Screening fluffer

A technology of deflagging machine and deflagging area, which is applied in the direction of textile and papermaking, fiber raw material processing, raw material separation, etc. It can solve the problems that cannot be deflagged, achieve the effect of reducing the number of equipment, improving work efficiency, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

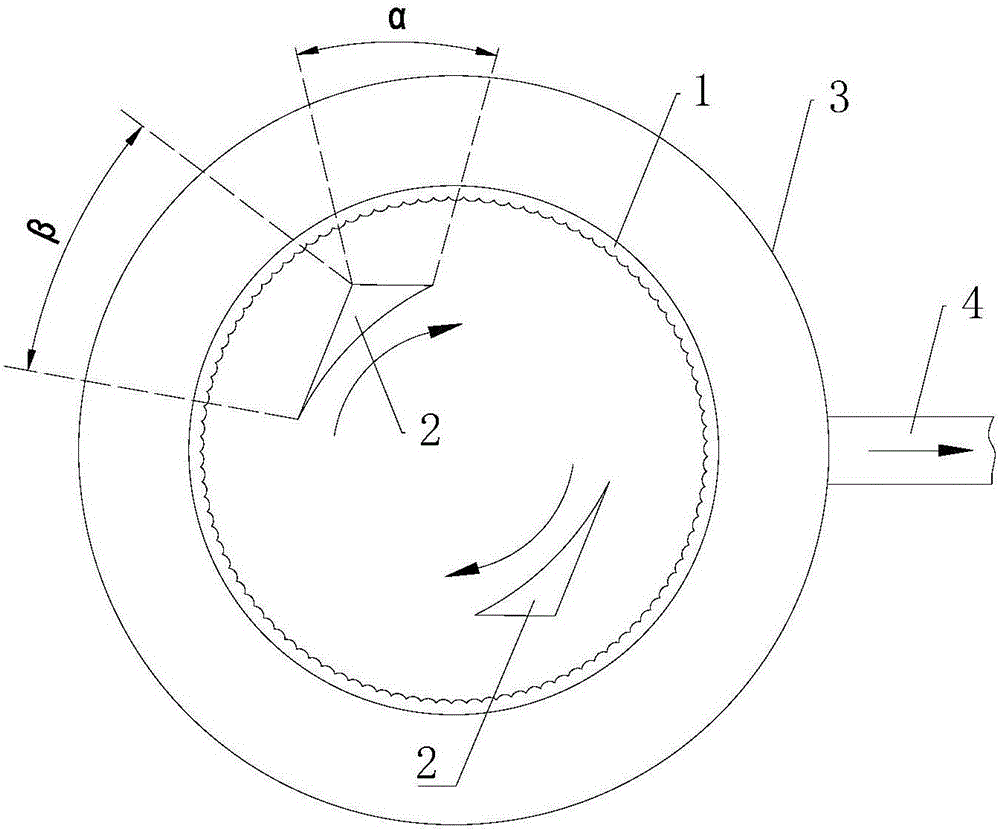

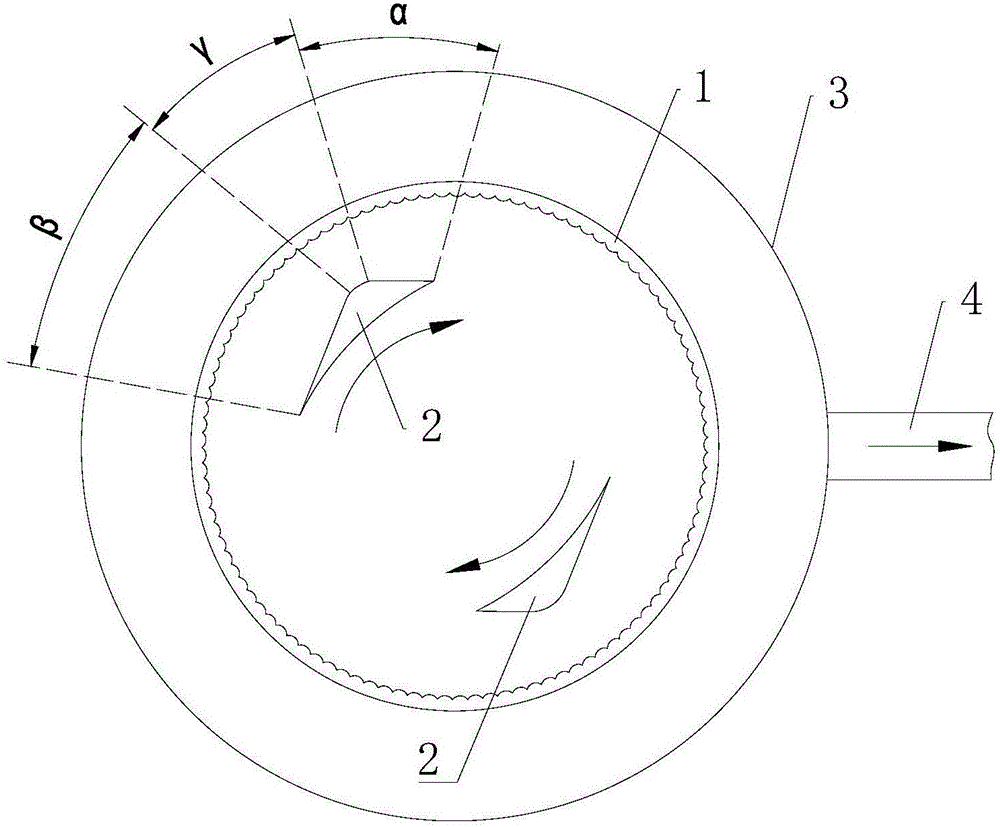

[0023] Such as figure 2 As shown, this embodiment is based on the prior art, and a circular arc transition section is set between the positive pressure section and the negative pressure section of the rotor 2, and the arc transition section is concentric with the screen drum 1 In this way, a debonding zone γ is formed between the arc transition section and the screen drum 1, and the paper sheets or fiber bundles will receive bite, friction, and agitation from the arc transition section and the screen drum in the decompression zone γ until they are dispersed In order to be able to pass through the holes / slots on the surface of the screen drum 1 and enter the fibers of the good stock, the finally formed good stock is discharged from the good stock outlet 4 .

