Flow improver for shale gas reservoir fracturing and preparation method thereof

A flow improver and shale gas reservoir technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as large air flow resistance, large formation damage, low shale porosity and permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

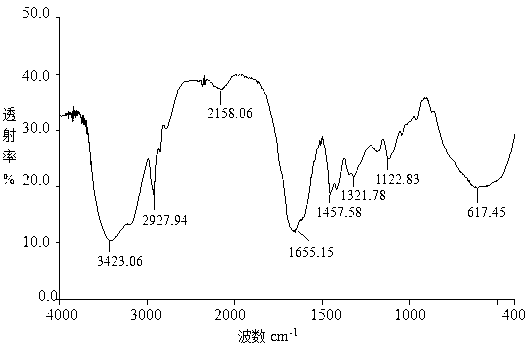

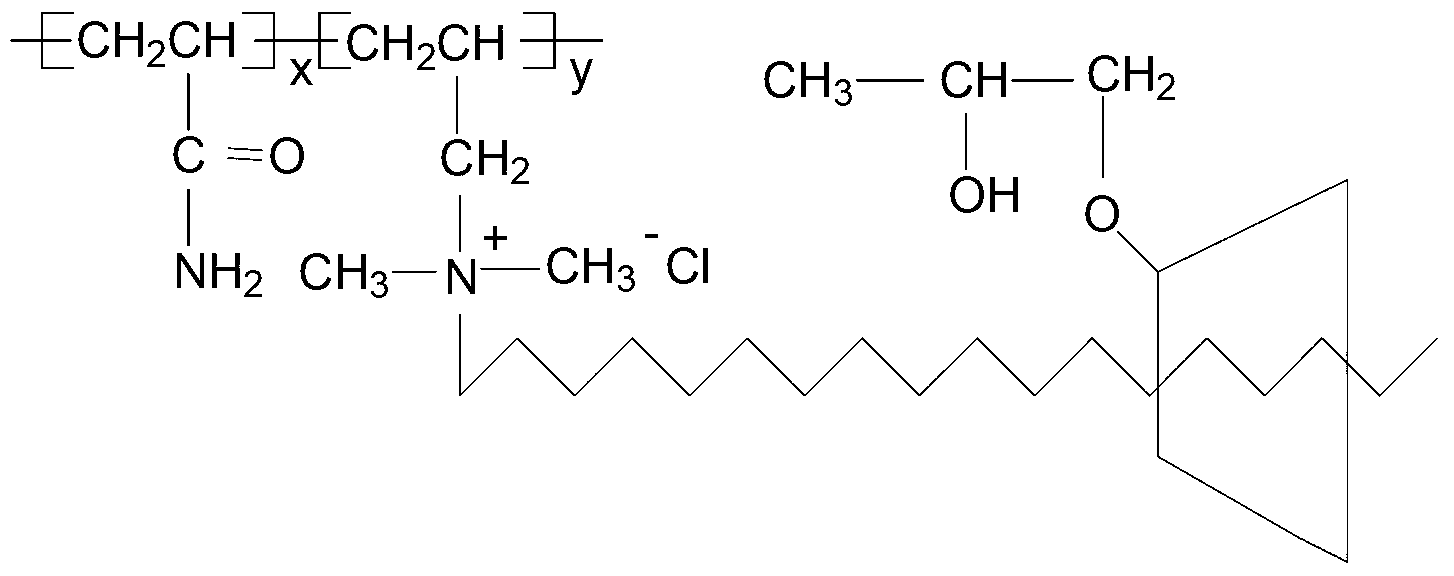

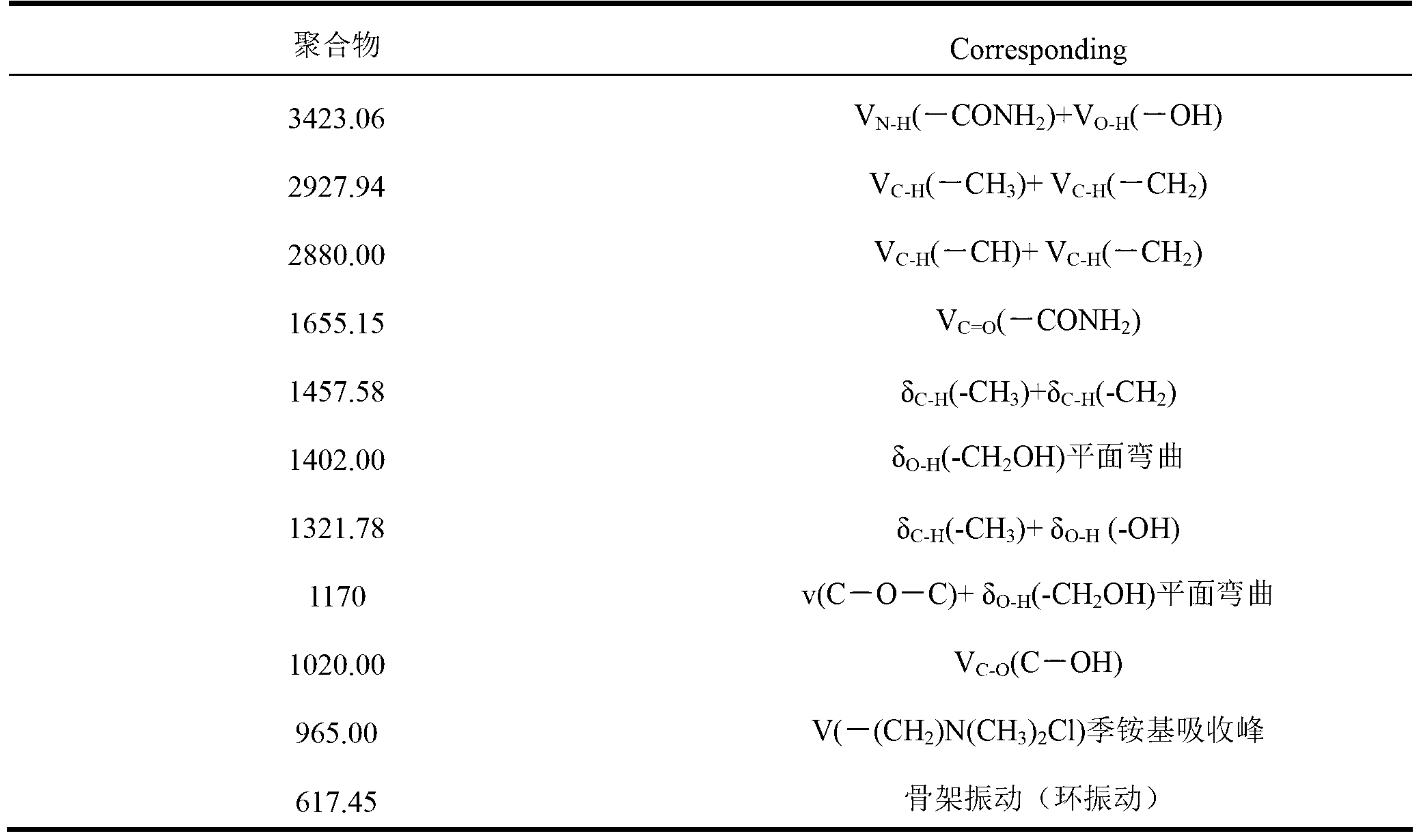

Image

Examples

Embodiment 1

[0014] Dissolve 6.95g of acrylamide in 10g of water to prepare an acrylamide solution, and dissolve 0.56g of dimethyl allyl octadecyl ammonium chloride in 1g of 50% ethanol aqueous solution to prepare a dimethyl alkene solution. Propyloctadecylammonium Chloride Solution. Move the above two solutions into a three-necked flask, add 5 mL of ammonium persulfate solution initiator with a volume concentration of 40 mg / L, fill with nitrogen for 30 minutes, and put it in a magnetically stirred water bath at 45°C for 18 hours. , in acrylamide and dimethyl allyl octadecyl ammonium chloride binary polymer. Then add 36 g of 50% aqueous solution of hydroxypropyl cyclodextrin to the above-mentioned binary polymer solution and continue to stir for 18 hours at a temperature of 60° C. to obtain acrylamide and dimethylallyl octadecyl chloride A flow improver for fracturing of shale gas reservoirs, which is a supramolecular compound of hydroxypropyl cyclodextrin inclusion of ammonium chloride b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com