Preparation method of A type molecular sieve with hierarchical duct

A technology of molecular sieves and channels, which is applied in the field of preparation of multi-channel A-type molecular sieves, can solve the problems of single channels and poor separation effects, and achieve the effects of shortening the cycle, increasing the force, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

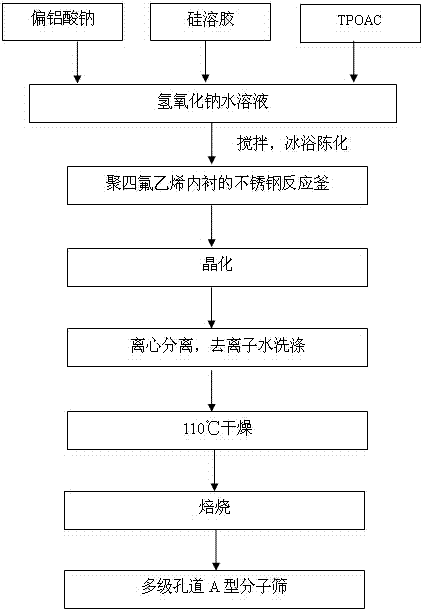

Method used

Image

Examples

Embodiment 1

[0024] Weigh 2.40g of sodium hydroxide solid and 1.64g of sodium metaaluminate and dissolve them in 14.13mL of deionized water, stir and dissolve until clear; add 4.80g of silica sol and 0.12g of TPOAC to the above solution while stirring, and stir and age for 1h; Then transfer the mixture to a stainless steel kettle lined with polytetrafluoroethylene, put it in an oven at 80°C for crystallization for 4 hours; filter and separate, wash the filter residue with deionized water until the pH is lower than 9, and place the washed filter residue in the oven Dry at 90°C overnight, then put it in a muffle furnace, and bake at 500°C for 3 hours to remove the organosilane template, and then obtain a type A molecular sieve with hierarchical channels.

[0025] The specific surface area of the multi-stage channel type A molecular sieve described in this embodiment is 589m 2 / g, the channels are evenly distributed between mesopores and micropores.

Embodiment 2

[0027] Weigh 1.60g of sodium hydroxide solid and 3.28g of sodium metaaluminate and dissolve in 17.64mL of deionized water, stir and dissolve until clear; add 12.00g of silica sol and 2.36g of TPOAC to the above solution while stirring, and stir and age for 5h; Then transfer the mixture to a stainless steel kettle lined with polytetrafluoroethylene, put it in an oven at 110°C for crystallization for 9 hours; filter and separate, wash the filter residue with deionized water until the pH is lower than 9, and place the washed filter residue in the oven Dry at 90°C overnight, then place it in a muffle furnace, and bake at 600°C for 6 hours to remove the organosilane template to obtain a molecular sieve with hierarchical channels A.

[0028] The specific surface area of the multi-stage channel type A molecular sieve prepared in this example is 621m 2 / g, the channels are evenly distributed between mesopores and micropores.

Embodiment 3

[0030] Weigh 1.76g of sodium hydroxide solid, 1.31g of sodium metaaluminate and dissolve in 18.50mL of deionized water, stir and dissolve until clear; add 3.60g of silica sol and 1.18g of TPOAC to the above solution while stirring, and stir and age for 4h; Then transfer the mixture to a stainless steel kettle lined with polytetrafluoroethylene, put it in a 90°C oven for crystallization for 7 hours; filter and separate, wash the filter residue with deionized water until the pH is lower than 9, and place the washed filter residue in the oven Dry at 90°C overnight, then place in a muffle furnace, and bake at 550°C for 4 hours to remove the organosilane template to obtain a molecular sieve with hierarchical channels A.

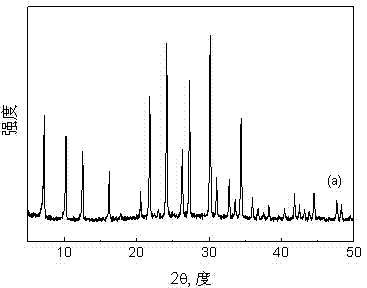

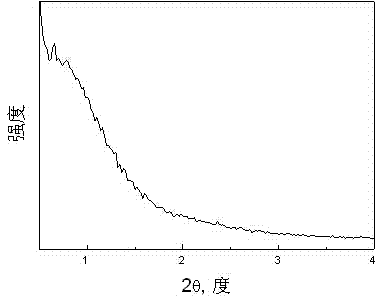

[0031] The XRD spectrogram of the multi-stage channel type A molecular sieve prepared in this embodiment is as follows Figure 2~3 shown, where figure 2 The XRD spectrum of the multi-stage channel A molecular sieve, image 3 It is the small-angle diffraction sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com