[0024] In addition, by adding a circular arc transition section, a buffer zone can be formed between the positive pressure zone α and the negative pressure zone β. If there is no such buffer zone, the pulp will change fro...

Embodiment 2

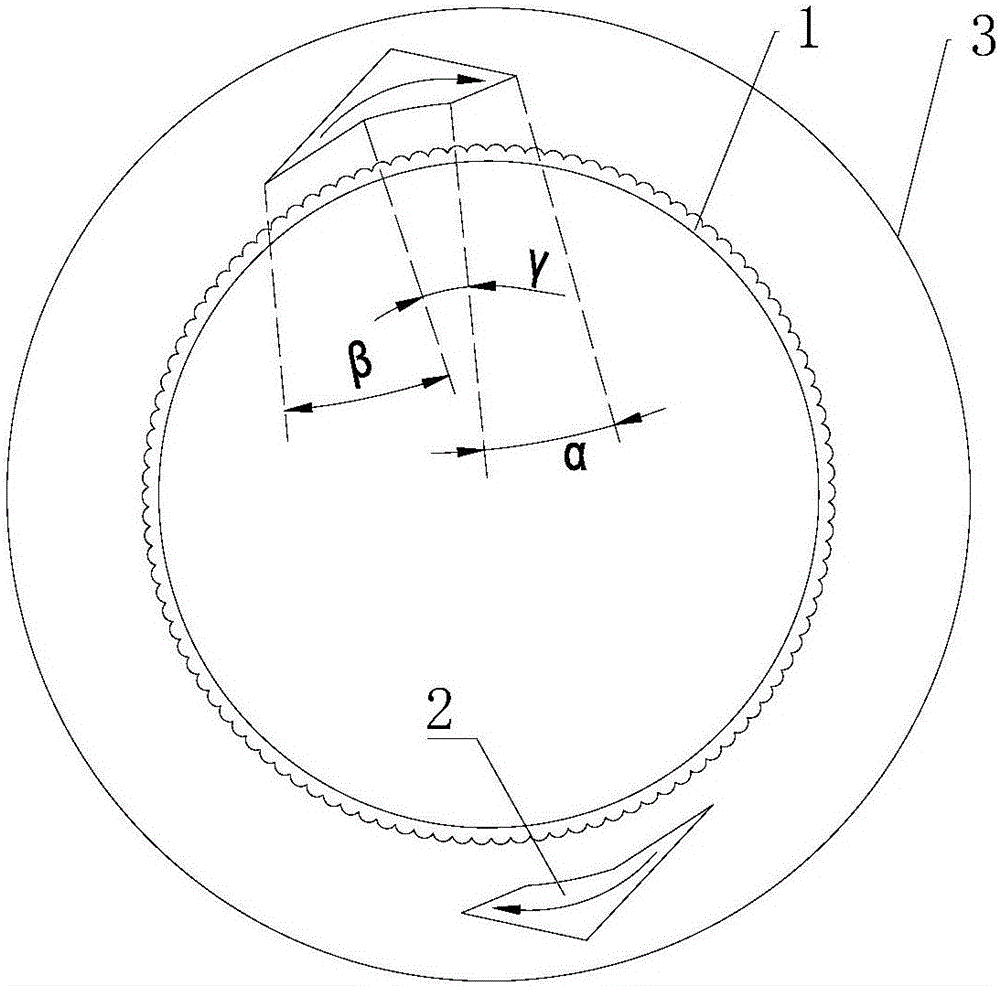

[0026] Such as image 3 As shown, it is another embodiment of the patent of the present invention, which is the same as figure 2 The difference is that the rotor 2 in this embodiment is located outside the screen drum 1. At this time, the pulp passes into the area between the screen drum 1 and the shell 3. Under the action of the positive pressure area α, the good pulp is discharged into the screen The inner cavity of the drum 1, while the paper sheets or fiber bundles are still deflated in the deflation zone γ area between the screen drum 1 and the circular arc transition section of the rotor 2.

Embodiment 3

[0028] Such as Figure 4 As shown, it is another embodiment of the patent of the present invention. This embodiment combines the characteristics of Embodiment 1 and Embodiment 2. It includes two concentric screen drums 1, and the rotor 2 is arranged between the two screen drums 1. In between, the pulp passes into the area between the two screen drums 1.

[0029] Such as Figure 5 Shown is a schematic structural view of the rotor 2 in this embodiment, wherein the inner positive pressure section 21, negative pressure section 22 and circular arc transition section 23 serve the inner screen drum 1, and the good pulp formed by it is discharged into The inner cavity of the inner screen drum 1; the outer positive pressure section 21, negative pressure section 22 and arc transition section 23 serve the outer screen drum 1, and the good pulp formed by it is discharged into the outer screen drum 1, of course , There is also a shell on the outside of the external screen drum 1 . The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com