Quick measurement method of coal seam gas pressure

A coal seam gas pressure and rapid measurement technology, applied in drilling equipment and methods, measurement, earthwork drilling and mining, etc., can solve problems such as hidden dangers of accidents, wrong technical judgments, etc., to reduce gas leakage, take a long time to solve, and reduce crack water gushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

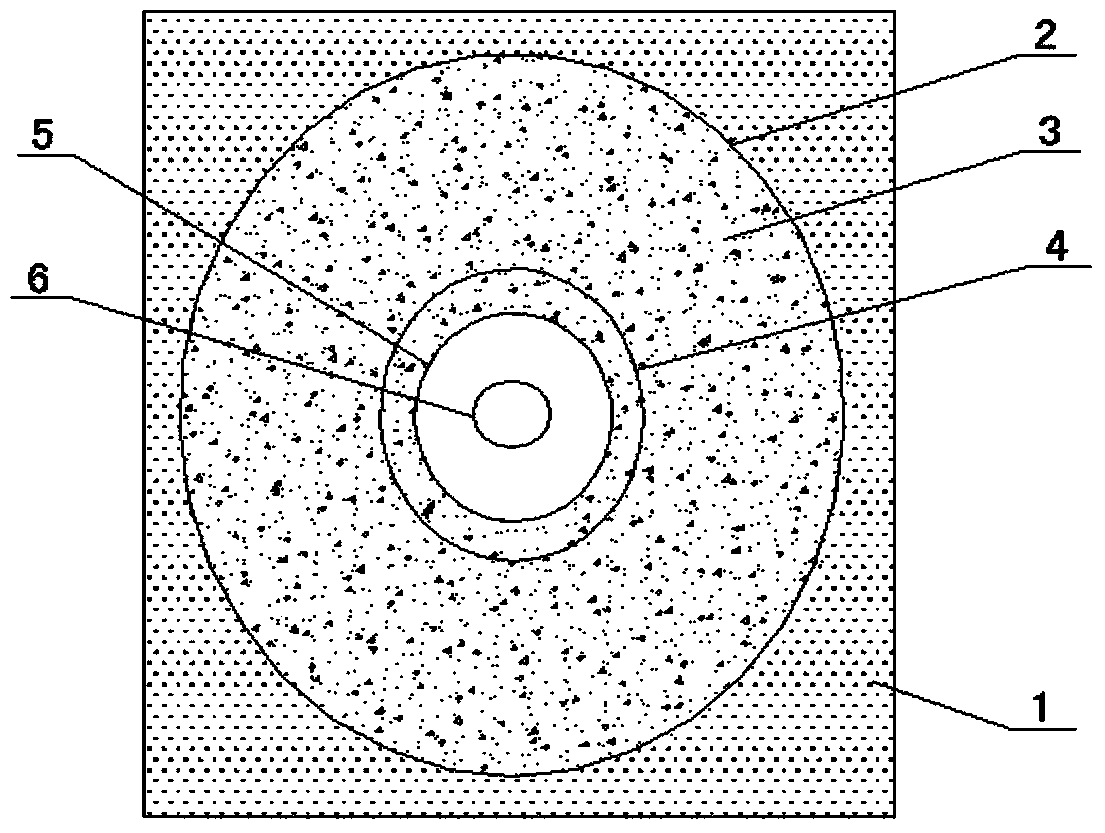

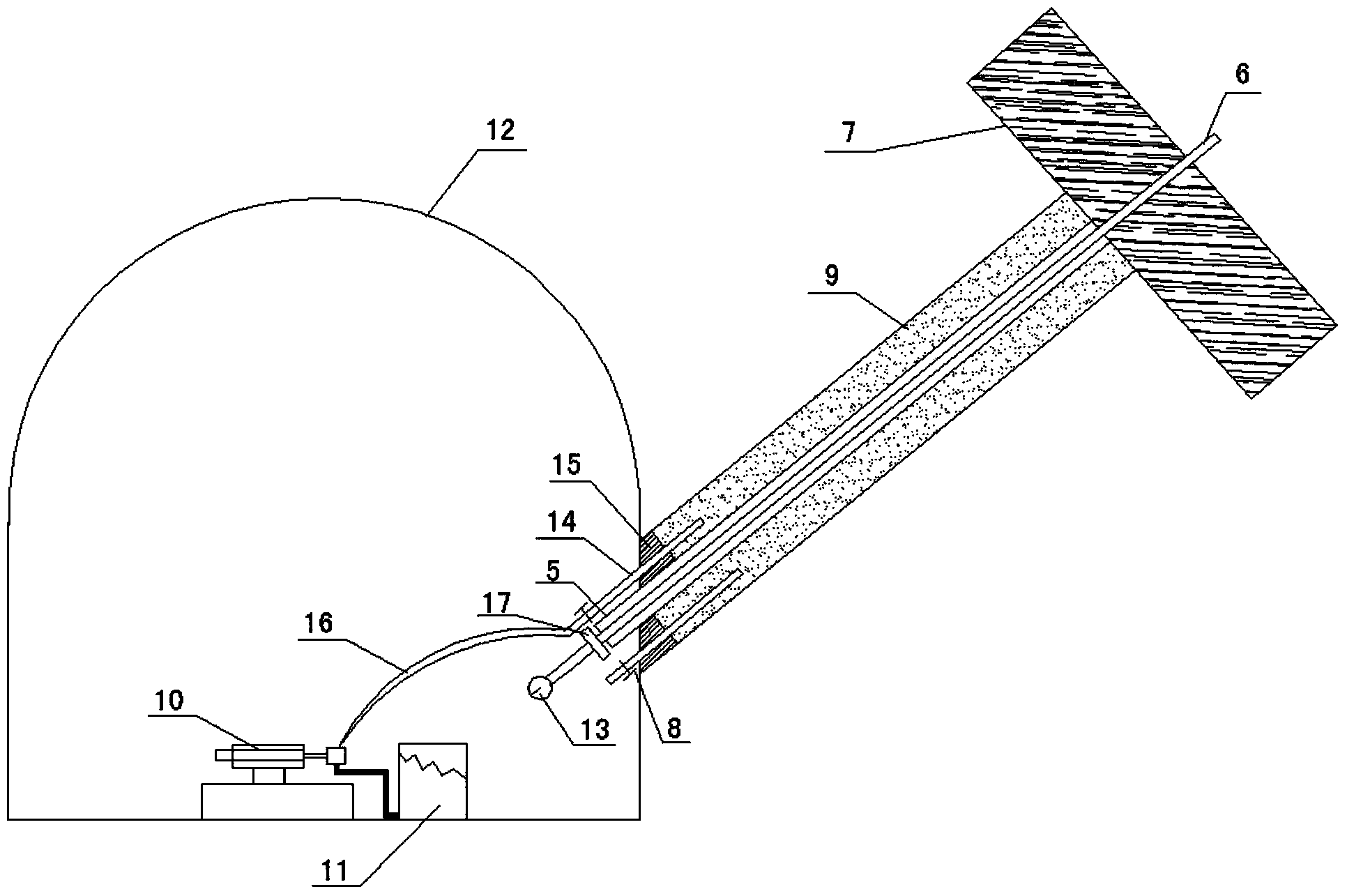

