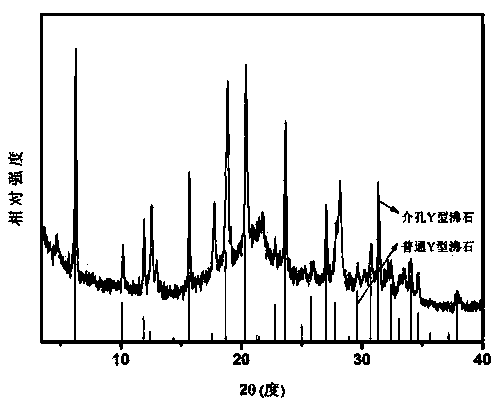

Mesoporous Y-type zeolite molecular sieve and preparation method thereof

A zeolite molecular sieve and mesoporous technology, which is applied in the directions of crystalline aluminosilicate zeolite, fajhedral crystalline aluminosilicate zeolite, etc., can solve the problems of unfavorable industrial production, complicated preparation steps and high synthesis cost, and achieves low cost and high preparation technology. The effect of simple, simplified compositing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) 5.425g of sodium hydroxide, 1.065g of sodium metaaluminate (44.7 wt% Na 2 O, 52.0 wt% Al 2 o 3 ), 22.511g of water glass (modulus 3.1), and 42.5ml of water were mixed evenly, aged at 30°C for 24h to obtain a Y-type zeolite directing agent.

[0031] (2) Mix 29.0ml of water glass (modulus 3.1), 3.0ml of water, and 4.0ml of the directing agent prepared in step (1) at room temperature. After stirring for 1 hour, add 3.5ml of TPOAC (60 wt% , J£K) was added slowly and continued to stir for 2h. Finally, 5.0 ml of aluminum sulfate octadecahydrate (24 wt%) aqueous solution and 6.0 ml of mixed aqueous solution of sodium metaaluminate and sodium hydroxide (17.8 wt% NaAlO 2 , 9.5 wt% NaOH), stirred at room temperature for 1 h to obtain a viscous aluminosilicate gel.

[0032] (3) Put the material produced in step (2) into a sealed stainless steel reaction kettle, and crystallize at 90°C for 24 hours. The organic template was removed by calcining at ℃ for 8 hours to obtain a...

Embodiment 2

[0034] (1) 6.0g of sodium hydroxide, 1.5g of sodium metaaluminate (44.7 wt% Na 2 O, 52.0 wt% Al 2 o 3 ), 21.0g of water glass (modulus 3.4), and 45.0ml of water were mixed evenly, aged at 35°C for 48h to obtain a Y-type zeolite directing agent.

[0035] (2) Mix 35.0ml of water glass (modulus 3.4), 6.0ml of water, and 7.0ml of the directing agent prepared in step (1) at room temperature. After stirring for 4 hours, add 5.0ml of TPOAC (60 wt% , J£K) was added slowly and continued to stir for 6h. Finally, 7.5 ml of aluminum sulfate octadecahydrate (24 wt%) aqueous solution and 8.0 ml of mixed aqueous solution of sodium metaaluminate and sodium hydroxide (17.8 wt% NaAlO 2 , 9.5 wt% NaOH), stirred at room temperature for 3 h to obtain a viscous aluminosilicate gel.

[0036] (3) Put the material produced in step (2) into a sealed stainless steel reaction kettle, and crystallize at 110°C for 60 hours. The organic template is removed by roasting at ℃ for 5 hours, so as to obtain ...

Embodiment 3

[0038] (1) Mix 8.0g of sodium hydroxide, 2.5g of sodium metaaluminate (44.7 wt% Na 2 O, 52.0 wt% Al 2 o 3 ), 23.0g of water glass (modulus 3.2), and 50.0ml of water were mixed evenly, aged at 32°C for 36h to obtain a Y-type zeolite directing agent.

[0039] (2) Mix 32.0 ml of water glass (modulus 3.2), 5.0 ml of water, and 6.0 ml of the directing agent prepared in step (1) at room temperature. After stirring for 2.5 hours, add 4.0 ml of TPOAC (60 wt % , J£K) was added slowly and continued to stir for 5h. Finally, 6.0 ml of aluminum sulfate octadecahydrate (24 wt%) aqueous solution and 7.5 ml of mixed solution of sodium metaaluminate and sodium hydroxide (17.8 wt% NaAlO 2 , 9.5 wt% NaOH), stirred at room temperature for 2 h to obtain a viscous aluminosilicate gel.

[0040] (3) Put the material produced in step (2) into a sealed stainless steel reaction kettle, and crystallize at 100°C for 40 hours. The organic template was removed by calcining at ℃ for 8 hours to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com