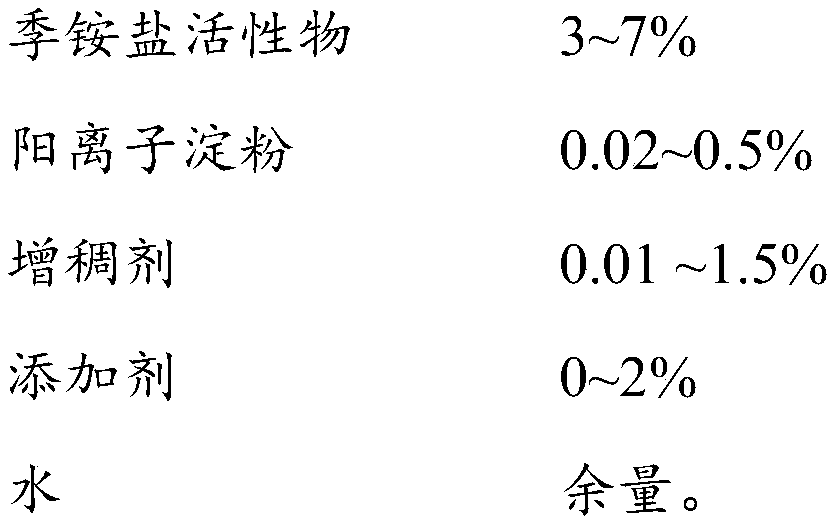

softener composition

A composition and softener technology, applied in the field of daily chemicals, can solve problems such as degree of substitution, starch source description, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

[0043] See Table 1 and Table 2.

[0044] Table 1

[0045]

[0046]

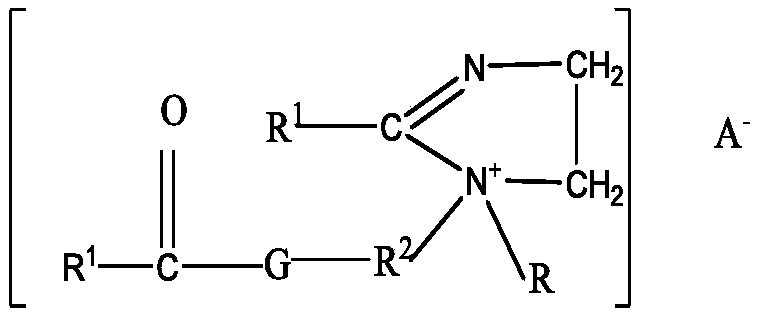

[0047] The quaternary ammonium salt active material is ethyl dipalmitate hydroxyethyl methyl methyl sulfate;

[0048] The thickener is: acrylamide / acryloyloxyethyl trimethylammonium chloride copolymer;

[0049] The cationic starch is starch hydroxypropyltrimethylammonium chloride. The specific parameters are shown in Table 2.

[0050] Table 2

[0051]

[0052] According to the raw material ratio in Table 1, the softener composition was formulated according to the method well known to those skilled in the art.

Embodiment 9-13

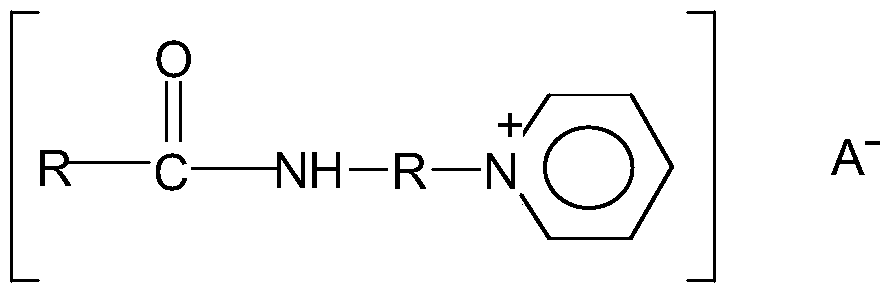

[0064] This embodiment is a softener composition, and the raw material ratio is the same as that of Example 5, except that the quaternary ammonium salt active substance used is different. See Table 4 for details.

[0065] Table 4

[0066]

[0067] The cationic starch is starch hydroxypropyltrimethylammonium chloride. The degree of substitution is 0.25, the viscosity of the 20wt% aqueous solution is 200mPa·s, and the amylose content is 25wt%;

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com