A kind of anti-temperature and anti-salt polymer oil displacement agent and preparation method thereof

A technology of oil displacement agent and polymer, which is applied in the field of temperature-resistant and salt-resistant polymer oil displacement agent and its preparation, which can solve the problems of temperature resistance, salt resistance, poor performance, poor viscosity increasing performance, shear thinning, etc. problems, to achieve the effect of improving salt resistance, poor salt sensitivity, and good viscosity increasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

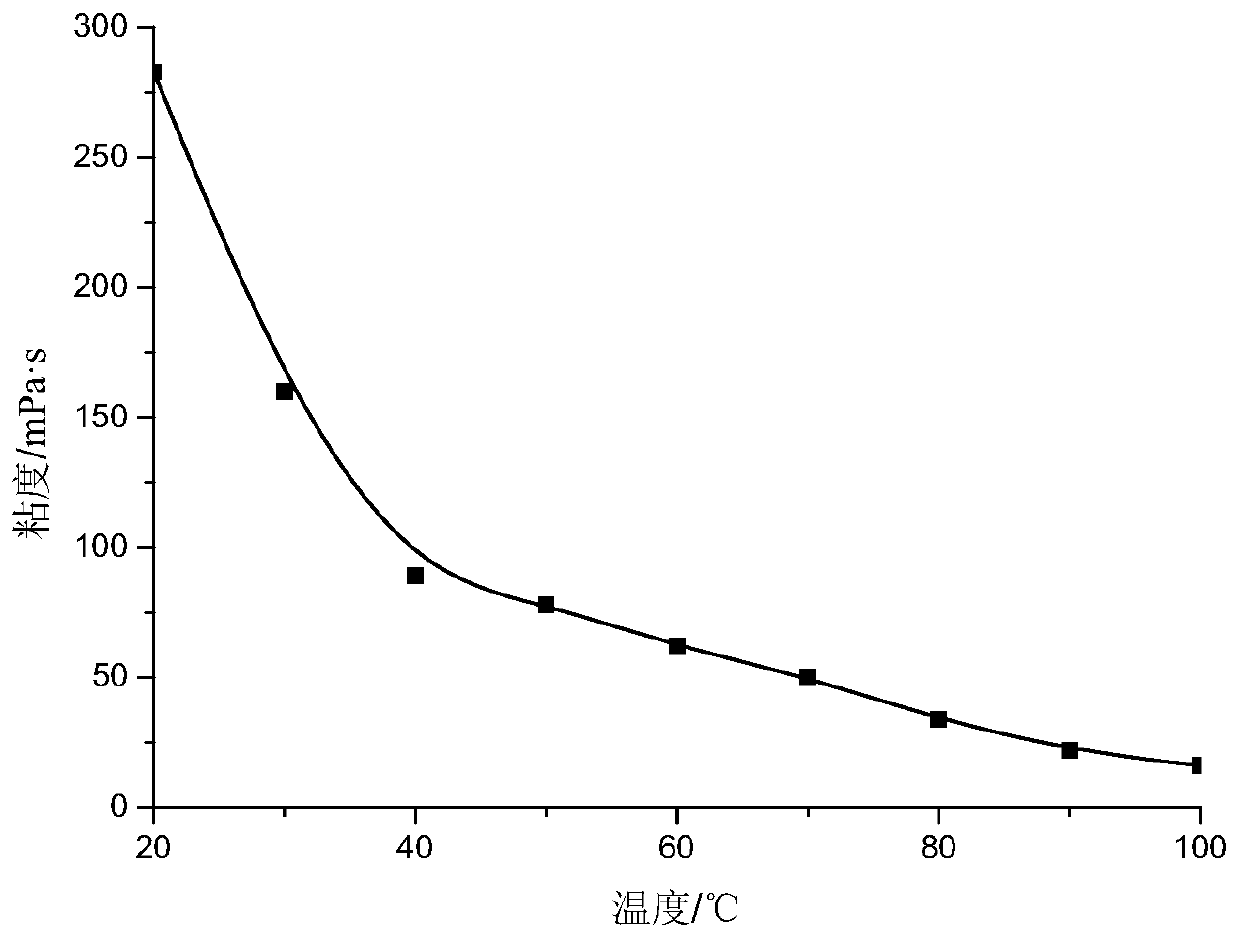

[0034] Effects of the weight ratio of polymerized monomers on the viscosity and temperature and salt resistance of oil displacement agent aqueous solution

[0035] Different monomer ratios will have different synergistic effects among their functional groups, which will affect the viscosity and temperature and salt resistance of the synthesized polymer oil displacement agent aqueous solution. A single factor method was used to study the effects of different ratios of monomers on the viscosity and temperature and salt resistance of oil displacement agent solutions, in which the monomers were acrylamide (AM) and allyl polyethylene glycol (APEG-700) respectively. , Sodium styrene sulfonate (SSS), dimethyl allyl octadecyl ammonium chloride (C-18), the monomer total mass concentration is 20% during the reaction, and the initiator is accounted for 20% of the total monomer mass 0.3%, the initiator consists of NaHSO in a weight ratio of 2:1 3 and (NH 4 ) 2 S 2 o 8 Composition, th...

