Method for using thin-wall bamboo materials to prepare bamboo scrimbers

A technology for reconstituting bamboo and bamboo materials, which is applied in the direction of wood compression, impregnation of wood, and manufacturing tools, etc., can solve the problems of unsatisfactory degree of destruction of bamboo green and bamboo yellow on the surface, poor uniformity of dispersing, etc., to ensure the depth and uniformity of penetration, and reduce the amount of consumption. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Select the green bamboo slices, use the mass concentration of 3% NaOH to process the green bamboo slices, the treatment temperature is 85 ° C, the treatment time is 1h, then rinse with water, then add 30IU / g lipase for 4h, add the treated bamboo slices In the deflagging machine, decompose until the water absorption rate of the bamboo bundles is 80%; the sizing process is to use the glue solution with a solid content of 20% diluted with the NaOH treatment waste liquid after cooking to carry out pre-vacuum-0.06MPa for the selected material for 10min , pressurization pressure 1.0MPa, pressurization 10min, vacuum -0.06MPa, time 5min; the conditions for hot pressing after paving are temperature 140 ℃, pressure 23MPa.

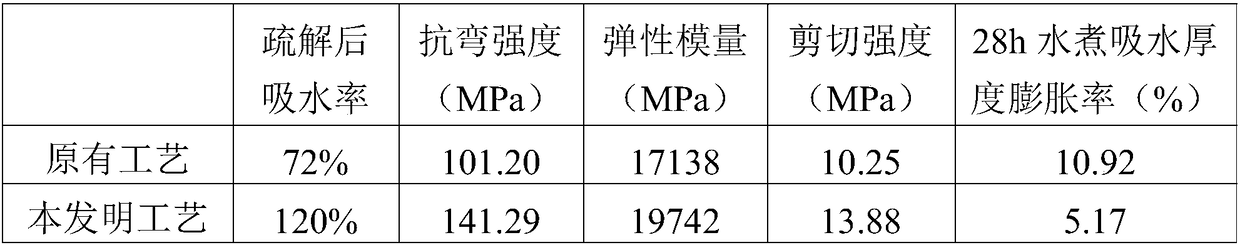

[0034] Adopt the existing debonding process (refer to the preparation process of the literature "The influence of decompression times on the properties of bamboo fiber composites [J]. Timber Industry, 2011, 25 (5), 1-4" for conventional decompression) and conve...

Embodiment 2

[0038] Select bamboo slices with a thickness of 3-5 mm at the tip of the bamboo, and treat the bamboo slices with a mass concentration of 4% NaOH at a temperature of 80 ° C for 1 hour, then rinse with water, and then add 40 IU / g lipase to treat them for 3 hours , the treated bamboo chips are added to the debulking machine, and the water absorption rate of the bamboo bundles is decomposed to 120%; Pre-vacuum-0.06MPa, treatment for 10min, pressurization pressure 0.8MPa, pressurization 8min, post-vacuum-0.06MPa, time 10min; the conditions for hot pressing after paving are temperature 130°C and pressure 20MPa.

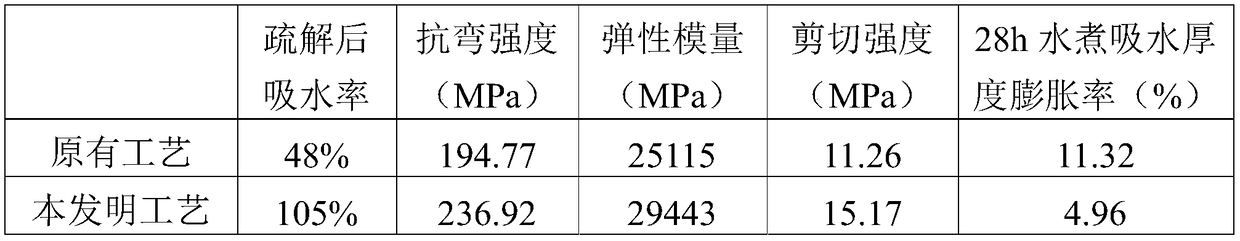

[0039] See Table 2 for the comparison between the performance of the recombined bamboo bamboo prepared by the existing decompression process and the conventional rubber dipping and paving process and the performance of the process of the present invention.

[0040] Table 2 adopts original technology and the performance comparison of the hemp bamboo recombined bamboo prepar...

Embodiment 3

[0043]Select Fendanzhu bamboo slices, process Fendanzhu bamboo slices with a mass concentration of 2% NaOH at a treatment temperature of 95°C for 0.5h, then rinse with water, add 50IU / g lipase for 2h, and treat the treated Bamboo slices are added into the deflagging machine, and the water absorption rate of the bamboo bundles is 105%; the sizing process is to use the glue with a solid content of 20% diluted with NaOH treatment waste liquid after cooking to carry out pre-vacuum-0.06MPa on the selected materials. , treatment for 10 minutes, pressurization pressure 1.2MPa, pressurization 5min, vacuum -0.06MPa, time 8min; the conditions for hot pressing after paving are temperature 140°C and pressure 25MPa.

[0044] See Table 3 for the comparison between the properties of the powdered single bamboo reconstituted bamboo prepared by the existing delamination process and the conventional dipping and paving process and the performance of this technology.

[0045] Table 3 adopts origin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com