Patents

Literature

30 results about "Dodecylammonium chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

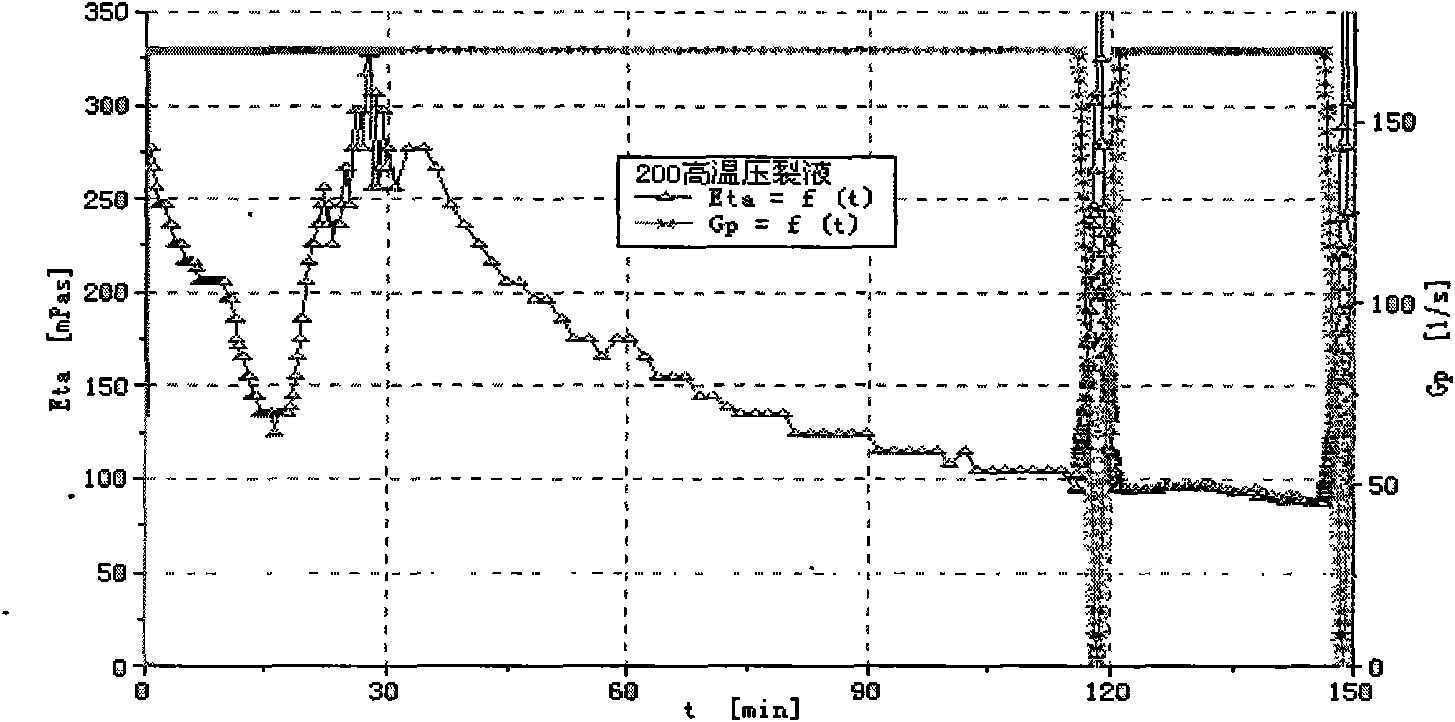

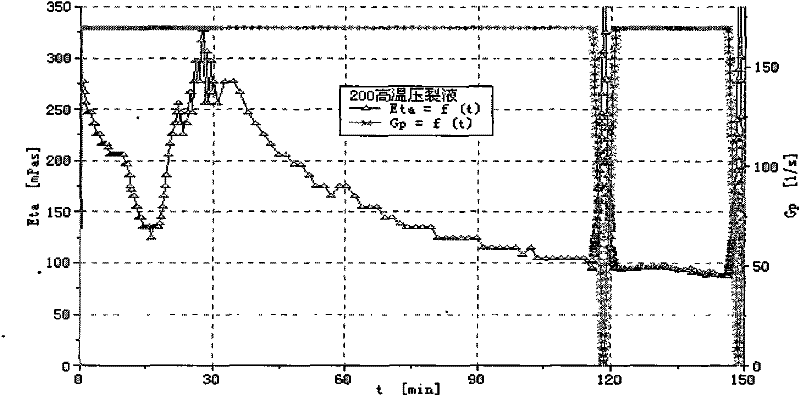

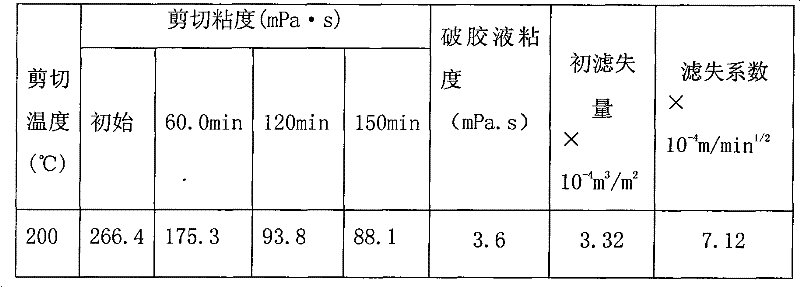

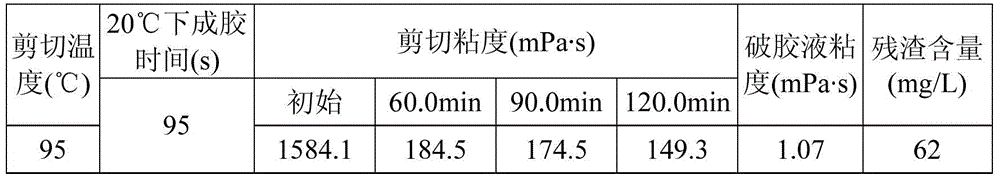

200-DEG C super-high temperature fracturing fluid

InactiveCN101633839AReduce broken linksReduce the possibility of broken linksDrilling compositionPersulfateFracturing fluid

The invention relates to a 200-DEG C super-high temperature fracturing fluid. The fracturing fluid comprises the following components in terms of mass percentage: 0.60% of carboxymethyl hydroxypropyl guar gum, 0.35% of polyacrylamide, 0.18% of organosilicon polyether, 0.09% of polyoxypropylene polyoxyethylene polyoxypropylene octadecanol ether, 0.24% of dodecyl ammonium chloride, 0.12% of cation long chain polymer, 0.33% of organo-metallic crosslinker, 0.00027% of persulfate, 0.0001% of high-valence oxysalt and the balance of water. The fracturing fluid is high-temperature-resistant and shear-resistant and has complete gel breaking property.

Owner:DAQING OILFIELD CO LTD

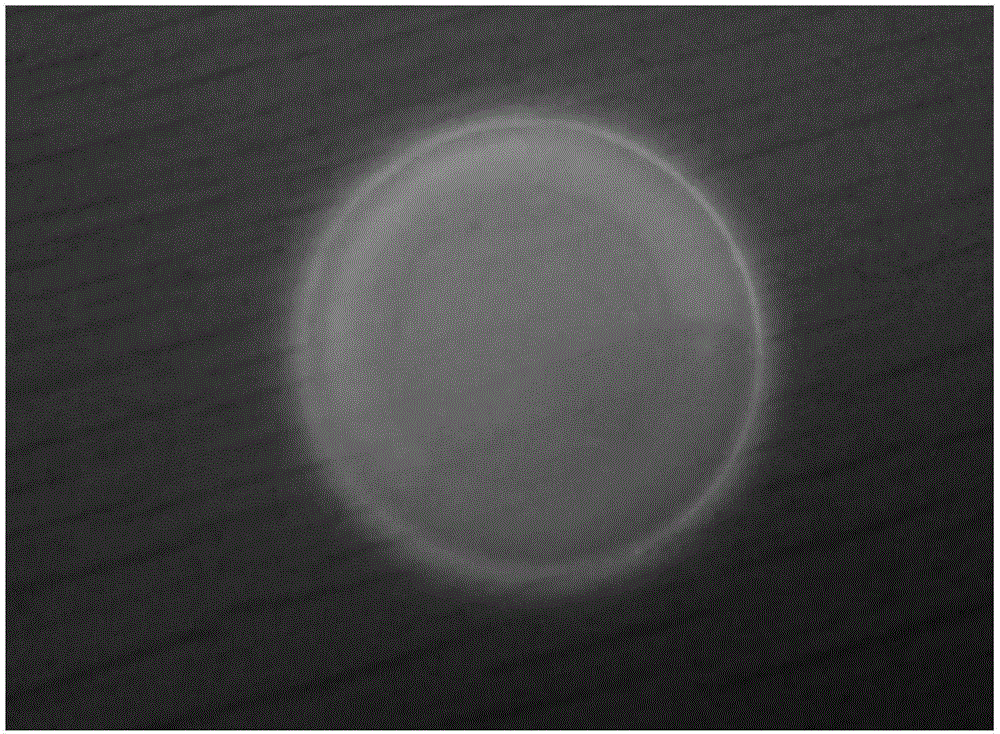

Fluorescent latex containing rhodamine B and preparing method thereof

InactiveCN105820283AEvenly wrappedExcellent fluorescence performanceLuminescent paintsLuminescent compositionsWater basedFluorescence

The invention discloses fluorescent latex containing rhodamine B and a preparing method thereof. The fluorescent latex is prepared from, 0.1-1wt% of rhodamine B, 5-25wt% of methyl methacrylate, 45-65wt% of styrene, 25-45wt% of butyl acrylate, cationic emulsifier and thermal initiator, the cationic emulsifier is one of cetyl trimethyl ammonium bromide, dodecyl ammonium chloride and dodecyl pyridine ammonium chloride, and the thermal initiator is azobis(2-methylpropionamidine) amidine hydrochloride or azobisisobutryamide imidazoline chloride. The relative amount of added water is controlled, and the solid content range of the prepared water-based fluorescent latex polymer is 10-40wt%. According to the prepared fluorescent latex containing rhodamine B, rhodamine B is evenly adsorbed on the surfaces of latex particles through charge attraction so as to be uniformly dispersed during solidification, and the aggregation-induced quenching effect is inhibited.

