Viscoelastic surfactant for high-temperature self-diverting acid and its preparation method and application

A surfactant and self-steering acid technology, which is applied in the preparation of carboxylic acid amides, organic compounds, amino compounds, etc., can solve the problem of fast reaction speed of reservoir rocks, difficulty in maintaining a stable chemical structure of VES, easy deterioration and decomposition, etc. problems, to achieve the effect of improving the acidizing operation time, excellent acid thickening performance, and large-scale use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] A kind of preparation method of described viscoelastic surfactant for high temperature self-steering acid, comprises the following steps:

[0047] S1: Add fatty acid and organic amine into the reactor, raise the temperature to 160-170°C and react for 11-13 hours to stop the reaction. During the reaction process, keep the circulating water to cool the organic amine to reflux. After the reaction liquid is cooled to 25-35°C, Pour it into cold acetone solution, stir and filter, wash and filter the solid with acetone for 2 to 3 times, and obtain a white solid intermediate after freeze-drying. Wherein, the molar ratio of organic amine to fatty acid is (1.1-1.5):1.

[0048] The fatty acid is at least one or a combination of saturated or unsaturated alkyl fatty acids with 18 to 28 carbon atoms, and the organic amine includes N,N-dimethylethylenediamine, N,N- Dimethyl-1,3-propanediamine, N,N-dimethyl-1,4-butanediamine, N,N-diethylethylenediamine, N,N-diethyl-1,3 -A combination...

