Composite material and method of making same

A technology of composite materials and metal materials, which is applied in the field of aircraft maintenance and manufacturing, can solve problems such as unfavorable structural weight, and achieve the effects of avoiding delamination, simplifying the production process, and improving the heat generation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Referring now to the accompanying drawings, specific embodiments of the present invention will be described in detail. What is described here is only a preferred embodiment of the present invention, and those skilled in the art can think of other ways to realize the present invention on the basis of the preferred embodiments, and the other ways also fall within the scope of the present invention.

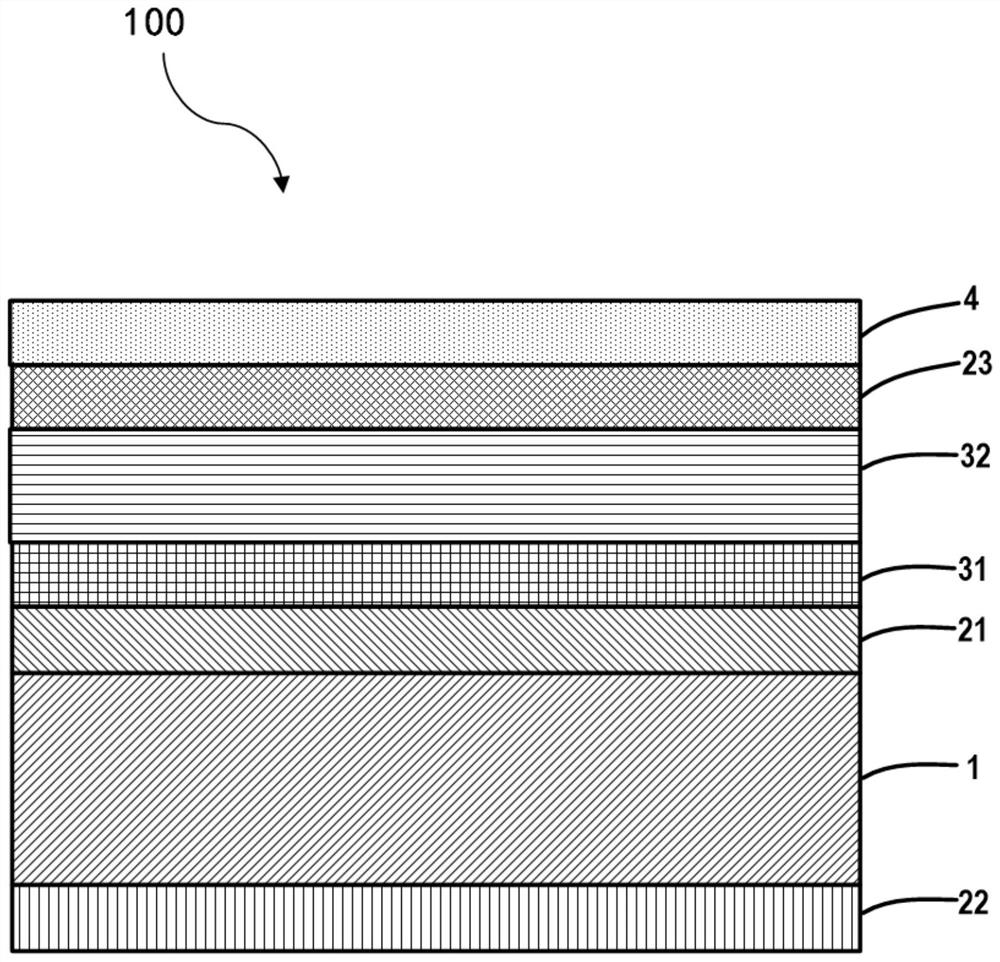

[0027] The invention provides a composite material for an aircraft and a method of manufacturing the composite material. figure 1 A composite material 100 according to a preferred embodiment of the invention is shown.

[0028] The composite material 100 mainly plays the role of anti-icing and de-icing, and includes a base layer and at least two electric heating layers located on the upper side of the base layer.

[0029] Specifically, refer to figure 1 , it can be seen that the base layer includes the main structural layer 1 and the first insulating layer 21 and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com