Owner:SUZHOU JIREN HIGH TECH MATERIAL CO LTD

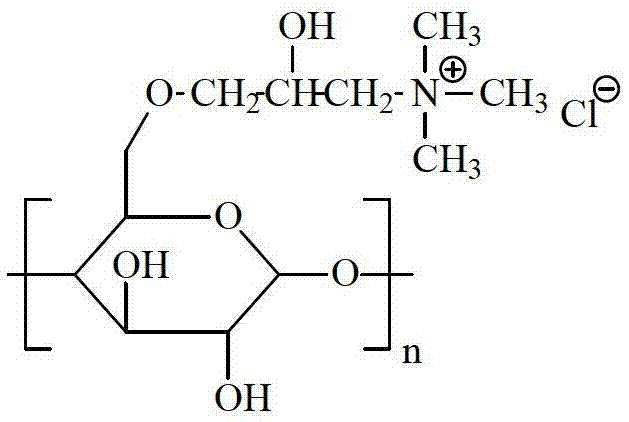

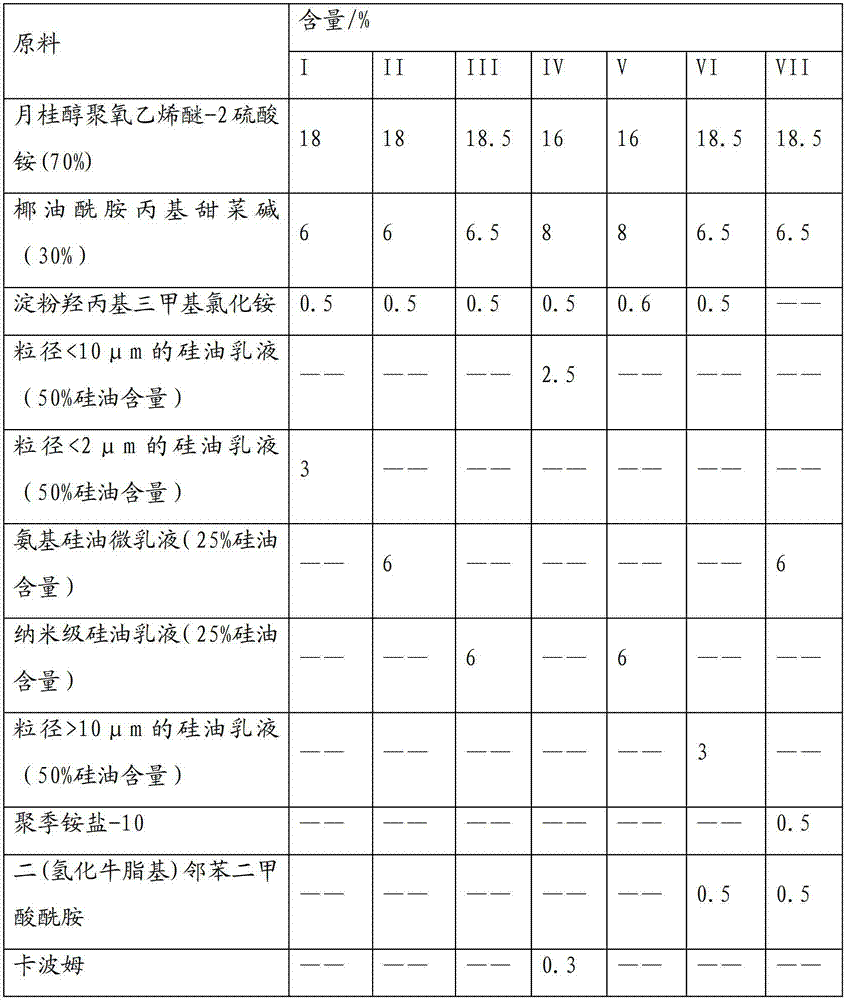

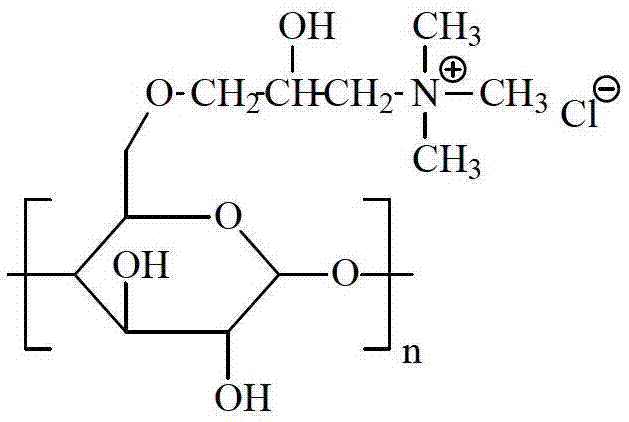

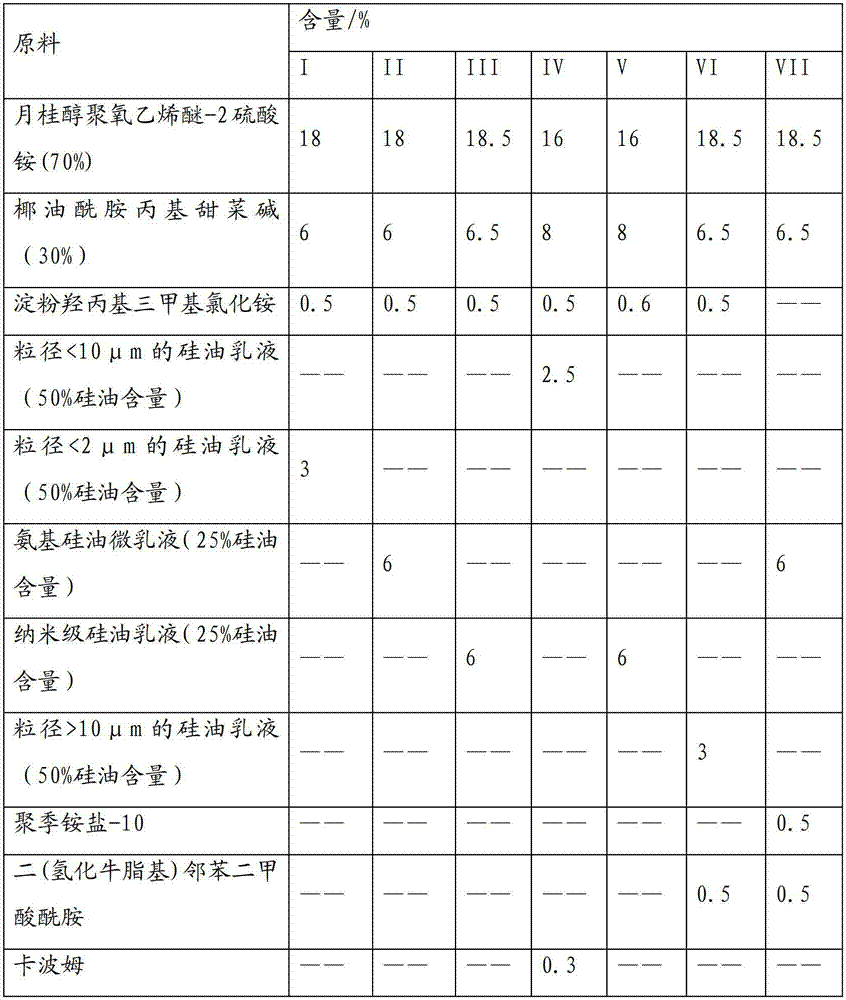

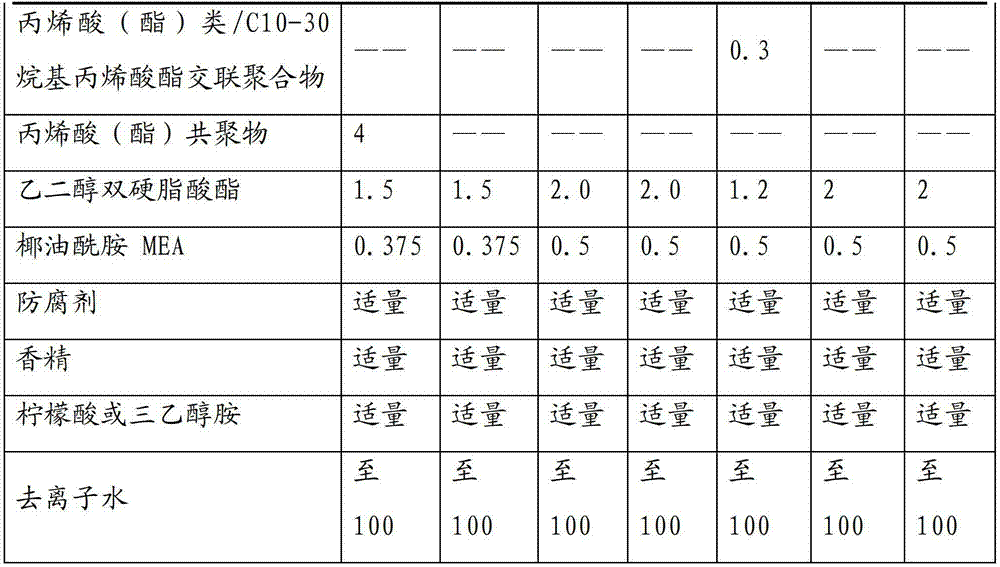

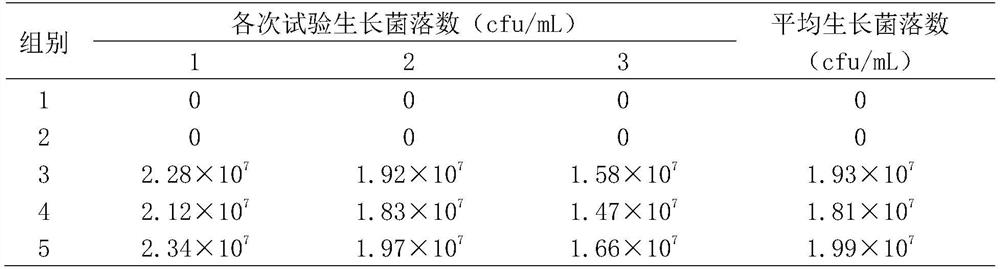

Shampoo composite containing cationic starch

ActiveCN103191033AWide variety of sourcesQuality is easy to controlCosmetic preparationsHair cosmeticsEmulsionEthyl Chloride

The invention discloses a shampoo composite containing cationic starch. The composite is prepared from the following raw materials in percentage by weight: a, 8-40% of a surfactant; b, 0.1-5% of cationic starch; c, 0.1-10% of silicone oil emulsion; and d, the balance of water, wherein the surfactant is selected from one or several anionic surfactants or ampholytic surfactants; the particle size of the silicone oil emulsion is 1 nanometer to 10 micrometers; and the cationic starch is prepared from starch and 2,3-epoxypropyl trimethyl ammonium chloride, 3-chlorine-2-hydroxypropyl trimethyl ammonium chloride or 3-chlorine-2-hydroxypropyl dimethyl-dodecyl ammonium chloride. According to the shampoo composite disclosed by the invention, the cationic starch is compounded with the silicone oil emulsion, so that the hand feeling of hair in a hairdressing process and the hand feeling, the carding performance and gloss of dried hair are improved; and an excellent use feeling is provided and the cost of the composite is reduced.

Owner:GUANGZHOU TINCI MATERIALS TECH

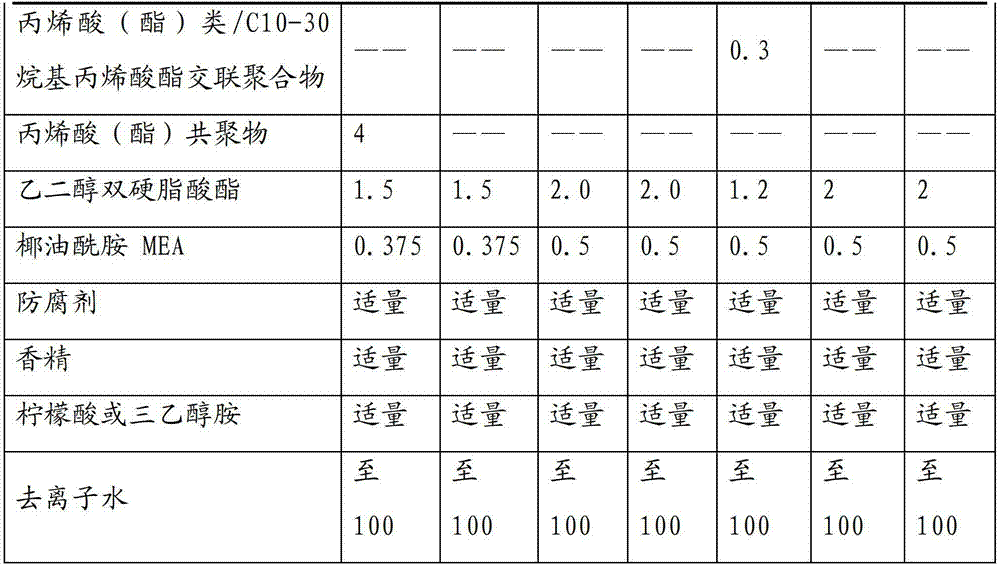

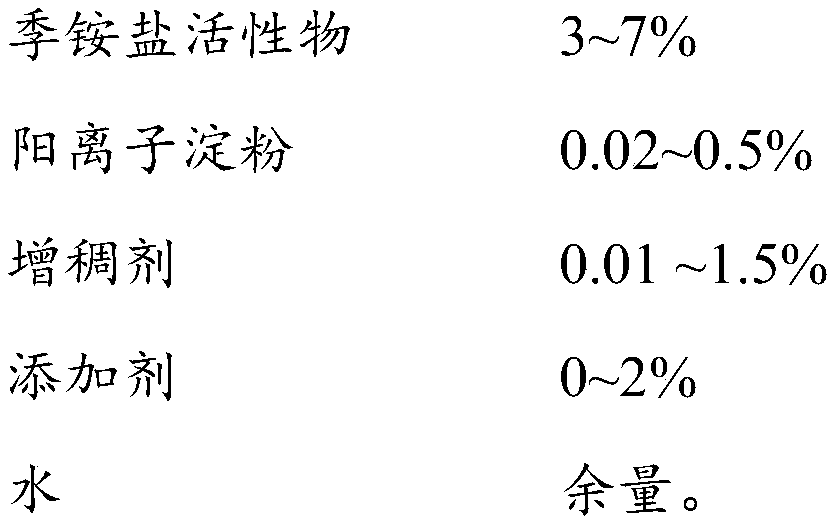

Softener compound

ActiveCN106835698AImproves the ability to soften fabricsImprove abilitiesGrip property fibresQuaternary ammonium cationDodecylammonium chloride

The invention relates to a softener compound which comprises the following components by weight percent: 3-7% of quaternary ammonium salt active matter, 0.02-0.5% of cationic starch, 0.01-0.5% of thickening agent, 0-2% of additive and the balance of water, wherein the cationic starch is prepared from starch and 2,3-glycidyl trimethyl ammonium chloride, 3-chlorine-2-hydroxypropyl trimethyl ammonium chloride, 3-chlorine-2-hydroxypropyl dimethyl-dodecyl ammonium chloride or 3-chlorine-2-hydroxypropyl dimethyl-octadecyl ammonium chloride. The softener compound is formed by compounding cationic starch with quaternary ammonium salt active matter; less cationic starch (accounting for 0.02-0.5wt% of the compound) is used together with quaternary ammonium salt; the softening fabric effect is better than that of singly used quaternary ammonium salt; the oily hand feel caused by the quaternary ammonium salt in higher saturability is relieved to some extent; a smoother experience is brought.

