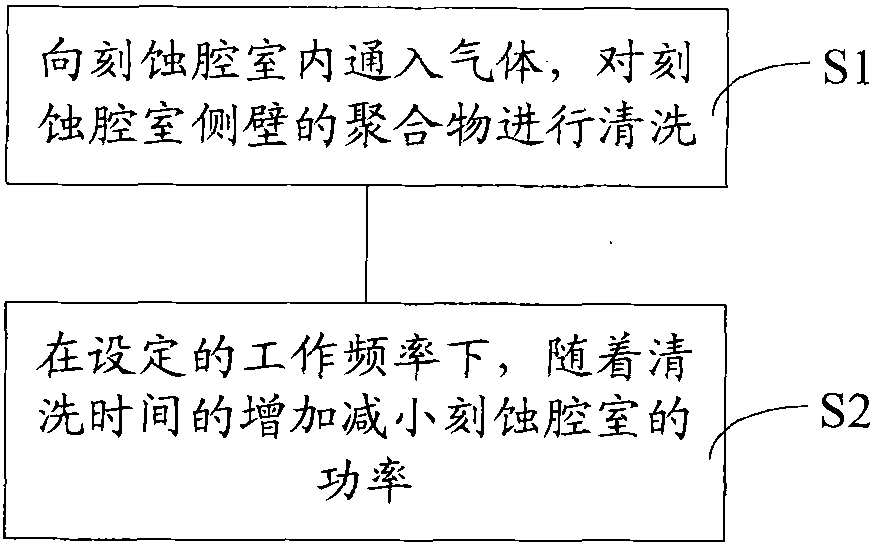

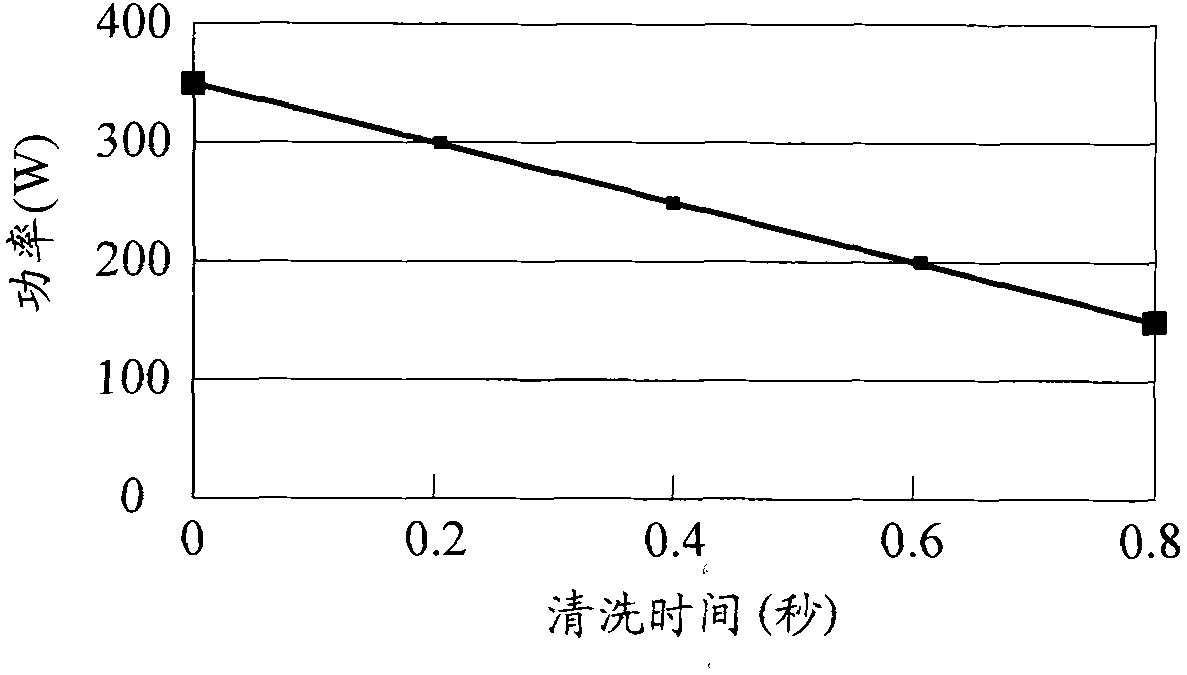

[0025] In order to solve the above problems, the present invention adopts a new method for cleaning the sidewall polymer of the etching chamber, and the specific process is as follows figure 1 As shown, step S1 is performed to inject gas into the etching chamber to clean the polymer on the side wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com