Petroleum drilling fluid additive and preparation method thereof

A technology of oil drilling and fluid additives, applied in the direction of chemical instruments and methods, drilling compositions, etc., to achieve the effects of good stability, high temperature and salt resistance, and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

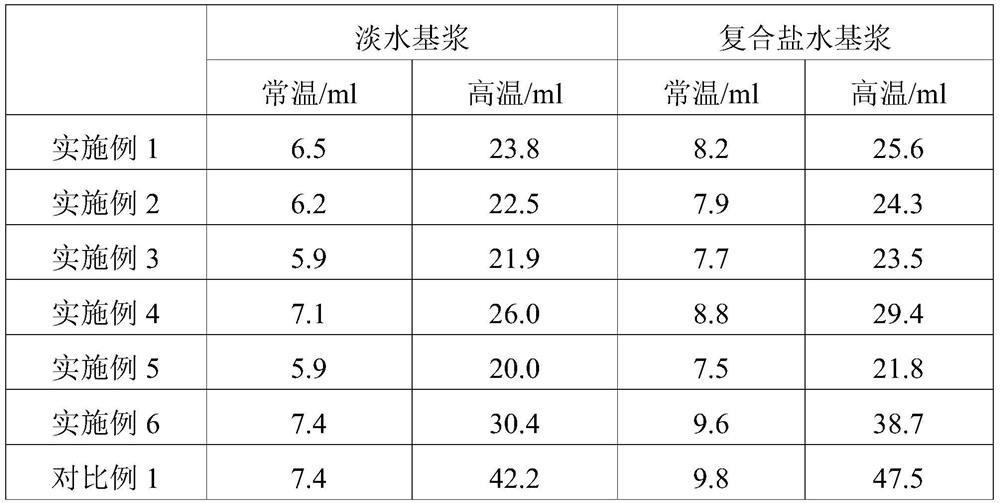

Embodiment 1

[0025] 1) Add 0.005mol sodium persulfate, 0.005mol sodium dodecyl sulfate, 2.5mol vinyl sulfonic acid, 2.5mol acrylamide, 3mol hydroxyethyl acrylate to water and stir to obtain a mixed solution, fill it with nitrogen, and Heat up to 60-70°C under nitrogen atmosphere, add 0.05mol macromolecular RAFT reagent, stir and react for 2-3h under nitrogen protection, then cool to room temperature to obtain polymer emulsion;

[0026] 2) Dissolve 3 mol of 2,3-epoxypropyltrimethylammonium chloride in water, then add dropwise to the polymer emulsion, adjust the pH of the emulsion system to 8-9, and heat up to 80°C for reaction 8h;

[0027] 3) After the reaction is completed, cool to room temperature, dialyze, and freeze-dry to obtain a cellulose zwitterionic polymer fluid loss additive with a core-shell structure.

Embodiment 2

[0028] Embodiment 2: same as embodiment 1, the difference is that vinylsulfonic acid is replaced by styrenesulfonic acid.

Embodiment 3

[0029] Embodiment 3: same as embodiment 1, the difference is that vinylsulfonic acid is replaced by 2-acrylamido dodecylsulfonic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com