Organic silicon deep dyeing promoter and preparation method thereof

A technology of darkening agent and organic silicon, which is applied in the field of organic silicon darkening agent and its preparation, can solve the problems of poor dyeing and dark fabrics, and achieve darkening effect, good effect and good washability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

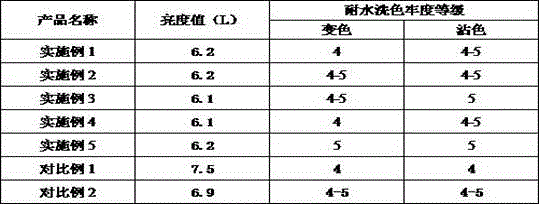

Examples

Embodiment 1

[0020] A silicone darkening agent, prepared from the following ingredients in parts by weight: 1 part of nano silicon dioxide, 1 part of sodium silicate, 2 parts of cetyltrimethylammonium bromide, 1 part of dodecyl chloride 3 parts of ammonium, 0.1 part of potassium sorbate, 2 parts of methyl glucose sesquistearate, 3 parts of polyoxyethylene oleate, 0.1 part of tetramethylammonium hydroxide, 20 parts of octamethylcyclotetrasiloxane , 1 part of vinyltriethoxysilane, 1 part of vinyltrimethoxysilane, 0.2 part of phytic acid, 1 part of glacial acetic acid, and 100 parts of deionized water.

[0021] The preparation method of above-mentioned organosilicon deepening agent is:

[0022] Step 1: Mix cetyltrimethylammonium bromide, dodecylammonium chloride, methylglucose sesquistearate, polyoxyethylene oleate and deionized water, and stir for 30 minutes;

[0023] Step 2: Add nano-silica, sodium silicate and octamethylcyclotetrasiloxane, and stir at high speed for 10 minutes;

[0024] ...

Embodiment 2

[0030] A silicone darkening agent, prepared from the following ingredients in parts by weight: 1.5 parts of nano silicon dioxide, 2 parts of sodium silicate, 3 parts of cetyltrimethylammonium bromide, dodecyl chloride 4 parts of ammonium, 0.2 parts of potassium sorbate, 3 parts of methyl glucose sesquistearate, 4 parts of polyoxyethylene oleate, 0.15 parts of tetramethylammonium hydroxide, 25 parts of octamethylcyclotetrasiloxane , 1.5 parts of vinyltriethoxysilane, 1-2 parts of vinyltrimethoxysilane, 0.35 parts of phytic acid, 1.5 parts of glacial acetic acid, and 125 parts of deionized water.

[0031] The preparation method of above-mentioned organosilicon deepening agent is:

[0032] Step 1: Mix cetyltrimethylammonium bromide, dodecylammonium chloride, methylglucose sesquistearate, polyoxyethylene oleate and deionized water, and stir for 40 minutes;

[0033] Step 2: Add nano-silica, sodium silicate and octamethylcyclotetrasiloxane, and stir at high speed for 20 minutes;

...

Embodiment 3

[0040] A silicone darkening agent, prepared from the following ingredients in parts by weight: 2 parts of nano silicon dioxide, 3 parts of sodium silicate, 4 parts of cetyltrimethylammonium bromide, dodecyl chloride 5 parts ammonium, 0.3 parts potassium sorbate, 4 parts methyl glucose sesquistearate, 5 parts polyoxyethylene oleate, 0.2 parts tetramethylammonium hydroxide, 30 parts octamethylcyclotetrasiloxane , 2 parts of vinyltriethoxysilane, 2 parts of vinyltrimethoxysilane, 0.5 part of phytic acid, 2 parts of glacial acetic acid, 150 parts of deionized water.

[0041] The preparation method of above-mentioned organosilicon deepening agent is:

[0042] Step 1: Mix cetyltrimethylammonium bromide, dodecylammonium chloride, methylglucose sesquistearate, polyoxyethylene oleate and deionized water, and stir for 50 minutes;

[0043] Step 2: Add nano-silica, sodium silicate and octamethylcyclotetrasiloxane, and stir at high speed for 30 minutes;

[0044] Step 3: Add vinyltriethox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com