Owner:GUANGZHOU TINCI MATERIALS TECH

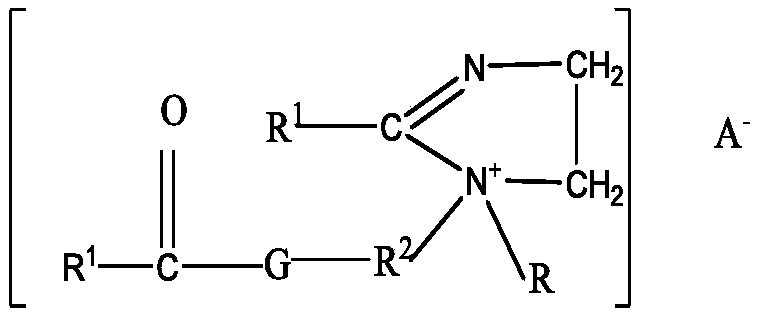

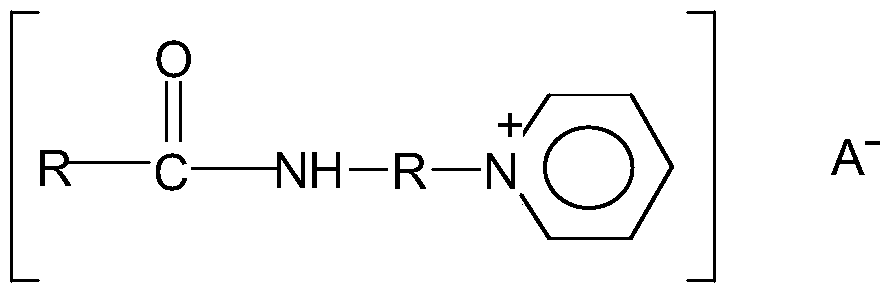

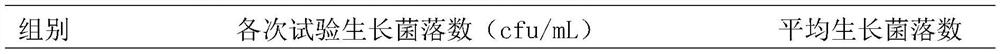

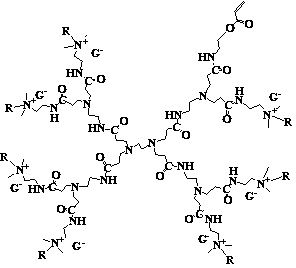

Amphipathic high-molecular viscous oil activator and application thereof

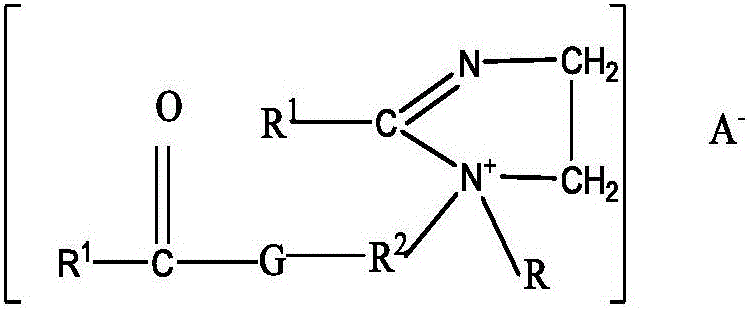

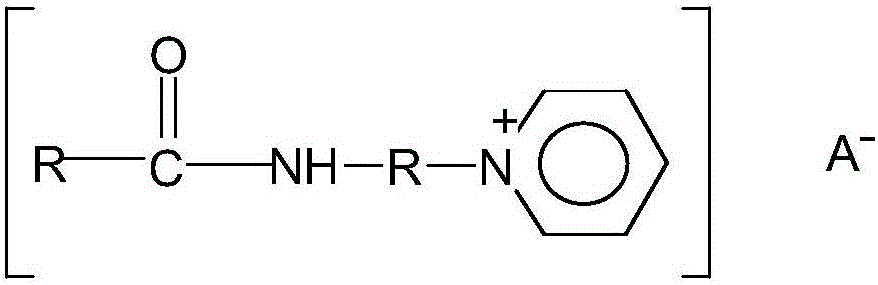

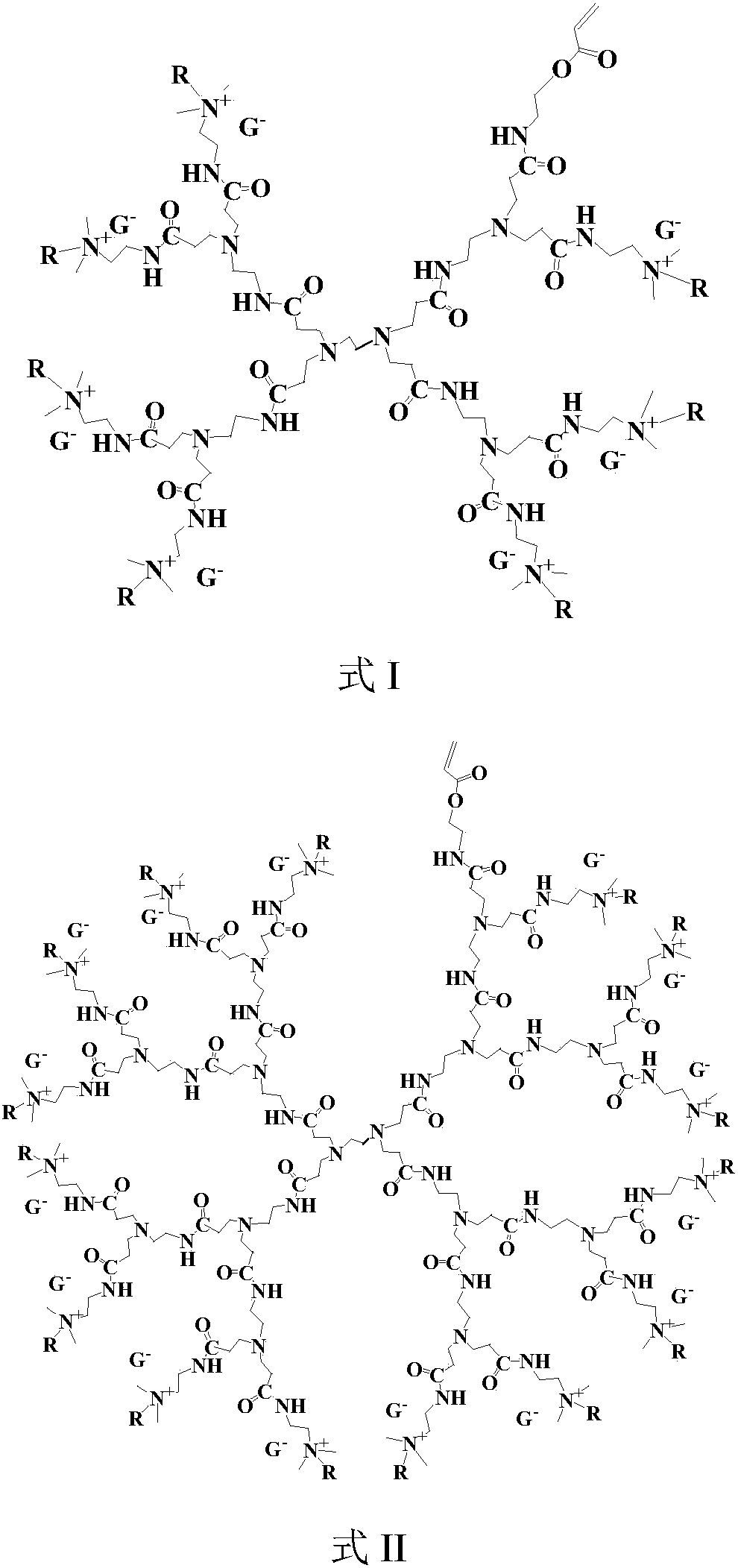

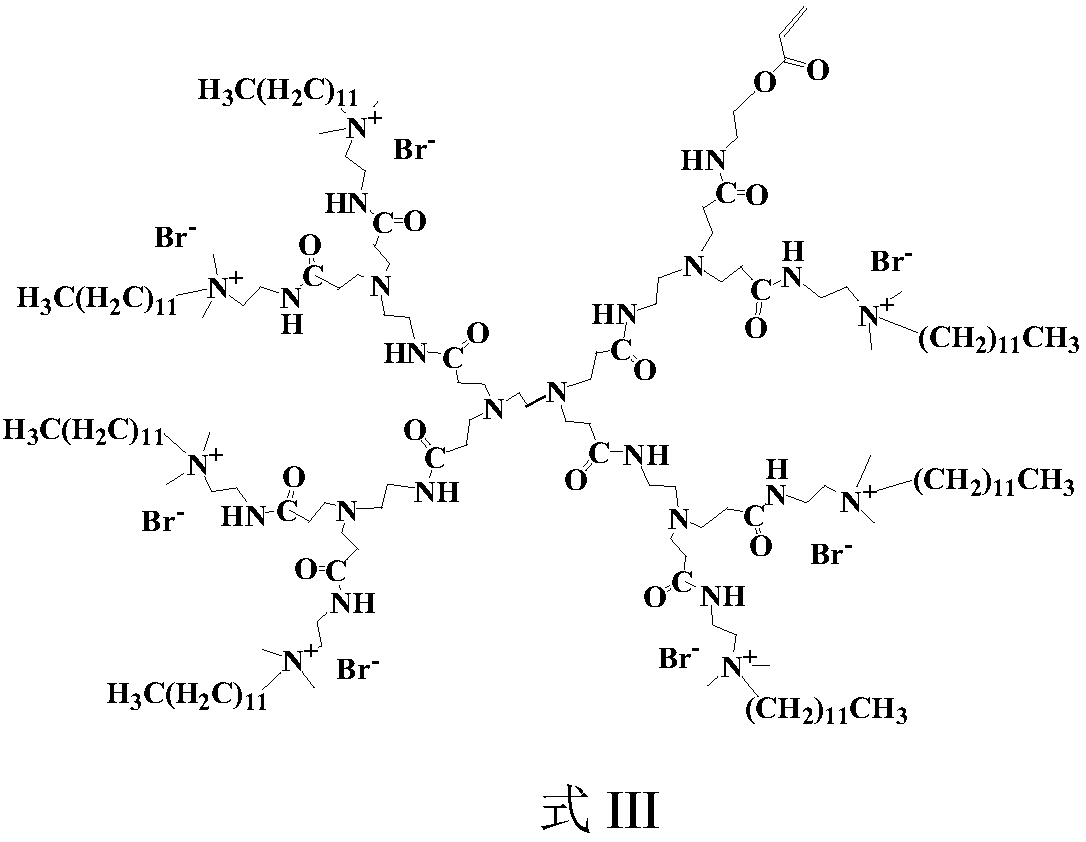

ActiveCN108822252ALow viscosityImprove liquidityDrilling compositionFunctional monomerAqueous solution

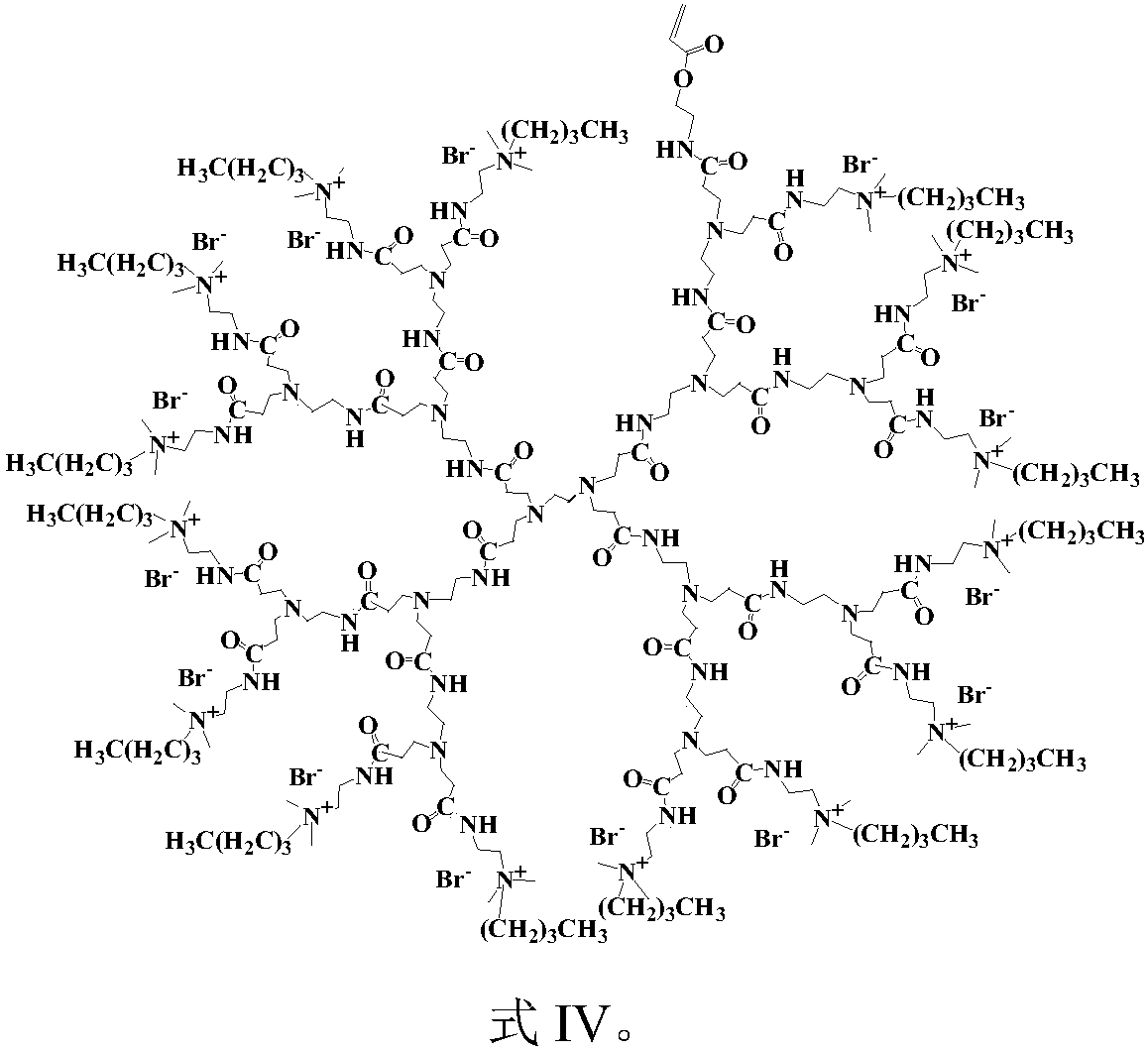

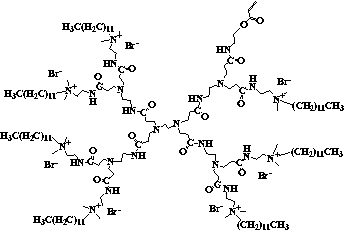

The invention discloses an amphipathic high-molecular viscous oil activator and application thereof. A preparation method of the amphipathic high-molecular viscous oil activator comprises the following steps: carrying out copolymerization reaction on acrylamide, acrylic alkali metal salt, maleic anhydride, dimethyl allyl dodecyl ammonium chloride and a dendritic unsaturated functional monomer which is expressed as a formula (I) or a formula (II) through an aqueous solution free radical. After the amphipathic high-molecular viscous oil activator is mixed with viscous oil, the viscosity of the viscous oil can be obviously reduced; the amphipathic high-molecular viscous oil activator is applicable to the field of reinforced cold exploitation of the viscous oil or exploitation of auxiliary steam viscous oil. The formula (I) and the formula (II) are as shown in the description; in the formula (I) or the formula (II), R represents alkyl with 4-16 carbon atoms, and G represents Cl or Br.

Owner:北京百特泰科企业管理中心(有限合伙)

Preparation method of anti-static carbon fibre functional composite paper

ActiveCN108035188AImprove surface activityImprove permeabilityCoatings with pigmentsPaper/cardboardCarbon fibersAdhesive

The invention discloses a preparation method of anti-static carbon fibre functional composite paper. The preparation method comprises the following steps: crushing wheat straw and waste paper, addingwater, standing, draining, soaking in a potassium hydroxide solution, steaming in a manner of insulating from water, drying, performing wet ball milling, concentrating, pulping, and performing papermaking to obtain blank paper; mixing waste paper and the potassium hydroxide solution, standing at a room temperature, then heating and stirring, performing suction filtration, washing a filter cake, drying to reach constant weight, adding a sepiolite powder, dodecyl ammonium chloride and silver nitrate solution, regulating the pH value of the system to be 6.4 to 6.8, stirring uniformly, adding a silane coupling agent KH-550, stirring uniformly, performing ultraviolet irradiation treatment, filtering, washing with deionized water, drying, and crushing to obtain a composite antibacterial agent; uniformly mixing graphite, carbon black, a coconut shell carbon powder and the composite antibacterial agent, adding an anti-static agent, a dispersing agent and an adhesive, mixing uniformly, concentrating, coating the surface of the blank paper with the mixture, drying, applying the adhesive to double surfaces, drying a finished product, and rolling paper.