Embodiment 1

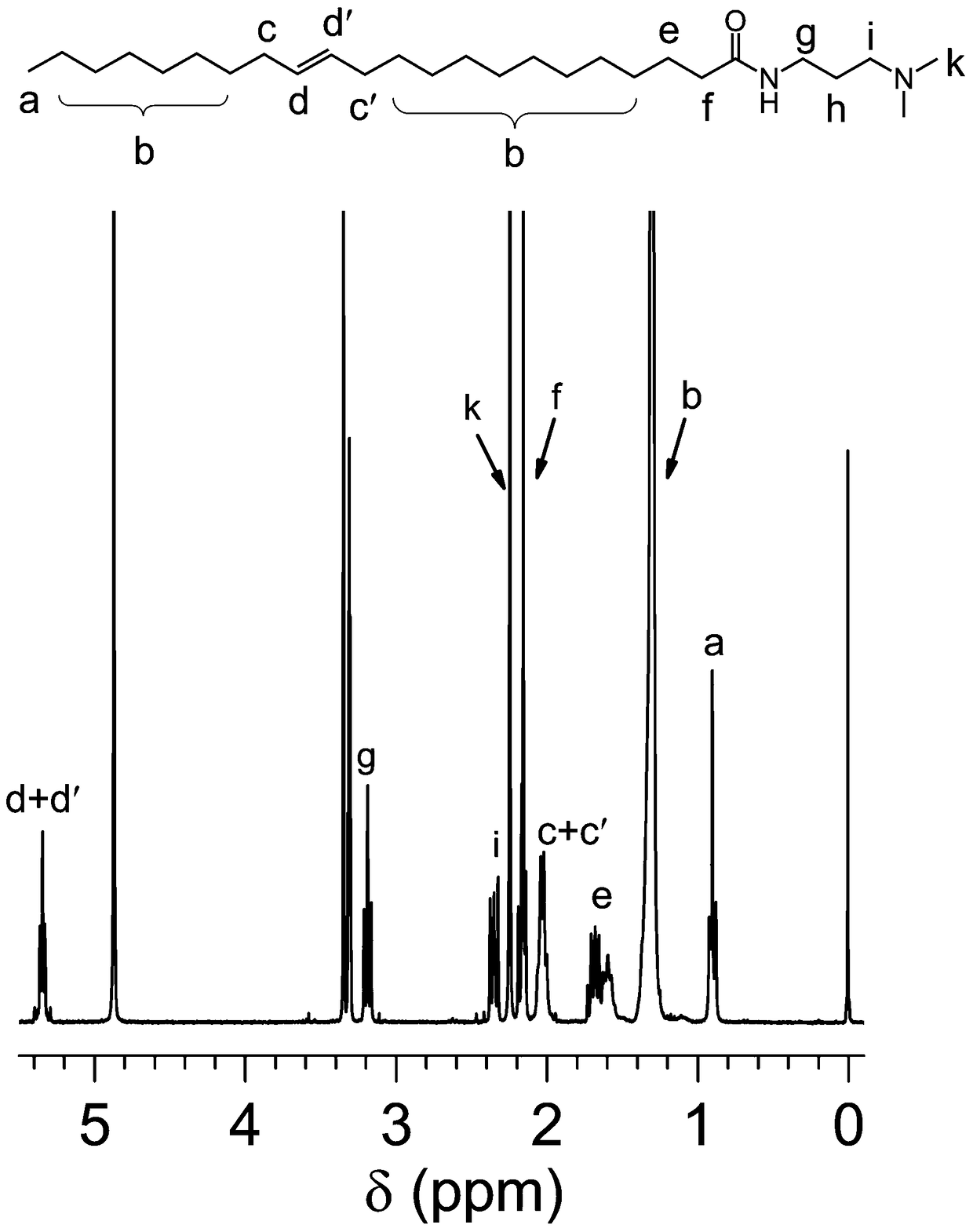

[0058] (1) Weigh 16.92g (0.05mol) cis-docos-13-enoic acid (commonly known as "erucic acid") and 7.66g (0.075mol) N,N-dimethylpropylenediamine (n=2, R 2 , R 3 (for methyl) was added into a three-neck reaction flask, and the temperature was gradually raised to 160°C. Stop the reaction after reacting for 11 hours. After the solution is cooled to room temperature, transfer it to an acetone solution, stir and filter, and freeze-dry to obtain a white powder solid, which is N-(cis-docos-9-enyl-amide propyl)-N,N-dimethyl tertiary amine, its structural characterization is shown in the NMR spectrum ( figure 1), the chemical shifts of each proton peak in the compound have been assigned in the spectrum, and the ratio of the integral area of each proton resonance peak is in good agreement with the theoretical value, indicating that the compound has been successfully synthesized.

[0059] (2) Add the obtained N-(cis-docos-9-enyl-amidopropyl)-N,N-dimethyl tertiary amine into a 500mL rou...

Embodiment 2

[0065] (1) Weigh 14.22g (0.05mol) octadecanoic acid (commonly known as "stearic acid") and 5.61g (0.055mol) N,N-dimethylpropylenediamine (n=2, R 2 , R 3 (for methyl) was added into a three-necked reaction flask, and the temperature was gradually raised to 170°C. After 13 hours of reaction, the reaction was stopped. After the solution was cooled to room temperature, it was transferred to an acetone solution, stirred and filtered, and freeze-dried to obtain a white powder solid, which was N-(octadecylamidopropyl)-N,N - tertiary dimethylamine.

