Preparation method of bamboo veneer and bamboo glue composite board

A composite board and veneer technology, which is used in the joining of wooden veneers, manufacturing tools, and reed/straw treatment, etc., can solve the problems of low mechanical properties, unfavorable promotion and application of bamboo plywood, and decreased mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

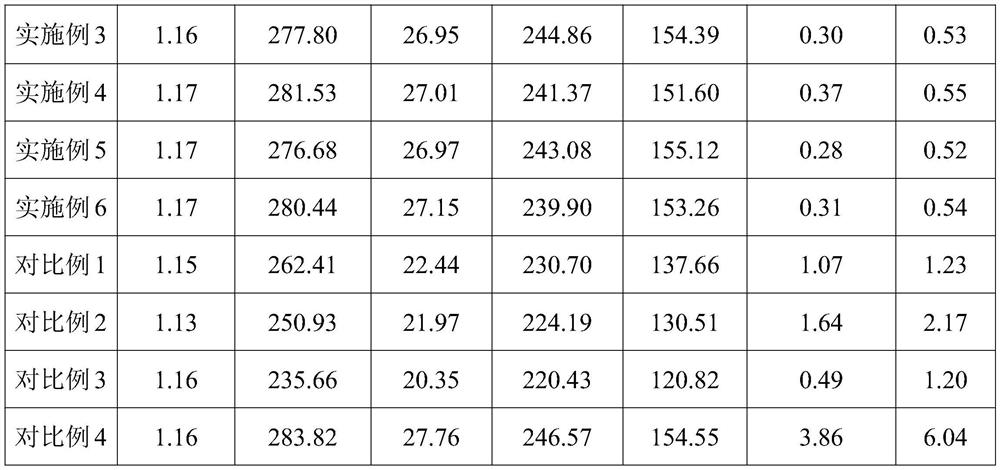

Examples

Embodiment 1

[0034] A preparation method of bamboo veneer;

[0035] Add the bamboo chips to the pretreatment solution, heat up to 50°C and cook for 50 minutes, take out the water and wash to neutrality, then air dry to a moisture content of 10%, and then send the bamboo chips into the decompression equipment, and the bamboo wood is subjected to longitudinal treatment by decompression rollers. The cutting force caused the bamboo pieces to form point-shaped and line-shaped cracks, and at the same time, a force was applied in the radial direction to flatten and stretch to form a fibrous bamboo veneer. , heat up to 70 ℃ and cook for 30 min, take out the water and wash until neutral, air dry to 10% moisture content, put the bamboo veneer in a heat treatment equipment with an oxygen content of 2.5%, heat up to 180 ℃ for 60 min, and then cool down The temperature was kept at 80°C for 40min, and after being naturally cooled to room temperature, it was transferred to the carbonization equipment for...

Embodiment 2

[0042] A preparation method of bamboo veneer;

[0043] Add the bamboo chips to the pretreatment solution, heat up to 50°C and cook for 40 minutes, take out the water and wash to neutrality, then air dry to a moisture content of 10%, and then send the bamboo chips into the decompression equipment, and the bamboo wood is subjected to longitudinal treatment by decompression rollers. The cutting force caused the bamboo pieces to form point-shaped and line-shaped cracks, and at the same time, a force was applied in the radial direction to flatten and stretch to form a fibrous bamboo veneer. , heat up to 70 ℃ and cook for 20 min, take out the water and wash until neutral, then air dry to a moisture content of 7%, put the bamboo veneer in a heat treatment equipment with an oxygen content of 2%, heat up to 160 ℃ for 60 min, and then cool down The temperature was kept at 80°C for 40 minutes, and after being naturally cooled to room temperature, it was transferred to the carbonization e...

Embodiment 3

[0050] A preparation method of bamboo veneer;

[0051] Add bamboo slices to the pretreatment liquid, heat up to 60°C and cook for 60 minutes, take out and wash with water until neutral, then dry to a moisture content of 16%, and then send the bamboo slices into the decompression equipment, and apply longitudinal dehydration to the bamboo by decompression rollers. The cutting force makes the bamboo slices form point-like and segment-like cracks, and at the same time exerts force in the radial direction to make it flatten and stretch to form a fibrous bamboo veneer, which is decomposed 5 times, and the bamboo veneer is added to the post-treatment solution In the middle, heat up to 80°C and cook for 30 minutes, take it out and wash it to neutral, then dry it to a moisture content of 10%, put the bamboo veneer in a heat treatment equipment with an oxygen content of 2.5%, heat up to 180°C for 90 minutes, and then cool down Keep warm at 100°C for 50 minutes, cool to room temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com