Owner:安徽鑫光新材料科技股份有限公司 +1

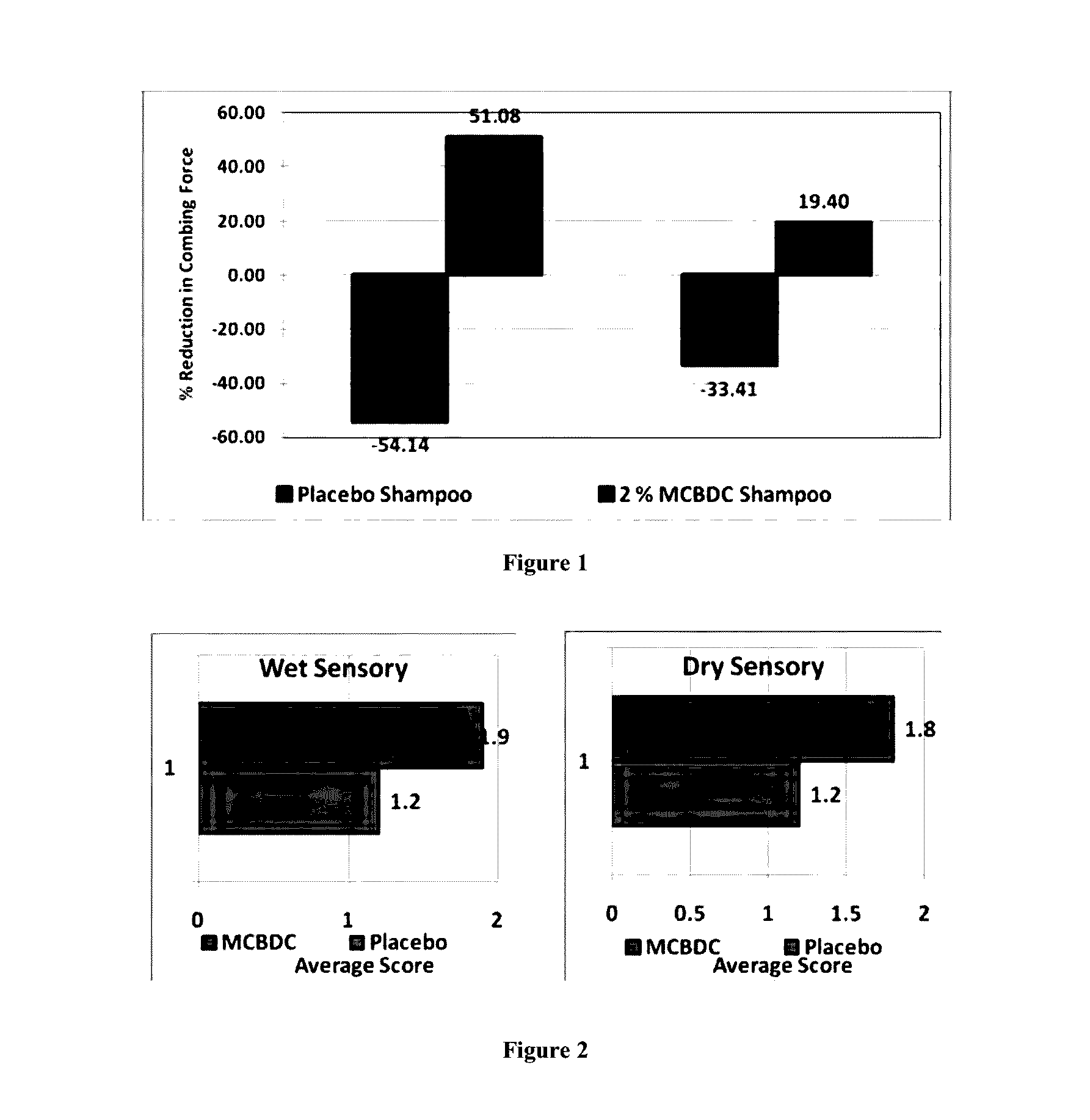

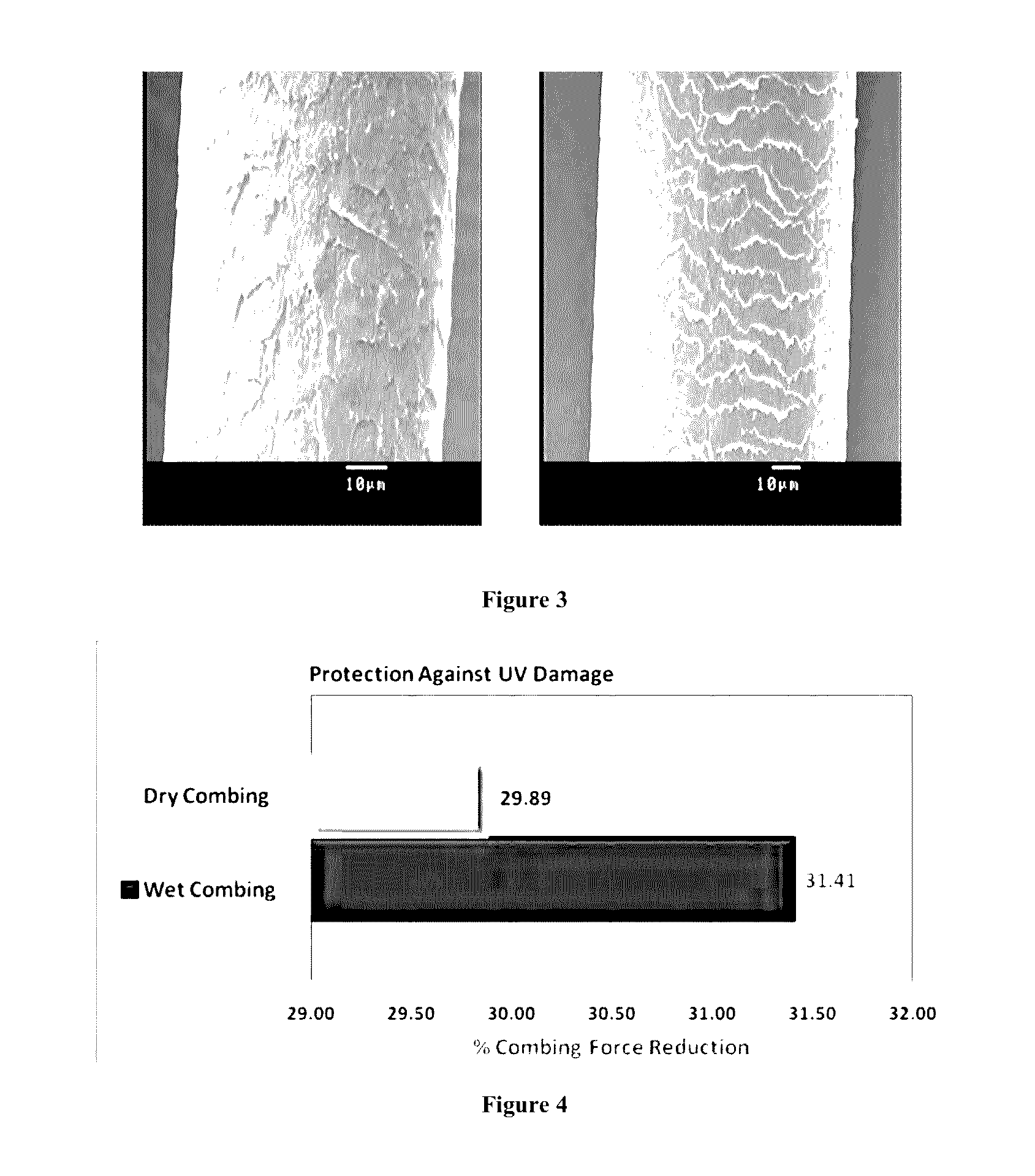

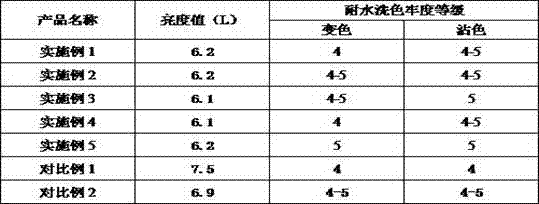

Organic silicon deep dyeing promoter and preparation method thereof

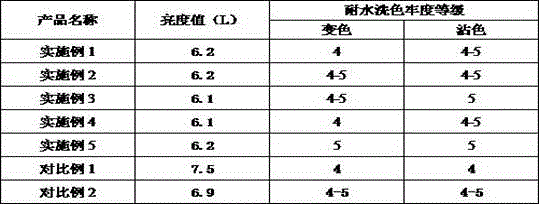

ActiveCN106012606ALow brightness valueGood deepening effectDyeing processTetramethylammonium hydroxidePhytic acid

The invention provides an organic silicon deep dyeing promoter and a preparation method thereof. The organic silicon deep dyeing promoter is prepared by the following steps: firstly mixing hexadecyl trimethyl ammonium bromide, dodecyl ammonium chloride, methyl glucose sesquistearate and oleic acid polyoxyethylene ester with deionized water, and mixing for 30-50 minutes; adding nanosilicon dioxide, sodium silicate and octamethylcyclotetrasiloxane, and stirring for 10-30 minutes at high speed; adding vinyl triethoxysilane and vinyl trimethoxy silane, continuously stirring for 10-20 mintues at high speed, homogenizing for 10-30 minutes, and heating to 80-85 DEG C; adding tetramethylammonium hydroxide, stirring for 5-10 minutes, preserving the temperature for 3-4 hours, and cooling down; adding potassium sorbate and phytic acid, and stirring for 10-20 minutes; and finally adding glacial acetic acid to neutralize to be neutral, thereby obtaining the organic silicon deep dyeing promoter. The prepared organic silicon deep dyeing promoter has relatively lower brightness value, excellent deep dyeing promotion effect, and also has excellent wash resistance.

Owner:常州新光印染有限公司

Composite waterproof coating composition

The invention relates to a composite waterproof coating composition. A montmorillonite material modified by lauryl ammonium chloride and triethanolamine is adopted in the composite waterproof coating composition; and the modified montmorillonite material has good dispersibility, thickening property and thixotropy and is capable of improving the stability of the coating. In addition, a specific proportion of modified nanometer composite powder is also adopted in the coating composition, and the nanometer composite powder subjected to surface modification can effectively modify the strength, toughness and scraping resistance of coatings. All the components in the specific composition of the coating interact synergistically so that after forming films, the coating has good adhesiveness, strength, hardness and waterproof performance.

Owner:李亮军

Scratching-resistant waterproof coating compound

InactiveCN104830133AImprove stabilityHigh strengthCoatingsPigment treatment with organosilicon compoundsThixotropyDodecylammonium chloride

The invention relates to a scratching-resistant waterproof coating compound. The scratching-resistant waterproof coating compound is made of a montmorillonite material modified by lauryl ammonium chloride and triethanolamine, and the modified montmorillonite material is excellent in dispersity, thickening performance and thixotropy and capable of improving stability of the coating compound. By adoption of modified nano compound powder in specific ratio, coating strength, toughness and scratching resistance can be effectively improved after the nano compound powder is subjected to surface modification. Owing to mutual synergy of specific compositions of the coating compound, the scratching-resistant waterproof coating compound is high in adhesiveness, strength, hardness and water resistance after film formation.

Owner:李亮军

Composite for forestation, wind protection and sand fixation along line of railway or highway and preparation method of composite

InactiveCN102061178AWater-absorbentPermeableClimate change adaptationOrganic fertilisersEcological environmentPolystyrene

The invention relates to a composite for forestation, wind protection and sand fixation along the line of railway or highway. The composite is prepared by the following raw materials in proportion by weight: 50-95 parts of polystyrene, 15-50 parts of plasticizer, 60-150 parts of organic solvent, 5-25 parts of sodiumhydroxymethyl cellulose, 15-35 parts of dodecyl ammonium chloride, 100-300 parts of distilled water, 30-75 parts of gelantinizer, 3-20 parts of humectant and 0.002-0.03 part of photosensitive curing agent. The composite in the invention is diluted by adding water until the solid-containing amount in the composite is 1-10%, the diluted composite can be sprayed on soil and desert and then solidified to a ground film; and the composite takes the effect of preventing earth, fixing sand and preventing a large amount of water from evaporating, and has important sense for improving soil, managing sand, vegetating and foresting and improving ecological environment.