Embodiment 2

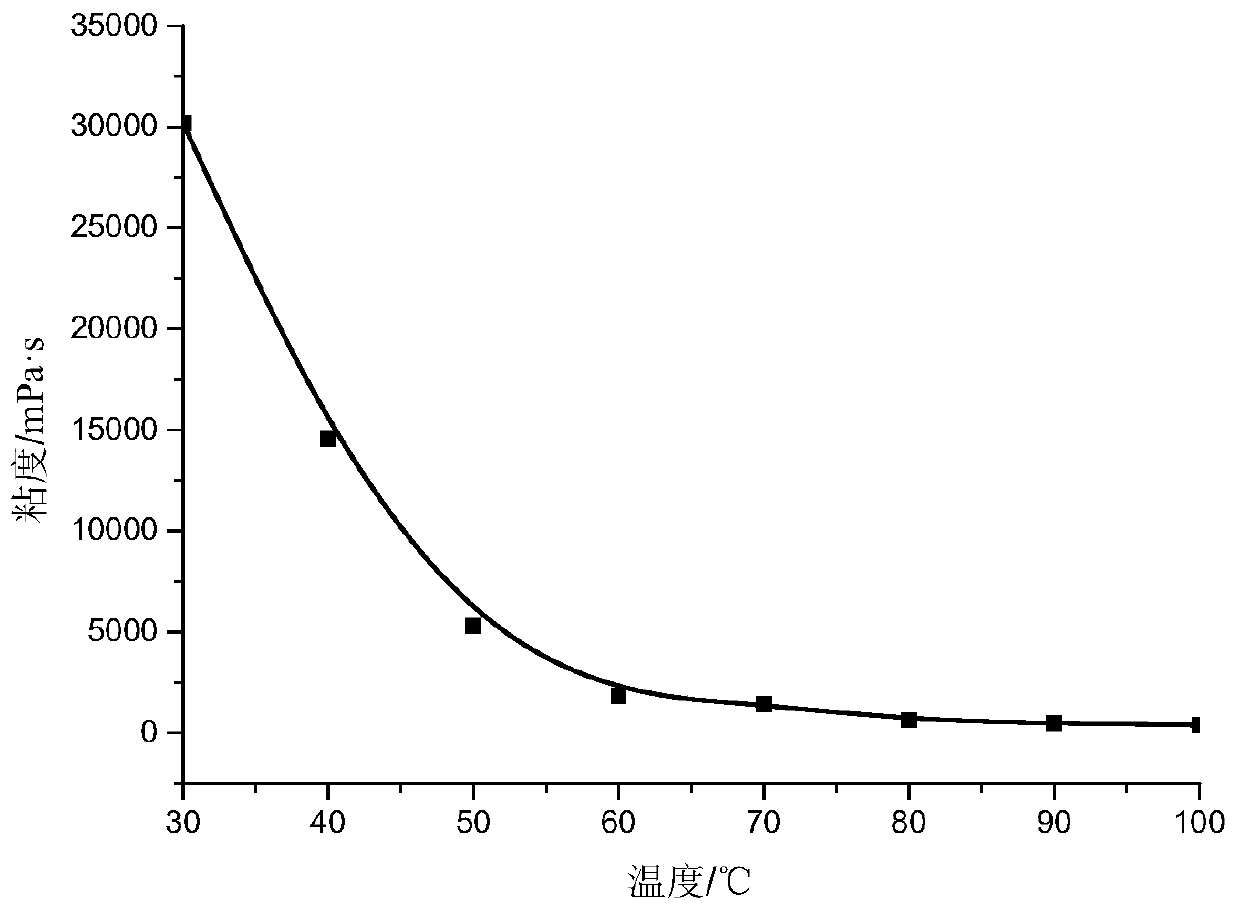

[0040] Effect of Reaction Temperature on Viscosity and Temperature and Salt Resistance of Oil Displacing Agent Aqueous Solution

[0041] The higher the reaction temperature is, the energy of the system will increase accordingly, the reaction polymerization rate will be accelerated, and the viscosity-increasing effect will be more significant, but as the reaction temperature continues to rise, the polymerization reaction will be too violent, forcing the chain termination to occur earlier, thus affecting The apparent viscosity of the polymer and its resistance to temperature and salt. Using the single factor method, under the condition that the fixed monomer ratio is n(AM):n(APEG-700):n(SSS):n(C-18)=97:1.7:0.3:1, during the reaction The total mass concentration of the monomer is 20%, the initiator is 0.3% of the total mass of the monomer, and the initiator is composed of NaHSO with a weight ratio of 2:1 3 and (NH 4 ) 2 S 2 o 8 Composition, the reaction time is 9 hours, chan...