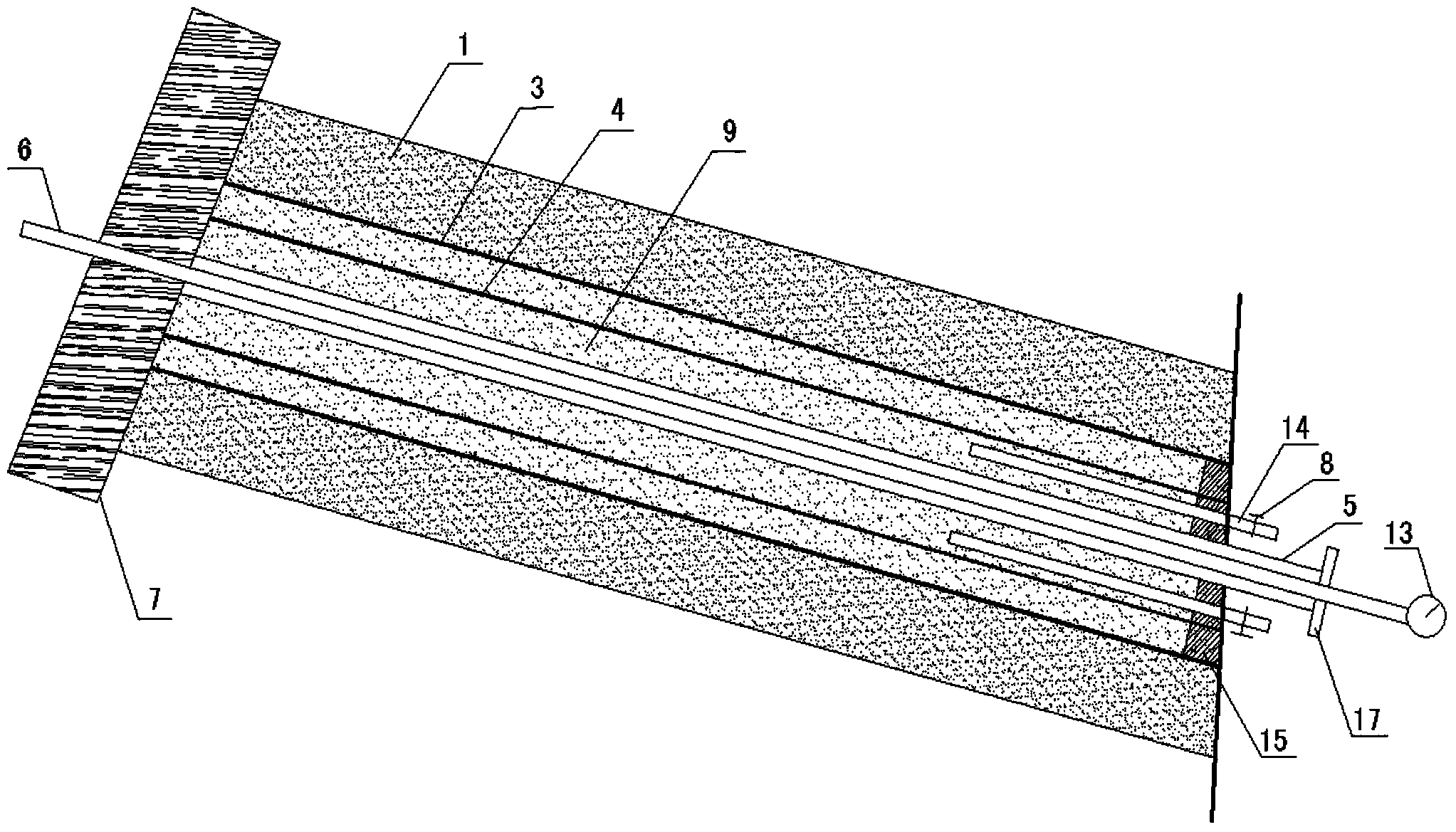

[0025] see figure 1 , figure 2 and image 3 , the rapid measurement method of coal seam gas pressure in the present embodiment is to operate according to the following process:

[0026] Step 1: Use the drill pipe in the roadway 12 to drill into the coal rock mass 1 until it reaches the level of the coal seam 7 to form a large-diameter borehole 4, take out the drill pipe and run the casing 5 into the large-diameter borehole 4 to the hole At the bottom, two grouting pipes 14 are lowered at the same time, and an annular cavity is formed between the casing 5 and the large-diameter borehole 4, and the grouting pipe 14 is located in the annular cavity; the casing 5 is a steel pipe with a diameter of 108 mm, and the The tail is welded with a flange.

[0027] Step 2, use fast-drying cement or polyurethane to seal the large-diameter borehole 4 at the orifice to form a seal 15; then use the high-pressure hose 16 to connect the grouting pipe 14 with the high-pressure grouting pump 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com