Owner:ZHONGHAO GUOYE BEIJING TECH

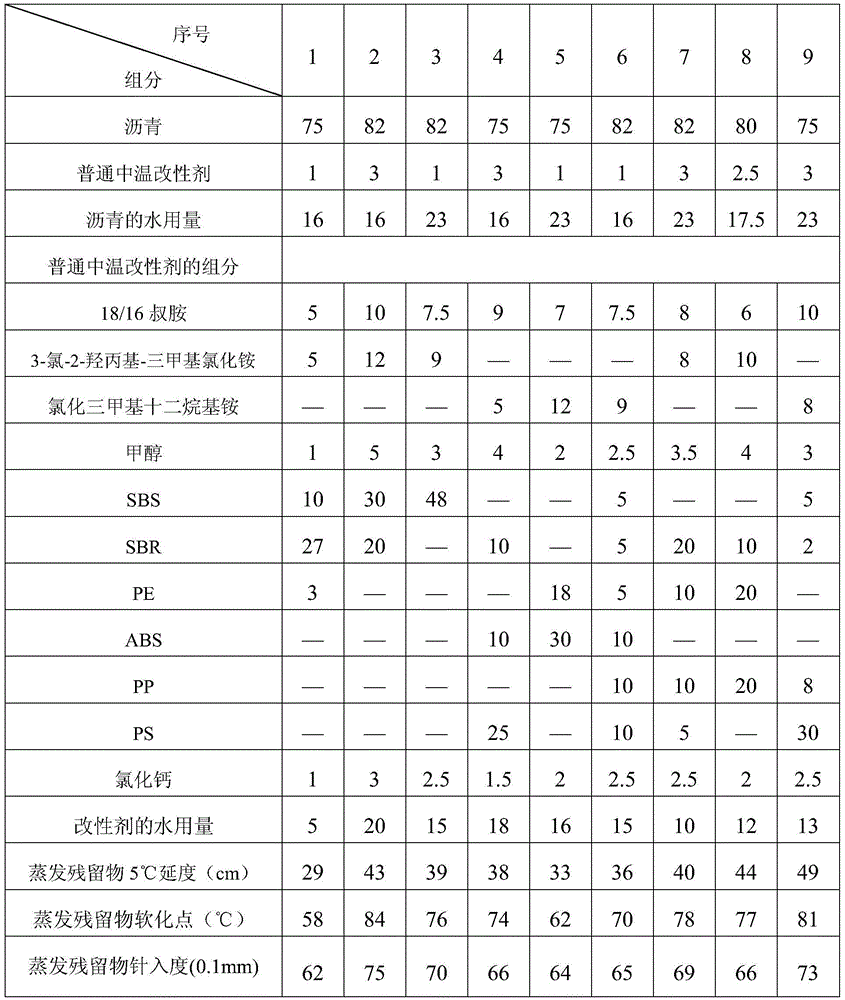

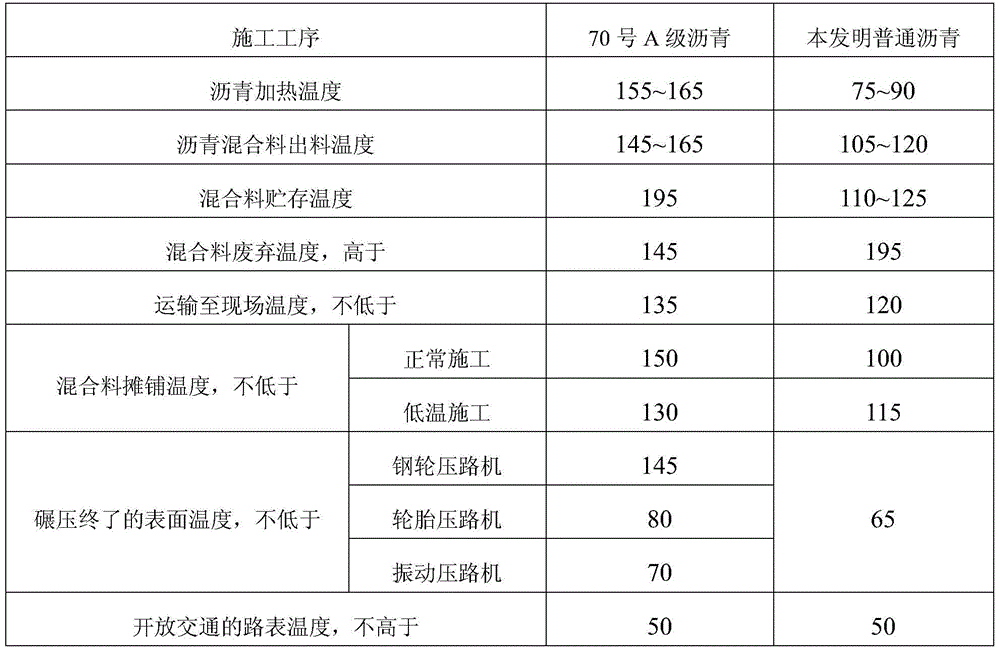

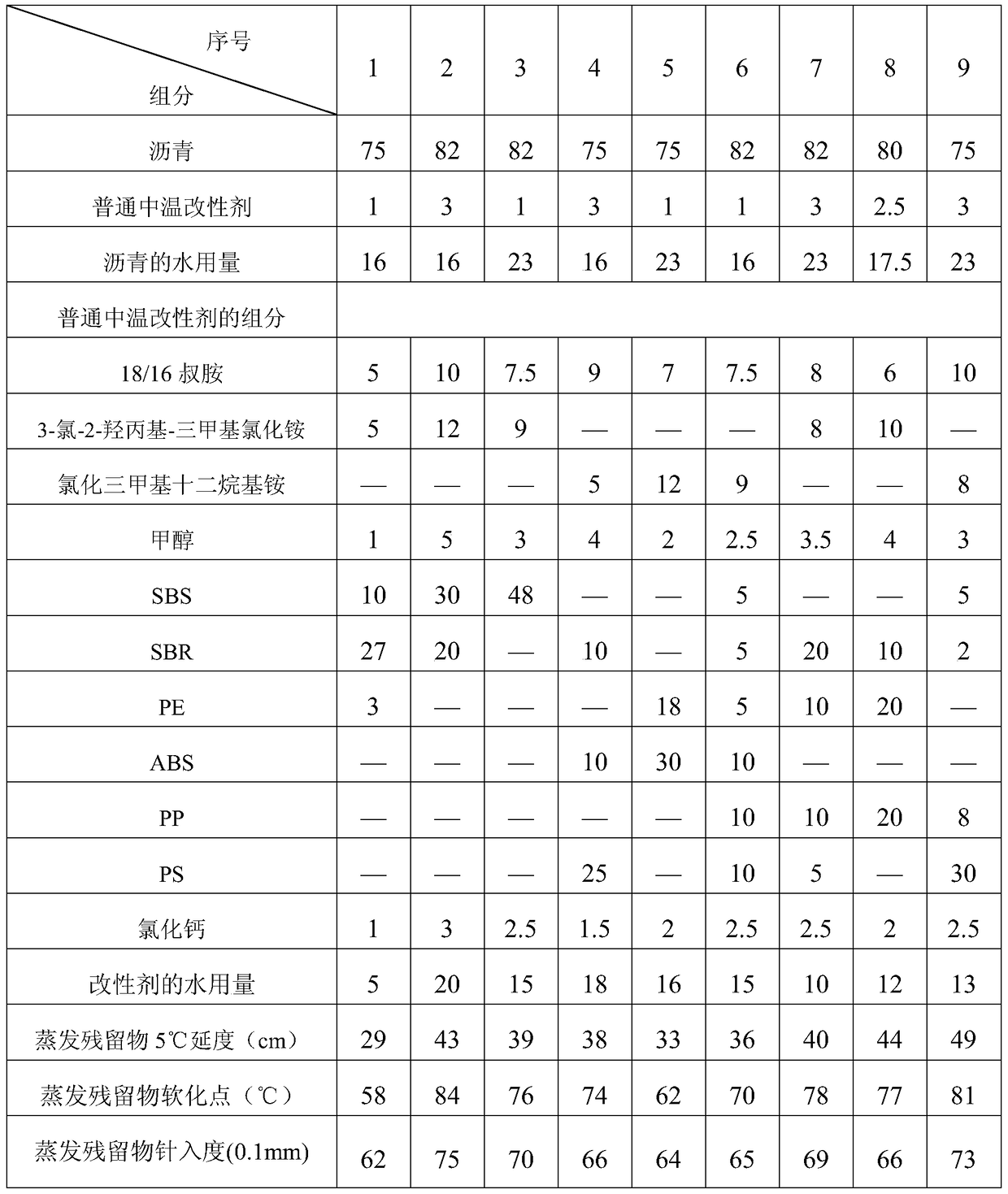

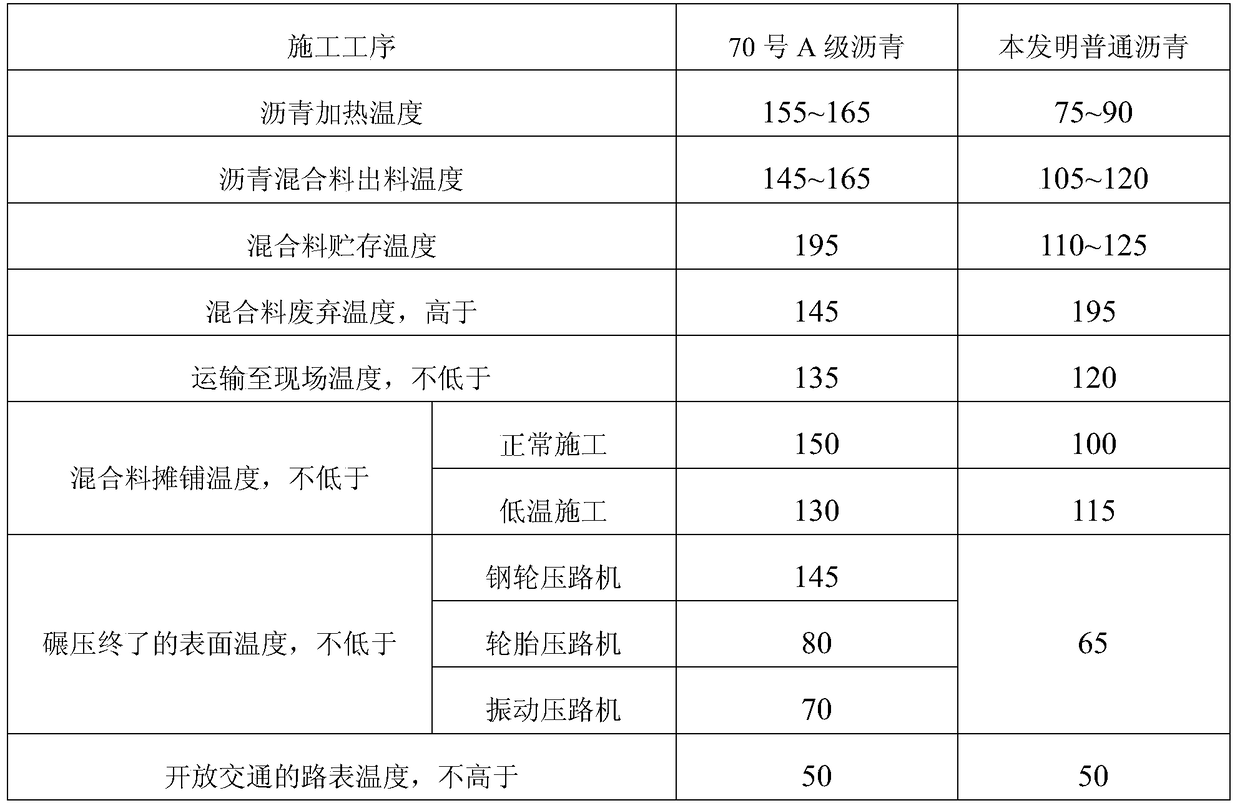

Common high-solid-content medium temperature pitch and preparing method thereof

The invention discloses common high-solid-content medium temperature pitch and a preparing method thereof. The common high-solid-content medium temperature pitch comprises 75-82 parts of matrix pitch, 1-3 parts of common medium-temperature modifying agent and 16-23 parts of water. The common medium-temperature modifying agent comprises, by mass, 5-10 parts of 18 / 16 tertiary amine, 5-12 parts of cationic additive, 1-5 parts of methyl alcohol, 40-50 parts of emulsifying agent, 1-3 parts of calcium chloride and 5-20 parts of deionized water, wherein the cationic additive is selected from 3-chlorine-2-hydroxypropyl-trimethylammonium chloride and trimethyl-dodecylammonium chloride; the emulsifying agent is selected from styrene-butadiene-styrene, butadiene styrene rubber, polyethylene, acrylonitrile-butadiene-styrene copolymer and high-polymer polypropylene and polystyrene. The pitch prepared with the method is wide in construction temperature range, construction can be carried out under the weather condition of being higher than -5 DEG C, and the requirement of road maintenance at the low temperature is met.

Owner:WUHAN CHENGSHITONG ENVIRONMENTAL ASPHALT ENG CO LTD

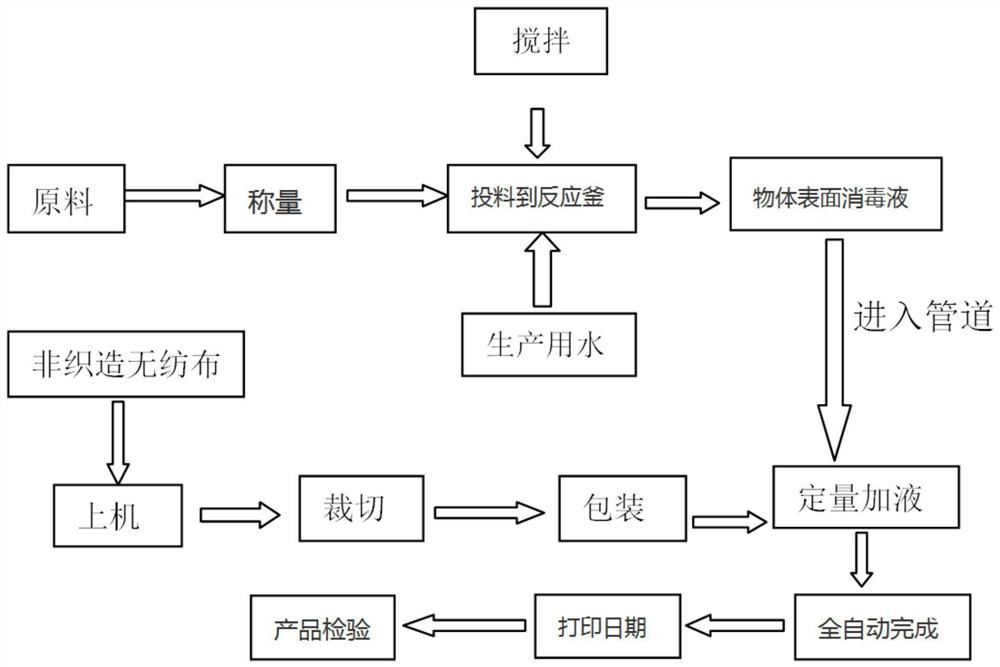

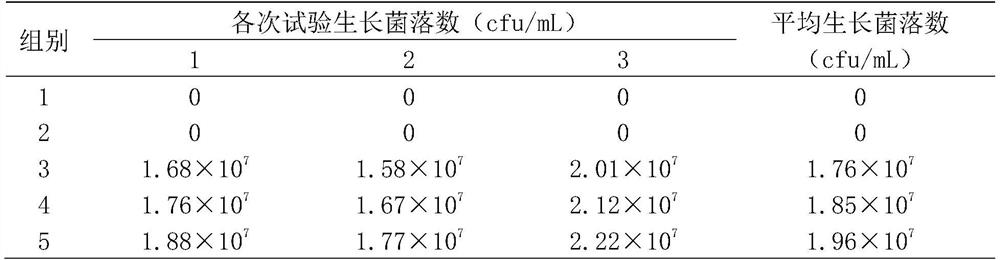

Non-corrosive and non-irritant sanitary wet tissue with disinfection function, and manufacturing method thereof

InactiveCN112189670AImprove performanceMeet the standardsInorganic/elemental detergent compounding agentsBiocideGlycerolDioxyethylene Ether

The invention discloses a non-corrosive and non-irritant sanitary wet tissue with a disinfection function, and a manufacturing method thereof. The wet tissue comprises a carrier and a disinfectant attached to the carrier, wherein the disinfectant comprises the following components in percentage by mass: 0.18-0.22% of compound ammonium chloride with a purity of 70%, 0.072-0.088% of dodecyl ammoniumchloride with a purity of 99%, 0.018-0.022% of fatty alcohol-polyoxyethylene ether with a purity of 99%, 0.99-1.10% of glycerol with a purity of 99%, 0.072-0.088% of sodium nitrite with a purity of 99% and 98.668-98.482% of purified water. The product has cleaning and disinfecting effects, does not corrode and disinfect medical instruments and precious metal articles, is non-irritant to skin, hands and the like, and is non-toxic after long-term use.

Owner:ZHENDE MEDICAL CO LTD

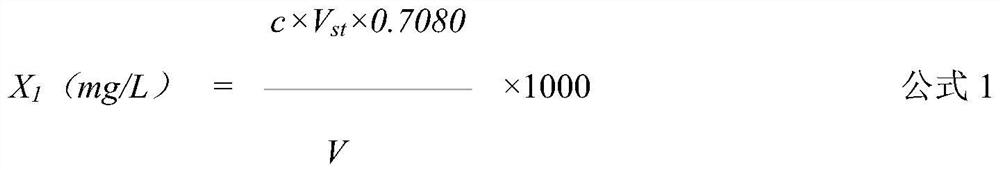

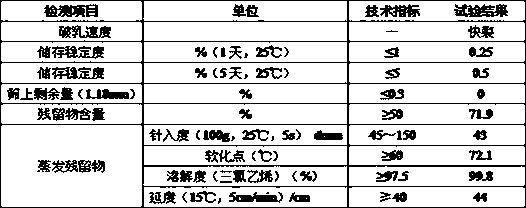

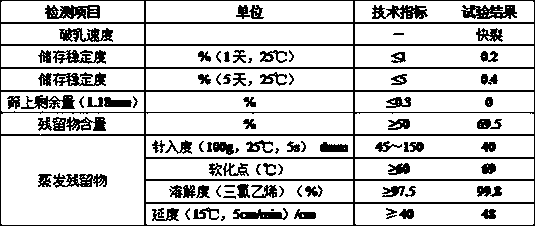

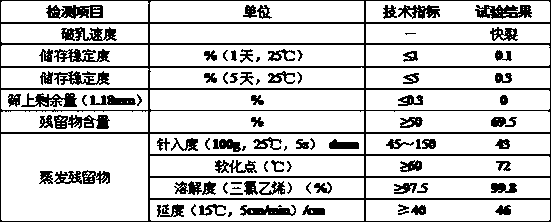

Emulsified asphalt with solid content higher than 70% and preparation method thereof

InactiveCN110373031AHigh solid contentImprove build qualityBuilding insulationsCelluloseRoad construction

The invention discloses modified emulsified asphalt with the high solid content higher than 67% and a preparation method thereof, and belongs to the technical field of emulsified asphalt. The emulsified asphalt is prepared from the raw materials in parts by mass: 67-75 parts of SBS and SBR compound modified 50# asphalt, 1-2 parts of a cationic emulsifier, 25-33 parts of distilled water and 0.03-0.3 part of a stabilizer, wherein the emulsifier is a mixture of dodecyl ammonium chloride and cetyl trimethyl ammonium bromide, the ratio of the dodecyl ammonium chloride to the cetyl trimethyl ammonium bromide is 7.5:2.5, and the stabilizer is cellulose. The solid content of the obtained emulsified asphalt is at least 67%, the evaporated residue needle penetration under 25 DEG C is 35-90 (0.1mm),the softening point is 65-75 DEG C, the viscosity is moderate, the stability is excellent, and the effect is good when the emulsified asphalt is applied to road construction.

