Stope face roof water pre-drainage construction method

A technology for mining working face and construction method, which is applied in the directions of drainage, mining equipment, earthwork drilling, etc., to achieve the effect of reducing water inflow, saving engineering investment, and eliminating impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

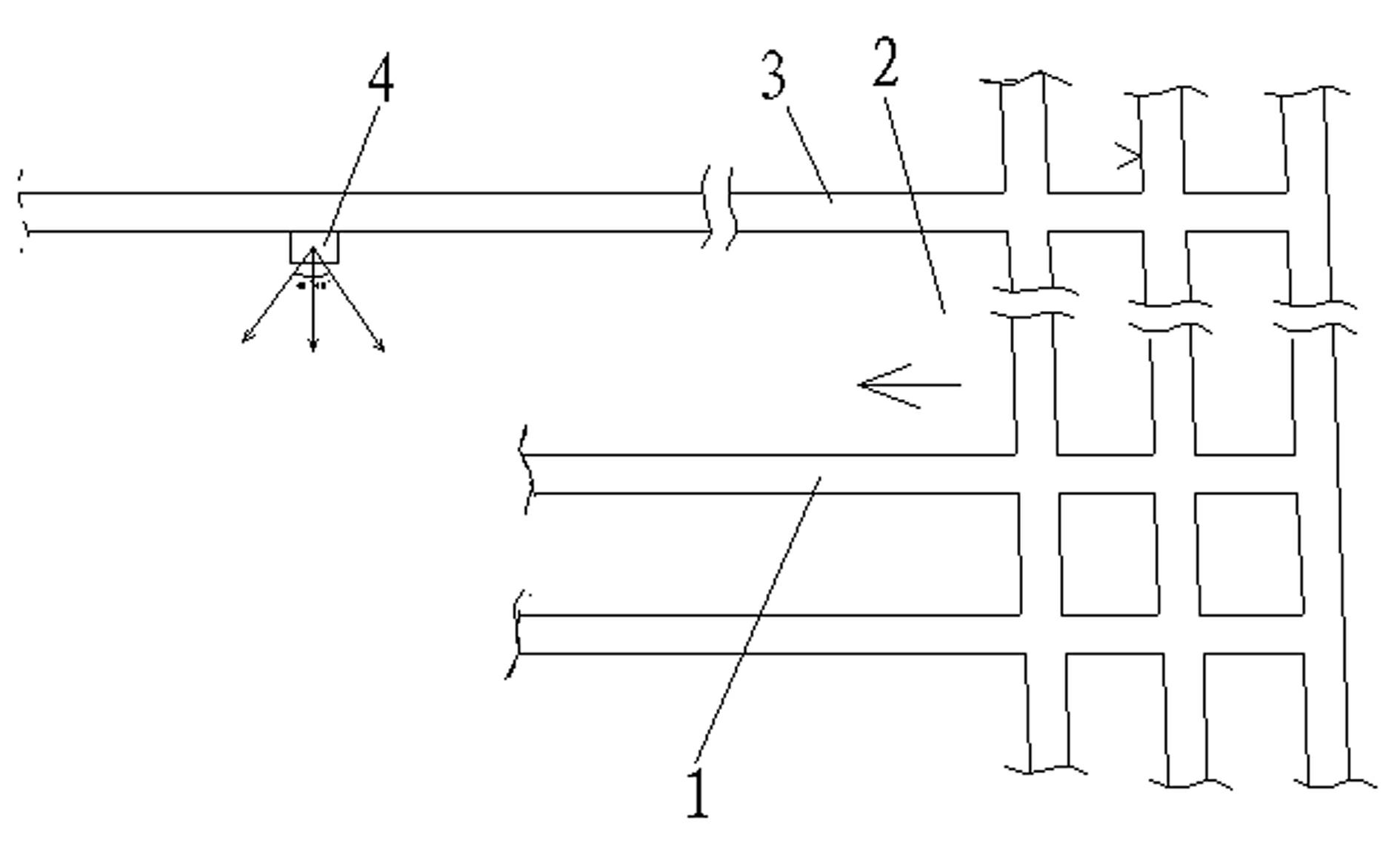

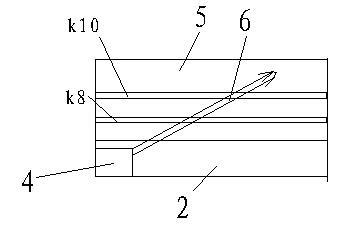

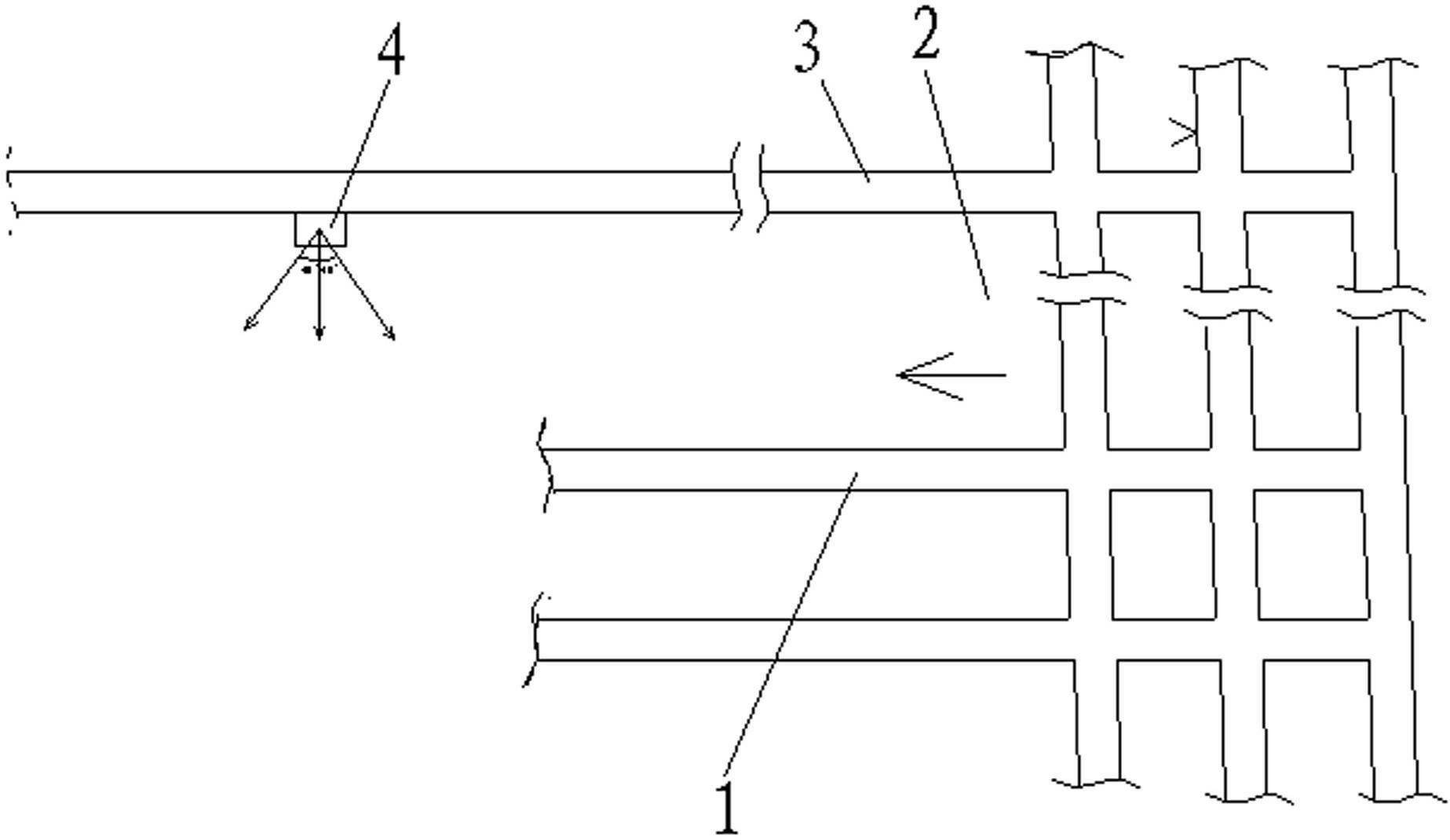

[0011] According to the comprehensive analysis of the hydrogeological conditions of the Changping Mine of our group company, the No. 3 coal seam to be exploited has a relatively high water content in the sandstone aquifers numbered K8 and K10. When the old top of the working face collapses after initial mining, the water output is large and sudden, which easily poses a serious threat to the normal production of the working face and at the same time creates a big impact on the drainage system of the working face.

[0012] However, the water-rich anomalous areas delineated in the ground electrical exploration data are relatively rich in water. If they are not released in advance, the water inflow in some areas may suddenly increase during mining, especially when mining from downhill to uphill terrain, the harm is even greater.

[0013] The No. 3 coal recovery working face was initially mined and the old top span was behind, and the outflow water was off-white. After analysis, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com