Embodiment 3

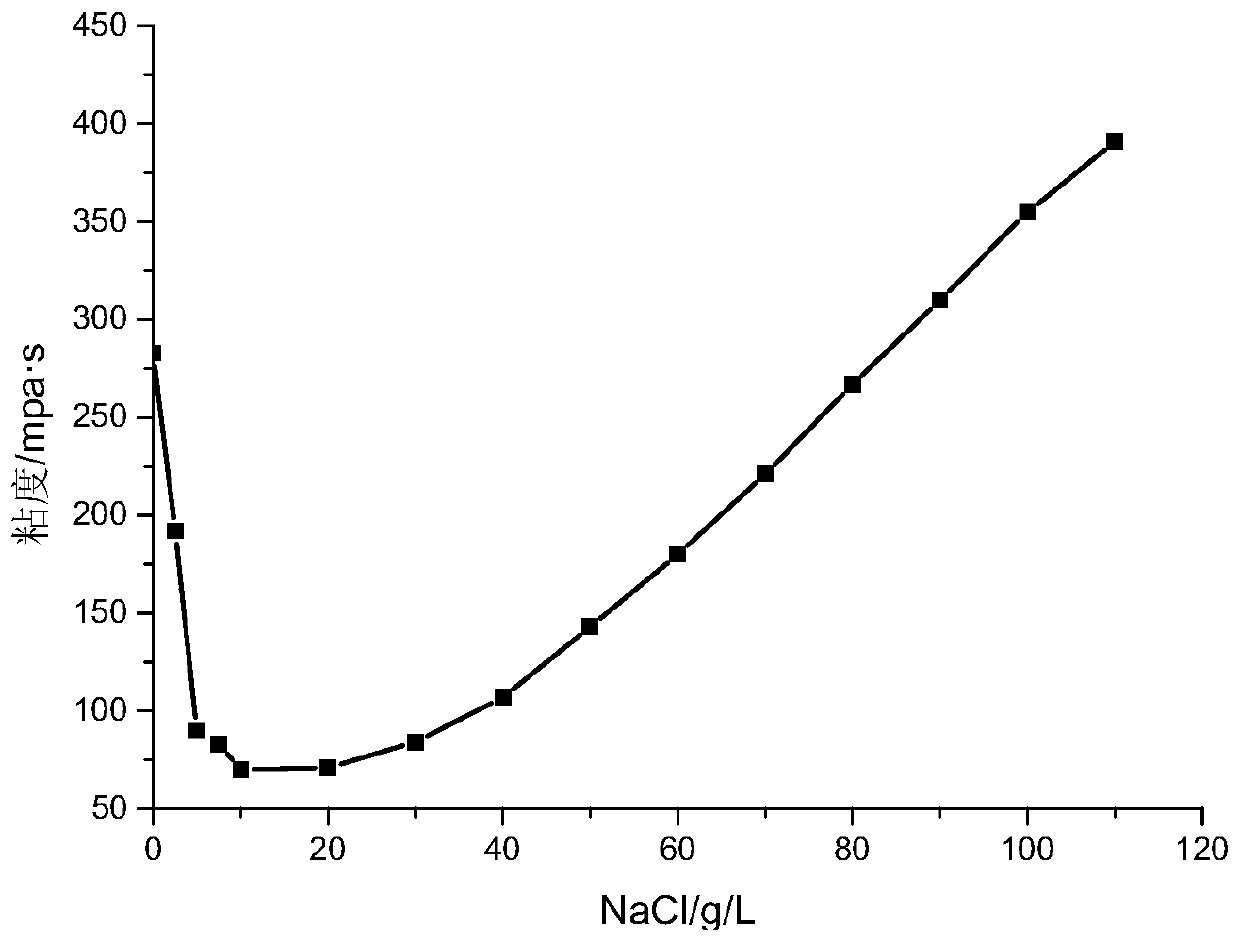

[0046] Effects of Initiator Addition on Viscosity and Temperature and Salt Resistance of Oil Displacing Agent Aqueous Solution

[0047] When the amount of the initiator added is small, the polymerization reaction occurs slowly and cannot effectively increase the viscosity. However, if the amount of the initiator added is large, the synthesis reaction of the polymer will be intensified, and the polymer chain will be terminated in advance, thus affecting The apparent viscosity of the polymer and its resistance to temperature and salt. Using the single factor method, under the condition that the fixed monomer ratio is n(AM):n(APEG-700):n(SSS):n(C-18)=97:1.7:0.3:1, during the reaction The total mass concentration of monomers is 20%, and the initiator consists of NaHSO with a weight ratio of 2:1 3 and (NH 4 ) 2 S 2 o 8 Composition, the reaction temperature is 45°C, and the reaction time is 9 hours. Change the dosage of the initiator according to Table 3, configure the syntheti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com