Tunnel water gushing treatment method

A water gushing and tunnel technology, applied in the field of tunnel water gushing control, can solve problems such as weak emergency treatment capabilities, inability to achieve precise grouting, and failure to consider the depth of water gushing points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

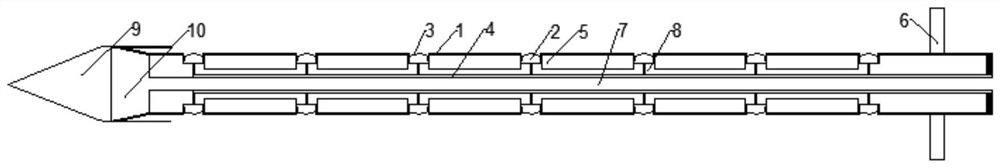

[0066] The method for controlling water gushing in a tunnel includes the following steps:

[0067] S1. Clean up the water gushing operation surface, remove the broken surrounding rock around the working surface, start from the water gushing hole, and drill holes in a direction perpendicular to the wall where the water gushing hole is located to form a water gushing channel;

[0068] S2. A flange plate is installed at the opening end of the water gushing channel, the flange plate has four first holes in a cross shape, and anchor rods are set through the first holes to fix the flange plate on the wall;

[0069] S3. Extend the grouting pipe through the flange into the water gushing channel, and the grouting pipe includes:

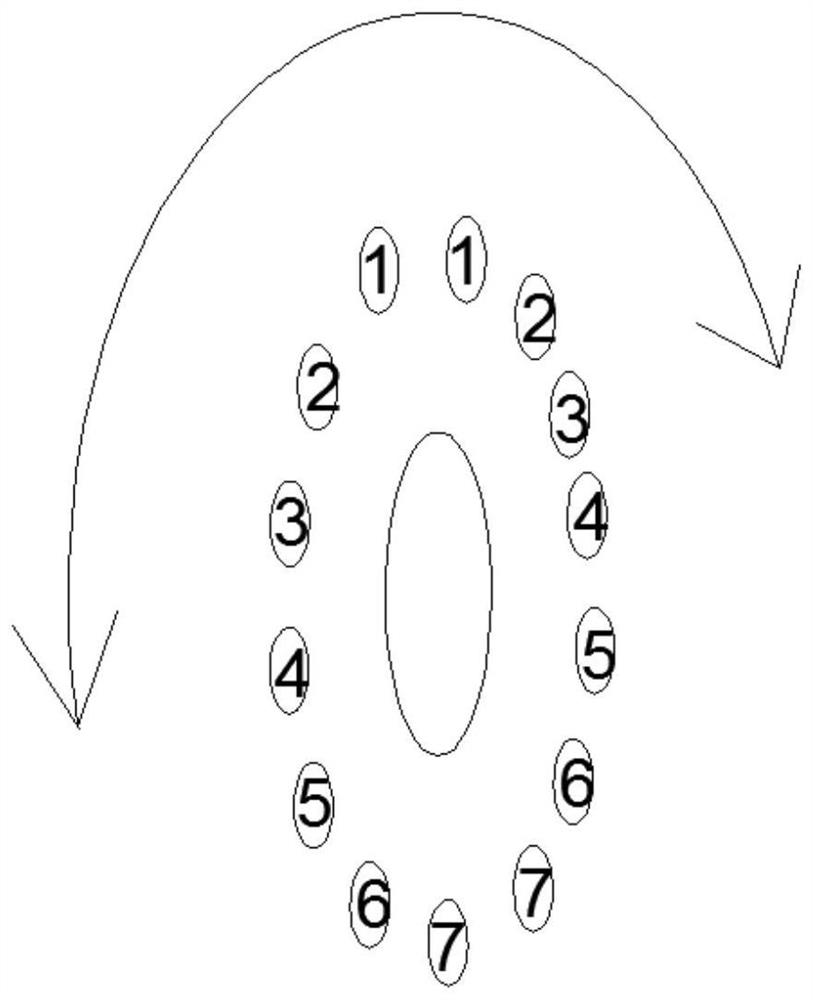

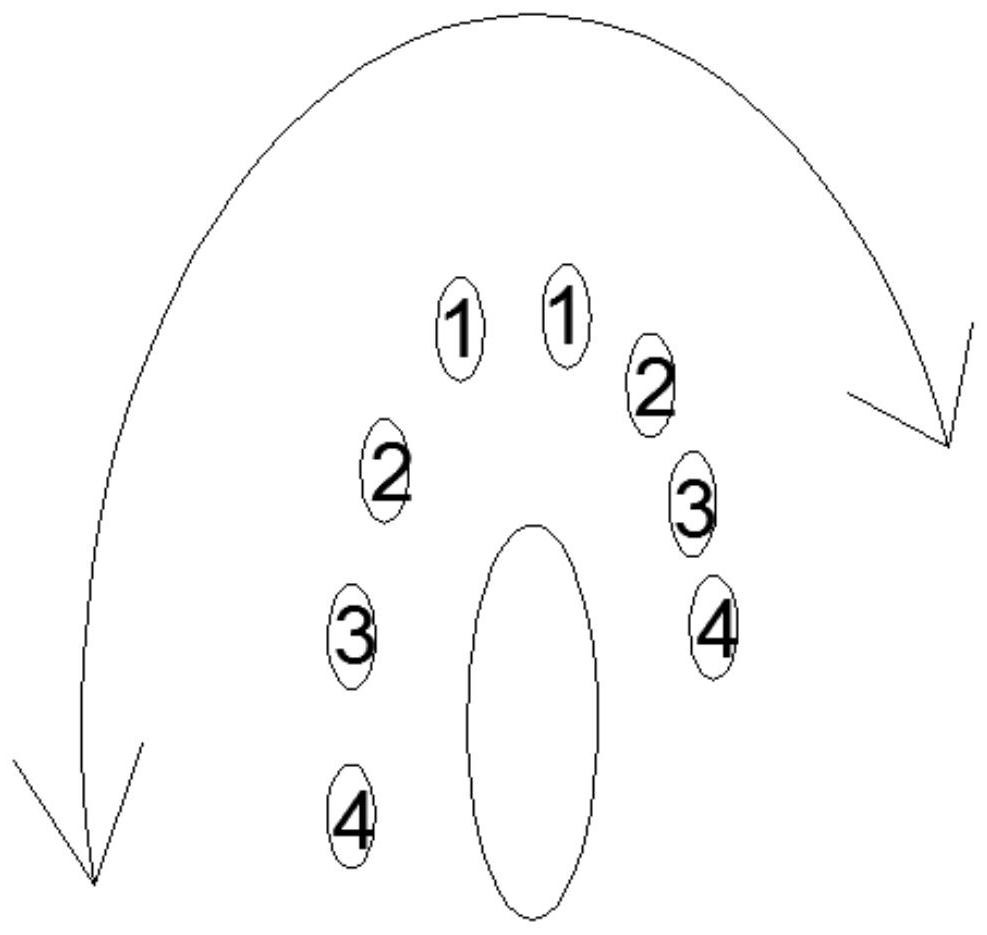

[0070] Grouting outer pipe 1, its outer circumference is recessed at equal intervals along the length direction and provided with circumferential grooves 2, and elastic rubber film 3 is stacked in the circumferential groove, so that the elastic rubber film 3 c...

Embodiment 2

[0080] The method for controlling water gushing in a tunnel includes the following steps:

[0081] S1. Clean up the water gushing operation surface, remove the broken surrounding rock around the working surface, start from the water gushing hole, and drill holes in a direction perpendicular to the wall where the water gushing hole is located to form a water gushing channel;

[0082] S2. A flange plate is installed at the opening end of the water gushing channel, the flange plate has four first holes in a cross shape, and anchor rods are set through the first holes to fix the flange plate on the wall;

[0083] S3. Extend the grouting pipe through the flange into the water gushing channel, and the grouting pipe includes:

[0084] The grouting outer pipe 1 is provided with annular grooves 2 at equal intervals along the length direction, and a pair of connecting grooves 11 are arranged between any two adjacent annular grooves, and the depth direction of the connecting grooves 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com