Owner:NANJING LUYIDA TRAFFIC TECH CO LTD

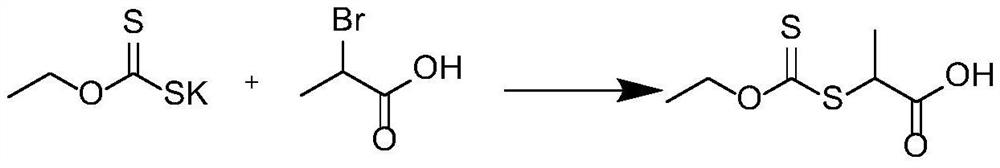

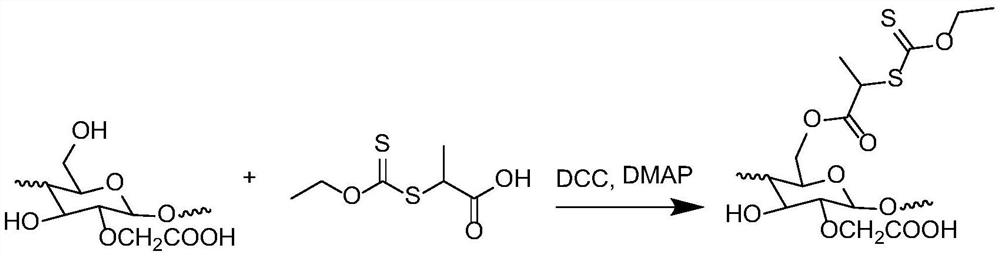

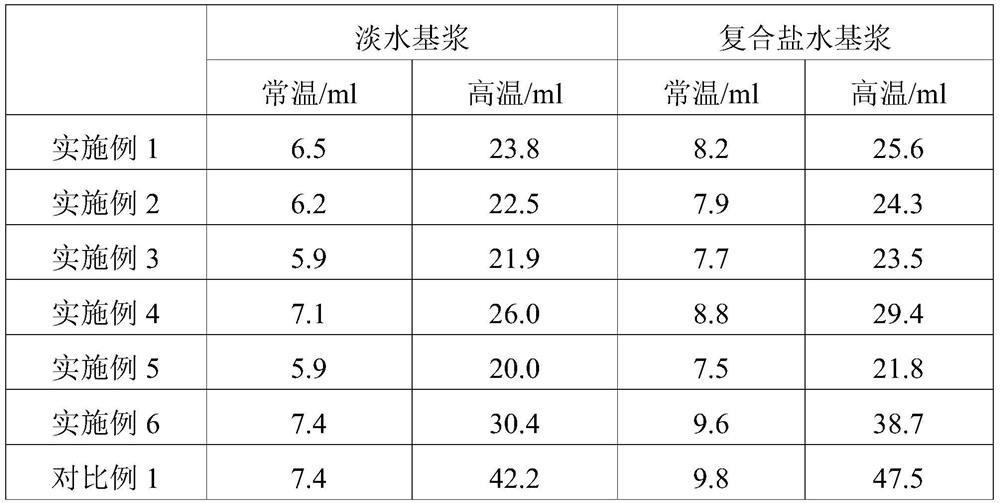

Petroleum drilling fluid additive and preparation method thereof

ActiveCN112409541AImprove stabilityGood resistance to high temperature and saltDrilling compositionCelluloseEpoxy

The invention relates to a petroleum drilling fluid additive and a preparation method thereof. Xanthate and carboxymethyl cellulose are used as initial raw materials to prepare a macro-molecular RAFTreagent, the macro-molecular RAFT reagent is used for emulsion polymerization with alkenyl sulfonic acid, acrylamide and hydroxyethyl acrylate, then 2,3-epoxy propyl trimethyl ammonium chloride or N,N-dimethyl epoxy propyl dodecyl ammonium chloride is added into the emulsion polymerization system to prepare the petroleum drilling fluid additive. The petroleum drilling fluid additive provided by the invention is a cellulose zwitterionic polymer filtrate reducer, cellulose is taken as a core, and a polymer chain is rich in molecular groups such as hydroxyl, carboxyl, acyl amino and sulfo, so that the polymer has relatively strong hydration capability, is insensitive to salt, strong in high temperature resistance, strong in adsorption capability to clay and good in stability; meanwhile, quaternary ammonium salt is used as a shell layer, the core-shell structure improves the adsorption stability of the filtrate reducer in a high-temperature and high-salt environment, and the filtration loss reducing effect, the high temperature resisting effect, and the salt resisting effect are good.

Owner:济源市天诚化工有限公司

200-DEG C super-high temperature fracturing fluid

InactiveCN101633839BReduce broken linksReduce the possibility of broken linksDrilling compositionPersulfateFracturing fluid

The invention relates to a 200-DEG C super-high temperature fracturing fluid. The fracturing fluid comprises the following components in terms of mass percentage: 0.60% of carboxymethyl hydroxypropyl guar gum, 0.35% of polyacrylamide, 0.18% of organosilicon polyether, 0.09% of polyoxypropylene polyoxyethylene polyoxypropylene octadecanol ether, 0.24% of dodecyl ammonium chloride, 0.12% of cation long chain polymer, 0.33% of organo-metallic crosslinker, 0.00027% of persulfate, 0.0001% of high-valence oxysalt and the balance of water. The fracturing fluid is high-temperature-resistant and shear-resistant and has complete gel breaking property.

Owner:DAQING OILFIELD CO LTD

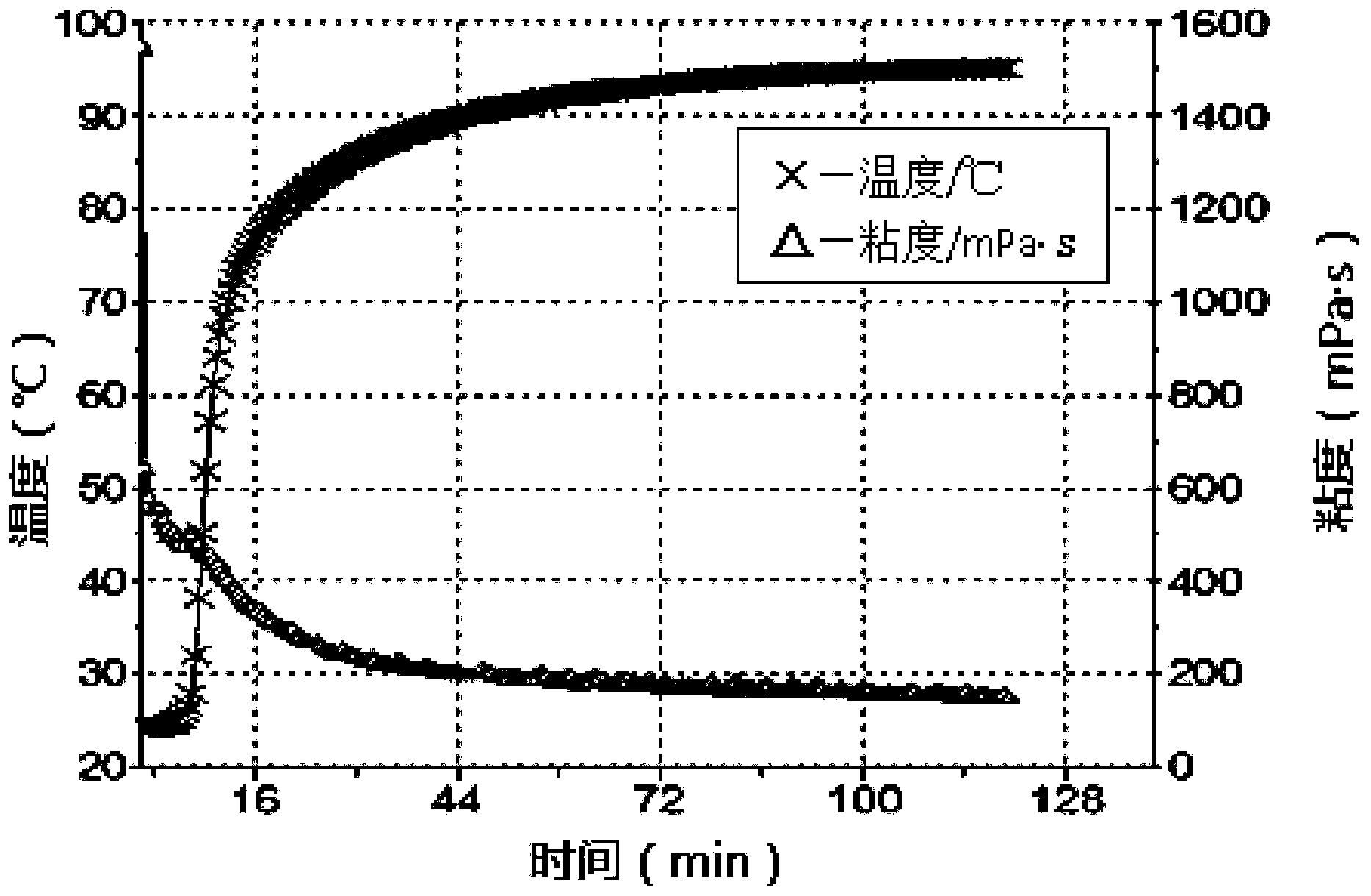

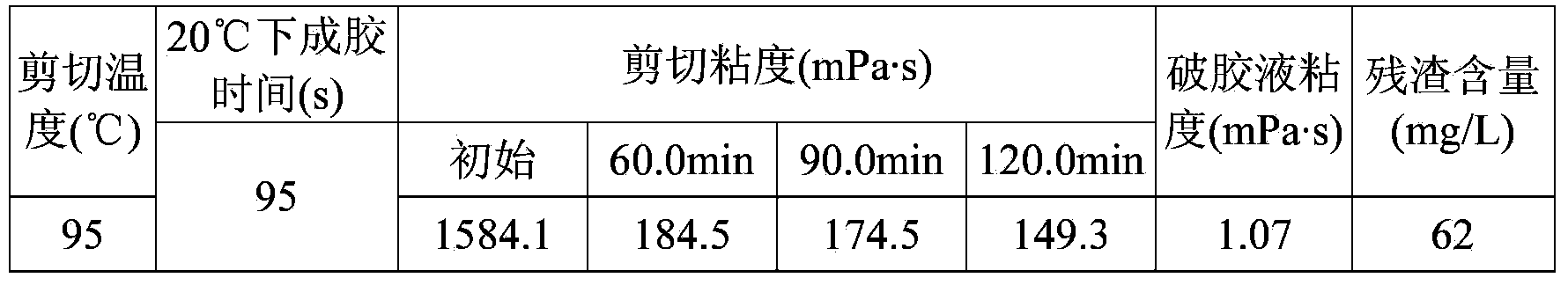

Fracturing fluid based on nonmetallic ion crosslinking agent as well as preparation method and application of fracturing fluid

ActiveCN104073234AFormation damage is smallAvoid secondary damage to the formationDrilling compositionDemulsifierPolymer science

The invention provides a fracturing fluid based on a nonmetallic ion crosslinking agent as well as a preparation method and application of the fracturing fluid. The fracturing fluid comprises the following components by weight percent: 0.07%-0.1% of a synthetic polymer, 0.1%-0.5% of a crosslinking agent, 0.01%-0.2% of a crosslinking promoter, 0.01%-0.2% of a pH regulator, 0.1%-1.0% of dodecyl ammonium chloride, 0.1%-0.3% of a demulsifier SP169, 0.01%-0.1% of ammonium persulfate, 0.1%-0.8% of formaldehyde and the balance of water. According to the fracturing fluid, the cost and the residue content of the fracturing fluid can be reduced; the fracturing fluid has the characteristics of high temperature resistance, shear resistance and complete gel breaking.

Owner:PETROCHINA CO LTD

softener composition

ActiveCN106835698BImproves the ability to soften fabricsImprove abilitiesGrip property fibresQuaternary ammonium cationDodecylammonium chloride

The invention relates to a softener compound which comprises the following components by weight percent: 3-7% of quaternary ammonium salt active matter, 0.02-0.5% of cationic starch, 0.01-0.5% of thickening agent, 0-2% of additive and the balance of water, wherein the cationic starch is prepared from starch and 2,3-glycidyl trimethyl ammonium chloride, 3-chlorine-2-hydroxypropyl trimethyl ammonium chloride, 3-chlorine-2-hydroxypropyl dimethyl-dodecyl ammonium chloride or 3-chlorine-2-hydroxypropyl dimethyl-octadecyl ammonium chloride. The softener compound is formed by compounding cationic starch with quaternary ammonium salt active matter; less cationic starch (accounting for 0.02-0.5wt% of the compound) is used together with quaternary ammonium salt; the softening fabric effect is better than that of singly used quaternary ammonium salt; the oily hand feel caused by the quaternary ammonium salt in higher saturability is relieved to some extent; a smoother experience is brought.

Owner:GUANGZHOU TINCI MATERIALS TECH

Shampoo composite containing cationic starch

ActiveCN103191033BWide variety of sourcesQuality is easy to controlCosmetic preparationsHair cosmeticsEmulsionEthyl Chloride

The invention discloses a shampoo composite containing cationic starch. The composite is prepared from the following raw materials in percentage by weight: a, 8-40% of a surfactant; b, 0.1-5% of cationic starch; c, 0.1-10% of silicone oil emulsion; and d, the balance of water, wherein the surfactant is selected from one or several anionic surfactants or ampholytic surfactants; the particle size of the silicone oil emulsion is 1 nanometer to 10 micrometers; and the cationic starch is prepared from starch and 2,3-epoxypropyl trimethyl ammonium chloride, 3-chlorine-2-hydroxypropyl trimethyl ammonium chloride or 3-chlorine-2-hydroxypropyl dimethyl-dodecyl ammonium chloride. According to the shampoo composite disclosed by the invention, the cationic starch is compounded with the silicone oil emulsion, so that the hand feeling of hair in a hairdressing process and the hand feeling, the carding performance and gloss of dried hair are improved; and an excellent use feeling is provided and the cost of the composite is reduced.

Owner:GUANGZHOU TINCI MATERIALS TECH

Wear-resistant polyvinyl chloride foam tube

The invention discloses a wear-resistant polyvinyl chloride foam tube, which is prepared from the following raw materials: banana leaf, steel fiber, 0.4% lignin coupling agent, azodicarbonamide, sodium bicarbonate, zinc oxide, polyvinyl chloride, potassium hexatitanate whisker, clamshell powder, an antioxidant, hydroxy propyl cellulose, zinc stearate, castor oil, titanium dioxide, butadiene styrene rubber, tartaric acid, lauryl ammonium chloride, glycerin, chlorinated polyethylene, molybdenum disulfide, and a proper amount of deionized water. By the use of potassium hexatitanate whisker, etc., internal structure of the tube is effectively enhanced, and mechanical strength, toughness and wear resistance are all raised. In addition, the wear-resistant polyvinyl chloride foam tube also has good ageing resistance, high mechanical strength and flame retardance, and is worth of promotion.