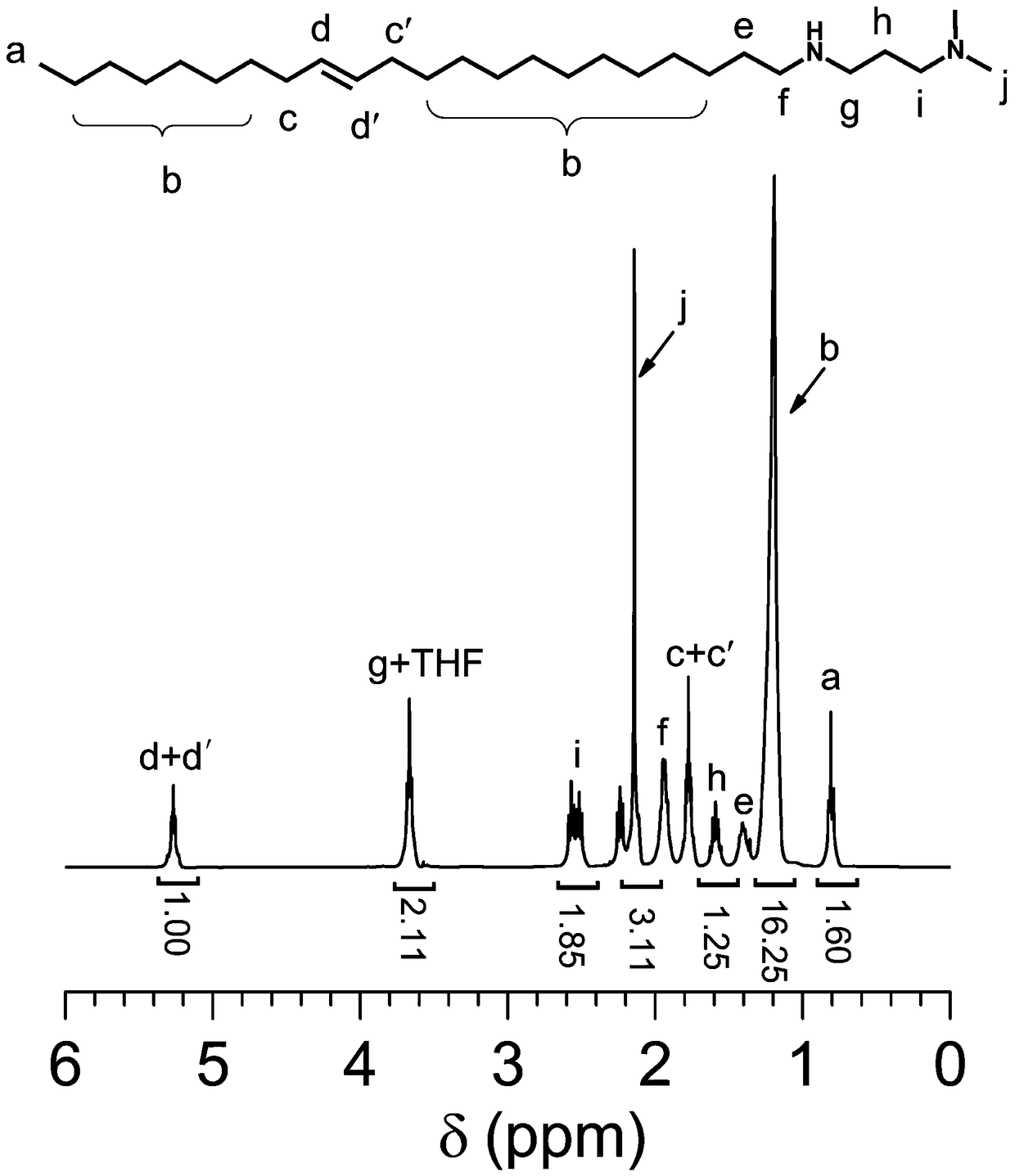

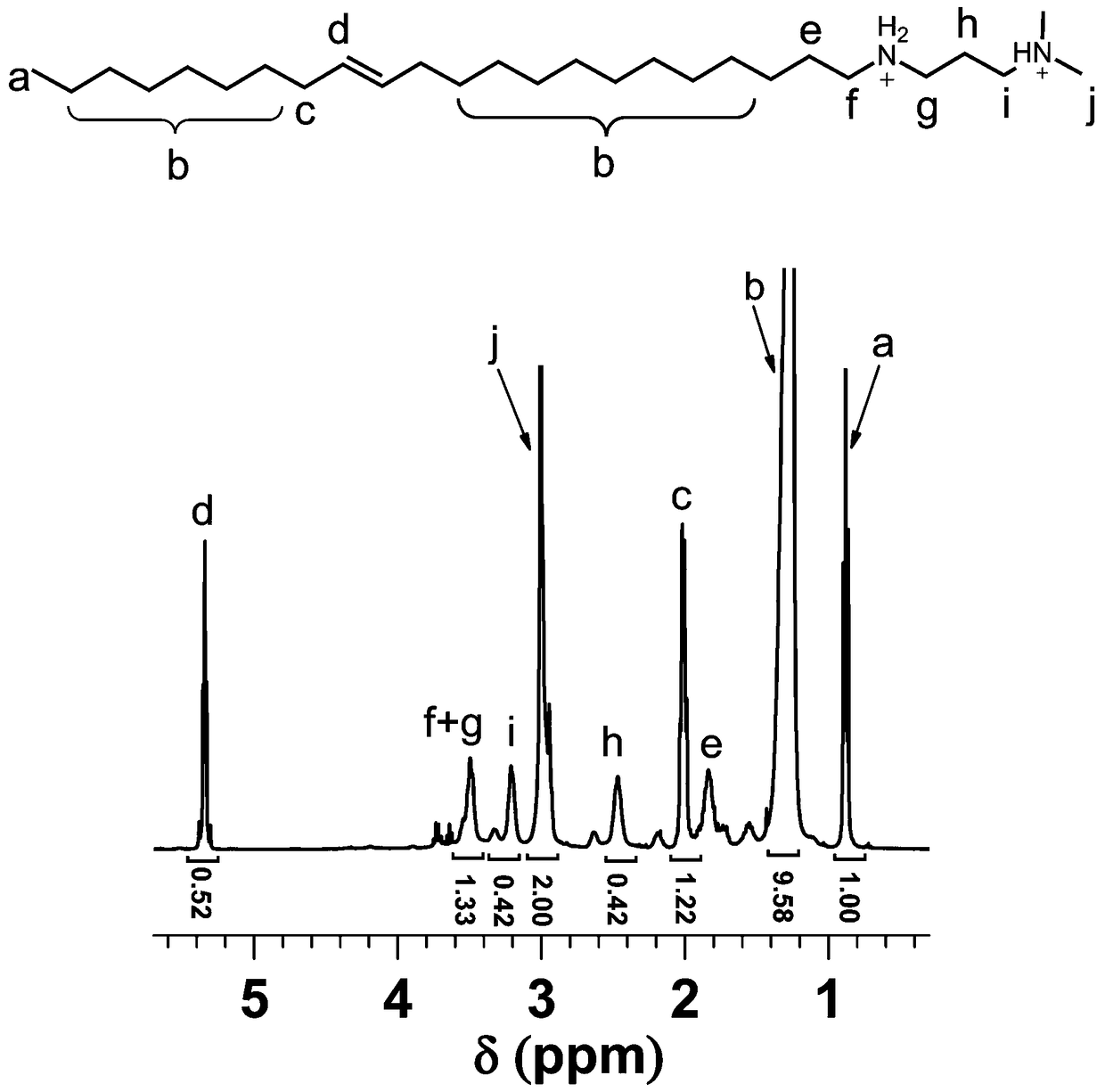

[0066] (2) Add the obtained N-(octadecylamidopropyl)-N,N-dimethyl tertiary amine into a 500mL round bottom flask, add 100mL tetrahydrofuran to dissolve, cool down to 5°C after complete dissolution, and gradually LiAlH was added dropwise 4 THF solution, wherein the molar ratio of N-(octadecylamidopropyl)-N,N-dimethyl tertiary amine to metal hydride is 1:2, after the dropwise addition is completed, the temperature is raised to 65°C for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com