Level-rotating drum defibering machine

A technology of horizontal rotation and deflagging machine, applied in the field of papermaking machinery, which can solve the problems of incomplete deflagging, low efficiency, and waste of raw materials, etc., and achieve the effects of simple structure, enhanced deflagging ability, and improved deflagging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

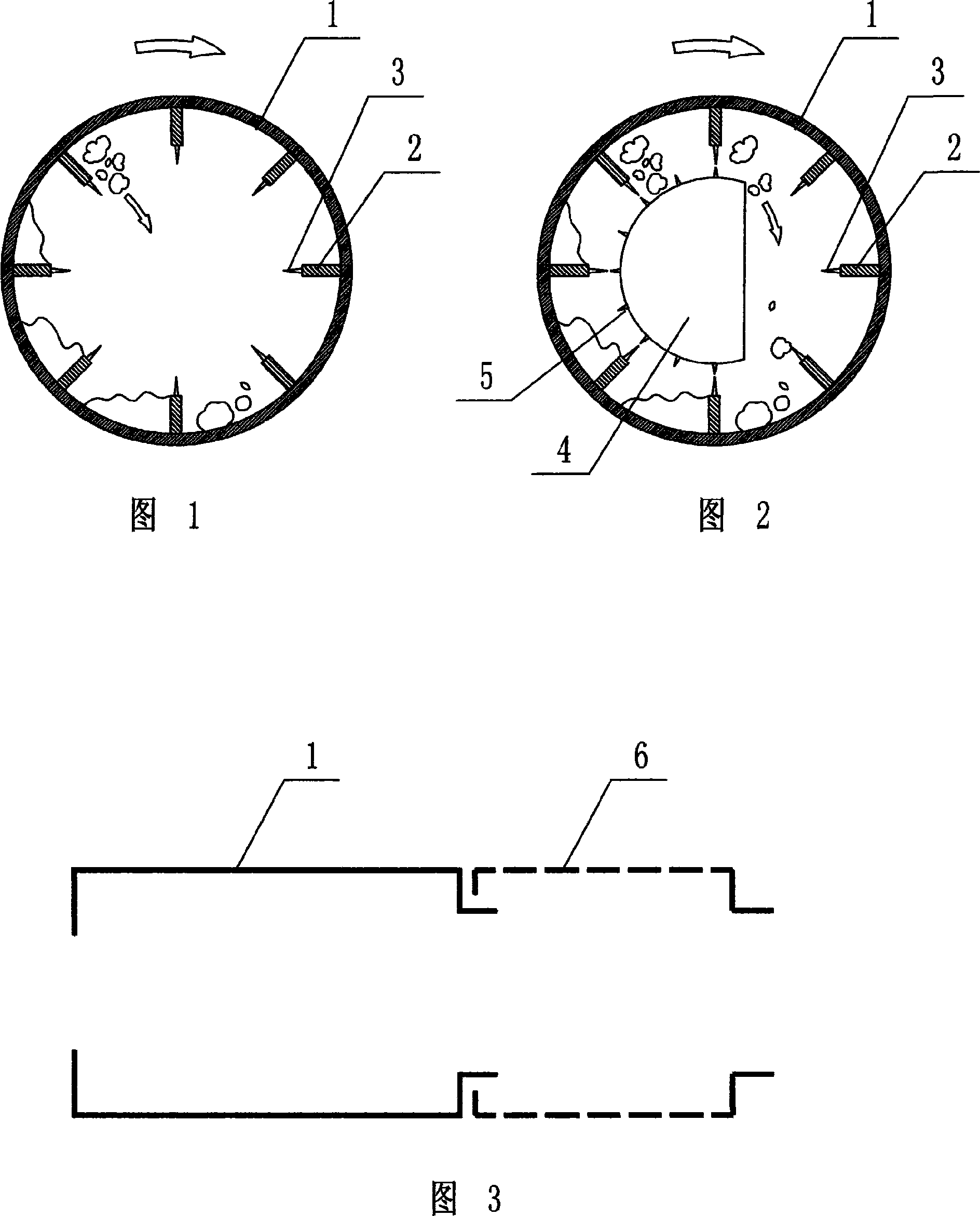

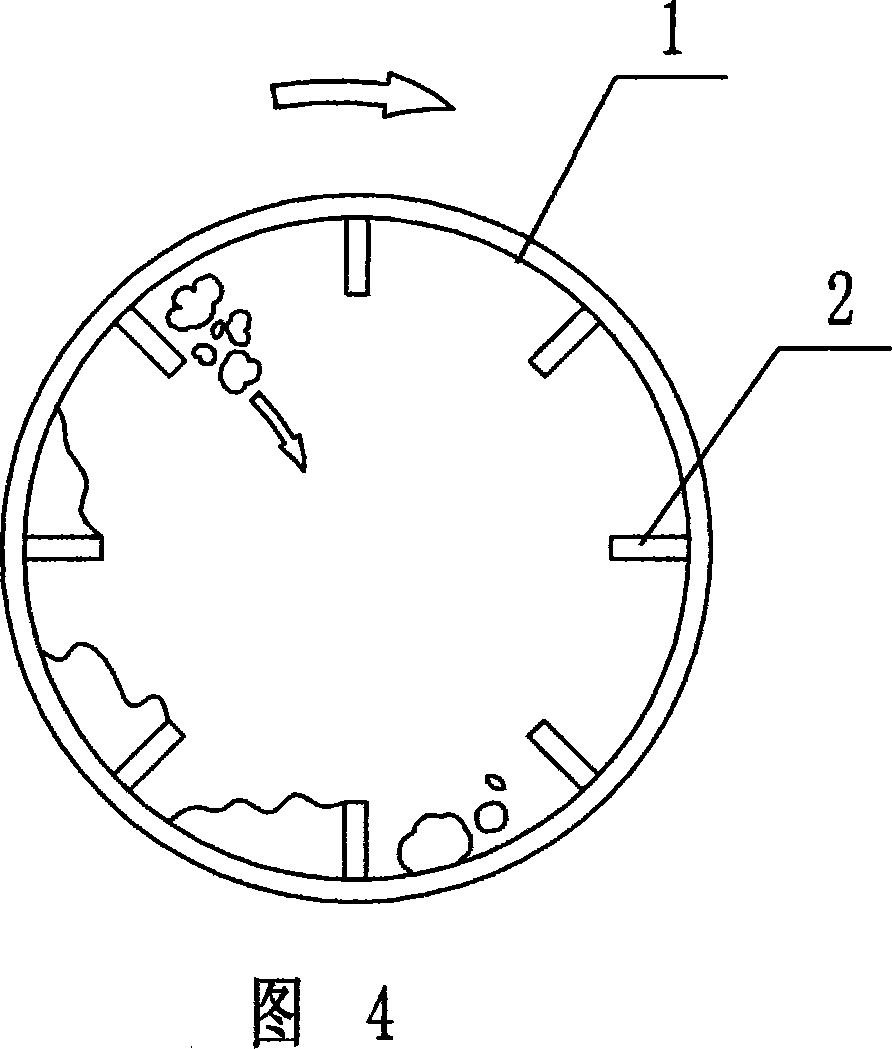

[0015] Embodiment 1: As shown in Figure 1, the horizontal rotary cylinder deflaker includes a deflaker cylinder, and the decompressor cylinder is divided into a pulping zone cylinder 1 and a screening zone cylinder 6, and the pulping zone A partition 2 is provided on the inner wall of the cylinder 1 , and loosening teeth 3 are provided at the end of the partition 2 . The cylinder 1 in the pulping area and the cylinder 6 in the screening area are integrated structures in the prior art. The working principle of the cylinder in the screening area of the cylinder is that the surface of the cylinder is processed with screening holes. After the waste paper is decomposed in the pulping area, it enters the screening area with holes in the surface of the cylinder. Here, the pulp is diluted. Sparse water is added from the water spray device installed above the screening area, so that the fibers blocked in the screen holes can be recoiled back into the cylinder, the good pulp flows int...

Embodiment 2

[0017] Embodiment two: as shown in Fig. 2, Fig. 3, horizontal rotary cylinder deflagging machine, comprises deflagging machine cylinder, and described deflagging machine cylinder is divided into crushing zone cylinder 1 and screening zone cylinder 6, described A baffle 2 is provided on the inner wall of the cylinder 1 in the pulping area, and loosening teeth 3 are provided at the end of the baffle 2 . The cavity of the cylinder 1 in the pulping area is provided with a "D"-shaped drum core 4 arranged axially in the pulping area of the cylinder. The circular surface of the "D"-shaped drum core 4 is located in the rising area of the waste paper cluster. The "D" shaped drum core 4 is also provided with loosening teeth 5 . The cylinder 1 in the pulping area and the cylinder 6 in the screening area are separated, and the cylinder 6 in the screening area is a cylindrical screen. This structure can make the cylinder 1 in the pulping area and the cylinder in the screening area 6. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com