Owner:MAANSHAN JINSHENG IND DESIGN

Non-corrosive and non-irritant disinfectant as well as preparation method and application thereof

The invention discloses a non-corrosive and non-irritant disinfectant as well as a preparation method and application thereof. The disinfectant is prepared from the following components in percentage by mass: 0.1008%-0.1232% of didecyl dimethyl ammonium chloride, 0.0792%-0.0968% of octyl decyl dimethyl ammonium chloride, 0.072%-0.088% of dodecyl ammonium chloride with the purity of 99%, 0.018%-0.022% of fatty alcohol-polyoxyethylene ether with the purity of 99%, 0.99-1.10% of glycerol with the purity of 99%, 0.072-0.0880%of sodium nitrite with the purity of 99%and 98.542-98.616%of purified water. The disinfectant prepared according to the formula disclosed by the invention not only has a good sterilizing effect on common pathogenic bacteria, but also has no corrosion and stimulation on metals, can be used for disinfecting medical apparatuses and instruments, and has broad market requirements.

Owner:ZHENDE MEDICAL CO LTD

Amphiphilic polymer heavy oil activator and its application

ActiveCN108822252BLow viscosityImprove liquidityDrilling compositionPolymer scienceFunctional monomer

Owner:北京百特泰科企业管理中心(有限合伙)

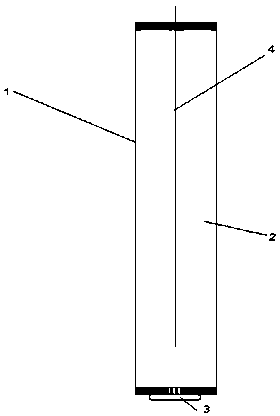

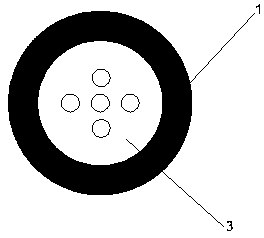

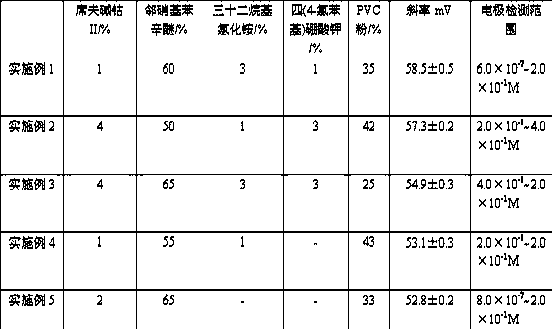

A kind of nitrite ion selective electrode and preparation method thereof

ActiveCN104849334BReduce contentRapid determinationMaterial analysis by electric/magnetic meansNitrite ionPotassium

The invention discloses a nitrite ion selective electrode and a preparation method thereof. The nitrite ion selective electrode comprises an electrode tube body, a redox system solution filled of nitrite is filled in the electrode tube body, a nitrite selective liquid film is arranged at lower end of the electrode tube body, platinum wire is arranged in the electrode tube body for being as an internal reference electrode, the platinum wire is immersed in the redox system solution, a PPS electrode cap, an O-shaped loop for fixing the platinum wire and the electrode tube body are arranged at port of the electrode tube body, the nitrite selective liquid film is a PVC active membrane, The PVC active membrane comprises the following components: 1-4% of schiff base cobalt II, 50-65% of 2-nitrophenyl octyl ether, 0-3% of tridodecylmethylammonium chloride, 0-3% of tetra(4-chlorophenyl) potassium borate and 25-43% of PVC powder. The nitrite ion selective electrode enables accurate determination without interference of anion such as nitrate and chloride ion, defect that the nitrite ions can only be determined under acidic condition by a traditional method can be simultaneously overcome, and the method can be widely used for industrial on-line measurement.

Owner:SHANGHAI WATERINST TECH

Anti-oil, anti-static and dustproof leather care agent as well as preparation method and application thereof

