Grouting treatment method for broken water-rich section of diversion tunnel in karst area

A technology for water diversion tunnels and areas, applied in drainage, tunnels, tunnel linings, etc., can solve problems such as tunnel construction safety and construction operation impact, water seepage in rock surface cracks, and poor stability of surrounding rocks, so as to reduce groundwater resource pollution and improve anti-corrosion Compressive strength, the effect of ensuring engineering safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

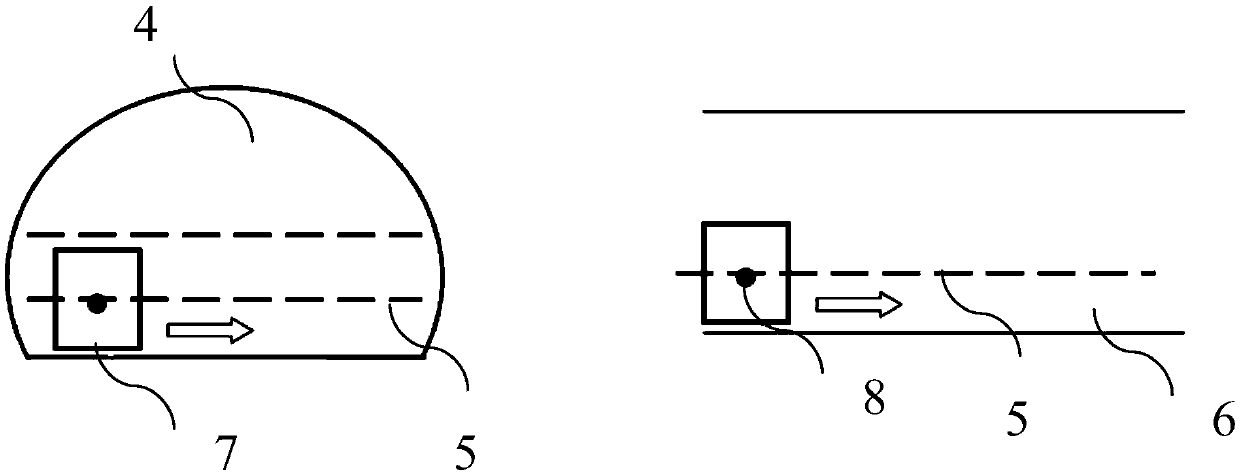

[0034] According to one embodiment of the present invention, the step of arranging the detection line 5 includes: drilling a detection hole with a diameter of 3 cm, a depth of 20 cm, and a 10-degree inclination of the axis diameter of the hole, and installing electrodes in the detection hole. The electrodes are electrically connected according to design requirements and are electrically connected with measuring instruments for data collection, and the number of detection holes can be set according to actual application conditions. Preferably, when each of the electrodes is installed in the detection hole, a coupling agent is used to couple with the detection hole wall, so as to reduce grounding resistance and improve signal collection quality.

[0035] According to one embodiment of the present invention, as image 3 As shown, the geological survey is transient electromagnetic detection, and the step S1) includes: setting a transmitting wire frame 7 and a receiving probe 8 at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com