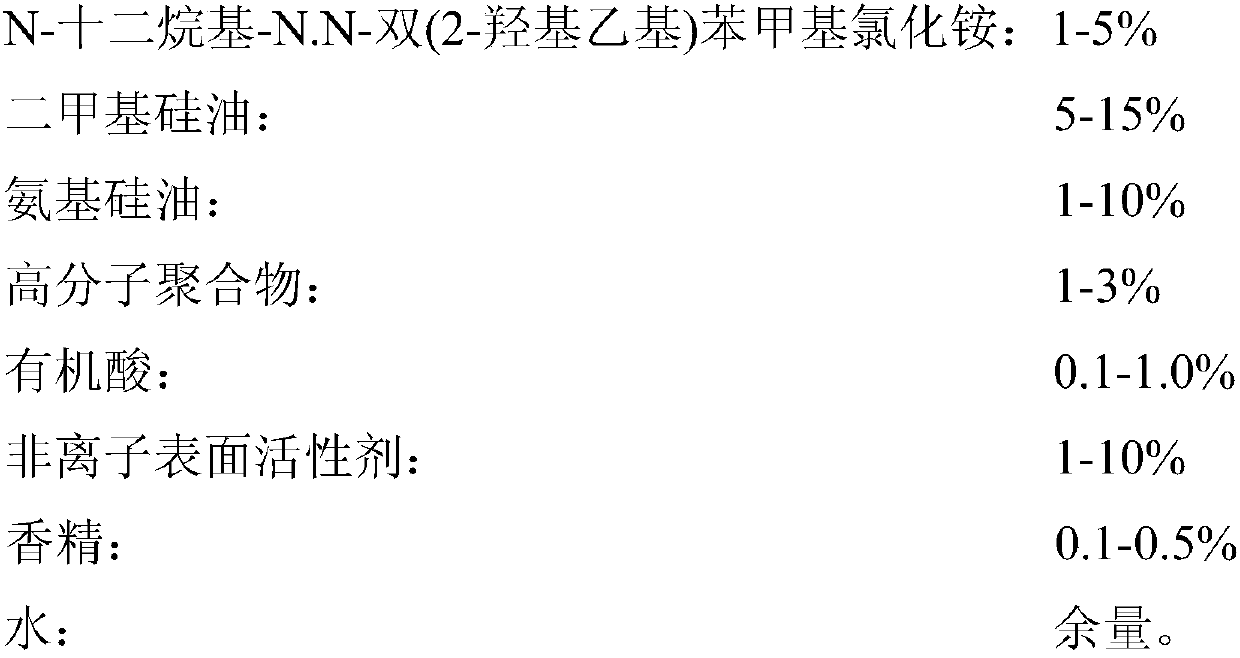

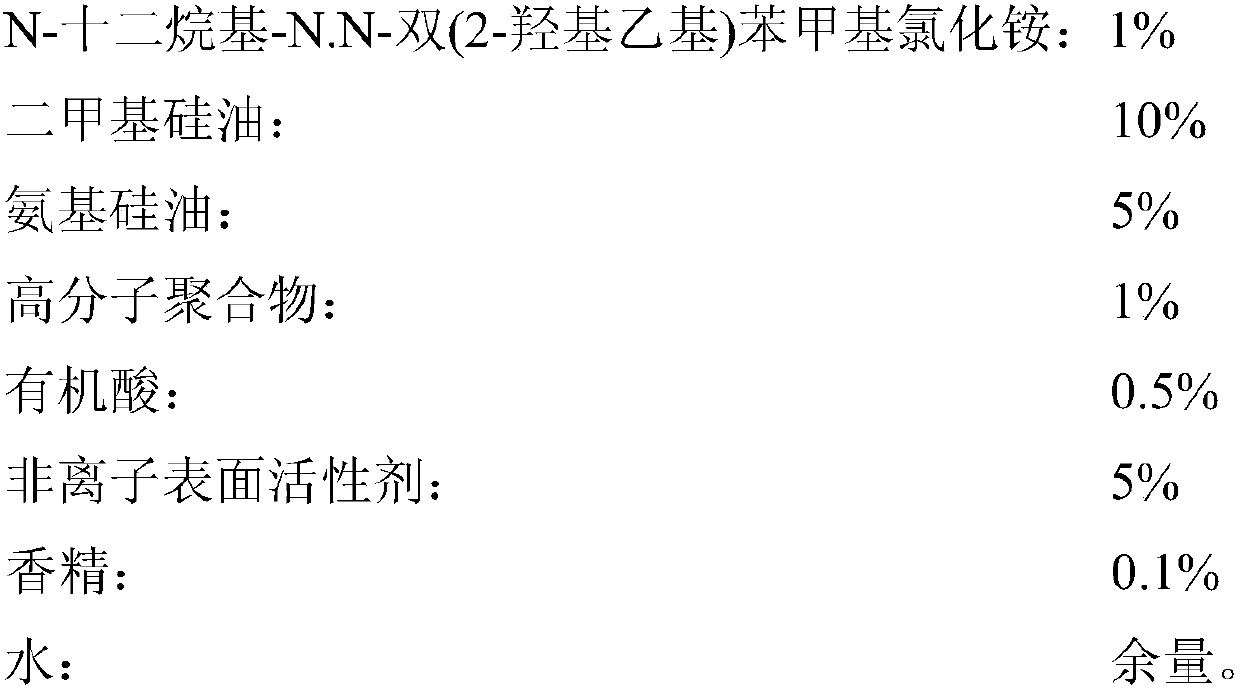

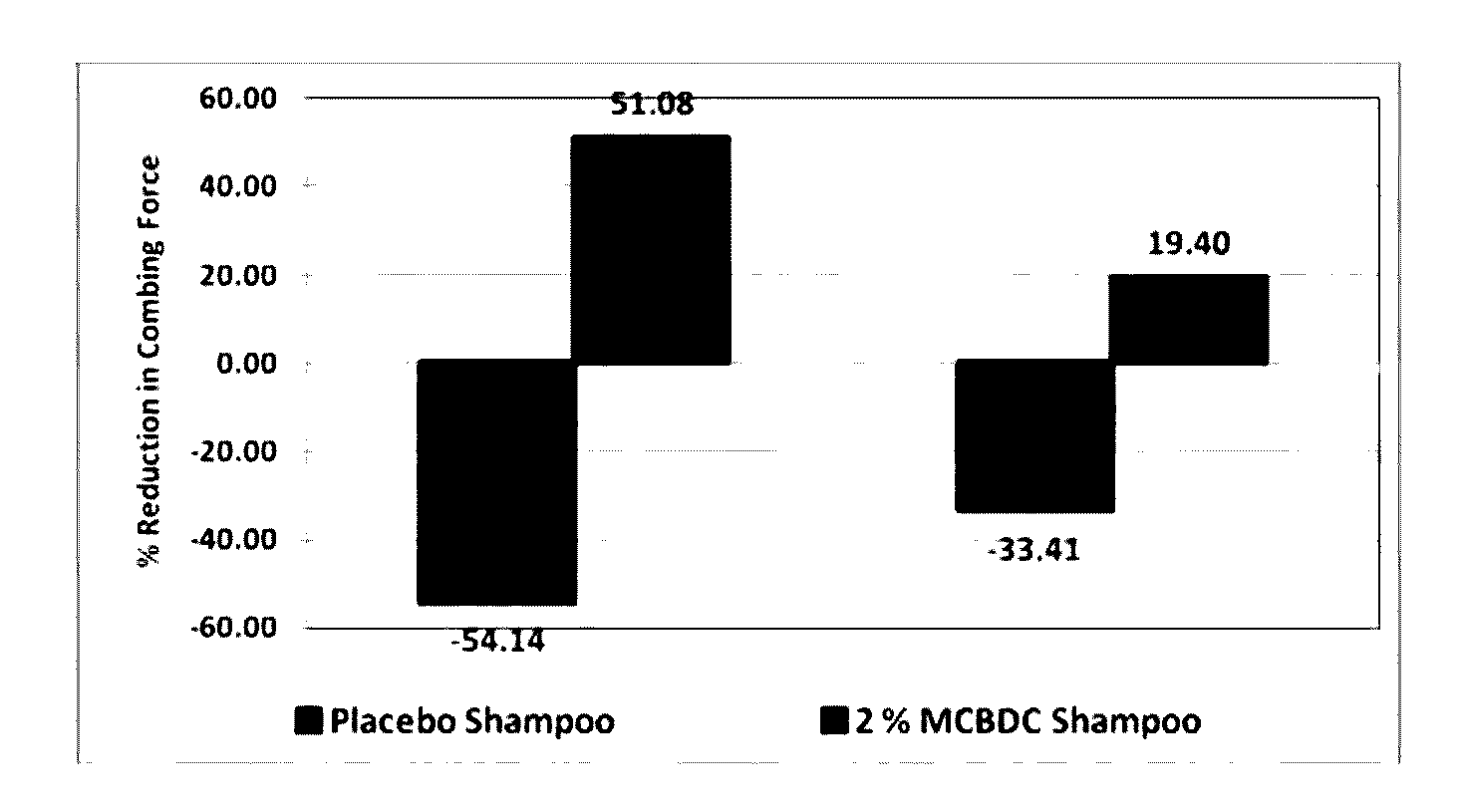

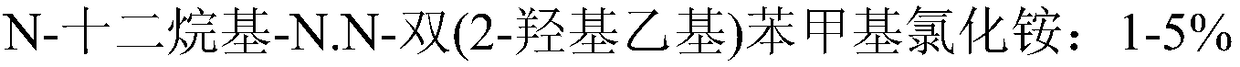

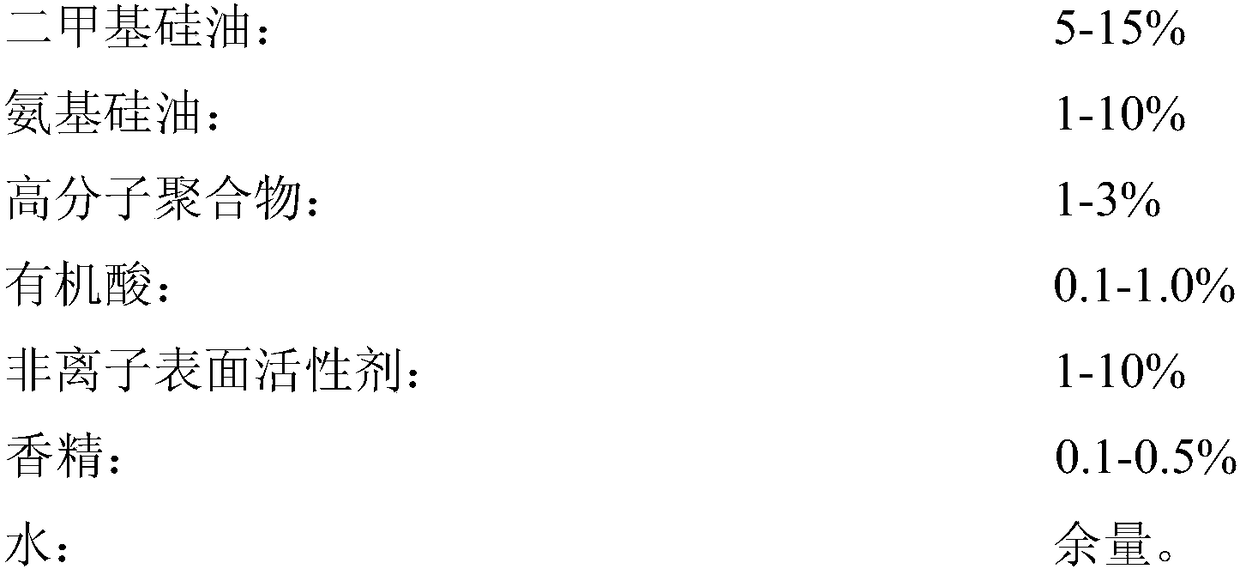

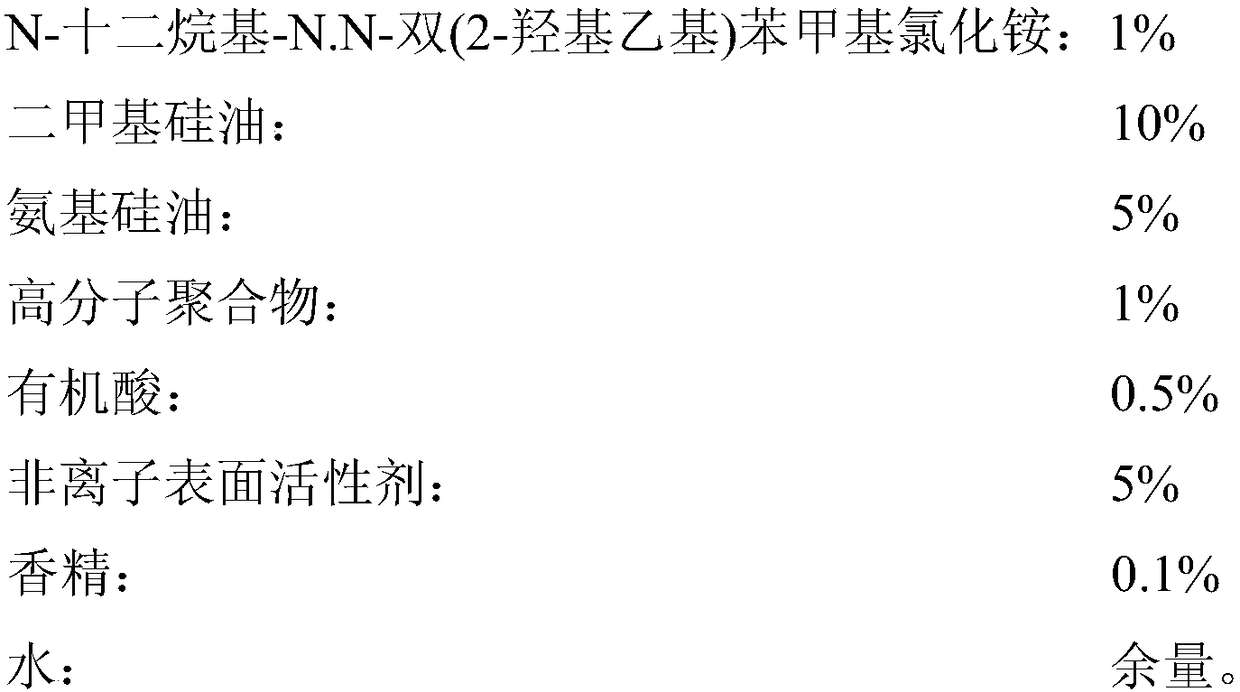

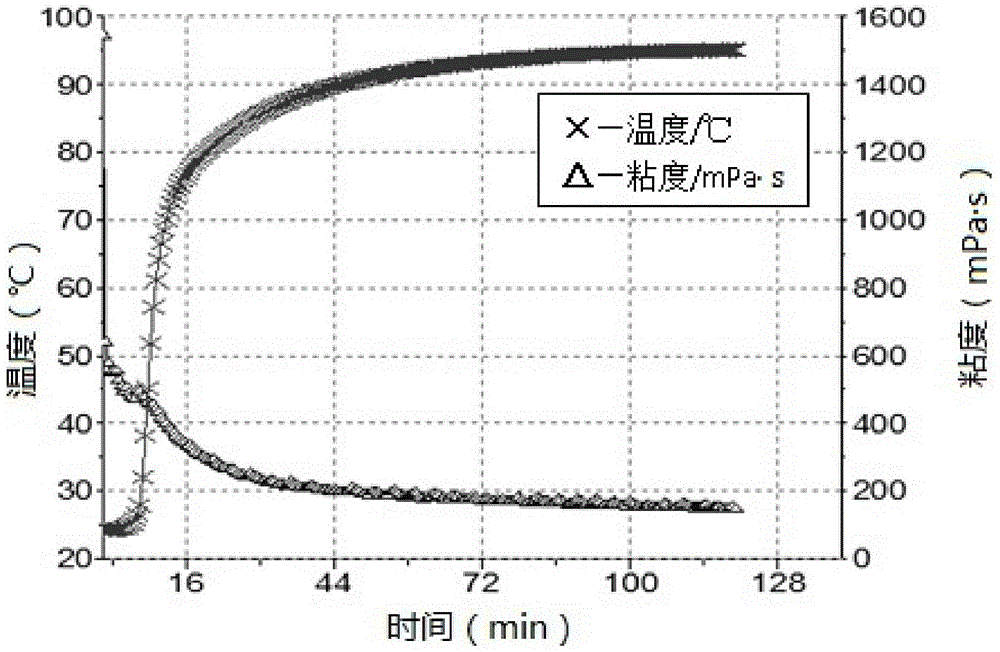

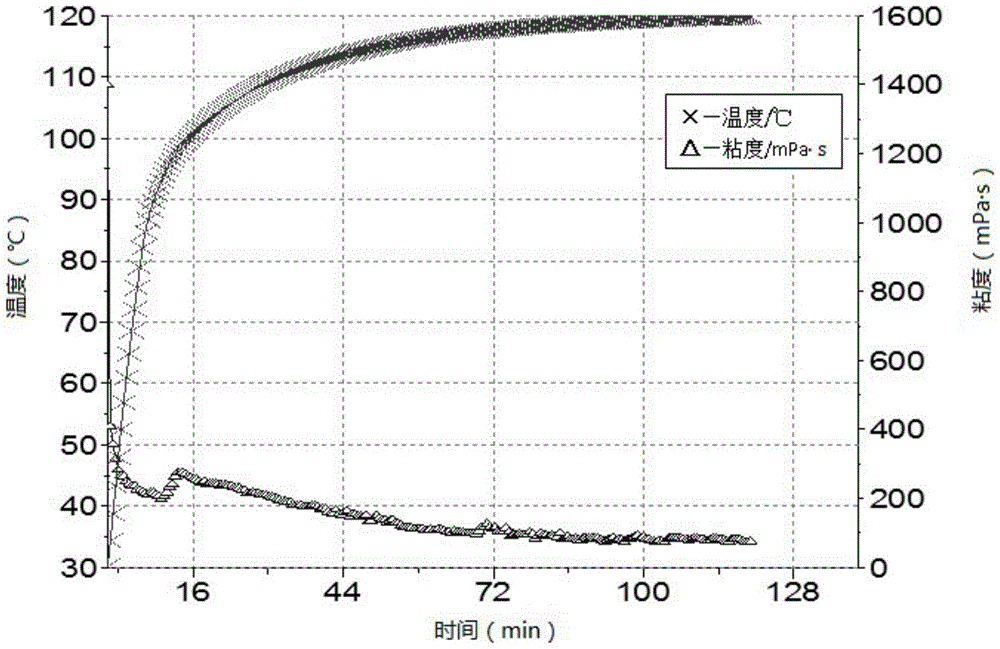

The invention discloses an anti-oil, anti-static and dustproof leather care agent as well as a preparation method and an application thereof. The leather care agent is prepared from bis(2-hydroxyethyl)benzyl-N-dodecylammonium chloride, dimethicone, amino silicon oil, high-molecular polymers, organic acid, a nonionic surfactant, essence and water. According to the formula, the solubility of dimethicone and amino silicon oil in raw materials such as the high-molecular polymers, bis(2-hydroxyethyl)benzyl-N-dodecylammonium chloride and the like is good, and the good synergistic effect is realized. The prepared leather care agent can form a protective film on the surface of a leather product, keep out ultraviolet rays, delay fracturing of the leather product caused by illumination and prolong the service life of leather. The care agent can endow the leather product with the excellent hand feeling and impression, and the leather treated with the care agent has the very good oil repellent and water repellent effects.

Owner:广州市毅沓化工科技有限公司

A kind of organosilicon deepening agent and preparation method thereof

ActiveCN106012606BLow brightness valueGood deepening effectDyeing processTetramethylammonium hydroxidePhytic acid

The invention provides an organic silicon deep dyeing promoter and a preparation method thereof. The organic silicon deep dyeing promoter is prepared by the following steps: firstly mixing hexadecyl trimethyl ammonium bromide, dodecyl ammonium chloride, methyl glucose sesquistearate and oleic acid polyoxyethylene ester with deionized water, and mixing for 30-50 minutes; adding nanosilicon dioxide, sodium silicate and octamethylcyclotetrasiloxane, and stirring for 10-30 minutes at high speed; adding vinyl triethoxysilane and vinyl trimethoxy silane, continuously stirring for 10-20 mintues at high speed, homogenizing for 10-30 minutes, and heating to 80-85 DEG C; adding tetramethylammonium hydroxide, stirring for 5-10 minutes, preserving the temperature for 3-4 hours, and cooling down; adding potassium sorbate and phytic acid, and stirring for 10-20 minutes; and finally adding glacial acetic acid to neutralize to be neutral, thereby obtaining the organic silicon deep dyeing promoter. The prepared organic silicon deep dyeing promoter has relatively lower brightness value, excellent deep dyeing promotion effect, and also has excellent wash resistance.

Owner:常州新光印染有限公司

A kind of preparation technology of coking sulfur-containing sewage demulsifier

InactiveCN106279669BEasy to separateEasy to useWater/sewage treatmentNature of treatment waterPolyesterAlkaline earth metal

The invention discloses a preparation process of a demulsifier for sulfur-containing coking wastewater. The preparation process comprises steps as follows: Step one, long carbon chain organic acid and polyethylene polyamine are subjected to a condensation polymerization reaction in the presence of an aromatic hydrocarbon solvent, reflux is kept, and a polyester initiator is prepared; Step two, propylene epoxide and ethylene oxide are added to the polyester initiator sequentially, and an ethylene oxide-epoxypropane segmented copolymer is prepared; Step three, lauryl ammonium chloride and an alkaline-earth metal catalyst are added to the ethylene oxide-epoxypropane segmented copolymer, and a polymer containing cation function groups is prepared; Step four, a nonionic surfactant, deionized water or alcohol is added to the polymer which contains the cation function groups and is prepared in the Step three, and a finished product of the demulsifier for the sulfur-containing coking wastewater is prepared; an oil-in-water type emulsified liquid in the wastewater not only has a good demulsification function, but also has certain extraction capability, the oil-water separation capability can be remarkably improved, the wastewater purification effect is realized, and the oil content of sewage discharge is reduced.

Owner:洛阳市华工实业有限公司

A kind of anti-oil, anti-static and anti-dust leather care agent and its preparation method and application

ActiveCN105950802BGood compatibilityGood synergyLeather surface finishingOrganic acidPolymer science

The invention discloses an anti-oil, anti-static and dustproof leather care agent as well as a preparation method and an application thereof. The leather care agent is prepared from bis(2-hydroxyethyl)benzyl-N-dodecylammonium chloride, dimethicone, amino silicon oil, high-molecular polymers, organic acid, a nonionic surfactant, essence and water. According to the formula, the solubility of dimethicone and amino silicon oil in raw materials such as the high-molecular polymers, bis(2-hydroxyethyl)benzyl-N-dodecylammonium chloride and the like is good, and the good synergistic effect is realized. The prepared leather care agent can form a protective film on the surface of a leather product, keep out ultraviolet rays, delay fracturing of the leather product caused by illumination and prolong the service life of leather. The care agent can endow the leather product with the excellent hand feeling and impression, and the leather treated with the care agent has the very good oil repellent and water repellent effects.

Owner:广州市毅沓化工科技有限公司

Preparation process of demulsifier for sulfur-containing coking wastewater

InactiveCN106279669AEasy to separateEasy to useWater/sewage treatmentNature of treatment waterPolyesterAlkaline earth metal

The invention discloses a preparation process of a demulsifier for sulfur-containing coking wastewater. The preparation process comprises steps as follows: Step one, long carbon chain organic acid and polyethylene polyamine are subjected to a condensation polymerization reaction in the presence of an aromatic hydrocarbon solvent, reflux is kept, and a polyester initiator is prepared; Step two, propylene epoxide and ethylene oxide are added to the polyester initiator sequentially, and an ethylene oxide-epoxypropane segmented copolymer is prepared; Step three, lauryl ammonium chloride and an alkaline-earth metal catalyst are added to the ethylene oxide-epoxypropane segmented copolymer, and a polymer containing cation function groups is prepared; Step four, a nonionic surfactant, deionized water or alcohol is added to the polymer which contains the cation function groups and is prepared in the Step three, and a finished product of the demulsifier for the sulfur-containing coking wastewater is prepared; an oil-in-water type emulsified liquid in the wastewater not only has a good demulsification function, but also has certain extraction capability, the oil-water separation capability can be remarkably improved, the wastewater purification effect is realized, and the oil content of sewage discharge is reduced.

Owner:洛阳市华工实业有限公司

A kind of fracturing fluid based on non-metal ion crosslinking agent and its preparation method and application

ActiveCN104073234BFormation damage is smallAvoid secondary damage to the formationDrilling compositionDemulsifierPolymer science

The invention provides a fracturing fluid based on a nonmetallic ion crosslinking agent as well as a preparation method and application of the fracturing fluid. The fracturing fluid comprises the following components by weight percent: 0.07%-0.1% of a synthetic polymer, 0.1%-0.5% of a crosslinking agent, 0.01%-0.2% of a crosslinking promoter, 0.01%-0.2% of a pH regulator, 0.1%-1.0% of dodecyl ammonium chloride, 0.1%-0.3% of a demulsifier SP169, 0.01%-0.1% of ammonium persulfate, 0.1%-0.8% of formaldehyde and the balance of water. According to the fracturing fluid, the cost and the residue content of the fracturing fluid can be reduced; the fracturing fluid has the characteristics of high temperature resistance, shear resistance and complete gel breaking.

Owner:PETROCHINA CO LTD

Ordinary medium temperature asphalt with high solid content and its preparation method

The invention discloses common high-solid-content medium temperature pitch and a preparing method thereof. The common high-solid-content medium temperature pitch comprises 75-82 parts of matrix pitch, 1-3 parts of common medium-temperature modifying agent and 16-23 parts of water. The common medium-temperature modifying agent comprises, by mass, 5-10 parts of 18 / 16 tertiary amine, 5-12 parts of cationic additive, 1-5 parts of methyl alcohol, 40-50 parts of emulsifying agent, 1-3 parts of calcium chloride and 5-20 parts of deionized water, wherein the cationic additive is selected from 3-chlorine-2-hydroxypropyl-trimethylammonium chloride and trimethyl-dodecylammonium chloride; the emulsifying agent is selected from styrene-butadiene-styrene, butadiene styrene rubber, polyethylene, acrylonitrile-butadiene-styrene copolymer and high-polymer polypropylene and polystyrene. The pitch prepared with the method is wide in construction temperature range, construction can be carried out under the weather condition of being higher than -5 DEG C, and the requirement of road maintenance at the low temperature is met.

Owner:WUHAN CHENGSHITONG ENVIRONMENTAL ASPHALT ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com